Beruflich Dokumente

Kultur Dokumente

Fast Charging of Lead Acid Batteries With Pulse Charger: Dr. S. N. Joshi, Lalit Consulting Services, Bangalore. INDIA

Hochgeladen von

pvenky_kkd100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

135 Ansichten24 Seitenpresentation

Originaltitel

2.4 Shashikant Joshi

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenpresentation

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

135 Ansichten24 SeitenFast Charging of Lead Acid Batteries With Pulse Charger: Dr. S. N. Joshi, Lalit Consulting Services, Bangalore. INDIA

Hochgeladen von

pvenky_kkdpresentation

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 24

Fast charging of Lead acid

batteries with pulse charger

Dr. S. N. Joshi,

Lalit Consulting Services,

Bangalore. INDIA

info@lalitconsultingservices.com

Lead acid battery application logic

Lead acid battery is a power source.

Need to put back energy once it is used.

Battery recharge becomes very

important.

Discharge followed by recharge is cycle.

Depending upon depth of discharge

recharge current & or voltage is decided

by the charger.

Fast charging of Lead acid battery

Lead acid batteries are very essential in

our daily life.

Many applications like SLI, UPS,

telecom etc. are well known.

Fast charging of batteries in case of

battery operated vehicles has

significance to the user.

Fast charging of Lead acid battery

Chargers used for battery operated

vehicles have basic features:

1.To convert AC to DC through rectifier

bridge.

2.Logic control & monitoring the charge

input.

3.Safety protection & display or record

events of the system.

Charging system for Lead acid battery

Selection of charger is very critical. It

depends on:

1.Design of the system & nature of its load

requirement.

2.Desired recharge time after every load

cycle.

3.Effect on battery life & maintenance

aspects.

Charging of Lead acid battery

Examples of recharging systems are:

1.SLI - Alternator charger

2.UPS - Float charging

3.Power plants / telecom applications -

Float-cum-boost charger.

4.Fork lift / EVs / Golf cart - Taper / two

step / fast charging.

Chemical equation in battery reaction

Consider electrochemical reactions in

Lead acid battery producing electron

transfer & voltage across electrodes,

-DC

PbO2 + 2 H2SO4 + Pb 2PbSO4 + 2 H2O

+DC

Lead acid battery side reactions

There are however side reactions:

1. Generation of gases like oxygen &

hydrogen.

2. Loss of water.

3. Effect on life of battery.

4. Maintenance issue plays part.

5. Charger, its design & method of

charging becomes crucial.

Fast charging of Lead acid battery

Fast charging in case of battery operated

vehicles is desired by users:

1. Fork lifts.

2. Pallet trucks.

3. Cars, buses.

4. Scoter, bikes.

Fast charging of Lead acid battery

Battery operated vehicle should get

recharged quickly after specific task.

1. Desired work is done the vehicle.

2. Waiting time is minimum.

3. Utilization of vehicle is improved.

Fast charging of Lead acid battery

Fast charging means:

1. Reduction from normal recharge time.

2. At least 80% energy should be put

back.

3. Battery plates should not be damaged.

4. Minimize side reactions loss of water.

5. Reduce maintenance aspects.

6. Covert lead sulphate back into active

mass !!!

Fast charging of Lead acid battery

Charger design:

Uses higher voltage for shorter time

intervals of seconds or mille-seconds.

DC current in PULSE form is applied

for short durations of seconds or mille-

seconds. Switched off for m-seconds.

Both voltage & pulse current are micro-

processor controller with programmed

embedded software.

Fast charging of Lead acid battery

Pulse charging:

1.The technique restores energy in quickest way

back into lead acid battery.

2.Pulse height & width are selected in such a

way that entire energy is accepted with least

loss.

3.Current in pulsating form is generated by

complex & intelligent electronic circuit coupled

with embedded software.

4.Temperature sensor employed to restrict

energy losses & undesired side reactions.

Laboratory testing

Fast charging of Lead acid battery

Bench test with DC motor

Table 1. Bench test results of recharge.

Bench test - DC Motor (250 W) testing system.

Duration 2 Hrs : 55 minutes, average current 5.5 A,

End voltage 44.3 V

B1 V B2 V B3 V B4 V Total V

OCV 11.95 11.86 11.85 11.92 47.5

6 hours 13.57 13.52 13.57 13.51 54.10

8 hours 14.69 14.67 14.65 14.66 58.67

Road test on e-bike

Charge coverage test on road:

Covered 62 kms of distance.

B1 V B2 V B3 V B4 V Total V

OCV 11.63 11.45 11.68 11.47 46.23

6 hrs. 13.58 13.52 13.51 13.57 54.18

8 hrs. 14.32 14.35 14.33 14.37 57.37

Second road test covered distance of 60 kms.

E Bike charging

Pulse charging of Lead acid battery

Application to battery operated vehicles

is very appropriate to bring in high

utilization of vehicles in shot time.

Electric vehicle (passenger) like cycle,

bike or car demands such type of fast

recharge of battery for the user.

Fork lifts / pallet trucks in industrial

application also need such charger.

Pulse charging of Lead acid battery

Pulse charger however calls for high end

complicated electronic circuit in combination with

1.battery chemistry,

2.impedance values of lead acid cell at various

SOC.

3.effect of temperature on charge acceptance.

4.correlation with battery voltages & pulse

amplitude and time.

PULSE CHARGER: MAIN FEATURES

Desulfates & charges at the same time.

Automatically shuts off when battery is

fully charged.

Helps ensure battery performance by

eliminating the main cause of lead-acid

battery failuresulfation buildup &

related problems.

Maximum Output: 110 volts DC, up to 35

amps DC.

PULSE CHARGER: MAIN FEATURES

Helps protect the environment.

Works with all conventional flooded lead-

acid batteries and sealed "maintenance-

free" batteries (VRLA).

Reverse polarity protection.

Over voltage protected.

Short circuit protection.

Overload protection.

Pulse charger 48 V 3 A

Acknowledgement

Pulse charger is commercially build & supplied:

By M/s CHIRRA POWER TECHNOLOGIES,

Bangalore with technical assistance from

Lalit Consulting Services, Bangalore. INDIA

E-mail: chirrapower@gmail.com

info@lalitconsultingservices.com

Thank you all

Das könnte Ihnen auch gefallen

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsVon EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsBewertung: 5 von 5 Sternen5/5 (2)

- Proposal Title: Design and Construction of 12V Car Battery Charger Circuit With Phone Charging USB PortDokument22 SeitenProposal Title: Design and Construction of 12V Car Battery Charger Circuit With Phone Charging USB PortobaidNoch keine Bewertungen

- Research Report On Electric CarsDokument25 SeitenResearch Report On Electric Carssyeda ume rubabNoch keine Bewertungen

- Rechargeable Batteries Applications HandbookVon EverandRechargeable Batteries Applications HandbookBewertung: 2 von 5 Sternen2/5 (1)

- UTBCDokument65 SeitenUTBCSylvester Delali DordziNoch keine Bewertungen

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Notes Unit 5 AEN 22656 AY 2023-24Dokument24 SeitenNotes Unit 5 AEN 22656 AY 2023-24yashwaghmare674Noch keine Bewertungen

- Definition of Project 6.0Dokument21 SeitenDefinition of Project 6.0MOHAMMAD ALINoch keine Bewertungen

- Sahil Mahadik SynopsisDokument3 SeitenSahil Mahadik SynopsisNawaz Raju MandevaliNoch keine Bewertungen

- Electric Car ChargingDokument6 SeitenElectric Car ChargingSaleh Al-SugairNoch keine Bewertungen

- Construction of Industrial Battery ChargerDokument33 SeitenConstruction of Industrial Battery ChargerPETERNoch keine Bewertungen

- A Weekly Presentation On Power Charger: Chapter 1: IntroductionDokument7 SeitenA Weekly Presentation On Power Charger: Chapter 1: Introductionlight yagamiNoch keine Bewertungen

- Battery ChargerDokument43 SeitenBattery ChargerAhmed SheirNoch keine Bewertungen

- Testing LA BatteriesDokument5 SeitenTesting LA BatteriesVembi DwiNoch keine Bewertungen

- Elec 03Dokument28 SeitenElec 03Candiano PopescuNoch keine Bewertungen

- Trade of Heavy Vehicle Mechanic: Battery Construction & MaintenanceDokument29 SeitenTrade of Heavy Vehicle Mechanic: Battery Construction & MaintenanceSeth yakoheneNoch keine Bewertungen

- UNIT 1 Moodle Lecture 1Dokument9 SeitenUNIT 1 Moodle Lecture 1aryanNoch keine Bewertungen

- 391 Shakirafaaizabintimazlan2012Dokument75 Seiten391 Shakirafaaizabintimazlan2012Rendra WijayaNoch keine Bewertungen

- Transformerless SoC-based Current Control Switchin PDFDokument5 SeitenTransformerless SoC-based Current Control Switchin PDFmuttakin rahmanNoch keine Bewertungen

- Automobile Engineering - Automobile Electric SystemsDokument20 SeitenAutomobile Engineering - Automobile Electric SystemsAhmed Zawad ShovonNoch keine Bewertungen

- Design of 2kW DC Charger For Two Wheelers: D. M. Chandwadkar, Azmina Gayasuddin Maniyar, S. P. UgaleDokument4 SeitenDesign of 2kW DC Charger For Two Wheelers: D. M. Chandwadkar, Azmina Gayasuddin Maniyar, S. P. UgaleDr Meena BoyNoch keine Bewertungen

- Different Fast Charging Methods and Topologies For EV ChargingDokument5 SeitenDifferent Fast Charging Methods and Topologies For EV ChargingKrishnakant DeshmukhNoch keine Bewertungen

- Ee-12 Volts Authomatic Battery Charger-2Dokument57 SeitenEe-12 Volts Authomatic Battery Charger-2Babatunde samuelNoch keine Bewertungen

- Simplified Lithium-Ion (Li+) Battery-Charger TestingDokument7 SeitenSimplified Lithium-Ion (Li+) Battery-Charger TestingpekiilicNoch keine Bewertungen

- Research of Intelligent Lead-Acid Batteries ChargeDokument8 SeitenResearch of Intelligent Lead-Acid Batteries Chargeerode els erodeNoch keine Bewertungen

- Chapter One 1.1 Background of The StudyDokument43 SeitenChapter One 1.1 Background of The StudyAmeerMuaviaNoch keine Bewertungen

- 4.battery Chargers in Electric VehiclesDokument3 Seiten4.battery Chargers in Electric VehiclesEssa SiddiquiNoch keine Bewertungen

- 12th Evaluation Ahmed Samy 17105552Dokument14 Seiten12th Evaluation Ahmed Samy 17105552Ahmed Samy El GoharyNoch keine Bewertungen

- Electric Vehicles For India: Overview and Challenges: June 2019Dokument5 SeitenElectric Vehicles For India: Overview and Challenges: June 2019thumula.rameshNoch keine Bewertungen

- Group1 Battery ChargerDokument18 SeitenGroup1 Battery ChargerNguyễn Nam AnhNoch keine Bewertungen

- Submitted by:-SHIV VISHAL Electricals Engineering (3 Year) Roll No.:-1742220040Dokument18 SeitenSubmitted by:-SHIV VISHAL Electricals Engineering (3 Year) Roll No.:-1742220040Asok RawatNoch keine Bewertungen

- Desulfation of Lead-Acid Battery by High Frequency Pulse: June 2017Dokument5 SeitenDesulfation of Lead-Acid Battery by High Frequency Pulse: June 2017JohnnyNoch keine Bewertungen

- Topic:: Improving Efficiency of Battery Charging and Its DischargingDokument15 SeitenTopic:: Improving Efficiency of Battery Charging and Its DischargingKushagra VermaNoch keine Bewertungen

- PP 8498 10Dokument19 SeitenPP 8498 10Marvin GainesNoch keine Bewertungen

- Advantages of Electric Vehicle: Eveh-01-Ömer Türksoy-Battery Charger Technologies in Evs - 2Dokument9 SeitenAdvantages of Electric Vehicle: Eveh-01-Ömer Türksoy-Battery Charger Technologies in Evs - 2Adisu100% (1)

- Ex 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleDokument23 SeitenEx 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleKunal TanwarNoch keine Bewertungen

- Electric Vehicles For India: Overview and Challenges: June 2019Dokument5 SeitenElectric Vehicles For India: Overview and Challenges: June 2019PraveenMnNoch keine Bewertungen

- Synopsis Final LastDokument15 SeitenSynopsis Final LastImrannkhanNoch keine Bewertungen

- Buck Converter Control For Lead Acid Battery ChargDokument9 SeitenBuck Converter Control For Lead Acid Battery ChargS KhatibNoch keine Bewertungen

- Hazfizul - Research On Rapid Charging of Sealed Lead Acid BatteryDokument14 SeitenHazfizul - Research On Rapid Charging of Sealed Lead Acid BatteryAfandi Mohamad ZainiNoch keine Bewertungen

- Electric Vehicles Battery Management System: Electrical and Electronics Engineering DepartmentDokument13 SeitenElectric Vehicles Battery Management System: Electrical and Electronics Engineering DepartmentSam Moses MandapalliNoch keine Bewertungen

- Development of User Interface For Battery Status MonitoringDokument41 SeitenDevelopment of User Interface For Battery Status MonitoringTEMEC305 ATHARV HawareNoch keine Bewertungen

- 1270 BatteryChargerTechincalPrimer FINAL 29sep2006 PDFDokument29 Seiten1270 BatteryChargerTechincalPrimer FINAL 29sep2006 PDFDaniel AdebayoNoch keine Bewertungen

- Question Bank: AT6502 Automotive Electrical & ElectronicsDokument7 SeitenQuestion Bank: AT6502 Automotive Electrical & ElectronicsLovely BhuvaneshNoch keine Bewertungen

- Lead AcidBatteryEngbySefukitaronkaDokument18 SeitenLead AcidBatteryEngbySefukitaronkaRadhe ShamNoch keine Bewertungen

- Application Note 68 December 1996:, LTC and LT Are Registered Trademarks of Linear Technology CorporationDokument36 SeitenApplication Note 68 December 1996:, LTC and LT Are Registered Trademarks of Linear Technology CorporationHahdNoch keine Bewertungen

- Simister PROJECT POWER KFLAY ADokument27 SeitenSimister PROJECT POWER KFLAY AMintesnot AlemuNoch keine Bewertungen

- Universal Battery Charger enDokument12 SeitenUniversal Battery Charger encristianNoch keine Bewertungen

- f0 PDFDokument38 Seitenf0 PDFnbr67sceNoch keine Bewertungen

- Battery Test Procedures 1997Dokument7 SeitenBattery Test Procedures 1997Tara P. PradhanNoch keine Bewertungen

- MICHEALDokument5 SeitenMICHEALstephen olowoNoch keine Bewertungen

- CHAPTER OneDokument3 SeitenCHAPTER OneAung MyatNoch keine Bewertungen

- Low Power Inverter For Domestic ApplicationsDokument39 SeitenLow Power Inverter For Domestic ApplicationsNarendhar MudavathNoch keine Bewertungen

- Jennifer New Project (Correction)Dokument25 SeitenJennifer New Project (Correction)HASTINGS EMURASHENoch keine Bewertungen

- A New Pulse Charging Methodology For Lead Acid BatteriesDokument16 SeitenA New Pulse Charging Methodology For Lead Acid BatteriesMaja JovanovicNoch keine Bewertungen

- Vocational Training in Sealdah RailwayDokument57 SeitenVocational Training in Sealdah RailwaySourav GayenNoch keine Bewertungen

- Battery Charger: Rechargeable Battery Electric Current Voltage CurrentDokument12 SeitenBattery Charger: Rechargeable Battery Electric Current Voltage CurrentRonaldNoch keine Bewertungen

- cd3257 PDFDokument24 Seitencd3257 PDFesayarNoch keine Bewertungen

- A Project DocumentationDokument10 SeitenA Project DocumentationPrashanth YadavNoch keine Bewertungen

- School DetailsDokument4 SeitenSchool Detailspvenky_kkdNoch keine Bewertungen

- 3 PhaseLineConstantsDokument5 Seiten3 PhaseLineConstantspvenky_kkdNoch keine Bewertungen

- PV (Preliminary Data Request EProcurement) 9 19 11Dokument9 SeitenPV (Preliminary Data Request EProcurement) 9 19 11pvenky_kkdNoch keine Bewertungen

- 6380 AutoReconfig MT 20090918 WebDokument21 Seiten6380 AutoReconfig MT 20090918 Webpvenky_kkdNoch keine Bewertungen

- Kezunovic Cigre2005Dokument11 SeitenKezunovic Cigre2005pvenky_kkdNoch keine Bewertungen

- XLPE CableDokument44 SeitenXLPE CablescribdkkkNoch keine Bewertungen

- Project Overview: ENGR-1020-100 FALL 2007 Wind Turbine Team 1Dokument10 SeitenProject Overview: ENGR-1020-100 FALL 2007 Wind Turbine Team 1pvenky_kkdNoch keine Bewertungen

- Number First Part Second PartDokument33 SeitenNumber First Part Second Partpvenky_kkdNoch keine Bewertungen

- ASEE 2011 Spreadsheet Draft Jan21 2011Dokument12 SeitenASEE 2011 Spreadsheet Draft Jan21 2011haffaNoch keine Bewertungen

- ProtocolsDokument98 SeitenProtocolspvenky_kkdNoch keine Bewertungen

- Additional VBA Tips 05242012Dokument2 SeitenAdditional VBA Tips 05242012pvenky_kkdNoch keine Bewertungen

- FormulasDokument36 SeitenFormulaspvenky_kkdNoch keine Bewertungen

- TI 36X ProDokument6 SeitenTI 36X ProRem MessimerNoch keine Bewertungen

- #Value! 'File:///var/www/apps/conversion/tmp/scratch - 1/258410512.xls'#$sheet1 #Value! #Value! #Value!Dokument15 Seiten#Value! 'File:///var/www/apps/conversion/tmp/scratch - 1/258410512.xls'#$sheet1 #Value! #Value! #Value!pvenky_kkdNoch keine Bewertungen

- StatisticalDokument19 SeitenStatisticalpvenky_kkdNoch keine Bewertungen

- Lecture 11 PPDokument34 SeitenLecture 11 PPpvenky_kkdNoch keine Bewertungen

- StatisticalDokument19 SeitenStatisticalpvenky_kkdNoch keine Bewertungen

- Cond FormatDokument28 SeitenCond Formatpvenky_kkdNoch keine Bewertungen

- MathDokument41 SeitenMathpvenky_kkdNoch keine Bewertungen

- Cond FormatDokument28 SeitenCond Formatpvenky_kkdNoch keine Bewertungen

- Number Cell of MAX ValueDokument21 SeitenNumber Cell of MAX Valuepvenky_kkdNoch keine Bewertungen

- Advance SolutionsDokument15 SeitenAdvance Solutionspvenky_kkdNoch keine Bewertungen

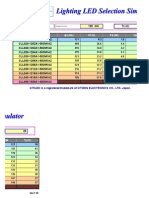

- LED Savings Calculator v1bDokument3 SeitenLED Savings Calculator v1bpvenky_kkdNoch keine Bewertungen

- Scada FunctionsDokument46 SeitenScada Functionspvenky_kkdNoch keine Bewertungen

- AlstomDokument11 SeitenAlstompvenky_kkdNoch keine Bewertungen

- Condition input: Product code φv (lm) Vf (V) Pd (W) lm/WDokument2 SeitenCondition input: Product code φv (lm) Vf (V) Pd (W) lm/Wpvenky_kkdNoch keine Bewertungen

- English Module3 Electrical HazardsDokument36 SeitenEnglish Module3 Electrical Hazardspvenky_kkdNoch keine Bewertungen

- PDF LV PVC CablesDokument32 SeitenPDF LV PVC Cablespvenky_kkdNoch keine Bewertungen

- PDF LT-XLPEDokument28 SeitenPDF LT-XLPEDheeraj YadavNoch keine Bewertungen

- 11 ABB - Latest Trends in PMUs and Wide Area SystemsDokument8 Seiten11 ABB - Latest Trends in PMUs and Wide Area Systemspvenky_kkdNoch keine Bewertungen

- Eastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateDokument6 SeitenEastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateTasheen MahabubNoch keine Bewertungen

- Tankguard AR: Technical Data SheetDokument5 SeitenTankguard AR: Technical Data SheetAzar SKNoch keine Bewertungen

- University of Nottingham Department of Architecture and Built EnvironmentDokument43 SeitenUniversity of Nottingham Department of Architecture and Built EnvironmentDaniahNoch keine Bewertungen

- Visa Requirements Austrian EmbassyDokument2 SeitenVisa Requirements Austrian Embassyadalcayde2514Noch keine Bewertungen

- UntitledDokument6 SeitenUntitledCoky IrcanNoch keine Bewertungen

- My New ResumeDokument1 SeiteMy New Resumeapi-412394530Noch keine Bewertungen

- Adding Print PDF To Custom ModuleDokument3 SeitenAdding Print PDF To Custom ModuleNguyễn Vương AnhNoch keine Bewertungen

- Supply DemandProblems With Solutions, Part 1Dokument16 SeitenSupply DemandProblems With Solutions, Part 1deviNoch keine Bewertungen

- All About Ignition Coils: Technical InformationDokument15 SeitenAll About Ignition Coils: Technical InformationTrương Ngọc ThắngNoch keine Bewertungen

- Application Form New - Erik WitiandikaDokument6 SeitenApplication Form New - Erik Witiandikatimmy lauNoch keine Bewertungen

- Tavera Vs Valdez 1 Phil 468Dokument2 SeitenTavera Vs Valdez 1 Phil 468John AmbasNoch keine Bewertungen

- Risk in Poject FinanceDokument20 SeitenRisk in Poject FinanceShahid KhanNoch keine Bewertungen

- KL1508 KL1516: 8/16-Port Cat 5 High-Density Dual Rail LCD KVM SwitchDokument5 SeitenKL1508 KL1516: 8/16-Port Cat 5 High-Density Dual Rail LCD KVM SwitchnisarahmedgfecNoch keine Bewertungen

- Application Form-Nguyen Huy CuongDokument4 SeitenApplication Form-Nguyen Huy Cuongapi-3798114Noch keine Bewertungen

- Application Letters To Apply For A Job - OdtDokument2 SeitenApplication Letters To Apply For A Job - OdtRita NourNoch keine Bewertungen

- 50 Hotelierstalk MinDokument16 Seiten50 Hotelierstalk MinPadma SanthoshNoch keine Bewertungen

- Transport Phenomena 18.4.CDokument3 SeitenTransport Phenomena 18.4.CDelyana RatnasariNoch keine Bewertungen

- Philippine First Insurance V HartiganDokument3 SeitenPhilippine First Insurance V HartiganAlexander Genesis DungcaNoch keine Bewertungen

- cv20672778 Prashanth - Sadak Operations-ManagerDokument4 Seitencv20672778 Prashanth - Sadak Operations-ManagerBhasker NiftyNoch keine Bewertungen

- WTO & MFA AnalysisDokument17 SeitenWTO & MFA Analysisarun1974Noch keine Bewertungen

- OMS - Kangaroo Mother CareDokument54 SeitenOMS - Kangaroo Mother CareocrissNoch keine Bewertungen

- SMPLEDokument2 SeitenSMPLEKla AlvarezNoch keine Bewertungen

- Hi 3 Yt 318201Dokument3 SeitenHi 3 Yt 318201partha khatuaNoch keine Bewertungen

- Zapanta v. COMELECDokument3 SeitenZapanta v. COMELECnrpostreNoch keine Bewertungen

- LS Series Hand Crimping ToolsDokument4 SeitenLS Series Hand Crimping ToolsbaolifengNoch keine Bewertungen

- Nirma - Marketing PresentationDokument22 SeitenNirma - Marketing PresentationJayRavasa100% (2)

- ASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth ResistanceDokument5 SeitenASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth Resistance曾乙申100% (1)

- Stryker Endoscopy SDC Pro 2 DVDDokument2 SeitenStryker Endoscopy SDC Pro 2 DVDWillemNoch keine Bewertungen

- Web Server ProjectDokument16 SeitenWeb Server Projectمعتز العجيليNoch keine Bewertungen

- Grade 5 Olympiad: Answer The QuestionsDokument14 SeitenGrade 5 Olympiad: Answer The QuestionsVinieysha LoganathanNoch keine Bewertungen