Beruflich Dokumente

Kultur Dokumente

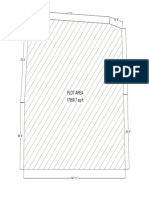

P 10

Hochgeladen von

Asghar Hussain ShahOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

P 10

Hochgeladen von

Asghar Hussain ShahCopyright:

Verfügbare Formate

Heavy Construction

Engineering

Course: CE-413

Instructor:

Engr. M. Adeel Arshad

adeel@civionics.pk

Lecture-10

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

2

Tractor Pulled Scrapers

SCRAPERS

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

3

Advantages of Scrapers

Tractor-pulled scrapers are designed to load, haul, and dump loose

materials.

The advantage of tractor scraper combinations is their versatility.

They can be used in a wide range of material types (including shot

rock) and are economical over a wide range of haul lengths and haul

conditions.

To the extent that they can self-load, they are not dependent on

other equipment.

If one machine in the spread experience a temporary breakdown it

will not shut down the job, as would be the case for a machine which

is used exclusively for loading. If the loader breaks down, the entire

job must stop until repairs can be made.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

4

Advantages of Scrapers

Scrapers are available with loose heaped capacities up to about 44

cu yd, although in the past a few machines as large as 100 cu yd

have been offered.

For off-highway situations having hauls of less than a mile, scrapers

ability both to load and haul gives them an advantage.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

5

Application of Scrapers

Dozer: short haul, less than 300ft

Scraper: medium haul up to 3,000 ft

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

6

Types of Scrapers

There are several types of scrapers, primarily classified according to

the number of powered axles or by the method of loading.

Scrapers are all wheel-tractor pulled machines.

Available types include:

Push-loaded (conventional)

Single-powered axle

Tandem-powered axles

Self-loading

Push-pull, tandem-powered axles

Elevating

Auger

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

7

Single engine

Conventional (push-loaded)

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

8

Conventional (push-loaded)

Many models can achieve speeds up to 30 mph when fully loaded.

This extends the economic haul distance of the units.

Push-loaded scrapers are at a disadvantage when it comes to

individually providing the high tractive effort required for economical

loading. For the single-powered axle scraper only a portion, on the

order of 50-55% of the total loaded weight, bears on the drive

wheels.

Conventional (push-loaded) single engine scrapers become

uneconomical when:

Haul grades > 5%

Return grades > 12%

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

9

Elevating

Elevating scrapers are good for short hauls and in favourable material.

Can work alone in the cut.

Cost more initially & to operate

Elevator adds weight & takes power.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

10

Tandem powered twin engine

Tandem powered (twin engine) scrapers are good for jobs having

adverse grades and poor footing.

Owning and operating cost are about 25% higher.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

11

Push-Pull

Push-Pull scrapers can work as a team or can operate individually

with a pusher.

Tire wear will increase in rock or abrasive materials because of more

slippage from the four-wheel drive action.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

12

Auger

Auger scrapers can self-load in difficult conditions, laminated rock or

granular materials.

The auger adds weight to the scraper during travel and it is more costly to

own and operate than a conventional scraper.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

13

Volume of a Scraper

The volumetric load of a scraper may be specified as either the

struck or heaped capacity of the bowl expressed in cubic yards.

The struck capacity is the volume that a scraper would hold if the top

of the material were struck off even at the top of the bowl.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

14

Because of the compacting effect on the material in a push-loaded

scraper, resulting from the pressure required to force additional

material into the bowl, the swell is usually less than that for material

dropped into a truck by a hoe or loader.

Tests indicate that the swell factors specified in tables should be

increase by approximately 10% for material push-loaded into a

scraper.

When computing the bank measure volume for an elevating scraper,

no correction is required for the factors specified by the tables.

Volume of a Scraper

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

15

Scraper Operation

A scraper is loaded by lowering the front end of the bowl until the

cutting edge, which is attached to and extends across the width of

the bowl enters the ground. At the same time, the front apron is

raised to provide an open slot through which the earth can flow into

the bowl. As the scraper moves forward, a horizontal strip of

material is forced into the bowl. This is continued until the bowl is

filled, at which point the cutting edge is raised and the apron is

lowered to prevent spillage during the haul.

The dumping operation consists of lowering the cutting edge to the

desired height above the fill, raising the apron, and then forcing the

material out by means of a movable ejector mounted at the rear of

the bowl.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

16

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

17

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

18

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

19

Operating Efficiency and Production

The volume of material hauled would equal the product of the

number of trips and the average volume per load.

Reality is different from this perfect production. Delays occur on the

job; machines break down; men stop for water, or machines cluster

causing a queue in the cut for the pusher.

The estimator should always try to visualize the work site before

applying a factor:

If the pit will not be congested and if the dump area is wide open, a 55-

min hour may be appropriate.

If the cut involves a tight area, such as a ditch, the estimator should

consider a 45-min hour.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

20

Cycle Time for a Scraper

The cycle time for a scraper is the time to load, haul, dump, turn,

return, and turn back into position to pick up another load:

Ts = load

t

+ haul

t

+ dump

t

+ turn

t

+ return

t

+ turn

t

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

21

Cycle Time for a Scraper

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

22

Push Tractors Required

If push-loaded tractor scrapers are to attain their volumetric capacities, they

need the assistance of a push tractor during the loading operation.

Push tractor assistance will reduce the loading-time duration, and thereby

will reduce the total cycle time.

When using push tractors, we should match the number of pushers with the

number of scrapers available at a given time. If either the pusher or the

scraper must wait for the other, operating efficiency is lowered and

production costs are increased.

Caterpillar recommends calculating backtrack push-tractor cycle time, T

p

, by

the formula

T

p

= 1.4L

t

+ 0.25

where L

t

is the scraper load time (pusher contact time).

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

23

The formula is based on the concept that pusher cycle time is a

function of four components:

Load time of the scraper

Boost time, time assisting the scraper out of the cut, 0.15 min.

Manoeuvre time, 40% of load time.

Positioning for contact time, 0.10 min.

The number of scrapers that a push tractor can serve is the

ratio of the scraper cycle time to the pusher cycle time:

N = T

s

/T

p

where N is the number of scrapers per one pusher.

Pusher cycle time

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

24

Example-1

Assuming 50 min/hr as working efficiency of a push-loaded tractor scrapper

with 29.8 lcy payload capacity and (swell factor = 0.74 unadjusted), Calculate

the total time required for to complete a 4,000-ft haul cycle.

Lecturer: M. Adeel Arshad

email: adeel@civionics.pk

25

Example-1 (Continued)

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Eastern Europe SourcebookDokument110 SeitenEastern Europe SourcebookDaniel Alan93% (15)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Activities For Learner-Centered TeachingDokument56 SeitenActivities For Learner-Centered TeachingAmiga Mi100% (1)

- Table of ContentsDokument1 SeiteTable of ContentsAsghar Hussain ShahNoch keine Bewertungen

- Module 5 - Elements of Financial StatementsDokument34 SeitenModule 5 - Elements of Financial StatementsRandolph ColladoNoch keine Bewertungen

- PA SystemDokument4 SeitenPA SystemSnehal DambhareNoch keine Bewertungen

- Sense and NonsenseDokument263 SeitenSense and NonsenseAbdulRehmanKhilji100% (1)

- WCDMA19 Prfile Descriptions W19P8 08A APPRDokument254 SeitenWCDMA19 Prfile Descriptions W19P8 08A APPRoaguilar83Noch keine Bewertungen

- Air Defence Systems: Export CatalogueDokument105 SeitenAir Defence Systems: Export CatalogueserrorysNoch keine Bewertungen

- Lecture#15: Sub Structure: Sub-Structure or Foundation Is The Lower Portion of The Building, UsuallyDokument3 SeitenLecture#15: Sub Structure: Sub-Structure or Foundation Is The Lower Portion of The Building, UsuallyAsghar Hussain ShahNoch keine Bewertungen

- Computer Architecture - CS252Dokument2 SeitenComputer Architecture - CS252Asghar Hussain ShahNoch keine Bewertungen

- Lecture #01: BY Engineer Asghar Hussain ShahDokument9 SeitenLecture #01: BY Engineer Asghar Hussain ShahAsghar Hussain ShahNoch keine Bewertungen

- Network Analysis - II - EE150 - New - 09-08-12Dokument1 SeiteNetwork Analysis - II - EE150 - New - 09-08-12Asghar Hussain ShahNoch keine Bewertungen

- ACI The New Model Code Feb 2013Dokument87 SeitenACI The New Model Code Feb 2013Asghar Hussain ShahNoch keine Bewertungen

- Communications Skills - ENG 112Dokument1 SeiteCommunications Skills - ENG 112Asghar Hussain ShahNoch keine Bewertungen

- Physics I - GS111Dokument2 SeitenPhysics I - GS111Asghar Hussain ShahNoch keine Bewertungen

- Industrial Management MGT 427Dokument2 SeitenIndustrial Management MGT 427Asghar Hussain ShahNoch keine Bewertungen

- High Voltage Technology - EE463Dokument1 SeiteHigh Voltage Technology - EE463Asghar Hussain ShahNoch keine Bewertungen

- Syllabus Class NurseryDokument1 SeiteSyllabus Class NurseryAsghar Hussain ShahNoch keine Bewertungen

- KG Teacher Ist Teacher 2NDDokument4 SeitenKG Teacher Ist Teacher 2NDAsghar Hussain ShahNoch keine Bewertungen

- Abid 2 PDFDokument1 SeiteAbid 2 PDFAsghar Hussain ShahNoch keine Bewertungen

- Class 7thDokument15 SeitenClass 7thAsghar Hussain ShahNoch keine Bewertungen

- Kaka G Tangarr-ModelDokument1 SeiteKaka G Tangarr-ModelAsghar Hussain ShahNoch keine Bewertungen

- Abid 1Dokument1 SeiteAbid 1Asghar Hussain ShahNoch keine Bewertungen

- Abid 1 PDFDokument1 SeiteAbid 1 PDFAsghar Hussain ShahNoch keine Bewertungen

- Abid 2 PDFDokument1 SeiteAbid 2 PDFAsghar Hussain ShahNoch keine Bewertungen

- Abid 2Dokument1 SeiteAbid 2Asghar Hussain ShahNoch keine Bewertungen

- Lec 6 MetalsDokument4 SeitenLec 6 MetalsAsghar Hussain ShahNoch keine Bewertungen

- Unit-I Basic Concepts: Course Code: BTCS9504 Course Name: Network Operating SystemsDokument17 SeitenUnit-I Basic Concepts: Course Code: BTCS9504 Course Name: Network Operating SystemsPradeep BediNoch keine Bewertungen

- Network Tools and Protocols Lab 2: Introduction To Iperf3Dokument17 SeitenNetwork Tools and Protocols Lab 2: Introduction To Iperf3Fabio MenesesNoch keine Bewertungen

- Odt Article - Djo - Virtual Population Analysis Improves Orthopedic Implant Design 1 PDFDokument3 SeitenOdt Article - Djo - Virtual Population Analysis Improves Orthopedic Implant Design 1 PDFDragana RajicNoch keine Bewertungen

- Learning Spoken English in Half The TimeDokument86 SeitenLearning Spoken English in Half The TimeΔέσποινα ΤζουτNoch keine Bewertungen

- Character AnalysisDokument3 SeitenCharacter AnalysisjefncomoraNoch keine Bewertungen

- Analog Digital Thermopile Application Note PDFDokument18 SeitenAnalog Digital Thermopile Application Note PDFGopal HegdeNoch keine Bewertungen

- Essentials of Repertorization Tiwari Link PageDokument11 SeitenEssentials of Repertorization Tiwari Link PageBibin TSNoch keine Bewertungen

- Ibps RRB Po Scale - I Prelims Model Mock Test - 8Dokument7 SeitenIbps RRB Po Scale - I Prelims Model Mock Test - 8Sanjay DasNoch keine Bewertungen

- International Standard: Iso/Iec 7816-2Dokument16 SeitenInternational Standard: Iso/Iec 7816-2Anwar MohamedNoch keine Bewertungen

- Dinengdeng RecipeDokument1 SeiteDinengdeng RecipeFuNoch keine Bewertungen

- Operaton Q. PDokument47 SeitenOperaton Q. PPravin KeskarNoch keine Bewertungen

- EEE Sofware Lab Experiment 1, PDFDokument11 SeitenEEE Sofware Lab Experiment 1, PDF240 Sadman ShafiNoch keine Bewertungen

- Essay Writing TipsDokument4 SeitenEssay Writing TipsSubhasish MitraNoch keine Bewertungen

- BAFINAR - Quiz 2 ColarDokument3 SeitenBAFINAR - Quiz 2 ColarRonalyn ColarNoch keine Bewertungen

- Ism Practical File NothingDokument84 SeitenIsm Practical File NothingADITYA GUPTANoch keine Bewertungen

- English Paper 1 Mark Scheme: Cambridge Lower Secondary Sample Test For Use With Curriculum Published in September 2020Dokument11 SeitenEnglish Paper 1 Mark Scheme: Cambridge Lower Secondary Sample Test For Use With Curriculum Published in September 2020ABEER RATHINoch keine Bewertungen

- Scriptcase MacrosDokument6 SeitenScriptcase MacrosMeliana WangNoch keine Bewertungen

- Ricoh Aficio SP C420DN PARTS CATALOGDokument82 SeitenRicoh Aficio SP C420DN PARTS CATALOGYury Kobzar100% (2)

- Richard Dennis Sonterra Capital Vs Cba Nab Anz Macquarie Gov - Uscourts.nysd.461685.1.0-1Dokument87 SeitenRichard Dennis Sonterra Capital Vs Cba Nab Anz Macquarie Gov - Uscourts.nysd.461685.1.0-1Maverick MinitriesNoch keine Bewertungen

- Cutting Conics AsDokument3 SeitenCutting Conics Asbabe09Noch keine Bewertungen

- AAR Safety Fact SheetDokument2 SeitenAAR Safety Fact Sheetrogelio mezaNoch keine Bewertungen

- Sacramento County Compensation Survey Board of SupervisorsDokument13 SeitenSacramento County Compensation Survey Board of SupervisorsCBS13Noch keine Bewertungen

- Mrs. Saba Khan 15 Shahbad Diwan Khana, Bareilly, City, Bareilly, Bareilly, Utt AR PRADESH, 243003,9219172265Dokument28 SeitenMrs. Saba Khan 15 Shahbad Diwan Khana, Bareilly, City, Bareilly, Bareilly, Utt AR PRADESH, 243003,9219172265amitNoch keine Bewertungen