Beruflich Dokumente

Kultur Dokumente

ABB Overview

Hochgeladen von

josleinyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ABB Overview

Hochgeladen von

josleinyCopyright:

Verfügbare Formate

C

o

m

p

a

n

y

n

a

m

e

-

1

-

9

/

2

0

/

2

0

1

4

ABB Overview

A

B

B

O

y

2

0

0

7

-

2

-

Contents

Matti Turtiainen -

ABB today

ABB in Finland

Technology leadership

ABB Drives

Jere Syvnne

Kenttvylien kehitysty

Julle Ala-Lahti

RFID:n kytt logistiikassa

VAL - konsepti

A

B

B

O

y

2

0

0

7

-

3

-

ABB today

ABB Group:

Revenues 24 billion USD

111 000 in around 100 countries

R&D investments around 1.1 billion USD

Market leader in key businesses

www.abb.com

ABB is a global leader in power and automation technologies that

enable utility and industry customers to improve their performance while

lowering environmental impact.

A

B

B

O

y

2

0

0

7

-

4

-

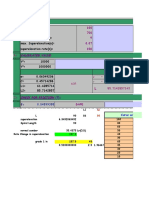

Key figures: ABB Group 2006

($ million)

2006 2005

Nominal Local

Orders received 28'401 23'194 22% 22%

Revenues 24'412 22'012 11% 10%

EBIT 2'586 1'778 45%

EBIT margin (%) 10.6% 8.1%

Net income 1'390 735 89%

Cash flow from operating activities 1'939 1,012

Net cash (debt) (at Dec. 31) 1'508 (513)

Return on capital employed 20% 14%

Change

A

B

B

O

y

2

0

0

7

-

5

-

ABB in Finland

ABB Oy:

revenues 1.7 billion EUR

more than 6000 employees on over

40 locations

R&D investments 7 % of revenues

factories in Helsinki and Vaasa

www.abb.fi

A

B

B

O

y

2

0

0

7

-

6

-

ABB Oy organization

Country Manager

Mikko Niinivaara

Finance

Erkki Luhta

Human Resources

Harri Mattila

Communications

Carita Jern

Legal Affairs &

Compliance

Tapio Metso

Technology

Kimmo Forsman

Drives

Pekka Tiitinen

Machines

Juha Silvennoinen

Motors

Mikko Helinko

Low Voltage

Products

Heikki Uusitalo

Low Voltage

Systems

Antti Heikkil

Process Industry

Juha Moisio

Marine &

Turbocharging

Lasse Mkelin

Substations

Jukka Soininen

Power Generation

Mikael Strmbck

Distribution

Automation

Kalle Huittinen

Medium Voltage

Apparatus and

Switchgear

Anders Zittra

Transformers

Jukka Auranen

Service Ilkka Tykkylinen

Product Support Pauli Jrvinen

Domestic Product Sales Kalle Mattila

Robotics

Timo Toissalo

Automation Products

Pekka Tiitinen

Process Automation

Lasse Mkelin

Power Systems

Jukka Soininen

Power Products

Mikko Niinivaara

A

B

B

O

y

2

0

0

7

-

7

-

Automation Technology

Systems

Electrification and

Automation Systems

Drive Systems

Propulsion systems for

ships

Improves energy efficiency and

productivity

Products

Drives

Motors

Machines

Low Voltage Products

Low Voltage Systems

Robots

Instruments

Services

Service and

maintenance

A

B

B

O

y

2

0

0

7

-

8

-

Power Technology

Improves reliability of

power distribution

Products

Transformers

Distribution Automation

Switchgear

MV-apparatus

HV-apparatus

Cables

Systems

Transmission and

distribution systems

Power generation

systems

Services

Service and

maintenance

A

B

B

O

y

2

0

0

7

-

9

-

ABB Oy key figures

(MEUR)

2006 2005 Change %

Orders received 2005 1 579 + 27

Export orders 1574 1 137 + 38

Revenues 1682 1 490 + 13

R&D 112 98 + 14

Order backlog 907 597 + 52

Employees 6131 6 070 + 1

A

B

B

O

y

2

0

0

7

-

1

1

-

ABB Oy R&D

0

20

40

60

80

100

120

1998 1999 2000 2001 2002 2003 2004 2005 2006

MEUR

R&D 112 MEUR, + 14 %

A

B

B

O

y

2

0

0

7

-

1

2

-

Permanent magnet technology applications

Gearless drives

based on new permanent

magnet motor technology with a

new patented rotor design

fewer components; no gears and

no encoders

lower engineering, installation

and maintenance costs

lower energy consumption

applications delivered to paper

mills, wind power and ships

A

B

B

O

y

2

0

0

7

-

1

3

-

Marine

Year 2006 was a record year for the division: totally 19

Azipod

-units were ordered to 11 ships.

Genesis the largest cruise ship ever

Owner: Royal Caribbean International

Built by Aker Yards, Finland

Delivery: autumn 2009

ABB scope of supply:

3 x Azipod Propulsion Units

3 x ACS6000SD Frequency Converters

6 x Main Generators

11 kV Main Switchboards

4 x Thruster Motors

Distribution and Propulsion Transformers

Substation Switchgears

A

B

B

O

y

2

0

0

7

-

1

4

-

Admiralty two Arctic shuttle tankers

Customer: Sovcomflot

Built at the Admiralty Shipyards in St. Petersburg,

Russia

Delivery: year 2009

ABB delivery:

two 8.5 MW Azipod units (Russian ice class LU6)

medium voltage generators

main switchboards

transformers

frequency converters

The first Azipod system delivery to Russian Shipyards.

Marine

In August, ABB Marine signed the contract to deliver a complete shaftline

propulsion and power system for the first Superyacht to be built by Fincantieri

in Italy. The 134 metre yacht will be completed in 2010 at the naval shipyard in

Muggiano.

A

B

B

O

y

2

0

0

7

-

1

5

-

Wind Power Generators

New, extended global frame

agreements with the biggest wind

turbine manufacturers

ABB is the world leader in Megawatt

class wind power generators

Demand of generators for wind power

generation was very high in 2006. A

new record of orders recieved and

generators delivered was made. The

order backlog is very high

First multi-megawatt permanent magnet

generator specificly designed for off-

shore turbines was delivered

A

B

B

O

y

2

0

0

7

-

1

6

-

Power Systems

Gas Engine Power Plants

Continuous co-operation with Wrtsil in

control system deliveries.

E.g. five gas engine power plant projects

to Azerbaizan including 52 engines.

Gas Turbine Power Plants

Contract with Svenska Kraftnt for retrofit

of Hallstavik and Lahall gas turbine power

plants in Sweden, 6 x 60 MW

Hydro Power Plants

Electrification and automation system to

Kierikki Hydro Power Plant, ~ 2x20 MVA

Electrification and automation system to

Kaltimo Hydro Power Plant, ~ 2 x 20 MVA

Astara, Azerbaizan

Kaltimo Hydro Power Plant

C

o

m

p

a

n

y

n

a

m

e

-

1

7

-

9

/

2

0

/

2

0

1

4

Introduction to

ABB drives

BU LV Drives

Updated

10/2006

A

B

B

O

y

2

0

0

7

-

1

8

-

LV Drives worldwide

About 2700 people in 50 countries

ABB Motors/Drives ,

Menden, Germany

Central Stock Europe

ABB Motors/Drives ,

Singapore

Central Stock Asia

ABB Automation,

Ladenburg,

Germany

DC Drives

ABB Oy , Helsinki,

Finland

LV AC Drives

ABB Inc.,

New Berlin, WI,

USA

LV AC Drives

ABB Beijing Drive

Systems,

Beijing, China

LV AC Drives

ABB Ltd, Peenya,

Bangalore, India

LV AC Drives

Manufacturing and R&D

Central stocks

Engineering & assembly

A

B

B

O

y

2

0

0

7

-

1

9

-

Worldwide market shares

Others

Vacon

Lenze/AC Tech

Fuji (incl. GE)

Emerson/CT

Danfoss

Schneider/

Toshiba

Yaskawa/Omron

Rockwell

Mitsubishi

Siemens

ABB

22.0%

3.0%

3.0%

5.0%

5.0%

6.0%

6.0%

7.0%

7.0%

7.0%

12.0%

17.0%

0.0 5.0 10.0 15.0 20.0 25.0%

2003 Share

2004 Share

2005 Share

Source IMS Studies 2004, 2005, 2006

The worldwide market for low voltage AC & DC drives was estimated to be worth $5.87 billion in

2005

A

B

B

O

y

2

0

0

7

-

2

0

-

The growth of ABBs low voltage AC drives

0

2000

4000

6000

8000

10000

12000

Y92 Y93 Y94 Y95 Y96 Y97 Y98 Y99 Y00 Y01 Y02 Y03 Y04 Y05

M

V

A

/

Y

e

a

r

A

B

B

O

y

2

0

0

7

-

2

1

-

The installed base of ABB drives saves 115 TWh per year, the equivalent of 14 nuclear

reactors

The installed base of ABB drives reduces CO2 emissions by 97 million ton per year,

more than the yearly emission of Finland

ABB drives save energy

0 20 40 60 80 100 120 140

Y92

Y93

Y94

Y95

Y96

Y97

Y98

Y99

Y00

Y01

Y02

Y03

Y04

Y05

Y

e

a

r

Energy savings (TWh)

A

B

B

O

y

2

0

0

7

-

2

2

-

Our offering

A

B

B

O

y

2

0

0

7

-

2

3

-

Building automation

Low voltage AC drives for ...

Industries

Original equipment manufacturers

A

B

B

O

y

2

0

0

7

-

2

4

-

1. Product AC strategy

2200 MUSD

Complete portfolio

AC induction Asynchronous servo Synchronous Servo

2000 MUSD

ACSM1 Dedicated product

Industrial Machinery

Operational Excellence

A

B

B

O

y

2

0

0

7

-

2

5

-

Machinery Market Opportunity

Drive market

8000 M$

ABB Market Share 17 %

100 %

17 %

M

a

r

k

e

t

s

h

a

r

e

8 4 0 11 B$

Source: ARC Servo Study 2007

General

Motion

Control

2 B$

CNC

1 B$

Robotics

0,5 B$

A

B

B

O

y

2

0

0

7

-

2

6

-

Machinery drives market Europe

AT BE DK FI FR DE IT NL NO PT ES SE CH GB East Europe Total

Food, Beverage & Tobacco Processing 2,6 1,8 9,8 2,0 23,1 41,7 49,1 13,7 0,4 1,7 12,7 2,5 7,8 19,1 5,1 193,2

Machine Tools 3,7 2,0 0,8 2,7 10,0 99,4 53,4 4,1 0,4 0,5 12,2 2,7 25,8 9,3 11,7 238,9

Materials Handling Equipment 2,5 1,3 3,9 7,3 22,0 80,6 19,5 5,0 1,1 0,6 13,0 2,9 11,6 17,8 11,4 200,4

Multi-Purpose Robots 0,0 0,0 0,0 0,0 1,5 12,1 4,8 0,0 0,4 0,0 0,0 19,4 0,0 0,0 0,0 38,2

Packaging Machinery 0,5 0,6 1,7 1,2 10,3 54,5 41,8 6,6 0,2 0,2 12,5 3,6 7,8 10,9 6,3 158,8

Paper & Paperboard Machinery 5,4 0,1 0,2 24,5 5,1 27,1 17,1 0,4 0,3 0,4 3,1 8,7 6,9 3,7 1,6 104,6

Printing Machinery 1,7 2,6 2,0 0,1 4,9 62,7 5,7 3,2 1,1 0,3 1,1 1,1 8,5 7,2 1,4 103,7

Rubber & Plastics Machinery 7,3 1,7 0,9 0,5 17,1 44,9 27,2 2,5 0,2 0,3 1,9 2,0 10,9 2,4 4,5 124,2

Semiconductor Machinery 1,1 0,0 0,0 0,0 2,3 7,1 0,3 13,2 0,0 0,0 0,0 0,0 2,5 4,3 0,0 30,8

Textile Machinery 2,0 8,3 1,3 0,2 9,3 42,6 36,9 1,2 0,2 0,7 3,0 0,9 17,1 4,5 5,3 133,4

Woodworking Machinery 2,2 0,1 1,3 1,1 1,4 33,0 21,8 0,2 0,2 0,1 1,3 0,4 1,8 0,3 1,7 67,0

Total 29,0 18,7 21,8 39,7 107,0 505,7 277,5 50,1 4,5 4,8 60,9 44,1 100,7 79,5 49,0 1393,1

Total 2 % 1 % 2 % 3 % 8 % 36 % 20 % 4 % 0 % 0 % 4 % 3 % 7 % 6 % 4 % 100 %

European market for drives (inc. inverters & servo drives)

by country and machine type in 2003

1000

A

B

B

O

y

2

0

0

7

-

2

7

-

F&B applications matching with portfolio

F

u

n

c

t

i

o

n

a

l

i

t

y

Flexibility

ACS350

ACS55

ACS150

Conveyors

Pumps

Cutting

Fans

ACSM1 Motion

Mills

Mixers

Extruders

Punching Stamping Slicing

Bottling,

labelling

Packaging

machines

ACSM1 S&T

C

o

m

p

a

n

y

n

a

m

e

-

2

8

-

9

/

2

0

/

2

0

1

4

ACSM1

Product specification

Help

ABB high performance machinery drives

A

B

B

O

y

2

0

0

7

-

2

9

-

ACSM1, ABB high performance machinery drive

High performance

For synchronous and

induction motors

Complete range of feedback

interfaces

Modular and compact design

Solution programs

Memory unit for easy drive

management

Safety as standard

A

B

B

O

y

2

0

0

7

-

3

0

-

Types & ratings (1/3)

Types and ratings

Standard

Option, external

* With a mains choke

Frame size A B C D E

Current & Power

Nominal current

Maximum current

2,57,0A

5,314,7A

9,516A

16,628A

2446A

4280A

6090A

105150A

110210A

165326A

Typical motor power 0,753 kW 47,5 kW 1122 kW* 3045 kW* 55110 kW

Braking chopper

Braking resistor

Mains choke

Mains filter (EMC)

A

B

B

O

y

2

0

0

7

-

3

1

-

Frame Height (mm) Width (mm) Depth (mm) * Weight (kg) *

A 364 90 146 3

B 380 100 223 5

C 467 165 225 10

D 467 220 225 17

E 700 314 398 64

Feature / Frame A B C D E

Mounting and cooling

Cold plate variant

Air cooled variant

- Back plate mounting

- DIN-rail mounting

Removable power connectors

Removable control connectors

Types & ratings (2/3)

Legend:

Standard

Product variant

Types and ratings

* without

options

A

B

B

O

y

2

0

0

7

-

3

2

-

Control connections

Control interface

1. Status display 7-segment display Main status and

fault messages

2. Control voltage supply Internal or external supply (24VDC)

input for the control unit

3. Digital I/O 6xDI, 3xDI/O, 1xRO

4. Analogue I/O 2xAI, 2xAO

5. Thermistor input Motor thermistor (PTC, KTY)

6. Drive to Drive link (D2D) Galvanic RS-485 link for

communication between drives

7. Safe Torque Off (STO) Designed for Safety Integrity Level 3

(SIL 3) acc. to IEC 61508 and

Safety Category 4 acc. to EN 954-1

8. User interface (HMI) PC-tools and control panel

connection (RJ45)

9. Memory unit (MU) Complete drive configuration and

settings are stored in the memory

unit.

1

2

3

4

5

6

7

8

9

A

B

B

O

y

2

0

0

7

-

3

3

-

ACSM1 Safe Torque Off interface

STO interface

Safe

Torque

Off

(STO)

SIL 3 / IEC 61508,

SILCL 3 / EN 62061

Category 4 / EN 954-1

PL e / EN 13849-1

STO

Safe Torque Off (X6)

Both circuits must be closed for

the drive to start.

OUT1 1

OUT2 2

IN1 3

IN2 4

A

B

B

O

y

2

0

0

7

-

3

4

-

Control & communication options

Three slots for control and communication options

Options Data

Install

in

Analogue & digital extension

Slot

1 or 2

FIO-01 4xDI/O, 2xRO

FIO-11 3xAI, 1xAO, 2xDO

Feedback interface

Slot

1 or 2

FEN-01

2 inputs (TTL incremental encoder),

1 output

FEN-11

2 inputs (SinCos absolute, TTL

incremental encoder), 1 output

FEN-21

2 inputs (Resolver,

TTL incremental encoder), 1 output

Communication

Slot 3

FPBA-01 PROFIBUS

FCAN-01 CANopen

FDNA-01 DeviceNet

FENA-01 Ethernet/IP, Modbus/TCP

1

2

3

A

B

B

O

y

2

0

0

7

-

3

5

-

External options

Mains filter (EMC)

Meet category C2 level with

installation including motor

(max. 50m cable).

Flexibility with different external options

Mains choke

Reduce harmonics and mains current RMS

Reduce mains disturbance and low-frequency interference

Increase the allowed DC bus continuous power

Braking resistor

Convert generated kinetic

energy into thermal energy

Available for different kind

of pulse duty performance

Equipped with a thermal

sensor as standard

EMC standards in general

EN 61800-3/A11

(2000),

product standard

EN 61800-3 (2004),

product standard

EN 55011

, product

family standard for

industrial, scientific and

medical (ISM) equipment

1

st

environment,

unrestricted distribution

Category C1 Group 1, Class B

1

st

environment,

restricted distribution

Category C2 Group 1, Class A

2

nd

environment,

unrestricted distribution

Category C3 Group 2, Class A

2

nd

environment,

restricted distribution

Category C4 Not applicable

A

B

B

O

y

2

0

0

7

-

3

6

-

PC Tools / Drive Studio, DriveSize

Motion

Control

Technology functions,

solution programs

Position sequence

CAM

Flying cut

Technology functions,

solution programs

Winder

Lift

Speed &

Torque

Control

ACSM1 / Memory Unit ACSM1 / Power Unit, Control

Unit, Control and comm. options

Synchronous

Asynchronous

Position

control

Speed

control

Motor control

Torque

control

M E

A

B

B

O

y

2

0

0

7

-

3

7

-

PC Tools / Drive Studio, DriveSize

Motion

Control

Technology functions,

solution programs

Position sequence

CAM

Flying cut

Technology functions,

solution programs

Winder

Lift

Speed &

Torque

Control

ACSM1 / Memory Unit ACSM1 / Power Unit, Control

Unit, Control and comm. options

Synchronous

Asynchronous

Position

control

M E

Speed and Torque control

Speed

control

Torque

control

A

B

B

O

y

2

0

0

7

-

3

8

-

PC Tools / Drive Studio, DriveSize

Motion

Control

Technology functions,

solution programs

Position sequence

CAM

Flying cut

Technology functions,

solution programs

Winder

Lift

Speed &

Torque

Control

ACSM1 / Memory Unit ACSM1 / Power Unit, Control

Unit, Control and comm. options

Synchronous

Asynchronous

Speed

control

Torque

control

M E

Motion control

Position

control

A

B

B

O

y

2

0

0

7

-

3

9

-

PC Tools / Drive Studio, DriveSize

Motion

Control

Technology functions,

solution programs

Position sequence

CAM

Flying cut

Technology functions,

solution programs

Winder

Lift

Speed &

Torque

Control

ACSM1 / Memory Unit ACSM1 / Power Unit, Control

Unit, Control and comm. options

Synchronous

Asynchronous

Position

control

Speed

control

Torque

control

M E

Application solutions

A

B

B

O

y

2

0

0

7

-

4

0

-

Sizing tool

MCSize

PC tool for sizing the motor

and drive

Motion profile and

mechanics

Different kind of linear or

rotary movement

mechanisms

Integral part of DriveSize tool

A

B

B

O

y

2

0

0

7

-

4

1

-

Other ABB products extending the portfolio

ACSM1

ACS350

ACS150

ACS55

Induction motors

Servo motors

A

B

B

O

y

2

0

0

7

-

4

2

-

ACSM1 Trainings (eLearning Modules)

1. Introduction*)

2. Motion control basics

3. Product specification

4. Control&Performance: -

Part A Speed&Torque*) -

Part B Motion

5. Servomotor theory

6. Servomotors product

specification *)

7. Feedback Devices

8. Fieldbus communication *)

1. Tools overview *)

2. DriveStudio *)

3. Solution Program

Composer *)

4. Motion Sizing

5. MCSize

6. DriveCAM (tbd)

7. User Panel (tbd)

8. Commissioning (tbd)

9. Hands-On-Cases (tbd)

1. System Engineering

Guide HW (tbd)

2. Control Engineering *)

3. Sales Network Support

(tbd)

4. Customer Support *)

5. Competitor analysis *)

6. Expert Package (tbd)

Step 1

Step 2 Step 3

*) Only For Internal Use

7. AC500 Introduction

8. AC500 Configurations

9. AC500 .

A

B

B

O

y

2

0

0

7

-

4

3

-

ABB Machinery Drives Portfolio is Ready

It is time to work for growth in the

machinery business!

A

B

B

O

y

2

0

0

7

-

4

4

-

OEM Machinery applications

Tekstiili

Textile

Elintarvikkeet

Food & Beverage

Ruiskupuristus

Extruding

Liikkeen ohjaus

Motion Control

Pienet nosturit

Small Cranes

P llystys

Converting

Koneen rakennus

Machinery Building

Pienet J rjestelm t

Small Systems

A

B

B

O

y

2

0

0

7

-

4

5

-

Some ACSM1 Cases

Stove pipe grabber in Germany Ship ramp winch in Sweden Lathe application in Spain

Lifting the curtain in Vienna Opera Tube pending in Switzerland Elevator position control in Italy

A

B

B

O

y

2

0

0

7

-

4

6

-

Das könnte Ihnen auch gefallen

- Py0uk12 Cellcube DecryptedDokument12 SeitenPy0uk12 Cellcube DecryptedGabriel ColtNoch keine Bewertungen

- Configure Victron Products with VE ConfigureDokument13 SeitenConfigure Victron Products with VE ConfigureVoltamarine SrlNoch keine Bewertungen

- Transnorm Motors: Low Voltage and High Voltage Design 200 KW Up To 1000 KWDokument37 SeitenTransnorm Motors: Low Voltage and High Voltage Design 200 KW Up To 1000 KWShivani GuptaNoch keine Bewertungen

- Aalborg University Microgrid Research GuideDokument49 SeitenAalborg University Microgrid Research Guideniakinezhad100% (2)

- ElectricalDokument6 SeitenElectricalPaulNoch keine Bewertungen

- VA To Watts and KVA To KilowattsDokument12 SeitenVA To Watts and KVA To KilowattsS.senthil KuamrNoch keine Bewertungen

- Hager Full Line CatalogDokument543 SeitenHager Full Line CatalogSecurity Lock DistributorsNoch keine Bewertungen

- Battery Charging: Led-AcidDokument18 SeitenBattery Charging: Led-Acidgirish_prajapati55100% (2)

- Compact CHP Units 40-400 kW for Efficient EnergyDokument6 SeitenCompact CHP Units 40-400 kW for Efficient EnergysilvercristiNoch keine Bewertungen

- MasterPact MTZDokument234 SeitenMasterPact MTZfirasalthiyabyNoch keine Bewertungen

- Guide To Size Hybrid SystemsDokument7 SeitenGuide To Size Hybrid SystemsAmr JmNoch keine Bewertungen

- Device Function Numbers for Power Distribution EquipmentDokument10 SeitenDevice Function Numbers for Power Distribution EquipmentSherleanne PintoNoch keine Bewertungen

- Super CapacitorsDokument24 SeitenSuper CapacitorsShyam KumarNoch keine Bewertungen

- DRV Sinamics s120 Booksize ManualDokument806 SeitenDRV Sinamics s120 Booksize ManualCarmeloCardadoNoch keine Bewertungen

- General Characteristics: 3029DFS29 G3Dokument6 SeitenGeneral Characteristics: 3029DFS29 G3Praveen SreedharanNoch keine Bewertungen

- Angola Power Transmission Optimization Plan Through 2027Dokument98 SeitenAngola Power Transmission Optimization Plan Through 2027Apot AlerteNoch keine Bewertungen

- AF09 ... AF30 3-Pole Contactors Up To 25 HP / 600 VAC: Contactors and Overload RelaysDokument33 SeitenAF09 ... AF30 3-Pole Contactors Up To 25 HP / 600 VAC: Contactors and Overload RelaysJohn LorenzoNoch keine Bewertungen

- Solar Cell Materials: Developing TechnologiesVon EverandSolar Cell Materials: Developing TechnologiesGavin J. ConibeerNoch keine Bewertungen

- Load Share Gateway WOODWARD PCC3100 PARALLEL PDFDokument29 SeitenLoad Share Gateway WOODWARD PCC3100 PARALLEL PDFquangtruc106Noch keine Bewertungen

- Control Engineering 2018-02Dokument54 SeitenControl Engineering 2018-02Zigor Larrabe UribeNoch keine Bewertungen

- Differences Between Single-Phase and Three-Phase PowerDokument2 SeitenDifferences Between Single-Phase and Three-Phase Powerjob_p100% (1)

- NiCd Batteries PDFDokument30 SeitenNiCd Batteries PDFanon_480056542Noch keine Bewertungen

- Variable Frequency Drive BasicsDokument8 SeitenVariable Frequency Drive Basicssrithu1008100% (2)

- RIO600 PG 757487 ENfDokument36 SeitenRIO600 PG 757487 ENfZeckrey JikurunNoch keine Bewertungen

- LV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring InstructionsDokument113 SeitenLV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring Instructionsedvaldo alves pintoNoch keine Bewertungen

- KUHSEDokument25 SeitenKUHSESyed Mohammad Naveed100% (1)

- ABB ManualDokument896 SeitenABB ManualNikola_TeslaNoch keine Bewertungen

- Prospect NORDEX N54Dokument2 SeitenProspect NORDEX N54Станимир МихалевNoch keine Bewertungen

- Technical Comparison of NiCd and Lead - Acid BatteryDokument3 SeitenTechnical Comparison of NiCd and Lead - Acid BatteryRajarsi Ray100% (1)

- DocumentDokument5 SeitenDocumentBahrowi Adi WijayaNoch keine Bewertungen

- 34 - Design of Energy Monitoring System Based On IOTDokument4 Seiten34 - Design of Energy Monitoring System Based On IOTFelipe Osmar de AvizNoch keine Bewertungen

- Masterk Instructions ProgrammingDokument268 SeitenMasterk Instructions Programmingmkspenang183055% (11)

- ElsafeDokument328 SeitenElsafespnreddy100% (1)

- Microgrid PDFDokument160 SeitenMicrogrid PDFmadhuhanuNoch keine Bewertungen

- BioSolar CellsDokument1 SeiteBioSolar CellsArpita Singh50% (2)

- Installation manual for Logic C22 / Logic C22S electric gate control boardDokument8 SeitenInstallation manual for Logic C22 / Logic C22S electric gate control boardRobson FernandesNoch keine Bewertungen

- InteliGen NTC GC Datasheet - 2016 09 PDFDokument4 SeitenInteliGen NTC GC Datasheet - 2016 09 PDFPablo Gaspar D'Agostini AmengualNoch keine Bewertungen

- UPS Power 10 KVA, 20kva, 30 Kva, 40kva Redundant UPS - Uninterruptible Power SupplyDokument4 SeitenUPS Power 10 KVA, 20kva, 30 Kva, 40kva Redundant UPS - Uninterruptible Power SupplyGamatronicNoch keine Bewertungen

- Gensizing For MotorsDokument4 SeitenGensizing For MotorsaderezoNoch keine Bewertungen

- Improved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)Von EverandImproved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)Noch keine Bewertungen

- Siemens G2 Platform 2.3 MW.Dokument8 SeitenSiemens G2 Platform 2.3 MW.Uhrin ImreNoch keine Bewertungen

- ManualDokument163 SeitenManualafsalmohmdNoch keine Bewertungen

- DataKom 309J - USERDokument61 SeitenDataKom 309J - USERKhaleel KhanNoch keine Bewertungen

- Generator CourseDokument61 SeitenGenerator Courseprasad5034Noch keine Bewertungen

- InteliSys NTC BaseBox Leaflet 2014-01 CPLEISBB PDFDokument4 SeitenInteliSys NTC BaseBox Leaflet 2014-01 CPLEISBB PDFdo phuongNoch keine Bewertungen

- 5'' AC Charger Slim General Data Sheet (TB5S)Dokument3 Seiten5'' AC Charger Slim General Data Sheet (TB5S)Stanley Y, H, CHIUNoch keine Bewertungen

- Electronic Throttle Control SystemsDokument4 SeitenElectronic Throttle Control SystemsPrabhu MohanNoch keine Bewertungen

- Eee-Vii-Industrial Drives and Applications Notes PDFDokument90 SeitenEee-Vii-Industrial Drives and Applications Notes PDFJoywin CutinhaNoch keine Bewertungen

- Variable Frequency Drive (VFD)Dokument8 SeitenVariable Frequency Drive (VFD)vishnurajpattambiNoch keine Bewertungen

- Lorentz Psk2 2016 Manual en Es FRDokument320 SeitenLorentz Psk2 2016 Manual en Es FRNimonaNoch keine Bewertungen

- Isolation Transformers Reduce Drive Neutral Point VoltageDokument5 SeitenIsolation Transformers Reduce Drive Neutral Point Voltagescrib_111Noch keine Bewertungen

- REF FuseApplicationGuide PDFDokument17 SeitenREF FuseApplicationGuide PDFyetignrNoch keine Bewertungen

- CA Vd4 40ka (En) M 1vcp000001 CatalogDokument86 SeitenCA Vd4 40ka (En) M 1vcp000001 Catalogdorin serbanNoch keine Bewertungen

- Be2k Plus Application DiagramDokument1 SeiteBe2k Plus Application DiagramJercy SanchezNoch keine Bewertungen

- Ni CD Bateries From SAFTDokument12 SeitenNi CD Bateries From SAFTmerebookNoch keine Bewertungen

- TIAPortalOpennessenUS en USDokument278 SeitenTIAPortalOpennessenUS en USrmorenodx4587Noch keine Bewertungen

- Speed Control of DC Motor Using PWM 555 TimerDokument20 SeitenSpeed Control of DC Motor Using PWM 555 TimerDEBABRATA DASNoch keine Bewertungen

- Digital Twin in Solar - SunSnifferDokument44 SeitenDigital Twin in Solar - SunSnifferPRATHAMESH KERKAR100% (1)

- Siemens - VFD Catalog 2019Dokument110 SeitenSiemens - VFD Catalog 2019SuryaRaoTirumallasetti100% (1)

- Understanding Emergency Lighting 2010 UpdateDokument6 SeitenUnderstanding Emergency Lighting 2010 Updateabpau01559Noch keine Bewertungen

- Basler Transformer Protection Application Guide PDFDokument33 SeitenBasler Transformer Protection Application Guide PDFAbrakain69Noch keine Bewertungen

- Performance of Frequency Relays For Distributed Generation ProtectionDokument8 SeitenPerformance of Frequency Relays For Distributed Generation ProtectionhuskeeNoch keine Bewertungen

- A Simple Approach To Short Circuit CalculationsDokument29 SeitenA Simple Approach To Short Circuit CalculationsRobert GalarzaNoch keine Bewertungen

- ABB Xiamen Switchgear: Product Lifecycle ManagementDokument3 SeitenABB Xiamen Switchgear: Product Lifecycle ManagementjosleinyNoch keine Bewertungen

- Codigos ANSI PDFDokument3 SeitenCodigos ANSI PDFjosleinyNoch keine Bewertungen

- Short-Circuit Calculations PDFDokument11 SeitenShort-Circuit Calculations PDFkgunaNoch keine Bewertungen

- ABB Load Interrupter Switchgear GuideDokument14 SeitenABB Load Interrupter Switchgear GuidejosleinyNoch keine Bewertungen

- The Art & Science of Protective Relaying - C. Russell Mason - GEDokument357 SeitenThe Art & Science of Protective Relaying - C. Russell Mason - GEAasim MallickNoch keine Bewertungen

- REL512 Setting Example for Short Lines Protection SettingsDokument18 SeitenREL512 Setting Example for Short Lines Protection Settingsjosleiny100% (1)

- RMU Safelink CB Product PresentationDokument37 SeitenRMU Safelink CB Product PresentationmentongNoch keine Bewertungen

- Protection System Fundamentals 060210Dokument55 SeitenProtection System Fundamentals 060210Vivek SinghNoch keine Bewertungen

- REF542plus OperationManual ConnectivityPackage 9ARD170952-009 ENaDokument127 SeitenREF542plus OperationManual ConnectivityPackage 9ARD170952-009 ENaWassim Helou100% (1)

- REF542plus IEC61850 ConfStatement 756361 ENd Rel3.0SP1Dokument74 SeitenREF542plus IEC61850 ConfStatement 756361 ENd Rel3.0SP1josleinyNoch keine Bewertungen

- ROLE MODEL Vijay MalyaDokument14 SeitenROLE MODEL Vijay Malyarohit singhNoch keine Bewertungen

- Demag SafeControl ensures safety and precision for cranesDokument9 SeitenDemag SafeControl ensures safety and precision for cranesPramuda SirodzNoch keine Bewertungen

- Husqvarna 2003 SM WRE 125 ManualDokument2 SeitenHusqvarna 2003 SM WRE 125 ManualNdae IskandarNoch keine Bewertungen

- JetstarDokument40 SeitenJetstartuan nguyenNoch keine Bewertungen

- AccentureDokument12 SeitenAccenturerobin70929Noch keine Bewertungen

- Fact Book March 2021Dokument64 SeitenFact Book March 2021saiNoch keine Bewertungen

- Reginald Anesu Tobaiwa: Professional ProfileDokument2 SeitenReginald Anesu Tobaiwa: Professional ProfileARUN VISHWAKARMANoch keine Bewertungen

- APSRTC Official Website For Online Bus Ticket Booking - APSRTConline1Dokument2 SeitenAPSRTC Official Website For Online Bus Ticket Booking - APSRTConline1Shahbaz AlamNoch keine Bewertungen

- SERVICE TOOL CATALOG Carrier Transicold PDFDokument98 SeitenSERVICE TOOL CATALOG Carrier Transicold PDFRoberto SalazarNoch keine Bewertungen

- Road Qty - S-R-SH-10-Total Project ECL - PCL OffsetDokument1 SeiteRoad Qty - S-R-SH-10-Total Project ECL - PCL OffsetStephen Rajkumar JayakumarNoch keine Bewertungen

- Technical Specification Saket Court Complex-Nit 108Dokument279 SeitenTechnical Specification Saket Court Complex-Nit 108Manoj RanaNoch keine Bewertungen

- Concrete Saw Core Drilling Swms 10067-8Dokument12 SeitenConcrete Saw Core Drilling Swms 10067-8JamesNoch keine Bewertungen

- 1 Medio Ruta de Aprendizaje 07 - 08 - 09Dokument32 Seiten1 Medio Ruta de Aprendizaje 07 - 08 - 09nanolakesNoch keine Bewertungen

- Corona PDFDokument98 SeitenCorona PDFrosanateamoNoch keine Bewertungen

- 830e-1ac SM A30240-A30560 Ing Cebm021903Dokument1.143 Seiten830e-1ac SM A30240-A30560 Ing Cebm021903Dany C.100% (1)

- viewNitPdf 4073448Dokument20 SeitenviewNitPdf 4073448Bittudubey officialNoch keine Bewertungen

- Horizontal Curve Excel SheetDokument9 SeitenHorizontal Curve Excel SheetTarunNoch keine Bewertungen

- CH 1 Improv Traffic SchoolDokument6 SeitenCH 1 Improv Traffic Schoolkev0% (1)

- PlanDokument132 SeitenPlanpvpallasigui3126Noch keine Bewertungen

- Crane Safety and Awareness PresentationDokument99 SeitenCrane Safety and Awareness Presentationnex1984Noch keine Bewertungen

- Brand Presentation Hero Honda HunkDokument68 SeitenBrand Presentation Hero Honda HunkDeepak NandaNoch keine Bewertungen

- 5Dokument65 Seiten5indrajeetNoch keine Bewertungen

- STPO Wo. DELDokument9 SeitenSTPO Wo. DELDurgesh KadamNoch keine Bewertungen

- Warehousing PPT TemplateDokument3 SeitenWarehousing PPT TemplateSandip BesraNoch keine Bewertungen

- Wind Turbine Foundations Eric Marchegiani AVECDokument30 SeitenWind Turbine Foundations Eric Marchegiani AVECFantaziu CosminNoch keine Bewertungen

- USSBS Report 64, The Effect of Air Action On Japanese Ground Army Logistics, OCRDokument112 SeitenUSSBS Report 64, The Effect of Air Action On Japanese Ground Army Logistics, OCRJapanAirRaidsNoch keine Bewertungen

- Scientific American Architects and Builders Edition 1890 Jan-JunDokument240 SeitenScientific American Architects and Builders Edition 1890 Jan-JunNickiedeposieNoch keine Bewertungen

- Network MarketingDokument32 SeitenNetwork MarketingAvinash Kumar Singh100% (2)

- IRC SP 15-1996 Ribbon Development Along The Highway - Its PreventionDokument103 SeitenIRC SP 15-1996 Ribbon Development Along The Highway - Its Preventionjitendra100% (1)

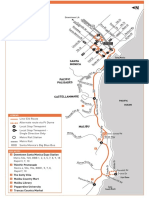

- Route 534 Santa Monica MalibuDokument3 SeitenRoute 534 Santa Monica MalibudazulzulNoch keine Bewertungen