Beruflich Dokumente

Kultur Dokumente

Kaga - SOEM KL QualityDel Performance Review - FY13

Hochgeladen von

Dustin Robertson0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten13 Seitena

Originaltitel

Kaga_ SOEM KL QualityDel Performance Review_FY13

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldena

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten13 SeitenKaga - SOEM KL QualityDel Performance Review - FY13

Hochgeladen von

Dustin Robertsona

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 13

1

Sony Kaga Compo (M)

FY13 Quality & Delivery Performance Review

FY 14 2Q Action Plan

KGCOMPO(M)

Towards Stronger Partnership

Agenda Present By

Session 1 FY13 KGM Quality & Delivery Performance. By SOEM

Session 2

FY13 KGM Major Quality Issue Review.

By SOEM

Session 3 FY14 KGM Action Plans By KGM

KGCOMPO(M)

KGCOMPO(M)

FY13 KGM Quality & Delivery

Performance Review.

FY13 KGM Major Quality Issue

Review.

By SOEM

FY14 KGM Action Plan

KGCOMPO(M)

FY13 2

nd

Half 2Q Trend

KGCOMPO(M)

24

6

56

8

0

45

21

28

4

0

70

40

0

20

40

60

80

100

Nov-13 Dec-13 Jan-14 Feb-14 Mar-14

SMLD Trend BDP Model

200

234

199

100

19

36

130

42

10

0

200

100

0

100

200

300

Nov'13 Dec'13 Jan'14 Feb'14 Mar'14

SMLD Trend BDRE Model

Quality Trend

AMT - Kaga

HMT - Kaga

Thank U

6

FY14

Continual Kaizen

Programs

Key Processes

Compliance

Re-training Program

KGM 2014

2QTarget

KGCOMPO(M)

Quality Awareness

promotion

2Q Targets

Achieved

Soldering

Enhancement

FY13

KAGA FY14 Quality Improvement Pan

Continual Kaizen Program

KGM Customer

0

1

2

3

4

5

Monthly Kaizen Programs

Leak out Prevention

Defect Reduction

Flux On PWBA Reduction

Defect Prevention

Defects Prevention / Reduction By

Upstream Controls

KAGA FY14 Quality Improvement Program

Follow PM Shcedule

Daily Audits

Change model

Solder dross cleaning

Machine parameter check

Maintain

solder dross

cleaning

frequency change

New check sheet

Maintain

Maintain

Spray fluxed and

dipping start up

Spray fluxed check

sheet

Enhancement on

daily

compliance

through IPQC

audit

Key Parameters

Authorization

Specify Job Responsibility

X

Opt Skill-up Training Programme

1. Re-define Training

Material

2. Job Rotation/Break

time to Reduce

Human Fatigue. (FVI)

3. Soldering Skill Re-

certification program.

Re-certification Flow

Class Room Training

Certification Test

(Pass yield>90%)

Supervisor Monitor (2

weeks)

Update badge iD

KAGA FY14 Quality Improvement Program

Model Before After Current LDR(2013) Target Y14 Status

B6100

Sampling check

70% check at

CN201 & CN701

20cases 10 cases 0 case

B6069

Sampling check

70% check at

CN201 & CN701

35cases 12 cases 0 case

B1303

Sampling check

70% check at

CN201 & CN701

NA ( New Model) 12 cases 0 case

B1304

Sampling check

70% check at

CN201 & CN701

NA ( New Model) 6 cases 0 case

B6259

Sampling check

70% check at CN104 &

ND301

NA (New Model) 6 cases 0 case

B6248

Sampling check 70% check at CN402 NA (New Model) 6 cases 2 cases

1.Before : Inspection base on level III sampling table for all point as per WI

2.After : 70% inspection for all HM connectors (eg: CN201, CN701)

and sampling to other location.

No

OLNI

RE-STRUCTURE OQC INSPECTION PLAN (OLNI)

KAGA FY14 Quality Improvement Plan

Focusing On Potential Defects

LeakOut Sampling

Nama: Surwatie

No Pekerja: QA 3398I

Achievement:

Best no of detection

No Defects Leak Out to Customer

Proactive Feedback

Quality Awareness Promotion

KGCOMPO(M)

Monthly Best Performances Awards..Contl

Delivery Improvement Activities

12

KGCOMPO(M)

24H ETD Commitment Thru

Production Lost Time Reduction Program

BEFORE

Issuing SMTA PCB To HM Production

NOT follow lots basis.

AFTER

Issuing SMTA PCB By Lots Basis.

Zero PCBA

Awaiting

Lost Time

KGCOMPO(M)

Thank You

Das könnte Ihnen auch gefallen

- 0000004421-Chap 9Dokument42 Seiten0000004421-Chap 9Srinivas AmaraNoch keine Bewertungen

- QCC Young On Top ForDokument27 SeitenQCC Young On Top Forpatch_fighterNoch keine Bewertungen

- Chapter 15 - Six SigmaDokument8 SeitenChapter 15 - Six Sigmaumme mouNoch keine Bewertungen

- PresentingSixSigma NewDokument56 SeitenPresentingSixSigma Newpbp2956Noch keine Bewertungen

- Group 07 Sec B Case AnalysisDokument14 SeitenGroup 07 Sec B Case AnalysisSaurabh Singh100% (2)

- Ss OverviewDokument24 SeitenSs Overviewjitendrasutar1975Noch keine Bewertungen

- Saravana Kumar.M ResumeDokument6 SeitenSaravana Kumar.M ResumeHariNoch keine Bewertungen

- Curriculum Vitae: Current Salary: 2.80 Lacks P.A. Expected: 3.50 Lacks P.ADokument3 SeitenCurriculum Vitae: Current Salary: 2.80 Lacks P.A. Expected: 3.50 Lacks P.AASHUTOSH RANJANNoch keine Bewertungen

- SQA-General Customer Pres - 200909Dokument27 SeitenSQA-General Customer Pres - 200909franco_pelo_1970Noch keine Bewertungen

- Gautam C.V.Dokument4 SeitenGautam C.V.Gautam GuptaNoch keine Bewertungen

- RTMDokument21 SeitenRTMPuryCoyNoch keine Bewertungen

- Training On CTQ & CTPDokument32 SeitenTraining On CTQ & CTPPiyush MishraNoch keine Bewertungen

- MazegetDokument73 SeitenMazegetwatnaNoch keine Bewertungen

- Kra 12-13Dokument9 SeitenKra 12-13Saran KumarNoch keine Bewertungen

- GM APQP For SuppliersDokument73 SeitenGM APQP For Supplierscalinfn50% (2)

- 03 Q1 RequirementsDokument26 Seiten03 Q1 RequirementsARTURO SEGURANoch keine Bewertungen

- Six SigmaDokument46 SeitenSix Sigmaaminchhipa6892Noch keine Bewertungen

- Process Audit Check ListDokument24 SeitenProcess Audit Check ListSorin FrentoniNoch keine Bewertungen

- Anand Kumar ResumeDokument3 SeitenAnand Kumar ResumeArun ShishodiaNoch keine Bewertungen

- Step by Step Process Takes Place in QM: This Question Has BeenDokument7 SeitenStep by Step Process Takes Place in QM: This Question Has BeenVenkat ChakriNoch keine Bewertungen

- TQM PolaroidDokument36 SeitenTQM Polaroiduttam.nift100% (1)

- Work Load Sheet - StoresDokument90 SeitenWork Load Sheet - StoresSiddharth PalNoch keine Bewertungen

- Continuous ImprovementDokument88 SeitenContinuous Improvementkgkganesh8116Noch keine Bewertungen

- GM 1927-30 QSB AuditDokument38 SeitenGM 1927-30 QSB Auditmanune01Noch keine Bewertungen

- Six Sigma Green Belt Project - by Imran Haq 23-11-2010Dokument34 SeitenSix Sigma Green Belt Project - by Imran Haq 23-11-2010r_waseem100% (2)

- Old ResumeDokument6 SeitenOld ResumeRushikesh GirameNoch keine Bewertungen

- 012 QualityNewsLetter - January2012Dokument8 Seiten012 QualityNewsLetter - January2012ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Process Audit Check ListDokument47 SeitenProcess Audit Check ListAnas NazriNoch keine Bewertungen

- MoD DGQA Initiatives Towards EODBDokument59 SeitenMoD DGQA Initiatives Towards EODBSanjay Kumar DashNoch keine Bewertungen

- Ravi Shankar Tiwari: Automation & Service Operations, Process Excellence & Project Delivery ProfessionalDokument2 SeitenRavi Shankar Tiwari: Automation & Service Operations, Process Excellence & Project Delivery Professionalrajubhuyan1893Noch keine Bewertungen

- ACE Silver 2015 PresentationDokument20 SeitenACE Silver 2015 PresentationY BNoch keine Bewertungen

- Quality DocumentDokument15 SeitenQuality Documenttanto_deep_15Noch keine Bewertungen

- S. Raman: Mobile: +91 9600883617Dokument3 SeitenS. Raman: Mobile: +91 9600883617Praveen kumarNoch keine Bewertungen

- VSM 27janDokument21 SeitenVSM 27janShweta SinghNoch keine Bewertungen

- B Ravindra: V Guard Quarters V Guard Industries LTD K G ChavadiDokument5 SeitenB Ravindra: V Guard Quarters V Guard Industries LTD K G Chavadikavas26Noch keine Bewertungen

- 6 Sigma Projects PresentationDokument31 Seiten6 Sigma Projects Presentationbellbesh0% (1)

- Six Weeks Training Report or Presentation For B.techDokument38 SeitenSix Weeks Training Report or Presentation For B.techDeepinder SinghNoch keine Bewertungen

- QMA 10-10qs (Prestice) .Cs - enDokument15 SeitenQMA 10-10qs (Prestice) .Cs - enMphumzi NginaseNoch keine Bewertungen

- Guideline Release Procedure-SQPDokument19 SeitenGuideline Release Procedure-SQPfraspaNoch keine Bewertungen

- Question Bank - OPMDokument17 SeitenQuestion Bank - OPMRavi Kiran SunkaraNoch keine Bewertungen

- Apqp GMDokument73 SeitenApqp GMpbvrNoch keine Bewertungen

- Work Content of Production Team LeaderDokument18 SeitenWork Content of Production Team LeaderSivakumar VedachalamNoch keine Bewertungen

- Six Sigma Yellow Belt Training: Sudhakar SRDokument61 SeitenSix Sigma Yellow Belt Training: Sudhakar SRmartinimintyNoch keine Bewertungen

- Sap Standard QM ReportsDokument5 SeitenSap Standard QM Reportsamittal111100% (1)

- Quaity DefinitionDokument39 SeitenQuaity DefinitionArno Primaditya100% (1)

- Opm58 - Exam (Dec 2015) - AnswersDokument11 SeitenOpm58 - Exam (Dec 2015) - AnswersHammadNoch keine Bewertungen

- Saur Danfoss - SMDokument24 SeitenSaur Danfoss - SMPurushothama Nanje GowdaNoch keine Bewertungen

- Personal Details:: College Hill: Central: Uitenhage: 6241Dokument4 SeitenPersonal Details:: College Hill: Central: Uitenhage: 6241mdolleyNoch keine Bewertungen

- Kaizen Lean Management Service Sector2Dokument22 SeitenKaizen Lean Management Service Sector2Mahathir FansuriNoch keine Bewertungen

- SDT Paper Answersheet (Part B)Dokument4 SeitenSDT Paper Answersheet (Part B)kaushal dhapareNoch keine Bewertungen

- Final Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoDokument10 SeitenFinal Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoVikas KashyapNoch keine Bewertungen

- Sivaraman Eswaran ResumeDokument3 SeitenSivaraman Eswaran ResumeSabari BtechNoch keine Bewertungen

- 4-6s TrainingDokument28 Seiten4-6s TrainingAbdul Saboor KhanNoch keine Bewertungen

- QM AdditionalDokument11 SeitenQM AdditionalAnonymous IVxadA7HRNoch keine Bewertungen

- Practical Guide To Production Planning & Control [Revised Edition]Von EverandPractical Guide To Production Planning & Control [Revised Edition]Bewertung: 1 von 5 Sternen1/5 (1)

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionVon EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionNoch keine Bewertungen

- PHOTO OF Defect PWB (Qty 1) : PCB Overcut and R1 Scratch (Cavity 1)Dokument1 SeitePHOTO OF Defect PWB (Qty 1) : PCB Overcut and R1 Scratch (Cavity 1)Dustin RobertsonNoch keine Bewertungen

- 4130942611Dokument116 Seiten4130942611Dustin RobertsonNoch keine Bewertungen

- 2) Cap Cera Exposed Land Are Not BalanceDokument2 Seiten2) Cap Cera Exposed Land Are Not BalanceDustin RobertsonNoch keine Bewertungen

- KSP-45 Operator Training ProcedureDokument2 SeitenKSP-45 Operator Training ProcedureDustin Robertson50% (2)

- IwanDokument10 SeitenIwanMohd Isa HarunNoch keine Bewertungen

- Hacking: Name: Farah Hanani Binti Mohd Isa I.C. NUMBER: 890418-02-6192 Class: 4 Fikrah Ict Teacher: Pn. DzulianaDokument3 SeitenHacking: Name: Farah Hanani Binti Mohd Isa I.C. NUMBER: 890418-02-6192 Class: 4 Fikrah Ict Teacher: Pn. DzulianaDustin RobertsonNoch keine Bewertungen

- Wrong Part Supplied by SupplierDokument6 SeitenWrong Part Supplied by SupplierDustin RobertsonNoch keine Bewertungen

- Wrong Part Supplied by SupplierDokument6 SeitenWrong Part Supplied by SupplierDustin RobertsonNoch keine Bewertungen

- Yamaha Ddcon Measurement: Terminal Protrude 0.1 0.2Mm Terminal Same Level As The BodyDokument1 SeiteYamaha Ddcon Measurement: Terminal Protrude 0.1 0.2Mm Terminal Same Level As The BodyDustin RobertsonNoch keine Bewertungen

- Toto Controller Rework Flow 20140724Dokument1 SeiteToto Controller Rework Flow 20140724Dustin RobertsonNoch keine Bewertungen

- Yamaha Ddcon Measurement: Terminal Protrude 0.1 0.2Mm Terminal Same Level As The BodyDokument1 SeiteYamaha Ddcon Measurement: Terminal Protrude 0.1 0.2Mm Terminal Same Level As The BodyDustin RobertsonNoch keine Bewertungen

- 2013 SGS ISO9001 Audit Non Confirmation RecordDokument3 Seiten2013 SGS ISO9001 Audit Non Confirmation RecordDustin RobertsonNoch keine Bewertungen

- Lead LengthDokument1 SeiteLead LengthDustin RobertsonNoch keine Bewertungen

- 1402 1404 ObservationDokument2 Seiten1402 1404 ObservationDustin RobertsonNoch keine Bewertungen

- c4 CrackDokument15 Seitenc4 CrackCheryl McgeeNoch keine Bewertungen

- PHOTO Bare Board 1-734-376-21Dokument3 SeitenPHOTO Bare Board 1-734-376-21Dustin RobertsonNoch keine Bewertungen

- Presentation DelcorteDokument15 SeitenPresentation Delcortecarlos2685Noch keine Bewertungen

- Service ManualDokument582 SeitenService ManualBogdan Popescu100% (5)

- Shear and Diagonal Tension in BeamDokument16 SeitenShear and Diagonal Tension in BeamMouy PhonThornNoch keine Bewertungen

- Module 3: Literature Review and CitationDokument3 SeitenModule 3: Literature Review and CitationLysss EpssssNoch keine Bewertungen

- Bike Share ReportDokument16 SeitenBike Share Reportsanjay975100% (1)

- LogDokument67 SeitenLogRudhi Al GhaisanNoch keine Bewertungen

- Lithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileDokument29 SeitenLithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileAbdiel MuñozNoch keine Bewertungen

- NCR Supplier PPAP Training PresentationDokument166 SeitenNCR Supplier PPAP Training PresentationRajeev ChadhaNoch keine Bewertungen

- Wish Upon A STAR: Presented By: Daulo, Eunice R. III - Block 3Dokument17 SeitenWish Upon A STAR: Presented By: Daulo, Eunice R. III - Block 3nhyce18Noch keine Bewertungen

- Summative 1Dokument4 SeitenSummative 1Nean YsabelleNoch keine Bewertungen

- Capital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisDokument16 SeitenCapital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisHaris FendiarNoch keine Bewertungen

- Om en A: F in Ite D Iffe Ren Ce-B Ase DN Um Eri Ca L M Eth Od SDokument426 SeitenOm en A: F in Ite D Iffe Ren Ce-B Ase DN Um Eri Ca L M Eth Od SPrateek Kumar PandeyNoch keine Bewertungen

- ZTE V4 RNC Commissioning and Integration TrainingDokument2 SeitenZTE V4 RNC Commissioning and Integration TrainingBeena SinghNoch keine Bewertungen

- INS2015 Fundamentals of Finance HungCV 1Dokument3 SeitenINS2015 Fundamentals of Finance HungCV 1Phương Anh NguyễnNoch keine Bewertungen

- Python - Data EngineeringDokument34 SeitenPython - Data EngineeringChetan PatilNoch keine Bewertungen

- Q1 Practical Research 2 - Module 1bDokument15 SeitenQ1 Practical Research 2 - Module 1bRhea Mae MacabodbodNoch keine Bewertungen

- Strategic Cost AnalysisDokument24 SeitenStrategic Cost AnalysisBusiness Expert Press100% (10)

- TCS3400 DS000411 4-00Dokument34 SeitenTCS3400 DS000411 4-00Miguel_Angel92Noch keine Bewertungen

- SFN ProfileDokument4 SeitenSFN Profiledinesh panchalNoch keine Bewertungen

- Silenat Berhanu SimaDokument6 SeitenSilenat Berhanu SimaSilenat BerhanuNoch keine Bewertungen

- Term Test Pointers For Review - 1st TermDokument2 SeitenTerm Test Pointers For Review - 1st Termjessica holgadoNoch keine Bewertungen

- Malraux Anti-MemoiresDokument9 SeitenMalraux Anti-MemoiresNevenaRistićNoch keine Bewertungen

- Pile Capacity - An Overview - ScienceDirect TopicsDokument15 SeitenPile Capacity - An Overview - ScienceDirect TopicssurNoch keine Bewertungen

- ISO 20000-1 Gap Analysis QuestionaireDokument15 SeitenISO 20000-1 Gap Analysis QuestionaireUsman Hamid67% (6)

- Thursday / January 2019 Thursday / January 2019Dokument572 SeitenThursday / January 2019 Thursday / January 2019Zie EikinNoch keine Bewertungen

- Submission Letter To LBUDokument46 SeitenSubmission Letter To LBUramesh bajracharyaNoch keine Bewertungen

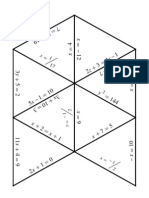

- Algebra1 Review PuzzleDokument3 SeitenAlgebra1 Review PuzzleNicholas Yates100% (1)

- Application Bright Ideas Education Grant Program For TeachersDokument6 SeitenApplication Bright Ideas Education Grant Program For Teachersapi-320983699Noch keine Bewertungen

- Rule Based ClassificationsDokument14 SeitenRule Based ClassificationsAmrusha NaallaNoch keine Bewertungen

- Hemo TecaDokument17 SeitenHemo TecaMafer PilcoNoch keine Bewertungen

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)