Beruflich Dokumente

Kultur Dokumente

Dry Gas Seal

Hochgeladen von

dhanu_aquaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dry Gas Seal

Hochgeladen von

dhanu_aquaCopyright:

Verfügbare Formate

Dry Gas Seal

Rotary Group

Topics to be covered:

How Dry gas seal works?

Types of Dry Gas Seal

Dry Gas Seal systems

Gas Seal Contamination

How Dry Gas Seal works?

Dry gas seals are basically mechanical face seals, consisting

of a mating (rotating) ring and a primary (stationary) ring

During operation, grooves in the mating ring generate a fluid

dynamic force causing the primary ring to separate from the

mating ring creating a running gap between the two rings

A sealing gas is injected into the seal, providing the working

fluid for the running gap and the seal between the

atmosphere or flare system and the compressor internal

process gas.

Grooves

Spring

How Dry Gas Seal works? (Continue)

A balance of Spring forces, hydrostatic forces and

hydrodynamic forces acting on the stationary seal ring

controls the width of the running gap.

The pattern of the grooves in the sealing surface may work

in only one direction (unidirectional) or can work in either a

clockwise or counterclockwise direction (bidirectional).

During Normal operation, the primary seal absorbs the total

pressure drop to a vent system, and the secondary seal

serving as a back up to primary seal fail.

Types of Dry Gas Seal

Single

Double Opposed

Tandem

Tandem with internal labyrinth

Single

In this arrangement, there will be one set of

sealing faces, rotating and stationary.

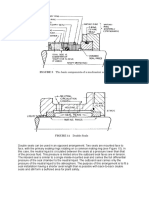

Double opposed

In this arrangement, two sets of sealing faces

face each other, and the buffer gas is injected

between them.

Double opposed seals are commonly specified

when the process gas is not suitable as a buffer

gas and an inert gas is supplied.

Tandem style seal

In this arrangement, two sets of sealing faces

arranged in series, contained within a single

cartridge.

The Tandem style seal is typically applied in

process gas service

Tandem with internal labyrinth

In this arrangement, there will be Intermediate

labyrinth seal between two sets of sealing faces.

Typical P&ID

NFL P&B

Synthesis Gas Compressor

(Siemens Offer)

Dry Gas Seal Systems

Two basic types of gas seal systems

Differential Pressure (DP) Control

Flow control

Differential Pressure control

D P systems control the supply of seal gas to the

seal by regulating the seal gas pressure to a

predetermined value above a reference (sealing)

pressure.

This is accomplished through the use of a

differential pressure control valve.

Differential Pressure Control System

Flow control systems

Flow control systems control the supply of seal

gas to the seal by regulating the seal gas flow

through an orifice upstream of the seal.

This is accomplished with a simple needle valve,

or through the use of a differential pressure

control valve monitoring pressures on either side

of the orifice.

Flow Control System

Gas Seal Contamination

Three primary sources of gas seal contamination:

Process gas (from the inboard or high-pressure

side of the seal)

Bearing lubrication oil (from the outboard or

low-pressure side of the seal)

Seal gas supply itself (injected into the seal)

Thank You

Das könnte Ihnen auch gefallen

- Dry Gas Seals ReportDokument19 SeitenDry Gas Seals ReportBilal Javed JafraniNoch keine Bewertungen

- Selection Guidelines For Dry Gas SealsDokument26 SeitenSelection Guidelines For Dry Gas SealsVivek RathodNoch keine Bewertungen

- Compressor Dry Gas SealsDokument12 SeitenCompressor Dry Gas SealsRajeev Domble100% (3)

- Dry Gas Seal For CompressorsDokument15 SeitenDry Gas Seal For CompressorsHoney Tiwari100% (2)

- DGS SealDokument87 SeitenDGS SealAhtsham Ahmad50% (2)

- Dry Gas SealDokument15 SeitenDry Gas Seal5skyNoch keine Bewertungen

- Dry Gas Seal DesignDokument26 SeitenDry Gas Seal DesignCALLESJ100% (1)

- Compressor Dry Gas Seal SystemDokument26 SeitenCompressor Dry Gas Seal SystemAnonymous KpVxNXs100% (4)

- Dry Gas SealDokument16 SeitenDry Gas SealRampageDraggerNoch keine Bewertungen

- Gas Seal IntroductionDokument10 SeitenGas Seal IntroductionIjatnaim Isa100% (1)

- Dry Gas SealDokument15 SeitenDry Gas SealViplav Kumar Singh100% (1)

- Dry Gas Versus Wet Gas Compressor Seals PDFDokument5 SeitenDry Gas Versus Wet Gas Compressor Seals PDFMANSINoch keine Bewertungen

- Dry Gas Seal ContaminationDokument12 SeitenDry Gas Seal ContaminationnguyennhatbaoNoch keine Bewertungen

- Dry Gas SealsDokument52 SeitenDry Gas Sealsshahan92ali100% (1)

- Burgmann Gas SealDokument47 SeitenBurgmann Gas SealGeorge J Alukkal100% (1)

- Dry Gas Seals 101 - PresentationDokument52 SeitenDry Gas Seals 101 - Presentationrico.fortuna78% (9)

- Dry Gas Seal ManualDokument61 SeitenDry Gas Seal ManualAbd El-rahman Mohamed100% (9)

- Dry Gas Seal - SIEMENSDokument107 SeitenDry Gas Seal - SIEMENSreguii100% (3)

- Introduction To DGSDokument58 SeitenIntroduction To DGSAan Sarkasi AmdNoch keine Bewertungen

- Compressor Dry Gas Seal SystemDokument26 SeitenCompressor Dry Gas Seal SystemAchraf Boudaya100% (1)

- Compressor Dry Gas SealsDokument53 SeitenCompressor Dry Gas SealsMuhammad Imtiaz100% (1)

- Article On Dry Gas Seals PDFDokument7 SeitenArticle On Dry Gas Seals PDFanoopthazhath100% (1)

- Dry Gas Seal Trouble ShootingDokument20 SeitenDry Gas Seal Trouble ShootingRama kalyan100% (1)

- Dry Gas Seal - BasicDokument11 SeitenDry Gas Seal - BasicRameez SaidNoch keine Bewertungen

- EPT 07-T-07 Dry Gas Seals For Centrifugal CompressorsDokument34 SeitenEPT 07-T-07 Dry Gas Seals For Centrifugal CompressorsConnor Sailor100% (1)

- 002 - Reciprocating CompressorDokument16 Seiten002 - Reciprocating CompressorMuhammad TariqNoch keine Bewertungen

- Troubleshooting Centrifugal Gas Compressor Shaft Oil SealsDokument33 SeitenTroubleshooting Centrifugal Gas Compressor Shaft Oil SealsMuhammad afzal100% (1)

- Intro To Centrifugal Compressor ComponentsDokument7 SeitenIntro To Centrifugal Compressor ComponentsMuhammad Ridhwan100% (2)

- 5-DRY Dry Seal2Dokument45 Seiten5-DRY Dry Seal2Dang XmanNoch keine Bewertungen

- Compressor Seal Selection Justification t32-18Dokument12 SeitenCompressor Seal Selection Justification t32-18Pedro Diaz100% (1)

- Dry Gas Seals ManualDokument31 SeitenDry Gas Seals ManualAtif Khan100% (2)

- Dry Gas Seal Centrifugal CompressorDokument23 SeitenDry Gas Seal Centrifugal CompressorSomen Mukherjee100% (1)

- Dry Gas SealDokument23 SeitenDry Gas Sealdrg100% (1)

- DGS NewDokument20 SeitenDGS NewKanishk KothariNoch keine Bewertungen

- Kaydon Dry Gas SealDokument12 SeitenKaydon Dry Gas Sealxsi666Noch keine Bewertungen

- Dry Gas Seals SiemensDokument11 SeitenDry Gas Seals Siemensahbabar808Noch keine Bewertungen

- Dry Gas Seal Control SystemDokument9 SeitenDry Gas Seal Control SystemnetozxNoch keine Bewertungen

- GE - System 1 Extender Dry Gas Seal RulepakDokument4 SeitenGE - System 1 Extender Dry Gas Seal RulepaklerplataNoch keine Bewertungen

- Compressor Thermodynamics Rev3Dokument28 SeitenCompressor Thermodynamics Rev3Diego1980bNoch keine Bewertungen

- S 28AT XP EXP EngDokument6 SeitenS 28AT XP EXP EngpramodtryNoch keine Bewertungen

- 02 - 04 Seal ElementsDokument61 Seiten02 - 04 Seal ElementsSreekanthMylavarapuNoch keine Bewertungen

- Dresser Rand - TMTTV - Trip & Throttle ValveDokument2 SeitenDresser Rand - TMTTV - Trip & Throttle Valverosliyu50% (2)

- Understanding Process Gas Compressor - SealingDokument20 SeitenUnderstanding Process Gas Compressor - Sealinganiruddha balasubramanyaNoch keine Bewertungen

- Centrifugal Compressor Manual1Dokument21 SeitenCentrifugal Compressor Manual1ammohamed1973100% (3)

- Article Surge Control Analysis For Centrifugal CompressorsDokument3 SeitenArticle Surge Control Analysis For Centrifugal CompressorsHatem Ali100% (1)

- Dry - Gas - Seal - Blowdown PDFDokument5 SeitenDry - Gas - Seal - Blowdown PDFchemsac2Noch keine Bewertungen

- Dry Gas Seal ContaminationDokument1 SeiteDry Gas Seal Contaminationuak107080100% (1)

- Pressure Packing PresentationDokument20 SeitenPressure Packing PresentationVIJAYIOCL100% (2)

- Compressor PPT - Part 1Dokument37 SeitenCompressor PPT - Part 1Ahmed AlhinaiNoch keine Bewertungen

- Mechanical SealDokument22 SeitenMechanical Sealkamal arabNoch keine Bewertungen

- Dry Gas Versus Wet Gas Compressor SealsDokument5 SeitenDry Gas Versus Wet Gas Compressor Sealsasimozma100% (1)

- DryGasSealCentrifugCompressors PDFDokument15 SeitenDryGasSealCentrifugCompressors PDFDeepak GoyalNoch keine Bewertungen

- Wet Seal To Dry Gas Seal ConversionDokument5 SeitenWet Seal To Dry Gas Seal Conversion•SANTRI SHARE•ITNoch keine Bewertungen

- Process Compressor Gas SealsDokument3 SeitenProcess Compressor Gas SealsGaurav SinghNoch keine Bewertungen

- Ge Dry Gas Seal RetrofitDokument4 SeitenGe Dry Gas Seal RetrofitlubangjarumNoch keine Bewertungen

- Tank BlanketingDokument5 SeitenTank BlanketingRahul LavandNoch keine Bewertungen

- Compressor Training ModuleDokument29 SeitenCompressor Training ModuleHyundianto AgNoch keine Bewertungen

- 5 Pressure Relief ValvesDokument11 Seiten5 Pressure Relief ValvesNyoman RakaNoch keine Bewertungen

- APIDokument54 SeitenAPIpramod_tryNoch keine Bewertungen

- Maintenance Engineering Management of A LNG Plant Critical System A Case Study of Gas Turbine Dry Gas SealDokument9 SeitenMaintenance Engineering Management of A LNG Plant Critical System A Case Study of Gas Turbine Dry Gas SealMiguel Angel BeltranNoch keine Bewertungen

- Turboexpanders: CompressorsDokument4 SeitenTurboexpanders: Compressorsdhanu_aquaNoch keine Bewertungen

- Selection Strategy of Mechanical SealDokument7 SeitenSelection Strategy of Mechanical Sealdhanu_aquaNoch keine Bewertungen

- Pump Suction PipeDokument6 SeitenPump Suction Pipedhanu_aquaNoch keine Bewertungen

- Seal Plans That I UseDokument9 SeitenSeal Plans That I Usedhanu_aquaNoch keine Bewertungen

- Calgary Presentation API 610 and 682Dokument90 SeitenCalgary Presentation API 610 and 682dhanu_aqua100% (1)

- Your Gas Compression ApplicationDokument26 SeitenYour Gas Compression Applicationdhanu_aqua100% (1)

- Fact Sheet Vibration Mitigation Solutions For Power Generation With Sylomer and Sylodyn enDokument4 SeitenFact Sheet Vibration Mitigation Solutions For Power Generation With Sylomer and Sylodyn endhanu_aquaNoch keine Bewertungen

- PTC 10 1997Dokument202 SeitenPTC 10 1997SANDEEP KUMAR RAHEJA100% (6)

- 118 Questionnaire GGK en 150702 STDokument2 Seiten118 Questionnaire GGK en 150702 STdhanu_aquaNoch keine Bewertungen

- Compressor Tech2 May2016Dokument60 SeitenCompressor Tech2 May2016dhanu_aquaNoch keine Bewertungen

- Centrifugal Com by Lapina PDFDokument77 SeitenCentrifugal Com by Lapina PDFdhanu_aqua100% (1)

- Calculating Stuffing Box Pressures PDFDokument2 SeitenCalculating Stuffing Box Pressures PDFdhanu_aqua100% (1)

- Calculating Stuffing Box PressuresDokument2 SeitenCalculating Stuffing Box Pressuresdhanu_aqua0% (1)

- and 330425 Accelerometer Acceleration Transducers - Datasheet - 141638 - Cda - 000 PDFDokument8 Seitenand 330425 Accelerometer Acceleration Transducers - Datasheet - 141638 - Cda - 000 PDFdialixhNoch keine Bewertungen

- Why Curves Slope DownDokument4 SeitenWhy Curves Slope Downdhanu_aquaNoch keine Bewertungen

- Guidel Pump Syst-ExtractDokument2 SeitenGuidel Pump Syst-Extractdhanu_aquaNoch keine Bewertungen

- Cryogenic Heat Exchangers For Process Cooling and Renewable Energy StorageDokument16 SeitenCryogenic Heat Exchangers For Process Cooling and Renewable Energy StoragelalithaNoch keine Bewertungen

- Vapor Pressure of A Pure LiquidDokument9 SeitenVapor Pressure of A Pure LiquidLuluaNoch keine Bewertungen

- Hidraulic Hammers Yekn0343Dokument12 SeitenHidraulic Hammers Yekn0343Andy DellepianeNoch keine Bewertungen

- Preboards 2-PipeDokument4 SeitenPreboards 2-PipeBenedictVillaminPolicarpioNoch keine Bewertungen

- Output 16 TO 1540 KW Pressure Jet Fuel Oil BurnersDokument16 SeitenOutput 16 TO 1540 KW Pressure Jet Fuel Oil BurnersRawan Alwan ZarifNoch keine Bewertungen

- Curriculum of B. Tech. (Mechanical Engineering)Dokument36 SeitenCurriculum of B. Tech. (Mechanical Engineering)KharaPrasadNoch keine Bewertungen

- Man l32 44Dokument274 SeitenMan l32 44Tran Duy NamNoch keine Bewertungen

- Manual Compresor Water FurnaceDokument50 SeitenManual Compresor Water FurnaceFred GarciaNoch keine Bewertungen

- Aci 318 Code Provisions For Deflection Control of Two-Way Concrete SlabDokument81 SeitenAci 318 Code Provisions For Deflection Control of Two-Way Concrete SlabwelwelNoch keine Bewertungen

- H-3860D - Man - 0816 DesgasteDokument8 SeitenH-3860D - Man - 0816 Desgastealvaro almendarezNoch keine Bewertungen

- LR Energy Guidance Notes For The Calculation of Probabilistic Explosion LoadsDokument18 SeitenLR Energy Guidance Notes For The Calculation of Probabilistic Explosion LoadsjmScriNoch keine Bewertungen

- NFPA 25 Form AES 5.4 ITM Electric Fire Pump Annual 2013 - 2 of 7Dokument1 SeiteNFPA 25 Form AES 5.4 ITM Electric Fire Pump Annual 2013 - 2 of 7Mark Louie GuintoNoch keine Bewertungen

- BPW 3Dokument58 SeitenBPW 3ВЛАДИМИРNoch keine Bewertungen

- De Walt 1450 - 1250 Radial Arm Saw Assembly InstructionsDokument6 SeitenDe Walt 1450 - 1250 Radial Arm Saw Assembly Instructionsloach71100% (1)

- BOQ Hotel CiputraDokument2 SeitenBOQ Hotel CiputraHendra AdriansyahNoch keine Bewertungen

- Las2 PSDokument1 SeiteLas2 PSlukewendellrNoch keine Bewertungen

- What Is Sewing M/C?: The M/C Which Is Used To Stitch Fabric or Other Material Together With ThreadDokument48 SeitenWhat Is Sewing M/C?: The M/C Which Is Used To Stitch Fabric or Other Material Together With ThreadDewan Ajuad Hossain RifatNoch keine Bewertungen

- Caterpillar Parts Manual - C15 Generator SetsDokument1.281 SeitenCaterpillar Parts Manual - C15 Generator SetsZafeer100% (1)

- User Requirement SpecificationDokument14 SeitenUser Requirement SpecificationDoan Chi Thien86% (7)

- Model Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorDokument18 SeitenModel Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorBoubekeur HamegNoch keine Bewertungen

- AT 402 - OM 1 DescriptionDokument17 SeitenAT 402 - OM 1 DescriptionCarlos Alberto Rozo R.Noch keine Bewertungen

- Cilindro Roemheld 1474Dokument2 SeitenCilindro Roemheld 1474AdrianaNoch keine Bewertungen

- Class 18 March 2020 PDFDokument13 SeitenClass 18 March 2020 PDFMuskan NehraNoch keine Bewertungen

- Report - Maintainability Design ReviewDokument94 SeitenReport - Maintainability Design ReviewNtoko100% (1)

- Fluid3a Trawneh PDFDokument39 SeitenFluid3a Trawneh PDFWesam abo HalimehNoch keine Bewertungen

- Hydraulic Power Unit EDokument8 SeitenHydraulic Power Unit EDipankar KhawasNoch keine Bewertungen

- Coolex Fcu PDFDokument24 SeitenCoolex Fcu PDFVISHALNoch keine Bewertungen

- Chapter 8 - Kinematics of GearsDokument37 SeitenChapter 8 - Kinematics of GearskbashokNoch keine Bewertungen

- Installation Manual: Generator SetDokument72 SeitenInstallation Manual: Generator SetVictor EstrellaNoch keine Bewertungen

- Physics XI STBB MOC 2023Dokument3 SeitenPhysics XI STBB MOC 2023Habib U Zaman MemonNoch keine Bewertungen