Beruflich Dokumente

Kultur Dokumente

Lpgbottlingplant 12494506726011 Phpapp03 (Repaired)

Hochgeladen von

Rajesh GuptaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lpgbottlingplant 12494506726011 Phpapp03 (Repaired)

Hochgeladen von

Rajesh GuptaCopyright:

Verfügbare Formate

Abhishek Vats(02)

Amit Singh(04)

Nitin Sarawat(35)

Subodh Maithani(62)

Operation Processes in

LPG Bottling Plant

Inputs

cylinders

water

LPG.

Management

Land

Labour

Material

Equipment

Processes

Washing

Drying

Purging

Evacuation

Auto cap fixing

Aluminum

crimping unit

Adjustments

Weighing corr.

Valve change

Random Fluctuations

Operational Defects

Market Forces

Natural Calamities

Availabilities of Crude

Comparison:

Weighing scale.

Valve testing

SQC system

Outputs

LPG Cylinder

Monitor Outputs

Degassing unit.

Chain conveyor

system.

Telescopic conveyor

system.

pushers, stoppers,

line controls.

Washing unit

The Washing unit is on-

line equipment used to

wash the incoming

cylinders with multiple

forced jet of water to

remove mud, dirt,

stains, etc., from the

outer surfaces.

Drying unit

The Drying unit is an on-

line equipment used to

dry the cylinders,

coming out of washing

unit by blowing the air

on the sides and top

surfaces of the cylinders

as they move.

Purging unit: Purging Unit is an on-line

equipment used to create vacuum in the first

stage and filling LPG vapor in the second stage

in new / hot repaired empty cylinders.

Evacuation system: Evacuation unit is an on-

line equipment used to remove LPG liquid and

depressurize cylinders identified leaky during

post fill valve performance testing.

Auto cap fixing unit: Auto cap fixer is on-line

equipment used to fix safety caps on to the

valve of LPG cylinders.

Aluminum seal crimping unit/Hot air sealing

unit: Seal crimping unit is on-line equipment

used to crimp the aluminum cap seal around

the cylinder valve as a final operation on the

filled LPG cylinder.

Check weigh scale

The digital check weighing system with segregation unit

is designed to check the gross weight of a filled LPG

cylinder and reject the cylinder from main stream on to

a loop conveyor if the gross weight is more or less than

the stipulated value. The electronic check scale is

programmed in such a way to subtract 14.2 Kg or 19 Kg

from total weight of cylinder and the tare weight will

be displayed. Operator has to compare the displayed

tare weight value with the tare weight value punched

on the cylinder and if the value is beyond the

permissible limit, the cylinder will be rejected.

Weigh correction unit

The unit is an on-line

equipment used to

ensure that correct

weight of LPG fuel is

carried in the cylinders.

Under-filled cylinders

are filled with additional

quantity of LPG and the

weight is corrected.

Overfilled cylinders are

checked and the weight

of LPG fuel is corrected

by evacuation process.

Compact valve testing: The compact valve

testing unit is on-line equipment designed to

test for leakage in the cylinder valve O-ring

and in the valve seat and to distinguish

between these leaks.

SQC system: The on-line SQC system checks

the weight as well as valve and 'O' ring leak of

the filled cylinders.

Valve change system: Valve change unit is an

on-line equipment used to remove or replace

the valve of LPG cylinder by unscrewing or

screwing operation at a set torque and speed.

Valve change system

Degassing system: Degassing unit is an on-line

equipment used to remove LPG vapor from a

batch of damaged cylinders identified during

post fill inspection using water and air.

Pushers stoppers and line controls: Pushers

and stoppers are fabricated units with

pneumatic cylinders along with proper guides.

Smooth transfer of cylinders between the

parallel conveyors .

Conveyor system

Chain

Chain Conveyor System is a

fabricated structural

assembly, in which the

fabricated chain moves in a

track with the help of

geared motor drive.

Telescopic

Telescopic Conveyor is

employed mainly for loading

and unloading of LPG Cylinder

to and from lorries of filled

and empty cylinders

respectively.

The Largest and The Highest

largest LPG bottling plant, at Bajwan north of

Baghdad (Iraq)

Indian oil refinery major, Indian Oil

Corporation's Leh bottling plant set enjoys the

distinction of being the highest bottling plant

in the world - situated at 11,500ft above sea

level.

References

www.wikipedia.org

www.raplindia.com

www.wtrg.com

www.mottmac.in

Thank You

Das könnte Ihnen auch gefallen

- SOP Filling Plant SectionDokument21 SeitenSOP Filling Plant SectionBesan LaduNoch keine Bewertungen

- Filling Plant PresentationDokument29 SeitenFilling Plant PresentationBrian CbtngnNoch keine Bewertungen

- Air Blowing ProcedureDokument11 SeitenAir Blowing ProcedureBhayu Eka AnggitaNoch keine Bewertungen

- Gas Cylinder RulesDokument24 SeitenGas Cylinder RulesAnuj SinhaNoch keine Bewertungen

- Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerDokument6 SeitenDesign of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerHoàng KakaNoch keine Bewertungen

- The Red Book MY3Dokument47 SeitenThe Red Book MY3Syed Arsalan AfsarNoch keine Bewertungen

- LPG Induction Course NewDokument28 SeitenLPG Induction Course NewMha RizNoch keine Bewertungen

- Project Work Estimation: Mumbai Office: C-62/204, Sector-9, Shantinagar, Miraroad (East), Thane-401107, Maharashtra, IndiaDokument6 SeitenProject Work Estimation: Mumbai Office: C-62/204, Sector-9, Shantinagar, Miraroad (East), Thane-401107, Maharashtra, IndiaAmul AmnajeNoch keine Bewertungen

- Operating and Setting Up An LPG Plant in NigeriaDokument5 SeitenOperating and Setting Up An LPG Plant in NigeriaAJAGUN JOHNSONNoch keine Bewertungen

- LPG Finishd Abiola Faluyi FinalDokument19 SeitenLPG Finishd Abiola Faluyi FinalAmir O. OshoNoch keine Bewertungen

- Gas Installation PDFDokument31 SeitenGas Installation PDFNelson VargasNoch keine Bewertungen

- LPG Tank Commissioning Training NotesDokument32 SeitenLPG Tank Commissioning Training NotesKajubi Edris100% (1)

- LPG RulesDokument12 SeitenLPG RulesAhmed KhanNoch keine Bewertungen

- LPG Cylinder Filling CenterDokument7 SeitenLPG Cylinder Filling CenterDayo Idowu100% (1)

- OLPG S1-01 - OESA LPG Depots and Filling PlantsDokument38 SeitenOLPG S1-01 - OESA LPG Depots and Filling PlantsGogne Rodolph100% (1)

- Blasting and Painting ProcedureDokument6 SeitenBlasting and Painting Procedureanon_994898767Noch keine Bewertungen

- Gas Facilities Audit ChecklistDokument2 SeitenGas Facilities Audit ChecklistEddie TaiNoch keine Bewertungen

- IMANI Ghana Gas Initial Report 2013 AprilDokument7 SeitenIMANI Ghana Gas Initial Report 2013 AprilIMANI Center for Policy and EducationNoch keine Bewertungen

- Aegis LPG TenderDokument147 SeitenAegis LPG TenderKazeem100% (1)

- 5000m3 LPG Tank FarmDokument2 Seiten5000m3 LPG Tank FarmLpgTankFarmNoch keine Bewertungen

- As LPG Bottle Filling EDokument9 SeitenAs LPG Bottle Filling EGerson AsmNoch keine Bewertungen

- Questor Training Example 1Dokument2 SeitenQuestor Training Example 1Gary NgNoch keine Bewertungen

- Process Description and Control FinalDokument7 SeitenProcess Description and Control Finalnaveedzia01Noch keine Bewertungen

- 5092-2009 CNG Refuelling StationsDokument44 Seiten5092-2009 CNG Refuelling StationsTim WilsonNoch keine Bewertungen

- Gaspipe SizingDokument15 SeitenGaspipe SizingmaxxhaloNoch keine Bewertungen

- Check List For LPG/LNG LicenseDokument8 SeitenCheck List For LPG/LNG LicenseChachi TerijanNoch keine Bewertungen

- Reticulated Gas SystemDokument5 SeitenReticulated Gas SystemKripa SriramNoch keine Bewertungen

- Operation and Maintenance Guidelines For PL and Compressor Booster StationsDokument83 SeitenOperation and Maintenance Guidelines For PL and Compressor Booster StationsUmer Khan100% (1)

- Feasibility For Small LPG CylindersDokument67 SeitenFeasibility For Small LPG Cylinderstulasinad123Noch keine Bewertungen

- Decommissioning 12710Dokument14 SeitenDecommissioning 12710xjaf01Noch keine Bewertungen

- Project of MPOL LPGDokument24 SeitenProject of MPOL LPGroihyNoch keine Bewertungen

- Cat Loading by Sock Method in Inert AtmosphereDokument5 SeitenCat Loading by Sock Method in Inert Atmospherevishal bailurNoch keine Bewertungen

- Full Thesis PDFDokument109 SeitenFull Thesis PDFTanjib Rahman NiloyNoch keine Bewertungen

- Project GuidelineDokument7 SeitenProject GuidelineNg Kee NainNoch keine Bewertungen

- P & ID For Complete LPG Terminal ProjectDokument1 SeiteP & ID For Complete LPG Terminal ProjectLPG TERMINALNoch keine Bewertungen

- LPG Safety Orientation 2015Dokument32 SeitenLPG Safety Orientation 2015Mha RizNoch keine Bewertungen

- 005 LPG Om & Sop PDFDokument109 Seiten005 LPG Om & Sop PDFRakesh Kumar100% (7)

- Chap 3 Gas Supply ActDokument89 SeitenChap 3 Gas Supply Actkimberly_87100% (1)

- Hot Oil Installation Procedure PDFDokument36 SeitenHot Oil Installation Procedure PDFshyam_adhikaryNoch keine Bewertungen

- LPGStatutory RequirementsDokument4 SeitenLPGStatutory RequirementsalwacsNoch keine Bewertungen

- Feasibility Study of Liquefied Natural Gas ProjectDokument13 SeitenFeasibility Study of Liquefied Natural Gas Projectkeshermech100% (1)

- LPG Marketing DOMESTIC & Non-DomesticDokument44 SeitenLPG Marketing DOMESTIC & Non-DomesticAkshay PatilNoch keine Bewertungen

- Project Report - CNG CylindersDokument23 SeitenProject Report - CNG CylindersNaresh DhakerNoch keine Bewertungen

- Flash Skim Vessel Descr.Dokument5 SeitenFlash Skim Vessel Descr.vanashley1Noch keine Bewertungen

- LPG CODE (English)Dokument36 SeitenLPG CODE (English)Nguyễn Xuân Điệp100% (1)

- Oil Refining Process Units For Sale and Relocation - All ClientsDokument1 SeiteOil Refining Process Units For Sale and Relocation - All ClientsRahim1850Noch keine Bewertungen

- ORYX Kigamboni LPG DepotDokument1 SeiteORYX Kigamboni LPG DepotHussein Boffu100% (1)

- Project Profile-LPG Bottling PlantDokument6 SeitenProject Profile-LPG Bottling PlantSagarTak50% (4)

- Eni Gas Pipeline Final Report PDFDokument30 SeitenEni Gas Pipeline Final Report PDFQudri SaufiNoch keine Bewertungen

- Gas Train Project PQDokument50 SeitenGas Train Project PQvrajakisoriDasiNoch keine Bewertungen

- MWP-C-CS-PC-0009 Tank Erection Procedure-BDokument17 SeitenMWP-C-CS-PC-0009 Tank Erection Procedure-BKing王Noch keine Bewertungen

- Tank Storage Istanbul 11/2010 LPG Loading Operations ManagementDokument18 SeitenTank Storage Istanbul 11/2010 LPG Loading Operations Managementpritam4321100% (1)

- Characteristics of LPGasDokument8 SeitenCharacteristics of LPGasAnkita KulshreshthaNoch keine Bewertungen

- LPG Consultancy BrochureDokument4 SeitenLPG Consultancy BrochureAnoop PrajapatiNoch keine Bewertungen

- Lpgbottlingplant 12494506726011 Phpapp03Dokument15 SeitenLpgbottlingplant 12494506726011 Phpapp03mdashrafalamNoch keine Bewertungen

- Class 4 EoowDokument74 SeitenClass 4 EoowRyan Cardoza0% (1)

- Booklet Ninnelt - EnglischDokument16 SeitenBooklet Ninnelt - EnglischLpg Power SupplyNoch keine Bewertungen

- Catalog Skid Mounted System PDFDokument56 SeitenCatalog Skid Mounted System PDFUmar AslamNoch keine Bewertungen

- Katalog PDFDokument56 SeitenKatalog PDFqaramanNoch keine Bewertungen

- The Book of OpticsDokument1 SeiteThe Book of OpticsRajesh GuptaNoch keine Bewertungen

- Ancient AstronomyDokument1 SeiteAncient AstronomyRajesh GuptaNoch keine Bewertungen

- Activity Series: Cu (S) + 2ag+ (Aq) - Cu2+ (Aq) + 2ag (Aq)Dokument6 SeitenActivity Series: Cu (S) + 2ag+ (Aq) - Cu2+ (Aq) + 2ag (Aq)Rajesh GuptaNoch keine Bewertungen

- CopperDokument3 SeitenCopperRajesh GuptaNoch keine Bewertungen

- Physics (From: Physik (Epist Mē)Dokument1 SeitePhysics (From: Physik (Epist Mē)Rajesh GuptaNoch keine Bewertungen

- Comparison Histamine-2 Receptor Antagonist & AntacidDokument5 SeitenComparison Histamine-2 Receptor Antagonist & AntacidRajesh GuptaNoch keine Bewertungen

- NMO 2017 Results: Inmo 2017 Awardee S Cut-Off Score: 60Dokument4 SeitenNMO 2017 Results: Inmo 2017 Awardee S Cut-Off Score: 60Rajesh GuptaNoch keine Bewertungen

- November 2017 Issue PDFDokument26 SeitenNovember 2017 Issue PDFRajesh GuptaNoch keine Bewertungen

- Astronomy For Kids - ConstellationsDokument6 SeitenAstronomy For Kids - ConstellationsRajesh GuptaNoch keine Bewertungen

- Readings of Experiment: Determine The Diameter of A Given Wire and Calculate It's Area by Using Screw GaugeDokument1 SeiteReadings of Experiment: Determine The Diameter of A Given Wire and Calculate It's Area by Using Screw GaugeRajesh GuptaNoch keine Bewertungen

- SR - Sc.registered Institution DetailsDokument132 SeitenSR - Sc.registered Institution DetailsRajesh GuptaNoch keine Bewertungen

- LPG Pricing A Producer Point of Vue: World Gas Conference Nice 6 - 9 JUNE 2000Dokument13 SeitenLPG Pricing A Producer Point of Vue: World Gas Conference Nice 6 - 9 JUNE 2000Rajesh GuptaNoch keine Bewertungen

- Ntse Delhi Stage-1 2016Dokument6 SeitenNtse Delhi Stage-1 2016Rajesh GuptaNoch keine Bewertungen

- LPG Supply Chain WlpgaDokument3 SeitenLPG Supply Chain WlpgaRajesh GuptaNoch keine Bewertungen

- Ntse Haryana Stage 1 ResultDokument9 SeitenNtse Haryana Stage 1 ResultRajesh GuptaNoch keine Bewertungen

- FDA Assignment1Dokument4 SeitenFDA Assignment1Rajesh GuptaNoch keine Bewertungen

- 9ha Power PlantsDokument2 Seiten9ha Power PlantsIzzadAfif1990Noch keine Bewertungen

- Dissertation Brinkmeier 061124Dokument180 SeitenDissertation Brinkmeier 061124AlbertoCostoyaNoch keine Bewertungen

- 2010 Yamaha 242 Limited Service ManualDokument343 Seiten2010 Yamaha 242 Limited Service ManualDerek SouthardNoch keine Bewertungen

- Excavadora Doosan Dx300lcaDokument5 SeitenExcavadora Doosan Dx300lcaXiomara Muñoz Mendoza100% (2)

- Cleaning of Pipeline PDFDokument9 SeitenCleaning of Pipeline PDFAnonymous Xy309m9Sm9100% (3)

- Manual de Armado de Motor Volvo D6ADokument32 SeitenManual de Armado de Motor Volvo D6Amarcos astete100% (3)

- MegaSquirt Toyota 22REDokument22 SeitenMegaSquirt Toyota 22REbluebelle2100% (2)

- Engine Analysis-Capstone ReportDokument13 SeitenEngine Analysis-Capstone ReportAman SharmaNoch keine Bewertungen

- CH 11 OrganizationDokument1 SeiteCH 11 OrganizationSaid Rahmansyah100% (1)

- Ir DD 70-21-15306 Eu 00xx INGERSOL DD70 Ficha TecnicaDokument2 SeitenIr DD 70-21-15306 Eu 00xx INGERSOL DD70 Ficha TecnicaLuis Toro100% (1)

- Commissioning Operational Test ListDokument19 SeitenCommissioning Operational Test ListzhangNoch keine Bewertungen

- ASTM PruebasDokument9 SeitenASTM PruebasCarlos Olivares ZegarraNoch keine Bewertungen

- Technical Data Heizohack 201112 - 20120101 PDFDokument37 SeitenTechnical Data Heizohack 201112 - 20120101 PDFSanthosh Kumar VempatiNoch keine Bewertungen

- Bunker Requisition Form - VLCC1Dokument1 SeiteBunker Requisition Form - VLCC1shipdesigner088Noch keine Bewertungen

- Mack-Aro de Fuego 45-Sb213042Dokument5 SeitenMack-Aro de Fuego 45-Sb213042cpaolinodNoch keine Bewertungen

- Defstan 91-91R7 Amendment2 PDFDokument38 SeitenDefstan 91-91R7 Amendment2 PDFlimhockkin3766Noch keine Bewertungen

- List of Captive Generation Plants in Tamil Nadu With Details of Capacity and Fuels Used (33 KV and Below)Dokument3 SeitenList of Captive Generation Plants in Tamil Nadu With Details of Capacity and Fuels Used (33 KV and Below)Anonymous YGIgEp3hGNoch keine Bewertungen

- API STD 618 vs. API STD 680 - Refining, Hydrocarbons, Oil, and Gas - CheresourcesDokument3 SeitenAPI STD 618 vs. API STD 680 - Refining, Hydrocarbons, Oil, and Gas - CheresourcesShantanuNoch keine Bewertungen

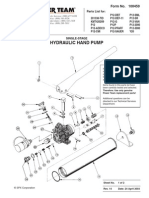

- PartsDokument4 SeitenPartsShaik MajeedNoch keine Bewertungen

- Alfa Laval Aalborg Os Tci Marine BoilerDokument2 SeitenAlfa Laval Aalborg Os Tci Marine Boilera.lobanov2020Noch keine Bewertungen

- Deliverable ListDokument2 SeitenDeliverable ListAnonymous wljt3yShcjNoch keine Bewertungen

- 7 - FTIR Analysis of Used Lubricating Oils General ConsiderationDokument4 Seiten7 - FTIR Analysis of Used Lubricating Oils General ConsiderationJoel CunhaNoch keine Bewertungen

- Denso CR - Hp2 NissanDokument31 SeitenDenso CR - Hp2 NissanMarcelo Diesel86% (7)

- 04 Monitoring DMSDokument13 Seiten04 Monitoring DMSJESSNoch keine Bewertungen

- Riello RG5D Burner ManualDokument11 SeitenRiello RG5D Burner ManualjadetorresNoch keine Bewertungen

- Case 430 Skid SteerDokument1.300 SeitenCase 430 Skid Steerlisandro fankhauser100% (1)

- API Standard 521 New Alternative Method To Evaluate Fire Relief For Pressure Relief Device Sizing and Depressuring System Design 2014 Journal of Loss PDFDokument11 SeitenAPI Standard 521 New Alternative Method To Evaluate Fire Relief For Pressure Relief Device Sizing and Depressuring System Design 2014 Journal of Loss PDFminhy100% (1)

- Cat Digital Voltage Regulator ManualDokument2 SeitenCat Digital Voltage Regulator ManualCrespo Jorge67% (6)

- Bidirectional Isolated DC-DC Converter For Hybrid Electric Vehicle ChargingDokument9 SeitenBidirectional Isolated DC-DC Converter For Hybrid Electric Vehicle ChargingIJSREDNoch keine Bewertungen

- Hidromotori PDFDokument40 SeitenHidromotori PDFDarkoNoch keine Bewertungen