Beruflich Dokumente

Kultur Dokumente

Robotics in Manufacturing

Hochgeladen von

YbrantSachinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Robotics in Manufacturing

Hochgeladen von

YbrantSachinCopyright:

Verfügbare Formate

By

Group 6

Amulya M 12066

Prithiv Prasad C 12078

Mythri H N 12090

Sandeep Haneefa 12102

Syam Thomas 12114

Robotics: The branch of technology that deals with the design,

construction, operation, and application of robots

Robot comes from the Czech word robota, meaning drudgery or

slave-like labor.

A robot is

A machine capable of carrying out a complex series of actions

automatically

A machine resembling a human being and able to replicate certain

human movements and functions

Some robots require some degree of guidance, which may be done

using

A remote control

With a computer interface

Artificial intelligence

Robotics and Robots

Father of Robotics: George Charles Devol .

1954: First industrial robot, The Unimate

1961:General Motors installed the Unimate for die casting

handling and spot welding

1963:Six-jointed Rancho Arm was created to assist

handicapped.

1968:Tentacle arm with 12 joints to lift a person was designed

by Marvin Minsky

1969:Stanford Arm - The first electronically powered,

computer-controlled arms

1974:Silver Arm was created by MIT's David Silver to perform

precise assembly using touch and pressure sensors and a

microcomputer

History

Greater accuracy, precision and consistency

Improved product quality, productivity and manufacturing cost

cuts

No more dull, hazardous or taxing tasks for workers

Robots can handle

Toxic substances

Repetitive and detail-driven jobs

Lifting, carrying and selecting products without tiring or stopping.

Return on investment (ROI) for an industrial robot is substantial

and quick.

Robots are tireless and faster

Prevents accidents

Why use Robots?

Robot Architecture

Controller

Brain of the robot

Runs on a set of instructions written in code

Robot Arms

Vary in size and shape

Have joints which give the robot three degrees of freedom

Up and Down

Left and Right

Forward and Backward

Basic components used

End Effector

Connected to the robot arm

Functions as a hand

Variations in an effector:

Gripper

Vacuum pump

Magnets

Welding Torches

Drive

Engine or Motor that moves the links or joints

Different types:

Hydraulic

Pneumatic

Electric

Basic Components Used(Cont.)

Sensors

Can give a limited sense of sight and sound

Collects information and sends it electronically to the

controller

Vision sensors allow a pick and place robot to

differentiate between items

Prevent two robots bumping into each other

Assist end effectors by adjusting part variances

Basic Components Used(Cont.)

Aerospace

Automotive manufacturing and supply

Chemical, rubber and plastics manufacturing

Electrical and electronics

Entertainment-movie making

Food stuff and beverage manufacturing

Glass, ceramics and mineral production

Printing

Wood and furniture manufacturing

Robots in Manufacturing

Handling dangerous materials

Cutting and polishing

Pick and Place Operations

Assembling products

Spot and Electric Arc Welding

Spraying finishes

Inspecting parts, produce, and

livestock

Tasks of Robots in Manufacturing

A Welding Robot

Programmed by

Guiding

Manual guiding of a robot from point to point through the phases of an

operation

Off-line programming

Points of an operation are defined through computer commands

Referred to as manipulator level off-line programming

Can be programmed to move through a specified continuous path also

Eg: Continuous path control- spray painting or arc welding a curved joint

A robot should be synchronized with the automated machine tools or

other robots with which it is working

Robot control systems are thus interfaced with a centralized control

system.

How are robots Programmed?

A program written, should consist of the following:

The path , robot should follow

The points it should reach

Details about how to interpret the sensor data

How and when the end-effectors should be activated

How to move parts between given locations

Essentials of a Program

1

st

Robot Language: VAL (Variable Assembly Language)-

used in Unimate Robots

Visual Programming Languages

Eg: LabVIEW

Programs are constructed by dragging icons into the

program area and adding or inserting into the sequence

For each icon, parameters are then specified(Data)

The program is then downloaded on a micro-controller for

testing

Scripting Languages

Eg: RoboLogix

High-level programming language used to control a

software application

Is interpreted in real-time, or "translated on the fly", instead

of being compiled in advance

Programming Languages Used

Today's robots:

Are not creative or innovative

Can not think independently

Can not make complicated decisions

Can not learn from mistakes

Can not adapt quickly to changes in their

surroundings

Every successful business must depend on real people

for these abilities.

Limitations of Robots

Bundles and stacks

boxes onto pallets for

storage and shipment

Palletizer

Automated Paint

Spraying

Robotic Sprayer

Robotics has enhanced the productivity of many

manufacturing industries.

But still, the question remains if justice is being done

to the human population as robots are taking over

their jobs.

Integrating Robotics with Human power is the only

feasible solution available.

Conclusion

Car Making in BMW

Das könnte Ihnen auch gefallen

- Selco Group4Dokument5 SeitenSelco Group4YbrantSachinNoch keine Bewertungen

- TCS Kalpesh VasvaniDokument3 SeitenTCS Kalpesh VasvaniYbrantSachinNoch keine Bewertungen

- Customer Satisfaction, Cash Flow, and Shareholder Value: Journal of Marketing August 2005Dokument18 SeitenCustomer Satisfaction, Cash Flow, and Shareholder Value: Journal of Marketing August 2005YbrantSachinNoch keine Bewertungen

- Overview of Russian EconomyDokument5 SeitenOverview of Russian EconomyYbrantSachinNoch keine Bewertungen

- PBoI's Digital Banking Innovation RoadmapDokument14 SeitenPBoI's Digital Banking Innovation RoadmapHarjas BakshiNoch keine Bewertungen

- Covariance, Correlation, Beta, Expost, and ExanteDokument6 SeitenCovariance, Correlation, Beta, Expost, and ExanteYbrantSachinNoch keine Bewertungen

- Analysis of RatiosDokument4 SeitenAnalysis of RatiosYbrantSachinNoch keine Bewertungen

- Name: Pratik Shah (FIN & MKT)Dokument4 SeitenName: Pratik Shah (FIN & MKT)YbrantSachinNoch keine Bewertungen

- Infosys Techn VeniDokument3 SeitenInfosys Techn VeniYbrantSachinNoch keine Bewertungen

- NoteDokument1 SeiteNoteYbrantSachinNoch keine Bewertungen

- 2015 Budget Speech Full TextDokument43 Seiten2015 Budget Speech Full TextYbrantSachinNoch keine Bewertungen

- 0.63433000 1431521300 Investor Presentation Fortis Investor Day April6 2015Dokument49 Seiten0.63433000 1431521300 Investor Presentation Fortis Investor Day April6 2015YbrantSachinNoch keine Bewertungen

- Logistics Supply Challenges HospitalsDokument10 SeitenLogistics Supply Challenges HospitalsYbrantSachinNoch keine Bewertungen

- BhimsenDokument374 SeitenBhimsenPrem Panicker50% (8)

- What Is Cost of Equity of TATA POWER Company Limited?Dokument6 SeitenWhat Is Cost of Equity of TATA POWER Company Limited?YbrantSachinNoch keine Bewertungen

- Case Analysis: Ford Motor Company - Supply Chain StrategyDokument7 SeitenCase Analysis: Ford Motor Company - Supply Chain StrategyYbrantSachinNoch keine Bewertungen

- DMO Case Presentation Group-B10Dokument13 SeitenDMO Case Presentation Group-B10YbrantSachinNoch keine Bewertungen

- SugarcaneDokument20 SeitenSugarcaneYbrantSachinNoch keine Bewertungen

- What Is Cost of Equity of TATA POWER Company Limited?Dokument6 SeitenWhat Is Cost of Equity of TATA POWER Company Limited?YbrantSachinNoch keine Bewertungen

- Brand Management by S Radhakrishnan (BRM)Dokument3 SeitenBrand Management by S Radhakrishnan (BRM)YbrantSachinNoch keine Bewertungen

- KsDokument12 SeitenKsYbrantSachinNoch keine Bewertungen

- Discipline and GrievanceDokument18 SeitenDiscipline and GrievanceYbrantSachinNoch keine Bewertungen

- Discipline and GrievanceDokument18 SeitenDiscipline and GrievanceYbrantSachinNoch keine Bewertungen

- Trade Unions AND Employers' AssociationsDokument9 SeitenTrade Unions AND Employers' AssociationsYbrantSachinNoch keine Bewertungen

- KsDokument12 SeitenKsYbrantSachinNoch keine Bewertungen

- Resume TemplateDokument3 SeitenResume TemplateYbrantSachinNoch keine Bewertungen

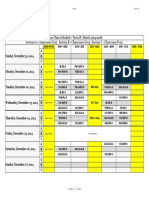

- I Year Class Schedule - Term II - Batch 2014-2016 Section A - Classroom G-03 Section B - Classroom G-04 Section C - Classroom F-04Dokument3 SeitenI Year Class Schedule - Term II - Batch 2014-2016 Section A - Classroom G-03 Section B - Classroom G-04 Section C - Classroom F-04YbrantSachinNoch keine Bewertungen

- Information Technology: Key ConceptsDokument21 SeitenInformation Technology: Key ConceptsYbrantSachinNoch keine Bewertungen

- Sudan: Political FactorsDokument6 SeitenSudan: Political FactorsYbrantSachinNoch keine Bewertungen

- Quality, Manufacturing Strategy, and Global Competition: An Empirical AnalysisDokument17 SeitenQuality, Manufacturing Strategy, and Global Competition: An Empirical AnalysisYbrantSachinNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lesson 7Dokument42 SeitenLesson 7Nithya NairNoch keine Bewertungen

- Advanced SAS Interview Questions You'll Most Likely Be AskedDokument27 SeitenAdvanced SAS Interview Questions You'll Most Likely Be AskedVibrant PublishersNoch keine Bewertungen

- Face RecogDokument26 SeitenFace RecogFavasNoch keine Bewertungen

- ZJ 5780s Instruction BookDokument102 SeitenZJ 5780s Instruction BookRATSITOHARA EricNoch keine Bewertungen

- Automata and ComputabilityDokument240 SeitenAutomata and ComputabilitySupiyanto HasanNoch keine Bewertungen

- Ion Luca Caragiale, ReferatDokument2 SeitenIon Luca Caragiale, ReferatComan DanielNoch keine Bewertungen

- Python - What Does Turtle - Tracer Do - Stack OverflowDokument2 SeitenPython - What Does Turtle - Tracer Do - Stack OverflowKassoum KobréNoch keine Bewertungen

- BN20 e PreDokument59 SeitenBN20 e PreTuan DinhNoch keine Bewertungen

- OAF TrainiingDokument23 SeitenOAF TrainiingCoral Shiny0% (1)

- Kyocera TASKalfa 3501i BrochureDokument8 SeitenKyocera TASKalfa 3501i Brochuretaunweer2Noch keine Bewertungen

- Ups MotherboardDokument5 SeitenUps MotherboardMustapha El MaouzouniNoch keine Bewertungen

- To Call A Function From BI PublisherDokument6 SeitenTo Call A Function From BI PublisherbalasukNoch keine Bewertungen

- Easychair Preprint: Adnene Noughreche, Sabri Boulouma and Mohammed BenbaghdadDokument8 SeitenEasychair Preprint: Adnene Noughreche, Sabri Boulouma and Mohammed BenbaghdadTran Quang Thai B1708908Noch keine Bewertungen

- Alert Broadcasting Conferencing: Broadcasts and Alert NotificationsDokument4 SeitenAlert Broadcasting Conferencing: Broadcasts and Alert Notificationsdaniel.bpmNoch keine Bewertungen

- Modelling Photovoltaic Systems Using Pspice@: Luis Castafier Santiago SilvestreDokument2 SeitenModelling Photovoltaic Systems Using Pspice@: Luis Castafier Santiago SilvestreLuiz Fernando F. De AndradeNoch keine Bewertungen

- 5-V Low-Drop Voltage Regulator TLE 4263: FeaturesDokument17 Seiten5-V Low-Drop Voltage Regulator TLE 4263: FeaturesWelleyNoch keine Bewertungen

- Jean Abreu CVDokument3 SeitenJean Abreu CVABREUNoch keine Bewertungen

- 2021 Anna University RegulationsDokument415 Seiten2021 Anna University RegulationsThamarai KannanNoch keine Bewertungen

- EADK Architecture GuideDokument31 SeitenEADK Architecture GuideUltrazikingNoch keine Bewertungen

- Critical Path MethodDokument6 SeitenCritical Path Method6 4 8 3 7 JAYAASRI KNoch keine Bewertungen

- Q4M2 Giving Technical and Operational Def.2.0Dokument60 SeitenQ4M2 Giving Technical and Operational Def.2.0Shadow Gaming YTNoch keine Bewertungen

- ENGG103 Course Specifications Eng v202Dokument7 SeitenENGG103 Course Specifications Eng v202Ibrahim MahamidNoch keine Bewertungen

- Characterization of SPT Grain Size Effects in GravDokument9 SeitenCharacterization of SPT Grain Size Effects in Gravstefanus fendisaNoch keine Bewertungen

- AQA Physics A-Level Electricity Questions (Pack 3)Dokument90 SeitenAQA Physics A-Level Electricity Questions (Pack 3)BDNoch keine Bewertungen

- GSM Technique Applied To Pre-Paid Energy MeterDokument9 SeitenGSM Technique Applied To Pre-Paid Energy MeterInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Oed 2,0 2022Dokument139 SeitenOed 2,0 2022Ellish ErisNoch keine Bewertungen

- 11 - Chapter 5Dokument22 Seiten11 - Chapter 5Parth MundhwaNoch keine Bewertungen

- Teams HandbookDokument18 SeitenTeams HandbookLudi D. LunarNoch keine Bewertungen

- RSRed DS RS200L Mod v5Dokument2 SeitenRSRed DS RS200L Mod v5liebherrmanNoch keine Bewertungen

- أسئلة دورات تجميعDokument131 Seitenأسئلة دورات تجميعRashed Abu AlsondosNoch keine Bewertungen