Beruflich Dokumente

Kultur Dokumente

Energy MGT Palawan

Hochgeladen von

Alvin Garcia PalancaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Energy MGT Palawan

Hochgeladen von

Alvin Garcia PalancaCopyright:

Verfügbare Formate

ENERGY MANAGEMENT

TECHNIQUES

ABOUT THE PRESENTOR

ARMANDO R. DIAZ

Master of Science in Business Administration (MBA)

Registered ASEAN Engineer

Professional Electrical Engineer ( PEE )

Certified Plant Mechanic( CPM )

Accredited Pollution Control Officer

Licensed Professional Electrical Engineer with more than 35 years

experience in the field of building and facility design and consultancy,

construction, operations and maintenance involving various mechanical,

and electrical equipment and systems.

Awarded 1998 as Most Outstanding Practitioner in Industry of the Philippine

2009 IIEE Vice-President for External Affairs

Awarded 2006 as IIEE FELLOW

Member : Society of Philippine Accredited Consultant

Energy Efficient Practitioner Asso. of the Phil.

Recipient of Various Civic Awards : Rotary,REACT,YMCA,LOBSET and MARS

Energy Management

- is a process for reviewing and minimizing the

energy costs and consumption of a facility without

reducing productivity or levels of services

- it also offers opportunities when energy demand is

greater than the supply to maximize the energy

available to the customers

Energy management

Can be:

Informal

Decentralized, not centrally

coordinated or managed

Project-oriented, not program-oriented

Cyclical (i.e. in the support a company

gives)

Thus, many companies or

institutions:

Miss important savings opportunities

because they lack a means for

addressing energy use across the

organization.

Organizations achieving the greatest

results have:

A top-down commitment to energy management

A commitment to continuous improvement

Embraced an approach that integrates energy

management across all aspects of the business

Management systems in place

A system to regularly assess and track energy

performance

Set measurable performance goals

An effective reward system for energy

performance

An empowered energy staff

ENERGY MANAGEMENT

-refers to the planning , organizing

directing , controlling , problem solving ,

decision- making and evaluating of the

acquisition , transmission and actual utilization

of all energy based resource inputs to the

various productive processes for the purpose

of enhancing their efficiency and effectiveness

A common misconception

in industry is to consider

energy reduction as simply

an energy conservation

program

COMPONENTS OF ENERGY MANAGEMENT

PROGRAM- suggest a schedule or system under which

action is taken toward a desired goal

one time event

PROCESS implies a continuing operation marked by

gradual changes toward a particular result

an ongoing effort

4 GOALS MARK A

SUCCESSFUL ENERGY

MANAGEMENT PROCESSES

*maximize product efficiency

*minimize energy input

*maintain high energy load factor

*use energy most economically

ENERGY MANAGEMENT

The FIRST Law of energy management states that ,

plant utilities must always be adequate to meet

production/process demands

Ist slide

BARRIERS FOR EFFECTIVE

ENERGY MANAGEMENT

-Lack of readily available information

-The need to combine engineering, economics,

human and management practices to

achieve energy savings

BARRIERS

HUMAN FACTORS

- the way human use energy is highly

variable

- It is the most difficult to control

BARRIERS

ENGINEERING FACTORS

-Use of massive and sophisticated

machine or equipment for engineering

processes without people understand it

-Interaction between various energy

saving measures

BARRIERS

ECONOMIC FACTORS

- Investment in time and money must

meet economic criteria

BARRIERS

MANAGEMENT OF ENERGY

-Management style

-Attitude of senior management

STEPS IN PREPARATION OF

ENERGY MANAGEMENT

PROGRAM

1.Make someone responsible for

managing the organizations use of

energy

- Energy Manager

2. Identify how energy is being

used now

-energy audit

3. Allocate responsibility for energy use

4. Start implementing energy

management measures

-NO cost measures first

5.Start monitoring and targeting system

6. Implement low,medium,then capital

cost energy management measures

Appoint Energy

Officer

Energy Use

Identification

Energy Management

Opportunity Implementation

Implement Low Cost/ No Cost

Savings

Monitor Energy Use

And Cost

Investment in Energy

Management Measures

Continue with the Energy

Management Program

1.Make someone responsible for the managing

the organization use of energy either in - house or

consultant

2.Identify how energy is being used now (energy

audit) historical data collection

3.Determine Low Cost / No Cost opportunities

and allocate responsibility for energy use

4.Start implementing energy management

measu res , NO COST measures first

5.Start monitoring and targeting system

6.Implement LOW, MEDIUM then CAPITAL

COST (CAPEX) energy management measures

OVERALL ENERGY MANAGEMENT PROGRAM

9 Major Guidelines in a

well-structured approach

to the energy

management processes

1.Obtain total management

commitments

The support of the company president is usually the critical

step

2.Obtain employee cooperation

The cooperation of the operating people is vital to the success of any

management effort. Employees should be asked for their input.In energy

management , nothing is sacred.

ACTION PLAN

1.Integrated ENERCON on the orientation for new

employees

2. Conduct ENERCON for new employees

3.Organize Enercon Patrol Team

3. Conduct monthly Meeting with all Supervisors and

Managers

3.Make appropriate energy

surveys

Although this step sounds obvious,it is often

one to which little time and effort dedicated.

4.Analyze survey results

What should be done with all the data gathered?

Again, often little time is devoted to analyzing

where and why energy is used.

5.Set conservation goals

Although realistic goals may be difficult to set initially, they are

absolutely necessary.Without goals ,plants have nothing to strive for

and no method for measuring performance.

Average

Consumption

Cost Monthly Billing Todays

Cost

To Date

Billing

ELECTRICITY

kWHr

P/ kWhr

?

P___/

kWHr

?

BUNKER OIL

Liters

P / Liter

?

P---/

Liter

?

WATER

4,212.81

Cu.meter

-

-

-

-

6.Develop reporting format

Good communication is a vital to energy

management as it is to any other program.

Reports should be simple so that they do not

intimidate or confuse the reader

FUEL CONSUMPTION (BUNKER)

LITERS

92,183

72,806

96,320

63,079

36,366

58,199

0

20,000

40,000

60,000

80,000

100,000

120,000

Liters

Aug Sep Oct Nov Dec Jan

Month

FUEL CONSUMPTION / MAIN LINE

OUTPUT

TARGET : 58.2 LITERS/MT OF ML OUTPUT

64.3

63.6

66.3

65.8

61.7

68.26

50.5

54.3

-5

5

15

25

35

45

55

65

75

Liter/Metric Ton of ML

Output

Aug Sep Oct Nov Dec Jan Feb Mar

Aug Sep Oct Nov Dec Jan Feb Mar

L1 (MT)

691.211 255.05 447.32 283.608 0 175.772 0 0

L2 (MT)

741.790 889.7 1,004.78 674.911 589.742 676.836 961.739 851.473

Total (MT)

1,433 1,144.75 1452.10 958.52 589.742 852.61 961.74 851.47

Bunker (L)

92,183 72,806 96,320 63,079 36,366 58,199 48,579 46,212

URC-PACKAGING DIVISION

SCHEDULE OF LIGHT & POWER USAGES

As of January 31, 2007

F.Y. 2006

Month KWHR Amount Unit Cost

Oct. 2005 2,439,851.78 14,607,592.92 5.99

Nov. 2005 1,667,047.31 10,549,564.68 6.33

Dec. 2005 1,307,947.35 7,896,997.32 6.04

Jan. 2006 1,854,743.70 10,287,152.68 5.55

Feb. 2006 1,948,709.21 11,224,946.77 5.76

March 2006 1,598,076.17 9,444,979.44 5.91

April 2006 1,230,255.19 7,061,011.87 5.74

May 2006 1,788,738.92 10,811,125.02 6.04

June 2006 1,950,063.18 10,744,434.49 5.51

July 2006 1,852,183.51 11,274,855.40 6.09

Aug. 2006 2,219,254.08 12,931,656.06 5.83

Sept. 2006 1,946,656.58 12,145,432.50 6.24

TOTAL 21,803,526.98 129,890,846.80 P 5.96 P

* Average unit cost per kwh. - P 5.96

F.Y. 2007

October 2006 2,253,155.11 12,537,156.16 5.56

November 2006 1,787,470.99 8,916,993.73 4.99

December 2006 1,210,297.54 6,223,001.87 5.14

January 2007 1,599,413.51 7,906,782.57 4.94

TOTAL 6,850,337.15 35,583,934.33 5.19 P

7.Implement engineering

changes

Activities on one end of the spectrum to the other should be

included ,whether it be disconnecting excess light fixtures or

adding computer-based enthalpy controls on air washers to

make use of outside air

8.Provide necessary equipment

Adequate equipment is important, but the urge

for overkill should be resisted.

A minicomputer to log kilowatt demand should

not be used when a simple data logger would

suffice at 10% the cost.

9.Monitor results

Situations tend to return to their original state unless they are monitored

continuously.A successful energy management process may fail in six

months, or even after several years, unless continuous monitoring is

monitored continuously.A successful energy management may fail in six

months, or even several years , unless continuous monitoring is maintained.

ENERGY SAVINGS

OPPORTUNITIES

FANS AND BLOWERS

ENERGY SAVINGS

OPPORTUNITIES

LIGHTING

SIX BASIC RULES FOR GOOD

LIGHTING COUPLED with ENERGY

CONSERVATION

1. Use the most efficient light source practicable

2. Use the Lamp light output Efficiently.

3. Maintain Lighting Equipment in Good Order

4. Use Well-Designed Energy Effective Lighting Schemes

5. Control the Switching Operation and Usage of the Lighting Installation

6. Consider the Effect of Surrounding Decor

ENERGY SAVINGS

OPPORTUNITIES

PRODUCTION MACHINES

ENERGY SAVINGS

OPPORTUNITIES

BOILER

Go to both

1. Equipment Scheduling and Operating Practices

2. Boiler Plant Efficiency Measurement

3. Air-Fuel Ratio

4. Draft Control

5.Condensate, Feedwater, and Water Treatment

6. Fuel Oil Systems

7.Steam and Water Leakage

8.Conduction and Radiation Losses

ENERGY SAVINGS

OPPORTUNITIES

CHILLERS

ENERGY SAVINGS

OPPORTUNITIES

MOTORS

*Use of New Energy Efficient Motors

*Improved motor management practicesEnergy

savings from better management of currently

installed motors with improved repair practices, more

properly matching motor size to the driven load, and

the adoption of motor management best practices.

*Improved motor system optimizationEnergy

savings from overall system optimization from better

matching fluid handling devices (e.g., pumps) to the

load, and implementing more optimal control

strategies and technologies (adjustable speed drives)

to accommodate fluctuating loads.

ENERGY SAVINGS

OPPORTUNITIES

AIR COMPRESSORS

ENERGY SAVINGS

OPPORTUNITIES

AIR CONDITIONING SYSTEM

ENERGY SAVINGS

OPPORTUNITIES

BUILDING

ENERGY SAVINGS

OPPORTUNITIES

Arranging and organizing the building configuration and

massing to reduce loads.

Reducing cooling loads by eliminating undesirable solar

heat gain.

Using natural light as a substitute for (or complement

to) electrical lighting.

Using natural ventilation whenever possible.

Using more efficient cooling equipment to

satisfy reduced loads.

Using computerized building control systems.

UNNECESSARY POWER USE

* DUE TO HUMAN NEGLIGENCE

IGNORANCE

ATTITUDE

*DUE UNIT INEFFICIENCY

DESIGN

DEFECT

*SYSTEMIC

Recognize Achievements

Providing and seeking recognition for energy

management achievements is a proven step for

sustaining momentum and support for your

program.

Providing recognition to those who helped the

organization achieve these results motivates staff

and employees and brings positive exposure to the

energy management program.

Receiving recognition from outside sources validates

the importance of the energy management program

to both internal and external stakeholders, and

provides positive exposure for the organization as a

whole.

Providing Internal Recognition

Recognizing the accomplishments of individuals

and teams is key to sustaining support and

momentum for energy management initiatives.

Rewarding particular efforts sets the example

for what constitutes success and helps motivate

employees through increased job satisfaction.

Recognition can strengthen the

morale of everyone involved in energy

management.

Determine recognition levels

The decision about who should receive recognition in

your organization will likely be shaped by the

purpose for providing recognition and your

organizational culture. Common recognition levels

include:

Individual Acknowledges the contributions and

accomplishments of specific people.

Teams Recognizes the achievements of teams,

departments, and other distinct groups within the

organization.

Facility Rewards the accomplishments or

performance of an entire facility.

Establish recognition criteria

Create criteria for recognition and communicate

these criteria and any process eligibility

requirements.

Recognition criteria might include thresholds of

achievement such as:

*Offered the best energy savings ideas

*Achieved the greatest energy use reduction

*Increased savings by X amount

External Recognition

Good work deserves to be acknowledged. Recognition

from a third party can provide validation for an

organization's energy management program. Not only

does it provide satisfaction to those involved in earning

the recognition, but it can also enhance an organization's

public image. A solid reputation

contributes to your competitive advantage by making your

organization more attractive to customers, students,

current and potential employees, lenders, business

partners and other stakeholders.Before seeking

recognition from external groups, you may want to

determine the most appropriate avenues to pursue. A few

ways to gain recognition for your organization's energy

management efforts may be:

Partnership programs

Examples include:

Professional associations

Trade associations

Government Agencies

Non-profit organizations

Inter company energy programs

Socially responsible investment funds

The ENERGY that you SAVE today

could dictate your tomorrow

THANK YOU

Das könnte Ihnen auch gefallen

- Inorganic Chemistry IIDokument23 SeitenInorganic Chemistry IIAlvin Garcia PalancaNoch keine Bewertungen

- Emergency Response On The Incident of Missing Radioactive SourceDokument9 SeitenEmergency Response On The Incident of Missing Radioactive SourceAlvin Garcia PalancaNoch keine Bewertungen

- Palawan MainteDokument91 SeitenPalawan MainteAlvin Garcia PalancaNoch keine Bewertungen

- Energy Design GuidelineDokument120 SeitenEnergy Design GuidelineAlvin Garcia PalancaNoch keine Bewertungen

- Transport Accident Involving A Radioactive Source: Hanna Saco Philip CaluyaDokument13 SeitenTransport Accident Involving A Radioactive Source: Hanna Saco Philip CaluyaAlvin Garcia PalancaNoch keine Bewertungen

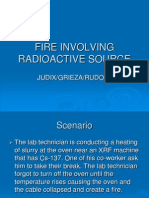

- Fire Involving Radioactive Source: Judix/Grieza/RudolfDokument10 SeitenFire Involving Radioactive Source: Judix/Grieza/RudolfAlvin Garcia PalancaNoch keine Bewertungen

- Radioactive Source Is Leaking: Michael Alvarez Christian EraDokument8 SeitenRadioactive Source Is Leaking: Michael Alvarez Christian EraAlvin Garcia PalancaNoch keine Bewertungen

- Deburring Work: A Worker Is Deburring A Steel Plate With An Air SunderDokument1 SeiteDeburring Work: A Worker Is Deburring A Steel Plate With An Air SunderAlvin Garcia PalancaNoch keine Bewertungen

- Heat Treatment of Parts For CorrectionDokument1 SeiteHeat Treatment of Parts For CorrectionAlvin Garcia PalancaNoch keine Bewertungen

- On-Site Gas Welding Work: A Service Mechanic Is Flame-Cutting A Steel Plate at An In-Field Repair SiteDokument1 SeiteOn-Site Gas Welding Work: A Service Mechanic Is Flame-Cutting A Steel Plate at An In-Field Repair SiteAlvin Garcia PalancaNoch keine Bewertungen

- A Worker Is Drilling A Hole On Work With A Bench Drilling MachineDokument1 SeiteA Worker Is Drilling A Hole On Work With A Bench Drilling MachineAlvin Garcia PalancaNoch keine Bewertungen

- Grinding Work: A Worker Is Grinding Small Parts, Holding It With A PlierDokument1 SeiteGrinding Work: A Worker Is Grinding Small Parts, Holding It With A PlierAlvin Garcia PalancaNoch keine Bewertungen

- Bolt Tightening: A Worker Is Retightening A Cylinder Pin Stopper BoltDokument1 SeiteBolt Tightening: A Worker Is Retightening A Cylinder Pin Stopper BoltAlvin Garcia PalancaNoch keine Bewertungen

- Engine Oil Replacement: An Operator Is About To Get Off A Hydraulic Excavator, While The Engine Oil Is Being ReplacedDokument1 SeiteEngine Oil Replacement: An Operator Is About To Get Off A Hydraulic Excavator, While The Engine Oil Is Being ReplacedAlvin Garcia PalancaNoch keine Bewertungen

- Transportation: Dismantled From A Hydraulic Excavator, A Boom Is Going To Be Moved With An Overhead CraneDokument1 SeiteTransportation: Dismantled From A Hydraulic Excavator, A Boom Is Going To Be Moved With An Overhead CraneAlvin Garcia PalancaNoch keine Bewertungen

- EHPT22Dokument1 SeiteEHPT22Alvin Garcia PalancaNoch keine Bewertungen

- Replacement of Cylinder: A Mechanic Is Driving A Connecting Pin in The Arm Cylinder Replacement WorkDokument1 SeiteReplacement of Cylinder: A Mechanic Is Driving A Connecting Pin in The Arm Cylinder Replacement WorkAlvin Garcia PalancaNoch keine Bewertungen

- EHPT27Dokument1 SeiteEHPT27Alvin Garcia PalancaNoch keine Bewertungen

- EHPT26Dokument1 SeiteEHPT26Alvin Garcia PalancaNoch keine Bewertungen

- EHPT23Dokument1 SeiteEHPT23Alvin Garcia PalancaNoch keine Bewertungen

- EHPT19Dokument1 SeiteEHPT19Alvin Garcia PalancaNoch keine Bewertungen

- EHPT21Dokument1 SeiteEHPT21Alvin Garcia PalancaNoch keine Bewertungen

- EHPT20Dokument1 SeiteEHPT20Alvin Garcia PalancaNoch keine Bewertungen

- EHPT1Dokument1 SeiteEHPT1Alvin Garcia PalancaNoch keine Bewertungen

- Sanity Check PresentationDokument28 SeitenSanity Check PresentationAlvin Garcia PalancaNoch keine Bewertungen

- EHPT18Dokument1 SeiteEHPT18Alvin Garcia PalancaNoch keine Bewertungen

- Rio Tuba FR Vol - I Main Report 090618Dokument114 SeitenRio Tuba FR Vol - I Main Report 090618Alvin Garcia PalancaNoch keine Bewertungen

- Bailey Net 90Dokument4 SeitenBailey Net 90Alvin Garcia PalancaNoch keine Bewertungen

- Product Catalog: Drilling & CompletionsDokument33 SeitenProduct Catalog: Drilling & CompletionsSergioBernardesNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- A) Explain Three Different Approaches To Calculate The GDP. Which Approach Should BeDokument2 SeitenA) Explain Three Different Approaches To Calculate The GDP. Which Approach Should BeHaris KhanNoch keine Bewertungen

- Sample Final Exam Fall 2019: Name: Class: DateDokument14 SeitenSample Final Exam Fall 2019: Name: Class: DateElovset OrucovNoch keine Bewertungen

- 2022 Fall Courses Taught in English (NEW)Dokument4 Seiten2022 Fall Courses Taught in English (NEW)Mariana MartínezNoch keine Bewertungen

- ECO - Chapter 01 The Subject Matter of EconometricsDokument42 SeitenECO - Chapter 01 The Subject Matter of EconometricsErmias GuragawNoch keine Bewertungen

- Department of Management Sciences, National University of Modern LanguagesDokument8 SeitenDepartment of Management Sciences, National University of Modern LanguagesSheiryNoch keine Bewertungen

- Module No. 2 Lesson 1 ABM112Dokument10 SeitenModule No. 2 Lesson 1 ABM112Rush RushNoch keine Bewertungen

- Market Segmentation For MarketingDokument4 SeitenMarket Segmentation For MarketingRahul KambleNoch keine Bewertungen

- Water Managementin 2020 and BeyondDokument5 SeitenWater Managementin 2020 and BeyondAnwar AliNoch keine Bewertungen

- 2008 BE SyllabusDokument97 Seiten2008 BE SyllabusPraveen NatarajanNoch keine Bewertungen

- Strategic Anaslysis of HSBC and RBSDokument26 SeitenStrategic Anaslysis of HSBC and RBSInformation should be FREE100% (13)

- Economics DifferencesDokument5 SeitenEconomics DifferencesAyappaNoch keine Bewertungen

- 2 Theme: Gross Domestic Product and Product AccountsDokument52 Seiten2 Theme: Gross Domestic Product and Product AccountsShahzod OltiboyevNoch keine Bewertungen

- SyllabusDokument4 SeitenSyllabusNikola_mneNoch keine Bewertungen

- Bator, 1958Dokument30 SeitenBator, 1958Francisco Pinheiro CatalãoNoch keine Bewertungen

- Final Assignment For Microeconomics IIIT Delhi-Winter 2020Dokument4 SeitenFinal Assignment For Microeconomics IIIT Delhi-Winter 2020Raghav RathiNoch keine Bewertungen

- Ricardian Theory of Rent/ Classical Theory of RentDokument4 SeitenRicardian Theory of Rent/ Classical Theory of Rentrspa100% (1)

- Economía Política Syllabus I JuradoDokument9 SeitenEconomía Política Syllabus I JuradoFELIPENoch keine Bewertungen

- Kotler Marketing, 2016Dokument1 SeiteKotler Marketing, 2016kurtdias1Noch keine Bewertungen

- OSRAM Case Study Solution - Strategic ManagementDokument6 SeitenOSRAM Case Study Solution - Strategic ManagementPiotr Bartenbach0% (1)

- Market Makers: Quantum Stone CapitalDokument3 SeitenMarket Makers: Quantum Stone CapitalCapRa Xubo33% (3)

- 3 FJIB-5-2019 Poverty Reduction in India Komal Chhikara 12 F p48-711Dokument25 Seiten3 FJIB-5-2019 Poverty Reduction in India Komal Chhikara 12 F p48-711Rajdeep SahaNoch keine Bewertungen

- GGSR CHAPTER 2 Copy 1Dokument16 SeitenGGSR CHAPTER 2 Copy 1Aspire DellNoch keine Bewertungen

- HBS Case MicrosoftDokument28 SeitenHBS Case MicrosoftYitchell ChowNoch keine Bewertungen

- Flipping Markets: Trading Plan 2.0Dokument51 SeitenFlipping Markets: Trading Plan 2.0Frisella Tobing100% (4)

- Offshore WindDokument18 SeitenOffshore WindHimanshu BhandariNoch keine Bewertungen

- Consumer Behaviour Utility AnalysisDokument28 SeitenConsumer Behaviour Utility Analysissunil020982Noch keine Bewertungen

- Turbulence After Lift-Off: Global Economic and Insurance Market Outlook 2022/23Dokument42 SeitenTurbulence After Lift-Off: Global Economic and Insurance Market Outlook 2022/23trietpmNoch keine Bewertungen

- Capital Asset Pricing Model (CAPM)Dokument13 SeitenCapital Asset Pricing Model (CAPM)vinodhknatrajanNoch keine Bewertungen

- FM - Chapter 32Dokument5 SeitenFM - Chapter 32Amit SukhaniNoch keine Bewertungen

- Module 5 Foreign Exchange MarketDokument19 SeitenModule 5 Foreign Exchange MarketjinalNoch keine Bewertungen