Beruflich Dokumente

Kultur Dokumente

Corrossion and Degradation

Hochgeladen von

ฮัสนุล ฮาดีCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Corrossion and Degradation

Hochgeladen von

ฮัสนุล ฮาดีCopyright:

Verfügbare Formate

Chapter 17 - 1

ISSUES TO ADDRESS...

How does corrosion occur?

Which metals are most likely to corrode?

What environmental parameters affect

corrosion rate?

How do we prevent or control corrosion?

Corrosion and Degradation of

Materials

Chapter 17 - 2

Deteriorative mechanisms are different for the three material

types:

1. Metals actual material loss either by dissolution

(corrosion) or by the formation of nonmetallic scale or film

(oxidation).

2. Ceramics resistant to deterioration which usually occurs

at elevated temperatures or in extreme environments,

also called corrosion.

3. Polymers may dissolve when exposed to a liquid

solvent, electromagnetic radiation (ultraviolet) and heat :

degradation.

Chapter 17 - 3

Corrosion:

-- the destructive electrochemical attack of a material.

-- Ex: Al Capone's

ship, Sapona,

off the coast

of Bimini.

Cost:

-- 4 to 5% of the Gross National Product (GNP)*

-- in the U.S. this amounts to just over $400 billion/yr**

* H.H. Uhlig and W.R. Revie, Corrosion and Corrosion Control: An Introduction

to Corrosion Science and Engineering, 3rd ed., John Wiley and Sons, Inc.,

1985.

**Economic Report of the President (1998).

Photos courtesy L.M. Maestas, Sandia

National Labs. Used with permission.

THE COST OF CORROSION

Chapter 17 - 4

Corrosion is defined as the destructive and unintentional attack

of a metal electrochemical and begins at the surface.

Electrochemical a chemical reaction in which there is

transfer of electrons from one chemical species to another.

Metal atoms characteristically lose or give up electrons

oxidation reaction. The oxidation takes place is called anode.

Oxidation sometimes called anodic reaction.

The electrons generated from the metal atom must be

transferred to another chemical species reduction reaction.

The location at which reduction occurs is called the cathode.

Reduction also called as cathodic reaction.

Chapter 17 - 5

Two reactions are necessary:

-- oxidation reaction:

-- reduction reaction:

Zn Zn

2+

+ 2e

2H

+

+2e

H

2

(gas)

Other reduction reactions in solutions with dissolved oxygen:

-- acidic solution -- neutral or basic solution

O

2

+4H

+

+4e

2H

2

O

O

2

+2H

2

O+4e

4(OH)

Adapted from Fig. 17.1,

Callister & Rethwisch 8e.

(Fig. 17.1 is from M.G.

Fontana, Corrosion

Engineering, 3rd ed., McGraw-

Hill Book Company, 1986.)

ELECTROCHEMICAL CORROSION

Zinc

Oxidation reaction

Zn

Zn

2+

2e

-

Acid

solution

reduction reaction

H

+

H

+

H

2

(gas)

H

+

H

+

H

+

H

+

H

+

flow of e

-

in the metal

Ex: consider the corrosion of zinc in an acid solution

Chapter 17 - 6

STANDARD HYDROGEN ELECTRODE

Two outcomes:

0

o

metal

< V (relative to Pt)

Standard Electrode Potential

Adapted from Fig. 17.2,

Callister & Rethwisch 8e.

-- Corrosion

-- Metal is the anode (-)

P

l

a

t

i

n

u

m

m

e

t

a

l

,

M

M

n+

ions

ne

-

H

2

(gas)

25C

1M M

n+

soln 1M H

+

soln

2e

-

e

-

e

-

H

+

H

+

-- Electrodeposition

-- Metal is the cathode (+)

M

n+

ions

ne

-

e

-

e

-

25C

1M M

n+

soln 1M H

+

soln

P

l

a

t

i

n

u

m

m

e

t

a

l

,

M

H

+

H

+

2e

-

0

o

metal

> V (relative to Pt)

H

2

(gas)

Chapter 17 - 7

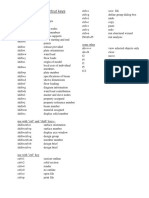

STANDARD EMF SERIES

metal

o

Metal with smaller

V corrodes.

EMF series

Au

Cu

Pb

Sn

Ni

Co

Cd

Fe

Cr

Zn

Al

Mg

Na

K

+1.420 V

+0.340

- 0.126

- 0.136

- 0.250

- 0.277

- 0.403

- 0.440

- 0.744

- 0.763

- 1.662

- 2.363

- 2.714

- 2.924

metal

V

metal

o

Data based on Table 17.1,

Callister 8e.

m

o

r

e

a

n

o

d

i

c

m

o

r

e

c

a

t

h

o

d

i

c

AV =

0.153V

o

Adapted from Fig. 17.2,

Callister & Rethwisch 8e.

-

1.0 M

Ni

2+

solution

1.0 M

Cd

2 +

solution

+

25C Ni Cd

Cd

o

Ni

o

Ex: Cd-Ni cell

V < V Cd corrodes

Chapter 17 - 8

EFFECT OF SOLUTION CONCENTRATION AND

TEMPERATURE

Ex: Cd-Ni cell with

standard 1 M solutions

V

Ni

o

V

Cd

o

= 0.153 V

-

Ni

1.0 M

Ni

2+

solution

1.0 M

Cd

2 +

solution

+

Cd 25C

Ex: Cd-Ni cell with

non-standard solutions

Y

X

ln

nF

RT

V V V V =

o

Cd

o

Ni Cd Ni

n = #e

-

per unit

oxid/red

reaction

(= 2 here)

F =

Faraday's

constant

= 96,500

C/mol.

Reduce V

Ni

- V

Cd

by

-- increasing X

-- decreasing Y

-- increasing T

-

+

Ni

Y M

Ni

2+

solution

X M

Cd

2 +

solution

Cd

T

Chapter 17 - 9

GALVANIC SERIES

Ranking of the reactivity of metals/alloys in seawater

Based on Table 17.2, Callister &

Rethwisch 8e. (Source of Table

17.2 is M.G. Fontana, Corrosion

Engineering, 3rd ed., McGraw-

Hill Book Company, 1986.)

Platinum

Gold

Graphite

Titanium

Silver

316 Stainless Steel (passive)

Nickel (passive)

Copper

Nickel (active)

Tin

Lead

316 Stainless Steel (active)

Iron/Steel

Aluminum Alloys

Cadmium

Zinc

Magnesium

m

o

r

e

a

n

o

d

i

c

(

a

c

t

i

v

e

)

m

o

r

e

c

a

t

h

o

d

i

c

(

i

n

e

r

t

)

Chapter 17 - 10

Uniform Attack

Oxidation & reduction

reactions occur uniformly

over surfaces.

Selective Leaching

Preferred corrosion of

one element/constituent

[e.g., Zn from brass (Cu-Zn)].

Stress corrosion

Corrosion at crack tips

when a tensile stress

is present.

Galvanic

Dissimilar metals are

physically joined in the

presence of an

electrolyte. The

more anodic metal

corrodes.

Erosion-corrosion

Combined chemical attack and

mechanical wear (e.g., pipe

elbows).

FORMS OF CORROSION

Forms

of

corrosion

Crevice Narrow and

confined spaces.

Fig. 17.15, Callister & Rethwisch 8e. (Fig. 17.15

is courtesy LaQue Center for Corrosion

Technology, Inc.)

Rivet holes

Intergranular

Corrosion along

grain boundaries,

often where precip.

particles form.

Fig. 17.18, Callister &

Rethwisch 8e.

attacked

zones

g.b.

prec.

Pitting

Downward propagation

of small pits and holes.

Fig. 17.17, Callister &

Rethwisch 8e. (Fig. 17.17

from M.G. Fontana,

Corrosion Engineering,

3rd ed., McGraw-Hill Book

Company, 1986.)

Chapter 17 - 11

-- Use metals that passivate

- These metals form a thin,

adhering oxide layer that

slows corrosion.

Lower the temperature (reduces rates of oxidation and

reduction)

CORROSION PREVENTION (i)

Metal (e.g., Al,

stainless steel)

Metal oxide

Apply physical barriers -- e.g., films and coatings

Materials Selection

-- Use metals that are relatively unreactive in the

corrosion environment -- e.g., Ni in basic solutions

Chapter 17 - 12

Add inhibitors (substances added to solution that decrease

its reactivity)

-- Slow oxidation/reduction reactions by removing reactants

(e.g., remove O

2

gas by reacting it w/an inhibitor).

-- Slow oxidation reaction by attaching species to

the surface.

CORROSION PREVENTION (ii)

Adapted

from Fig.

17.22(a),

Callister &

Rethwisch

8e.

Using a sacrificial anode

steel

pipe

Mg

anode

Cu wire

e

-

Earth

Mg

2+

Cathodic (or sacrificial) protection

-- Attach a more anodic material to the one to be protected.

Adapted

from Fig.

17.23,

Callister &

Rethwisch

8e.

steel

zinc zinc

Zn

2+

2e

-

2e

-

e.g., zinc-coated nail

Galvanized Steel

e.g., Mg Anode

Chapter 17 - 13

Metallic corrosion involves electrochemical reactions

-- electrons are given up by metals in an oxidation reaction

-- these electrons are consumed in a reduction reaction

Metals and alloys are ranked according to their

corrosiveness in standard emf and galvanic series.

Temperature and solution composition affect corrosion

rates.

Forms of corrosion are classified according to mechanism

Corrosion may be prevented or controlled by:

-- materials selection

-- reducing the temperature

-- applying physical barriers

-- adding inhibitors

-- cathodic protection

SUMMARY

Das könnte Ihnen auch gefallen

- Tuka SponsorDokument1 SeiteTuka Sponsorฮัสนุล ฮาดีNoch keine Bewertungen

- MalaysiaDokument17 SeitenMalaysiaฮัสนุล ฮาดีNoch keine Bewertungen

- Cover Page PraktikalDokument3 SeitenCover Page Praktikalฮัสนุล ฮาดีNoch keine Bewertungen

- Assignment PolitrDokument1 SeiteAssignment Politrฮัสนุล ฮาดีNoch keine Bewertungen

- Razali - Fyp1 Schedule - 15-16 Jun 2014-V5Dokument15 SeitenRazali - Fyp1 Schedule - 15-16 Jun 2014-V5ฮัสนุล ฮาดีNoch keine Bewertungen

- Carbon Fibres CompositesDokument13 SeitenCarbon Fibres CompositesSyed FaridNoch keine Bewertungen

- Publish 3.75 3.85 Repymt Table v1 ROUNDUP1Dokument3 SeitenPublish 3.75 3.85 Repymt Table v1 ROUNDUP1ฮัสนุล ฮาดีNoch keine Bewertungen

- ImaDokument4 SeitenImaฮัสนุล ฮาดีNoch keine Bewertungen

- CHAPTER 1: INTRODUCTION - Error! Bookmark Not DefinedDokument4 SeitenCHAPTER 1: INTRODUCTION - Error! Bookmark Not Definedฮัสนุล ฮาดีNoch keine Bewertungen

- Table of Content VryfiedDokument1 SeiteTable of Content Vryfiedฮัสนุล ฮาดีNoch keine Bewertungen

- Tool Wear MechanismsDokument5 SeitenTool Wear Mechanismsฮัสนุล ฮาดีNoch keine Bewertungen

- Phase 1: Inspection of Tool Wear/s Via Alicona/SemDokument1 SeitePhase 1: Inspection of Tool Wear/s Via Alicona/Semฮัสนุล ฮาดีNoch keine Bewertungen

- A. Project Planning: (List The Main Activities of The Project. Indicate The Length of Time Needed For Each Activity.)Dokument1 SeiteA. Project Planning: (List The Main Activities of The Project. Indicate The Length of Time Needed For Each Activity.)ฮัสนุล ฮาดีNoch keine Bewertungen

- Milo Open Karate Championship 2014 ScheduleDokument2 SeitenMilo Open Karate Championship 2014 Scheduleฮัสนุล ฮาดีNoch keine Bewertungen

- Fyp SubtopicDokument1 SeiteFyp Subtopicฮัสนุล ฮาดีNoch keine Bewertungen

- LiDokument1 SeiteLiฮัสนุล ฮาดีNoch keine Bewertungen

- Ball End MillDokument1 SeiteBall End Millฮัสนุล ฮาดีNoch keine Bewertungen

- Fyp SubtopicDokument1 SeiteFyp Subtopicฮัสนุล ฮาดีNoch keine Bewertungen

- Mission Building in FSX - Part 5Dokument5 SeitenMission Building in FSX - Part 5Anonymous 42xl4YizNoch keine Bewertungen

- Ent600 2Dokument4 SeitenEnt600 2ฮัสนุล ฮาดีNoch keine Bewertungen

- Candidate Name: Latest Passport PhotoDokument4 SeitenCandidate Name: Latest Passport Photoฮัสนุล ฮาดีNoch keine Bewertungen

- Topic CO PO AssessmentDokument1 SeiteTopic CO PO Assessmentฮัสนุล ฮาดีNoch keine Bewertungen

- Template Minute MeetingDokument1 SeiteTemplate Minute Meetingฮัสนุล ฮาดีNoch keine Bewertungen

- Semiconductor, Diode & BJT: ExerciseDokument3 SeitenSemiconductor, Diode & BJT: Exerciseฮัสนุล ฮาดีNoch keine Bewertungen

- HR (80 F, 60% RH) 0.0132 LB/LB D.A Water Added 20 LB (0.0132 - 0.0038Dokument1 SeiteHR (80 F, 60% RH) 0.0132 LB/LB D.A Water Added 20 LB (0.0132 - 0.0038ฮัสนุล ฮาดีNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- IPmux 4 ManualDokument117 SeitenIPmux 4 ManualRhakko RamirezNoch keine Bewertungen

- F-SERIES (250 - 550) (6.7L DIESEL) : Electronic Engine Controls Wiring DiagramDokument24 SeitenF-SERIES (250 - 550) (6.7L DIESEL) : Electronic Engine Controls Wiring DiagramDiego Lira100% (3)

- Assignemnt 2Dokument4 SeitenAssignemnt 2utkarshrajput64Noch keine Bewertungen

- Protel Design System Design Rule CheckDokument7 SeitenProtel Design System Design Rule Checknish1802Noch keine Bewertungen

- Playford TunesDokument36 SeitenPlayford Tunesyuretz100% (2)

- Generate high-purity oxygen with proven VPSA technologyDokument8 SeitenGenerate high-purity oxygen with proven VPSA technologyChanJunKai100% (1)

- Regulated DC or AC power supply wiring for dot matrix indicatorDokument1 SeiteRegulated DC or AC power supply wiring for dot matrix indicatorReza KühnNoch keine Bewertungen

- Kavo Instruction ManualDokument107 SeitenKavo Instruction ManualSwami Meera100% (4)

- Lesson 1 - Continental & Oceanic CrustDokument22 SeitenLesson 1 - Continental & Oceanic CrustKatana MistNoch keine Bewertungen

- RTU Vs PLCDokument3 SeitenRTU Vs PLCrod8silvaNoch keine Bewertungen

- Infobright Community Edition-User GuideDokument90 SeitenInfobright Community Edition-User GuidemishaIV100% (4)

- Kumaran Systems Chennai JD FormatDokument1 SeiteKumaran Systems Chennai JD FormatTharun kondaNoch keine Bewertungen

- MGMT 476 Homework #2Dokument2 SeitenMGMT 476 Homework #2FangNoch keine Bewertungen

- UA723Dokument13 SeitenUA723rordenvNoch keine Bewertungen

- 3 - Global Optimization by Differential Evolution in C++Dokument13 Seiten3 - Global Optimization by Differential Evolution in C++Khoi TruongNoch keine Bewertungen

- Options Straddles Using 0xremington Indicators - NadoDokument13 SeitenOptions Straddles Using 0xremington Indicators - Nadopuchio senpaiNoch keine Bewertungen

- Hands-On Workshop With Elasticsearch, Logstash, and Kibana: Course OutlineDokument2 SeitenHands-On Workshop With Elasticsearch, Logstash, and Kibana: Course OutlineYberê CampeloNoch keine Bewertungen

- 18mat411 MAT-1Dokument4 Seiten18mat411 MAT-1M.A rajaNoch keine Bewertungen

- Sim900 Rs232 GSM Modem OpnDokument49 SeitenSim900 Rs232 GSM Modem OpnAnonymous BkmsKXzwyKNoch keine Bewertungen

- Pnematic StructureDokument30 SeitenPnematic StructureparulNoch keine Bewertungen

- Structural Mechanics ReportDokument79 SeitenStructural Mechanics ReportOsvaldo C. NogueiraNoch keine Bewertungen

- DVB T PDFDokument188 SeitenDVB T PDFWilliam CetinaNoch keine Bewertungen

- MR 337 Clio DDokument492 SeitenMR 337 Clio Dlostris234100% (3)

- CH 11 Wooldridge 5e PPTDokument22 SeitenCH 11 Wooldridge 5e PPTMahmoud MounirNoch keine Bewertungen

- Sheet MicorDokument42 SeitenSheet MicorFiras TaherNoch keine Bewertungen

- Distinguishing Alcohols by Oxidation (40Dokument5 SeitenDistinguishing Alcohols by Oxidation (40EmmaNoch keine Bewertungen

- Chemistry Chapter 1 QPDokument10 SeitenChemistry Chapter 1 QPAsif AyazNoch keine Bewertungen

- Time & Work (A, B, Pipes) by Anupam Singh SirDokument13 SeitenTime & Work (A, B, Pipes) by Anupam Singh SirSuryansh KishoreNoch keine Bewertungen

- Dishwasher AM15 PDFDokument83 SeitenDishwasher AM15 PDFcarlosorizabaNoch keine Bewertungen

- Staad Pro Shortcut KeysDokument1 SeiteStaad Pro Shortcut KeysjomarNoch keine Bewertungen