Beruflich Dokumente

Kultur Dokumente

MBA Admission in India

Hochgeladen von

edholecom0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

20 Ansichten21 Seitenadmission in india 2015

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenadmission in india 2015

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

20 Ansichten21 SeitenMBA Admission in India

Hochgeladen von

edholecomadmission in india 2015

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 21

Chapter 11 -

MBA Admission in India

By:

admission.edhole.com

Chapter 11 -

Day 14: Heat treatments of Steel

Quenching and Tempering Steel (Basic, more

complete discussion later)

Spheroidizing

Full Annealing

Normalizing

Hardenability (More on the quenching and

tempering process.)

asmission.edhole.com

Chapter 11 - 3

Based on data provided in Tables 11.1(b), 11.2(b), 11.3, and 11.4, Callister 7e.

Steels

Low Alloy High Alloy

low carbon

<0.25 wt% C

Med carbon

0.25-0.6 wt% C

high carbon

0.6-1.4 wt% C

Uses auto

struc.

sheet

bridges

towers

press.

vessels

crank

shafts

bolts

hammers

blades

pistons

gears

wear

applic.

wear

applic.

drills

saws

dies

high T

applic.

turbines

furnaces

V. corros.

resistant

Example 1010 4310 1040 43 40 1095 4190 304

Additions none

Cr,V

Ni, Mo

none

Cr, Ni

Mo

none

Cr, V,

Mo, W

Cr, Ni, Mo

plain HSLA plain

heat

treatable

plain tool

austenitic

stainless

Name

Hardenability 0 + + ++ ++ +++ 0

TS - 0 + ++ + ++ 0

EL + + 0 - - -- ++

increasing strength, cost, decreasing ductility

asmission.edhole.com

Chapter 11 -

Quenching and Tempering

We have found that Martensite (M) is very hard,

strong, and brittle. It sees little use as an end

product.

But, if we reheat to below 727, (250-650) and leave

the M there for a while, it changes into something

with real usefulness. Tempered Martensite. (TM)

TM is ferrite, with an extremely fine dispersion of

roughly spherical particles of Fe

3

C. Extremely

strong, but has ductility and toughness. This is

the primo stuff, as far as steel goes.

asmission.edhole.com

Chapter 11 -

A Typical Q&T Steel

We will use Matweb to look over a couple of

steels.

Note the differences in strength and ductility in a

1060 Steel. The annealed steel with have very

coarse pearlite. The Q&T steel will have very

finely distributed cementite.

Process UTS Yield %EL Hardness

Annealed 90.6 ksi 53.7 ksi 22 88

Q & T 148.7 ksi 98.2 15 99

asmission.edhole.com

Chapter 11 -

Spheroidizing

Strangely, sometimes we would like the steel to

be just as soft and ductile as absolutely possible.

Why, do you think?

Pearlite is not the lowest energy arrangement

possible between ferrite and cementite. If heated

to just below the eutectoid temperature, and left

for an extended time, the pearlite layers break

down, and spherical clumps of cementite are

found.

These spherical clumps are hundreds or even

thousands of times larger that those in TM, and

spaced much further apart. Softest, most duct.

asmission.edhole.com

Chapter 11 -

http://info.lu.farmingdale.edu/depts

/met/met205/ANNEALING.html

asmission.edhole.com

Chapter 11 -

More on Spheroidite

You have to spend a lot of energy cooking steel.

Spheroidizing is not really used with low carbon

steels, since they are already soft and ductile

enough.

Spheroidizing is done with the higher carbon

steels, so they will be as ductile as possible for

shaping.

Spheroidizing is done to improve the

machineability of high carbon steels. Having the

massive cementite regions enhances chip

formation.

asmission.edhole.com

Chapter 11 -

Full Anneal

The idea is to get the soft metal and relieve

stresses. We contrast this anneal with the

process anneal associated with CW.

In the full anneal, we must fully austenitize the

steel. This is followed by a furnace cool, the

slowest cooling rate possible.

The result is coarse Pearlite mixed with primary

phase. This steel will be close to spheroidite in

its softness and ductility.

asmission.edhole.com

Chapter 11 -

Normalizing Steel

Here we austenitize the steel and then air cool as

opposed to furnace cooling.

The result is a uniform microstructure, very

uniformly spaced pearlite in equal sized grains

throughout.

It is stronger and somewhat less ductile than full

anneal.

Often done after forging to normalize the grain

structure.

asmission.edhole.com

Chapter 11 - 11

Annealing: Heat to T

anneal

, then cool slowly.

Based on discussion in Section 11.7, Callister 7e.

Thermal Processing of Metals

Types of

Annealing

Process Anneal:

Negate effect of

cold working by

(recovery/

recrystallization)

Stress Relief: Reduce

stress caused by:

-plastic deformation

-nonuniform cooling

-phase transform.

Normalize (steels):

Deform steel with large

grains, then normalize

to make grains small.

Full Anneal (steels):

Make soft steels for

good forming by heating

to get g , then cool in

furnace to get coarse P.

Spheroidize (steels):

Make very soft steels for

good machining. Heat just

below T

E

& hold for

15-25 h.

asmission.edhole.com

Chapter 11 - 12

a) Annealing

b) Quenching

Heat Treatments

c)

c) Tempered

Martensite

Adapted from Fig. 10.22, Callister 7e.

time (s)

10 10

3

10

5

10

-1

400

600

800

T(C)

Austenite (stable)

200

P

B

T

E

A

A

M + A

M + A

0%

50%

90%

a)

b)

asmission.edhole.com

Chapter 11 -

Hardenability

We have seen the advantage of getting

martensite, M. We can temper it, getting TM with

the best combination of ductility and strength.

But the problem is this: getting M in depth,

instead of just on the surface. We want a steel

where Pearlite formation is relatively sluggish so

we can get it to the cooler regions where M forms.

The ability to get M in depth for low cooling rates

is called hardenability.

Plain carbon steels have poor hardenability.

asmission.edhole.com

Chapter 11 -

Jominy Test for Hardenability

Hardenability not the same as hardness!

asmission.edhole.com

Chapter 11 - 15

Hardenability--Steels

Ability to form martensite

Jominy end quench test to measure hardenability.

Hardness versus distance from the quenched end.

Adapted from Fig. 11.11,

Callister 7e. (Fig. 11.11

adapted from A.G. Guy,

Essentials of Materials

Science, McGraw-Hill Book

Company, New York,

1978.)

Adapted from Fig. 11.12,

Callister 7e.

24C water

specimen

(heated to g

phase field)

flat ground

Rockwell C

hardness tests

H

a

r

d

n

e

s

s

,

H

R

C

Distance from quenched end

asmission.edhole.com

Chapter 11 - 16

The cooling rate varies with position.

Adapted from Fig. 11.13, Callister 7e.

(Fig. 11.13 adapted from H. Boyer (Ed.)

Atlas of Isothermal Transformation and

Cooling Transformation Diagrams,

American Society for Metals, 1977, p.

376.)

Why Hardness Changes W/Position

distance from quenched end (in)

H

a

r

d

n

e

s

s

,

H

R

C

20

40

60

0 1 2 3

600

400

200

A M

0.1 1 10 100 1000

T(C)

M(start)

Time (s)

0

0%

100%

M(finish)

asmission.edhole.com

Chapter 11 -

The Result is Presented in a Curve

Note:

1. Distance from

quenched end

corresponds to a

cooling rate, and a

bar diameter

2. Notice that some

steels drop off more

than others at low

cooling rates. Less

hardenability!

Rank steels in order of

hardenability.

asmission.edhole.com

Chapter 11 -

Factors Which Improve

Hardenability

1. Austenitic Grain size. The Pearlite will have an

easier time forming if there is a lot of g.b. area.

Hence, having a large austenitic grain size

improves hardenability.

2. Adding alloys of various kinds. This impedes

the g P reaction.

TTT diagram of a

molybdenum steel

0.4C 0.2Mo

After Adding

2.0% Mo

asmission.edhole.com

Chapter 11 - 19

Hardenability vs Alloy Composition

Jominy end quench

results, C = 0.4 wt% C

"Alloy Steels"

(4140, 4340, 5140, 8640)

--contain Ni, Cr, Mo

(0.2 to 2wt%)

--these elements shift

the "nose".

--martensite is easier

to form.

Adapted from Fig. 11.14, Callister 7e.

(Fig. 11.14 adapted from figure furnished

courtesy Republic Steel Corporation.)

Cooling rate (C/s)

H

a

r

d

n

e

s

s

,

H

R

C

20

40

60

10 0 20 30 40 50

Distance from quenched end (mm)

2 10 100 3

4140

8640

5140

50

80

100

%M

4340

T(C)

10

-1

10 10

3

10

5

0

200

400

600

800

Time (s)

M(start)

M(90%)

shift from

A to B due

to alloying

B

A

T

E

asmission.edhole.com

Chapter 11 - 20

Effect of quenching medium:

Medium

air

oil

water

Severity of Quench

low

moderate

high

Hardness

low

moderate

high

Effect of geometry:

When surface-to-volume ratio increases:

--cooling rate increases

--hardness increases

Position

center

surface

Cooling rate

low

high

Hardness

low

high

Quenching Medium & Geometry

asmission.edhole.com

Chapter 11 - 21

Ferrous Alloys

Iron containing Steels - cast irons

Nomenclature AISI & SAE

10xx Plain Carbon Steels

11xx Plain Carbon Steels (resulfurized for machinability)

15xx Mn (10 ~ 20%)

40xx Mo (0.20 ~ 0.30%)

43xx Ni (1.65 - 2.00%), Cr (0.4 - 0.90%), Mo (0.2 - 0.3%)

44xx Mo (0.5%)

where xx is wt% C x 100

example: 1060 steel plain carbon steel with 0.60 wt% C

Stainless Steel -- >11% Cr

asmission.edhole.com

Das könnte Ihnen auch gefallen

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelVon EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNoch keine Bewertungen

- Day 14 Heat Treatments of SteelDokument20 SeitenDay 14 Heat Treatments of Steelعزت عبد المنعمNoch keine Bewertungen

- Day 14: Heat Treatments of SteelDokument20 SeitenDay 14: Heat Treatments of SteelPedro Polastri PatriotaNoch keine Bewertungen

- Chapter 11: Metal Alloys Applications and Processing: Issues To Address..Dokument17 SeitenChapter 11: Metal Alloys Applications and Processing: Issues To Address..nurinsarahNoch keine Bewertungen

- Callister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysDokument35 SeitenCallister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysRini ArtikaNoch keine Bewertungen

- Heat Treatment: ME 318 Manufacturing TechniquesDokument12 SeitenHeat Treatment: ME 318 Manufacturing Techniquesmayur_mechNoch keine Bewertungen

- Materials Science MetalsDokument35 SeitenMaterials Science MetalsPelajar IndonesiaNoch keine Bewertungen

- Heat Treatment Steel: ObjectDokument10 SeitenHeat Treatment Steel: ObjectKetut Rizki FirmandanuNoch keine Bewertungen

- Thermal Processing of MetalsDokument63 SeitenThermal Processing of MetalsNagaVenkateshGNoch keine Bewertungen

- Heat TreatmentDokument56 SeitenHeat TreatmentAakarsh RastogiNoch keine Bewertungen

- Chapter 13 - Heat Treatment of SteelsDokument60 SeitenChapter 13 - Heat Treatment of Steelsahmedmagdi2009100% (1)

- Material Science 1 Assignment 2Dokument4 SeitenMaterial Science 1 Assignment 2Mehul BansalNoch keine Bewertungen

- Basic MetallurgyDokument55 SeitenBasic MetallurgyTina Miller100% (2)

- Day 14: Heat Treatments of SteelDokument20 SeitenDay 14: Heat Treatments of SteelBhushan Shankar KambleNoch keine Bewertungen

- Boiler MaterialsDokument47 SeitenBoiler MaterialsSaptarshi SenguptaNoch keine Bewertungen

- Lab 4 - Heat Treatment of Steels - Quenching & TemperingDokument14 SeitenLab 4 - Heat Treatment of Steels - Quenching & TemperingSarah AkuteyNoch keine Bewertungen

- Metals 07 00040 v2Dokument11 SeitenMetals 07 00040 v2Hany KhalifaNoch keine Bewertungen

- Presentation14 ALLOY STEELDokument41 SeitenPresentation14 ALLOY STEELMahadi HasanNoch keine Bewertungen

- Heat TreatmentDokument34 SeitenHeat Treatmentrahul72Noch keine Bewertungen

- Stainless Steel Metallurgy-Manufacturing Process, Grades & Role of Alloying ElementsDokument35 SeitenStainless Steel Metallurgy-Manufacturing Process, Grades & Role of Alloying ElementsLalit MohanNoch keine Bewertungen

- Heat Treatment (CHAPTER 3)Dokument48 SeitenHeat Treatment (CHAPTER 3)Muhammad AbdullahNoch keine Bewertungen

- PM - Lecture 02Dokument45 SeitenPM - Lecture 02Sheikh Sabbir SarforazNoch keine Bewertungen

- Effect of Solution Treatment On Grain Size and Toughness of Lightweight Fe-Mn-Al-C SteelDokument10 SeitenEffect of Solution Treatment On Grain Size and Toughness of Lightweight Fe-Mn-Al-C SteelJJNoch keine Bewertungen

- Heat Treatment Part 1Dokument32 SeitenHeat Treatment Part 1Naman DaveNoch keine Bewertungen

- Presentation17 Hardening or Strenghening PDFDokument23 SeitenPresentation17 Hardening or Strenghening PDFMahadi HasanNoch keine Bewertungen

- Difference Between Hardness and Harden AbilityDokument9 SeitenDifference Between Hardness and Harden AbilityJoydev GangulyNoch keine Bewertungen

- Materials Selection For Wear ResistanceDokument28 SeitenMaterials Selection For Wear ResistanceRECEP ÇETİNKAYANoch keine Bewertungen

- Maraging Steel - WikipediaDokument5 SeitenMaraging Steel - WikipediaVysakh VasudevanNoch keine Bewertungen

- Applying Computer Simulation in Improving Heat Treating Condition of Thin High-Carbon Steel PartsDokument5 SeitenApplying Computer Simulation in Improving Heat Treating Condition of Thin High-Carbon Steel PartssathishelakkiyaNoch keine Bewertungen

- What Is A Jominy End Quench Test?Dokument18 SeitenWhat Is A Jominy End Quench Test?faqhrulNoch keine Bewertungen

- Niobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener ApplicationsDokument7 SeitenNiobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener Applicationsnvc_vishwanathanNoch keine Bewertungen

- Jominy End Quench Hardenability Test: Tejas AtyamDokument15 SeitenJominy End Quench Hardenability Test: Tejas AtyamNaisarg ChauhanNoch keine Bewertungen

- Heat-Treatment of High Carbon Steel Wire - PatentingDokument4 SeitenHeat-Treatment of High Carbon Steel Wire - Patentingعزت عبد المنعم100% (1)

- 1.iron-Carbon Phasse DiagramDokument21 Seiten1.iron-Carbon Phasse Diagramnickboon100% (1)

- Materials QuestionsDokument30 SeitenMaterials QuestionsMatheus SouzaNoch keine Bewertungen

- Material Science and Engineering Ch. 11 SolDokument56 SeitenMaterial Science and Engineering Ch. 11 SolPatrick Gibson100% (1)

- Lecture 9 - Plain Carbon Steels - 2013Dokument45 SeitenLecture 9 - Plain Carbon Steels - 2013ArunNoch keine Bewertungen

- IJETR021548Dokument3 SeitenIJETR021548erpublicationNoch keine Bewertungen

- MMEN 120 - Surface HardeningDokument19 SeitenMMEN 120 - Surface HardeningnattydreadfathelahNoch keine Bewertungen

- Heat Treatment of SteelDokument7 SeitenHeat Treatment of Steelshganesh81gmailcomNoch keine Bewertungen

- Properties of SteelDokument14 SeitenProperties of SteelSIDDIQUI HasmataliNoch keine Bewertungen

- Heat Treatment Lecture NotesDokument48 SeitenHeat Treatment Lecture Notes22210021 TANWADE RUTURAJ RAVINDRANoch keine Bewertungen

- Wrought AlloysDokument33 SeitenWrought AlloysKanjiMasroorNoch keine Bewertungen

- Thermit Welding of Chromium Vanadium RailsteelDokument8 SeitenThermit Welding of Chromium Vanadium Railsteelsantu_23Noch keine Bewertungen

- Heat Treatment: Dr. Mohamed Abd Elmonem DahaDokument23 SeitenHeat Treatment: Dr. Mohamed Abd Elmonem DahashoroukNoch keine Bewertungen

- Theory of Heat TreatmentDokument8 SeitenTheory of Heat Treatmentayie740% (1)

- Heat TreatmentDokument179 SeitenHeat TreatmentDebye101100% (1)

- Write The Various Classification of Engineering MaterialsDokument7 SeitenWrite The Various Classification of Engineering Materialsashok pradhanNoch keine Bewertungen

- Iron Iron Carbon DiagramDokument9 SeitenIron Iron Carbon DiagramwaqarNoch keine Bewertungen

- TempleDokument17 SeitenTemplesan moedanoNoch keine Bewertungen

- Investigation and Application of High Strength Low Alloy Wear Resistant Cast SteelDokument4 SeitenInvestigation and Application of High Strength Low Alloy Wear Resistant Cast Steelz2aliNoch keine Bewertungen

- ADI - A Perfect Engineering MaterialDokument12 SeitenADI - A Perfect Engineering MaterialVS SaravananNoch keine Bewertungen

- Stainless SteelDokument56 SeitenStainless SteeljalindrepNoch keine Bewertungen

- Heat Treatment of SteelsDokument41 SeitenHeat Treatment of Steelsyaswanth1992Noch keine Bewertungen

- I Hardnenability of Steel Having Fine Grains Is Better That ofDokument14 SeitenI Hardnenability of Steel Having Fine Grains Is Better That of035K Ayush ChoudharyNoch keine Bewertungen

- Heat Treating BasicsDokument36 SeitenHeat Treating BasicsSuphi YükselNoch keine Bewertungen

- Closed-Book Practice-Ch 11 (2015!03!16)Dokument17 SeitenClosed-Book Practice-Ch 11 (2015!03!16)Juan100% (1)

- Table 7.7 (Continued) : 7.3.12 Stainless SteelsDokument21 SeitenTable 7.7 (Continued) : 7.3.12 Stainless SteelsumairNoch keine Bewertungen

- Maraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownDokument5 SeitenMaraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownVysakh VasudevanNoch keine Bewertungen

- Website Dsigning Company in IndiaDokument33 SeitenWebsite Dsigning Company in IndiaedholecomNoch keine Bewertungen

- Website Development Company SuratDokument42 SeitenWebsite Development Company SuratedholecomNoch keine Bewertungen

- CA in DwarkaDokument298 SeitenCA in DwarkaedholecomNoch keine Bewertungen

- Website Designing Company in DelhiDokument23 SeitenWebsite Designing Company in DelhiedholecomNoch keine Bewertungen

- Video Lecture For B.techDokument20 SeitenVideo Lecture For B.techedholecomNoch keine Bewertungen

- Website Designing Company in IndiaDokument32 SeitenWebsite Designing Company in IndiaedholecomNoch keine Bewertungen

- Video Lecture For BCADokument26 SeitenVideo Lecture For BCAedholecomNoch keine Bewertungen

- Free Video Lecture For MBADokument22 SeitenFree Video Lecture For MBAedholecomNoch keine Bewertungen

- Top School in IndiaDokument35 SeitenTop School in IndiaedholecomNoch keine Bewertungen

- Free Video Lecture For B.techDokument26 SeitenFree Video Lecture For B.techedholecomNoch keine Bewertungen

- Video Lecture For B.techDokument19 SeitenVideo Lecture For B.techedholecomNoch keine Bewertungen

- Video Lecture For MBADokument21 SeitenVideo Lecture For MBAedholecomNoch keine Bewertungen

- Methodology: 1. Surface PreparationDokument4 SeitenMethodology: 1. Surface PreparationMikee MejiaNoch keine Bewertungen

- Copper Pipe Welding Method Statement ForewordDokument3 SeitenCopper Pipe Welding Method Statement ForewordAbdullah Fazil100% (2)

- Sheet Metal and Non MetallicDokument28 SeitenSheet Metal and Non MetallicIrish Joy ValdehuezaNoch keine Bewertungen

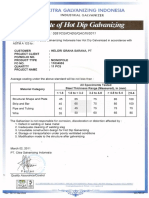

- Certificate of Hot Dip Galvanizing: Pt. Citra Galvanizing IndonesiaDokument2 SeitenCertificate of Hot Dip Galvanizing: Pt. Citra Galvanizing IndonesiaKarim Galal IsmailNoch keine Bewertungen

- Ferrous: Characteristics, Properties, and Identification of Common Alloy Steels Used in AircraftDokument40 SeitenFerrous: Characteristics, Properties, and Identification of Common Alloy Steels Used in AircraftErwan Eko PrasetiyoNoch keine Bewertungen

- Preparation of Specimen For Microscopic ExaminationDokument4 SeitenPreparation of Specimen For Microscopic ExaminationsunfaceselvamNoch keine Bewertungen

- Chip Formation 2Dokument8 SeitenChip Formation 2Ebrahim Abdullah HanashNoch keine Bewertungen

- Rolling DefectsDokument4 SeitenRolling DefectsSachith Praminda Rupasinghe100% (2)

- Secondary or Machining ProcessDokument49 SeitenSecondary or Machining ProcessHar QuinNoch keine Bewertungen

- Extrusion Complete PDFDokument22 SeitenExtrusion Complete PDFSantoshNoch keine Bewertungen

- Specialist in Castings & Forgings: Since 1923Dokument21 SeitenSpecialist in Castings & Forgings: Since 1923Srinivasan RajenderanNoch keine Bewertungen

- Clamp ModelDokument1 SeiteClamp ModelSai Theagarajan SKNoch keine Bewertungen

- Different Types of Manufacturing Processes, Their Advantages, Disadvantages and Ideal Applications Blog - MechGuruDokument4 SeitenDifferent Types of Manufacturing Processes, Their Advantages, Disadvantages and Ideal Applications Blog - MechGuruvsdeepakchandra0% (1)

- Guide To Small Tools: Section OrganizationDokument48 SeitenGuide To Small Tools: Section OrganizationKasia MazurNoch keine Bewertungen

- Hydraulic Roller Press FramDokument8 SeitenHydraulic Roller Press FramManish Verma100% (2)

- Procedimiento de Reparación TurbinaDokument4 SeitenProcedimiento de Reparación Turbinajaime huertasNoch keine Bewertungen

- Surface CoatingDokument11 SeitenSurface Coatingdu.maximeNoch keine Bewertungen

- BTU-B520-QMP-PR-025 Coating & Repair Coating For Welding Area (Outside) of Steel Box GirderDokument15 SeitenBTU-B520-QMP-PR-025 Coating & Repair Coating For Welding Area (Outside) of Steel Box GirderramdhaniNoch keine Bewertungen

- Sparks Academy Student - Test Series Result UcmpDokument14 SeitenSparks Academy Student - Test Series Result UcmpKanagarajanNoch keine Bewertungen

- w03 - LC - Introduction To 3D Printing V01Dokument7 Seitenw03 - LC - Introduction To 3D Printing V01coolshavaNoch keine Bewertungen

- 1.7225 en PDFDokument2 Seiten1.7225 en PDFTheodoros AtheridisNoch keine Bewertungen

- TDS RB-0152-BDokument1 SeiteTDS RB-0152-BGabriel MorosanuNoch keine Bewertungen

- Introduction To Manufacturing ProcessDokument23 SeitenIntroduction To Manufacturing ProcessGan Chong YaoNoch keine Bewertungen

- AI Session 2 SlidesDokument47 SeitenAI Session 2 SlidesShame BopeNoch keine Bewertungen

- Experiment No. 5 Centrifugal Casting ProcessDokument6 SeitenExperiment No. 5 Centrifugal Casting ProcessDhananjay ShimpiNoch keine Bewertungen

- Aws Bookstore. Aws d1.8 - d1Dokument2 SeitenAws Bookstore. Aws d1.8 - d1Caesar JJNoch keine Bewertungen

- AB Plastic Mold Steel For Moulds EngDokument28 SeitenAB Plastic Mold Steel For Moulds EngHoang LinhNoch keine Bewertungen

- Catalogue Eng PDFDokument20 SeitenCatalogue Eng PDFjojoNoch keine Bewertungen

- Solid-Liquid Separation Technology For Removing Contaminant Fines From Water Scrubbing, Clarifier Effluents and Grey WaterDokument24 SeitenSolid-Liquid Separation Technology For Removing Contaminant Fines From Water Scrubbing, Clarifier Effluents and Grey WaterBarry PerlmutterNoch keine Bewertungen

- Ms For Buttering of Thinning Area - Rev.0 - ReviewedDokument2 SeitenMs For Buttering of Thinning Area - Rev.0 - ReviewedAtuk SafizNoch keine Bewertungen