Beruflich Dokumente

Kultur Dokumente

Cementing Oil Wells

Hochgeladen von

Aderobaki GbengaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cementing Oil Wells

Hochgeladen von

Aderobaki GbengaCopyright:

Verfügbare Formate

1

Cementing

DRI LLI NG ENGI NEERI NG

2

CEMENTI NG

The purposes of this chapter are to present:

1. The primary objectives of cementing

2. The test procedures used to determine if the

cement slurry and set-cement have suitable

properties for meeting those objectives.

3. The common additives used to obtain the

desirable properties under various well

conditions.

4. The techniques used to place the cement at

the desired location in the well.

3

3.1 Composition of Portland Cement

Portland cement made by burning limestone and clay.

Oxides of Ca, Al, Fe, Si react at high temperatures in the

Klin (2600 2800

o

F).

When it cools, it becomes balls of cement clinker.

After aging in the storage, the seasoned clinker is taken to

the grinding mills where gypsum is added to (CaSO

4

.2H

2

O)

to retard setting time and increase ultimate strength.

It is sold in units of barrels = 376 lbm or four, 94 lbm sacks.

TYPES OF CEMENT

4

Cement is thought to be made up of four crystalline components

in the clinker that hydrate to form a rigid structure.

1. Tricalcium silicate (3 CaO.SiO

2

or C

3

S)

2. Dicalcium silicate (2 CaO.SiO

2

or C

2

S)

3. Tricalcium Aluminate (3 CaO.Al

2

O

3

or C

3

A)

4. Tetracalcium aluminoferrite(4CaO.Al

2

O

3

.Fe

2

O

3

C

4

AF)

The reaction is exothermic and generates a considerable quantity

of heat.

The main cementing compound is 3CaO.2SiO

2

.3H

2

O or

tobermorite gel = it has extremely fine particle size.

5

Manufacturing of Portland Cement

6

3.2 Cement Testing

API : Recommended Test procedures

Test Equipment

1. Mud balance: to determine slurry density.

2. Filter press: to determine filtration rate.

3. Rotational viscometer: to determine rheological properties.

4. Consistometer: to determine thickening rate characters.

5. Cement permeameter: to determine permeability of

the set cement.

6. Specimen molds and strength testing machines for

determining the tensile and compressive strength.

7. Autoclave : to determine the soundness of cement.

8. Turbidimeter : to determine the fineness of cement.

7

3.3 Standardization of Drilling Cements

API has defined eight standard classes and three standard

types of cement for use in wells.

Classes are designated by letters A to H.

Types are designated by O, MSR, HSR

To provide uniformity in testing it is necessary to specify

the amount of water to be mixed with each type of cement.

Water content ratio, or normal water content or API

water of the cement class. Table 3.6

8

9

Well depth and cementing time relationship used in

definition of API cement classes.

10

Physical Requirement of API Cement Types.

11

Normal Water Content Of Cement Recommended by API

12

For each wt% of bentonite added the water content should

be increased by 5.3%

For each wt% of barite added 0.2% of water should be

added.

For 3.5 : Cement mixing time =20 cuft/min

Displacement rate =50 cuft/min

Casing OD =7.0 in,

Area of Casing =33.57 sq.in.

13

Protect and support the casing

Prevent movement of the fluid through the annular

space outside the casing

Stop the movement of fluid into regular or fractured

formations.

Close an abandoned portion of the well.

Cement slurry is made by mixing powdered cement and

water.

It is placed by pumping it to the desired location.

The hardened-reacted-cement slurry becomes set cement

a rigid solid that exhibits strength.

PROPERTIES OF CEMENT

14

At present the cement classes G and H can be modified easily

through the use of additives to meet almost any job

specifications economically.

Types of cement additives:

(1)Density control additives

(2)Setting time control additives

(3)Lost circulation additives

(4)Filtration control additives

(5)Viscosity control additives

(6)Special additives

Yield of cement: the volume of slurry obtained per sack of

cement used.

Percent mix: Content of water expressed as weight percent.

3.4 CEMENT ADDITIVE

15

3.4.1 Density Control:

The density of the cement slurry must be high enough to

prevent the higher pressured formation fluids from flowing

into the well during cement operation. Yet not so high as to

cause fracture of the weaker formations.

Cement density is reduced by using a high water cement

ratio, or adding low specific gravity solids, or both.

16

Low specific gravity solids used to reduce slurry density

include:

1. Bentonite

2. Diatomaceous earth

3. Solid hydrocarbons

4. Expanded perlite

5. Pozzolan

Slurry density usually is increased by using a lower water

content or adding high specific gravity solids. High specific

gravity solids used to increase slurry density include:

(a) Hematite

(b) Ilmenite

(c) Barite

(d) Sand

17

EXAMPLE 3.5 : Use hematite to increase the density of

cement to 17.5 lbm/gal. I f the water requirement are 4.5

gal/94 lbm class H cement and 0.36 gal per 100 lbm

hematite compute the amount of hematite that should be

blended with each sack.

Solution:

Assume X = lbm of hematite / sack of cement

Total water requirement of slurry = 4.5 + .0036 X

X = 18.3 lbm hematite / sack of cement

volume total

mass total

) 0036 . 0 5 . 4 (

) 34 . 8 ( 02 . 5 ) 34 . 8 ( 14 . 3

94

) 0036 . 5 . 4 ( 34 . 8 94

5 . 17

X

X

X X

18

3.4.2 Bentonite

Use for building drilling fluid viscosity.

Also used extensively as an additive for lowering

cement density.

The addition of bentonite lowers the slurry density

because of its lower specific gravity and because

its ability to hydrate permits the use of much

higher water concentration.

In addition to lowering slurries density, the

addition of bentonite lowers slurry cost.

19

3.4.3 Diatomaceous

A special grade of diatomaceous earth is used in

portland cements to reduce slurry density.

Lower specific gravity than bentonite.

Permits higher water/cement ratios without

resulting in free water.

20

3.4.7 Hematite

Reddish iron oxide core (Fe

2

O

3

) having s specific

gravity of approximate 5.02.

Can be used to increase the density of a cement

slurry to as high as 19 lbm/gal.

The water requirement for the hematite is

approximately 0.36gal/100 lbm hematite.

21

3.4.9 Barite

Barite or barium sulphate is extensively used for

increasing the density of a cement slurry.

Water requirement for barite is about 2.4 gal/100

lbm of barite.

The large amount of water required decreases the

compressive strength of the cement and dilutes the

other chemical additives.

22

3.4.10 Sand

Sand having low specific gravity of about 2.63,

sometimes used to increase slurry density.

Sand requires no additional water to be added to

the slurry.

Has little effect on the strength or pumpability of

the cement, but causes the cement surface to be

relatively hard.

Also used to form a plug in an open hole as a base

for setting a whipstock tool used to change the

direction of the hole.

23

3.4.11 Setting Time Control

The cement must set and develop strength before

drilling activities can be resumed.

Compressive strength = 500 psi common

Tensile strength = 40 psi common

For shallow, low temperature wells it may be necessary

to accelerate the cement hydration so that the waiting

period after cementing is minimized.

24

Commonly used accelerators:

1. Calcium chloride (upto 4.0% T < 125

o

F)*

2. Sodium chloride (upto 5%) **

3. Hemihydrate form of gypsum (T=low)

4. Sodium Silicate (upto 7%)

Cement setting time is also a function of:

Cement composition

Fineness

Water content

Increases compressive strength (generally) at

saturations > 5% it acts as retarders used to cement

salt and shale formations.

NaCl, CaCl

2

, MgCl

2

, at concentrations present in sea

water all act as accelerators.

At T > 160

o

F use retarders when using sea water.

25

3.4.12 Calcium Chloride

Concentration up to 4% by weight commonly is

used as a cement accelerator in wells having

bottomhole temp < 125

o

F.

Available in regular grade (77% calcium chloride)

and an anhydrous grade (96% calcium chloride).

Anhydrous grade is in more general use because it

absorbs moisture less readily and is easier to

maintain in storage.

26

3.4.13 Sodium Chloride

An accelerator used in low concentration.

Max. accelerator occurs at a concentration of

about 5% (by weight of mixing water) for cements

containing no bentonite.

Saturated sodium chloride cements are used

primarily for cementing through salt formations

and through shale formation that are highly

sensitive to fresh water.

27

3.4.16 Retarders:

Deflocculants ( lignosulfonates)

(thinners, dispersants)

Halliburton (HR-12)

Borax

CM HEC

28

3.4.18 Filtration Control Additives

Functions:

(1) Minimize hydration of formations containing

water-sensitive shales.

(2) Prevent increases in slurry viscosity.

(3) Prevent formation of annular bridges which can

act as a packer to remove hydrostatic pressure

holding back high pressure zones.

(4) Reduce rate of cement dehydration when pumping into

abandoned perforated intervals allowing longer plugs.

Commonly used:

Latex

Bentonite with a dispersant

CMHEC

Various organic polymers, such as Halliburton HALAD-9

29

EXAMPLE 3.6

Bil =17 in

OD =13.375 in. csg

I D =12.415 in csg

Depth =2500 ft

high strength cement column at bottom =500 ft

composed of class A cement +2% CaCl

2

.

upper 2000 ft low density slurry class A cement +16%

bentonite +5% sodium chloride

Water cement ratio =13 gal/sack

Excess factor =1.75

Compute the slurry volume and number of cement sacks.

Annular capacity

s ft

in

ft

2

2

2

2 2

6006 .

4 . 14

) 375 . 13 17 (

4

SLURRY DESIGN

30

Volume of slurry required = 2000 (.6006) (1.75)

= 2102 cu. Ft.

Calculate the yield of cement

=

For Lead (low strength)

= Volume of one sack of cement (A) + Volume of added

bentonite per sack (B) + Volume of salt water per sack (C)

cement of sack

slurry of ft cu . .

sack

ft

ft lbm

sack lbm wt

a

w c v

3

3

4797 . 0

/ ) 4 . 62 ( 14 . 3

/ 94 94

) (

sack

ft Bentonite of wt

b

bentonite

3

0910 . 0

) 4 . 62 ( 65 . 2

) 94 )( 16 (. .

) (

31

(c) =Volume of water = Wt. Of 5% NaCl

= .05 (94) = 4.7 lbm

Water- cement ratio = 13 gal/sack

Water wt. = 13 g.(8.34 ppg)/sack

= 108.4 lbm/sack

Wt. of fraction of NaCl =

From Table 2.3,

NaCl

= 1.0279 by interpolation

Volume of salt water

Yield = 0.4797 + 0.0910 + 1.7633 = 2.334 cuft/sack

No. of sack = 2102 cuft/2.334 cuft/sack = 901 sacks

0415 . 0

7 . 4 4 . 108

7 . 4

sack

ft water of wt

salt

2

768 . 1

) 4 . 62 ( 0279 . 1

7 . 4 4 . 108

) 4 . 62 .(

.

32

High strength tail slurry volume

= (.6006) (500) (1.75) +

= 559.2 cuft

Yield = volume/sack

Volume = vol. of cement (one sack) + Vol. of CaCl

2

Cement Volume

Wt. of CaCl

2

= (0.02) (94) = 1.88 lbm

Wt. Water = (5.2) (8.34) = 43.4 lbm

Wt. Fraction =

144

40

) 45 . 12 (

4

2

sack ft / 4797 . 0

) 4 . 62 )( 14 3 (

94

3

0415 . 0

4 . 43 88 . 1

88 . 1

33

By interpolation from Table 2.4

Volume of salt water (Brine)

Yield = 0.4797 + 0.7025 = 1.182 cuft/sack

No. of sacks of cement sack of cement

Total slurry volume = 2102 + 559.2 = 2661.2 cu.ft.

Total no. of sack of cement = 901 + 473

= 1,374 sacks Answer

0329 . 1

2

CaCl

7025 . 0

) 4 . 62 ( 0329 . 1

88 . 1 4 . 43

473

182 . 1

2 . 559

34

Cement Casing Conventional

Equipment:

guide shoe

float collar

bottom plug

top plug

Outside casing:

centralizers

scratchers

cement basket

SUB-SURFACE CASING EQUIPMENT

35

Common Cement Placement Requirements.

36

Conventional Placement Technique

used for cementing casing

37

Guide Shoe (Courtesy World Oils Cementing Handbook)

38

Float collar (Courtesy World Oils Cementing Handbook)

39

Centralizers: (a) Bow springs welded on end rings (b) centralizer with

reflector vanes (c) slim-hole centralizer (Halliburton Sales and Service Catalog)

40

(a) Rotating and (b) reciprocating wall scratchers

(Courtesy World Oils Cementing Handbook)

41

Cement baskets (a) in place within the casing and (b) with

limit rings(Courtesy World Oils Cementing Handbook)

42

Cementing plugs: (a) top and (b)bottom plugs

(Courtesy World Oils Cementing Handbook)

43

Different cementing placement techniques are used for:

Cementing casing strings

Cementing liner strings

Setting cement plugs

Squeeze cementing

3.5.2 Stage Cementing

To avoid fracturing formations by reducing cement column

length.

To make sure cement is not lost in low-pressure highly

permeable zones.

3.5.3 I nner-String Cementing

To reduce cementing time and amount of cement left in the

shoe joint of large diameter casing.

Performed using drill pipe or tubing.

3.5 CEMENT PLACEMENT

44

3.5.4 Annular-Cementing through tubing:

It is used to bring cement top of the previously placed

cement to the surface

Or to repair casing.

3.5.5 Multiple String Cementing

It is a multiple completion method that involves

cementing several strings of tubing in the hold without

the use of an outer casing strings.

3.5.6 Reverse-Circulation Cementing

It is used when extremely low-strength formation were

present near the bottom of the hole.

The cement is displaced (pumped) down the annulus

and the mud is displaced back through the casing.

45

3.5.7 Delayed-Setting Cementing

It is used to obtain a more uniform mud displacement.

Use retarded cement slurry having good filtration property

in the well bore before running the casing.

Cement placement is achieved (accomplished) down the

drill pipe and up the annulus.

The drill pipe is then removed and casing is lowered to the

unset cement.

3.5.8 Cementing liners

Latch-down plug separator mud from cement.

When it reaches top of liner it actuates a special wiper

plug.

46

When wiper-plug reaches the float collar a pressure

increase at the surface signifies the end of the cement

displacement.

Liner setting tool are activated by:

1. mechanical device (drill pipe rotated and lowered)

2. hydraulic device : drill pipe rotated or a ball or a

plug is dropped and then set by applying pressure.

Tie-back liner = to the top.

Stub-liner = up the liner but not to the top = to repair leak

at liner top.

47

3.5.9 Plug Cementing

Prevent fluid communications between an abandoned

lower portion of the well and the upper part of the well.

Placed using drill pipe or tubing.

Bridge plug is used to assist in forming a good

hydraulic seal.

Das könnte Ihnen auch gefallen

- Peng 305: Drilling Engineering I Lecture NotesDokument39 SeitenPeng 305: Drilling Engineering I Lecture NoteskwesimarkNoch keine Bewertungen

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementVon EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Common Well Control Hazards: Identification and CountermeasuresVon EverandCommon Well Control Hazards: Identification and CountermeasuresBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersVon EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNoch keine Bewertungen

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Exploiting the Digital Oilfield: 15 Requirements for Business ValueVon EverandExploiting the Digital Oilfield: 15 Requirements for Business ValueBewertung: 5 von 5 Sternen5/5 (1)

- 6 Completion and StimulationDokument62 Seiten6 Completion and StimulationHamid Reza BabaeiNoch keine Bewertungen

- Strengthen Wellbores During DrillingDokument32 SeitenStrengthen Wellbores During Drillingrıdvan duranNoch keine Bewertungen

- Air and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHVon EverandAir and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHNoch keine Bewertungen

- Measurement While Drilling: Signal Analysis, Optimization and DesignVon EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNoch keine Bewertungen

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbVon EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbBewertung: 4.5 von 5 Sternen4.5/5 (11)

- Development of Volcanic Gas Reservoirs: The Theory, Key Technologies and Practice of Hydrocarbon DevelopmentVon EverandDevelopment of Volcanic Gas Reservoirs: The Theory, Key Technologies and Practice of Hydrocarbon DevelopmentNoch keine Bewertungen

- Open Hole FishingDokument89 SeitenOpen Hole FishingShiela O100% (1)

- Practical Petroleum Geochemistry for Exploration and ProductionVon EverandPractical Petroleum Geochemistry for Exploration and ProductionNoch keine Bewertungen

- Downhole Drilling Problems and SolutionsDokument45 SeitenDownhole Drilling Problems and SolutionsMrSebolliniNoch keine Bewertungen

- Oil Well Cementing Functions, Classes and EquipmentDokument12 SeitenOil Well Cementing Functions, Classes and EquipmentVinod KumarNoch keine Bewertungen

- Welcome To The Students: Presented byDokument18 SeitenWelcome To The Students: Presented byMajedur RahmanNoch keine Bewertungen

- RA Casing CementingDokument66 SeitenRA Casing CementingAnonymous 9AZe3w0% (1)

- Quartz School For Well Site SupervisorsDokument36 SeitenQuartz School For Well Site SupervisorsLeo Ivan Aviles RicaldiNoch keine Bewertungen

- 5 - Casing CementingDokument33 Seiten5 - Casing Cementing12011982100% (3)

- Basic Well Construction and Frac Design ConceptsDokument52 SeitenBasic Well Construction and Frac Design ConceptsRafael Arregui100% (2)

- Cementing Lectures 2019Dokument24 SeitenCementing Lectures 2019Uthman Mohammed100% (1)

- 11 CL-1.Primary Cementing 1Dokument45 Seiten11 CL-1.Primary Cementing 1Eslam Atif AzkolNoch keine Bewertungen

- Casing and Cement CourseDokument382 SeitenCasing and Cement CourseMortaja Ben KhalifaNoch keine Bewertungen

- Well Cementing Techniques & EquipmentDokument34 SeitenWell Cementing Techniques & EquipmentAngel Ngo100% (2)

- Bit Balling DJENANE YOUCEFDokument13 SeitenBit Balling DJENANE YOUCEFMohamed Kouchache100% (1)

- Stuck Pipe Book by DrillingFormulasDokument60 SeitenStuck Pipe Book by DrillingFormulashosam ali100% (1)

- Part VII Deepwater Drilling PDFDokument31 SeitenPart VII Deepwater Drilling PDFSlim.BNoch keine Bewertungen

- Well Plug AbandonmentDokument20 SeitenWell Plug AbandonmentKenneth Tan100% (2)

- Chapter 2 - CementingDokument31 SeitenChapter 2 - CementingSatees KrishnanNoch keine Bewertungen

- Topic 2 Well CompletionDokument308 SeitenTopic 2 Well CompletionAjay Suri100% (1)

- Cementing Operation - Part IDokument26 SeitenCementing Operation - Part IDoni KurniawanNoch keine Bewertungen

- CementingDokument47 SeitenCementingKarwan DilmanyNoch keine Bewertungen

- 5 - Volumes & MaaspDokument111 Seiten5 - Volumes & Maaspsouthernor100% (2)

- 03 Scott Jackson - Drilling FluidsDokument40 Seiten03 Scott Jackson - Drilling FluidsNicolas RoldanNoch keine Bewertungen

- FOCUSSTUCKPIPEDokument21 SeitenFOCUSSTUCKPIPEVikas kumar singhNoch keine Bewertungen

- Well Drilling DesignDokument26 SeitenWell Drilling DesignMajedur Rahman100% (1)

- 13 3-8" Cementing Program ChecklistDokument2 Seiten13 3-8" Cementing Program ChecklistYougchu LuanNoch keine Bewertungen

- Well CementingDokument8 SeitenWell CementingNima MoradiNoch keine Bewertungen

- Cavings Poster-1 SLBDokument1 SeiteCavings Poster-1 SLBEric Espiritu100% (3)

- CL-8.Squeeze CementingDokument43 SeitenCL-8.Squeeze CementingAli AliievNoch keine Bewertungen

- Drilling Optimization PDFDokument22 SeitenDrilling Optimization PDFRoyNoch keine Bewertungen

- 3 Stuck Pipe Problems Formations RelatedDokument33 Seiten3 Stuck Pipe Problems Formations RelatedRoyNoch keine Bewertungen

- Coil TubingDokument15 SeitenCoil TubingOgbadiboNoch keine Bewertungen

- Drilling ProblemsDokument7 SeitenDrilling ProblemsMEUBRONoch keine Bewertungen

- Drilling Fluids For Drilling of Geothermal Wells - Hagen HoleDokument8 SeitenDrilling Fluids For Drilling of Geothermal Wells - Hagen HoleAdil AytekinNoch keine Bewertungen

- 1.aramco Interview QuestionDokument140 Seiten1.aramco Interview QuestionWasif KarimNoch keine Bewertungen

- CementingDokument152 SeitenCementingEbenezer Amoah-KyeiNoch keine Bewertungen

- Mud Removal TechniquesDokument70 SeitenMud Removal TechniquesMohamed ElshoraNoch keine Bewertungen

- 3 WellPlan 2018 2019 CasingDesignDokument122 Seiten3 WellPlan 2018 2019 CasingDesigndca13100% (2)

- Casing Seat Selection in Weak FormationsDokument32 SeitenCasing Seat Selection in Weak FormationsG Vishwanath ReddyNoch keine Bewertungen

- Drilling Problems N Drilling OptimizationDokument68 SeitenDrilling Problems N Drilling Optimizationngecus50% (2)

- How To Grade Impregnated BitsDokument6 SeitenHow To Grade Impregnated BitsAderobaki GbengaNoch keine Bewertungen

- Elongation of Pipe Due To Temperature:: Elongation (Inches) 11.09748011328 Elongation (Meters) 0.28186224Dokument3 SeitenElongation of Pipe Due To Temperature:: Elongation (Inches) 11.09748011328 Elongation (Meters) 0.28186224Aderobaki GbengaNoch keine Bewertungen

- AnswersDokument21 SeitenAnswersPungky SuroyoNoch keine Bewertungen

- Vacation Budget Planner1Dokument4 SeitenVacation Budget Planner1Aderobaki GbengaNoch keine Bewertungen

- Conductor Setting Depth and Bearing LoadDokument5 SeitenConductor Setting Depth and Bearing LoadAderobaki GbengaNoch keine Bewertungen

- A2G8C3 - NPS 8 - Hydrotest Calculation Sheet - Beatton River Mainline Test MeOh - 2011-10-28 PDFDokument4 SeitenA2G8C3 - NPS 8 - Hydrotest Calculation Sheet - Beatton River Mainline Test MeOh - 2011-10-28 PDFsaravananselvamNoch keine Bewertungen

- Conductor Setting Depth and Bearing LoadDokument5 SeitenConductor Setting Depth and Bearing LoadAderobaki GbengaNoch keine Bewertungen

- Dipstick WorksheetDokument66 SeitenDipstick WorksheetAderobaki GbengaNoch keine Bewertungen

- Complete BOP Stack SpaceoutDokument10 SeitenComplete BOP Stack SpaceoutAderobaki GbengaNoch keine Bewertungen

- Subsea Well Test Flow DiagramDokument1 SeiteSubsea Well Test Flow DiagramAderobaki GbengaNoch keine Bewertungen

- Well Intervention Pressure Control Syllabus - Level 2Dokument28 SeitenWell Intervention Pressure Control Syllabus - Level 2Richard ReiersenNoch keine Bewertungen

- Well Intervention Pressure Control Syllabus - Level 3 4Dokument52 SeitenWell Intervention Pressure Control Syllabus - Level 3 4ryaneschultzhotmail.comNoch keine Bewertungen

- LM Drilling Riser Protection FLDRDokument4 SeitenLM Drilling Riser Protection FLDRAderobaki GbengaNoch keine Bewertungen

- Vacation Budget Planner1Dokument4 SeitenVacation Budget Planner1Aderobaki GbengaNoch keine Bewertungen

- Bourgoyne and Young Model Development ReDokument12 SeitenBourgoyne and Young Model Development ReAderobaki GbengaNoch keine Bewertungen

- Malaria PreventionDokument24 SeitenMalaria PreventionAderobaki GbengaNoch keine Bewertungen

- ME 130 Applied Engineering Analysis Chapter 3: Application of First Order Differential EquationsDokument49 SeitenME 130 Applied Engineering Analysis Chapter 3: Application of First Order Differential EquationsHithesh U Warrier100% (1)

- Compatibility With Elastomers: Section B7Dokument12 SeitenCompatibility With Elastomers: Section B7Aderobaki GbengaNoch keine Bewertungen

- Dynamic two-phase flow modellingDokument93 SeitenDynamic two-phase flow modellingAderobaki GbengaNoch keine Bewertungen

- Ultra-Deepwater Blowout Well Control and Abandonment Operations Through Relief Well Under Capping and Containment Scenario After Worst Case DischargeDokument20 SeitenUltra-Deepwater Blowout Well Control and Abandonment Operations Through Relief Well Under Capping and Containment Scenario After Worst Case DischargeAderobaki GbengaNoch keine Bewertungen

- Super Ii Fishing Jar: Instruction Manual 4102Dokument24 SeitenSuper Ii Fishing Jar: Instruction Manual 4102Aderobaki GbengaNoch keine Bewertungen

- Universal Blowout Preventers: Instruction Manual 8520Dokument23 SeitenUniversal Blowout Preventers: Instruction Manual 8520Aderobaki GbengaNoch keine Bewertungen

- 33inside A Traders Mind PDFDokument19 Seiten33inside A Traders Mind PDFmallinlrNoch keine Bewertungen

- Tubing and Casing Rollers: Instruction Manual 6200Dokument9 SeitenTubing and Casing Rollers: Instruction Manual 6200Aderobaki GbengaNoch keine Bewertungen

- Coflexip User Guide PDFDokument40 SeitenCoflexip User Guide PDFKaleem UllahNoch keine Bewertungen

- Well Integrity AnalysisDokument39 SeitenWell Integrity Analysishammad091Noch keine Bewertungen

- Pressure Balanced Drilling Bumper Sub: Instruction Manual 4410Dokument17 SeitenPressure Balanced Drilling Bumper Sub: Instruction Manual 4410Foros IscNoch keine Bewertungen

- Fibonacci Retracement Channel Trading StrategyDokument22 SeitenFibonacci Retracement Channel Trading StrategyAderobaki Gbenga100% (3)

- Unit conversion guide for oilfield measurementsDokument1 SeiteUnit conversion guide for oilfield measurementsAderobaki GbengaNoch keine Bewertungen

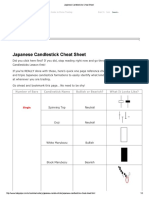

- Japanese Candlestick CheatsheetDokument3 SeitenJapanese Candlestick CheatsheetAderobaki GbengaNoch keine Bewertungen

- Composite Fish Culture PDFDokument2 SeitenComposite Fish Culture PDFHanumant JagtapNoch keine Bewertungen

- Chapter 14Dokument11 SeitenChapter 14Marco LuigiNoch keine Bewertungen

- Toxicology: Metal Chosen: MERCURYDokument13 SeitenToxicology: Metal Chosen: MERCURYsamarpita senguptaNoch keine Bewertungen

- Storage ProteinDokument3 SeitenStorage ProteinprincessicyjulietNoch keine Bewertungen

- ISO 17746-2016 Steel Wire Rope Net Panels and RollsDokument24 SeitenISO 17746-2016 Steel Wire Rope Net Panels and RollsOctavian Miclescu100% (1)

- Ssi Schaefer Container AsDokument8 SeitenSsi Schaefer Container AsRebecca HartmanNoch keine Bewertungen

- Evacuated Tube SystemDokument2 SeitenEvacuated Tube SystemAaron James RuedasNoch keine Bewertungen

- Metamorphic Petrology: Processes and ProductsDokument27 SeitenMetamorphic Petrology: Processes and ProductsAnnisaBestariNoch keine Bewertungen

- LIST OF TSD FACILITIESDokument18 SeitenLIST OF TSD FACILITIESAmelia SantosNoch keine Bewertungen

- Kolorsafe Liquid Acid Neutralizer - SDS - NA - 012115 - FINALDokument8 SeitenKolorsafe Liquid Acid Neutralizer - SDS - NA - 012115 - FINALJUAN FELIPE ORTIZ PARRANoch keine Bewertungen

- MX 2100 Gas MonitorDokument2 SeitenMX 2100 Gas MonitorForum PompieriiNoch keine Bewertungen

- BIOTERGEPAS8SDokument2 SeitenBIOTERGEPAS8SJefferson Ravello RiverosNoch keine Bewertungen

- Lecture 2 - Cellulose Structure PDFDokument55 SeitenLecture 2 - Cellulose Structure PDFpipers10Noch keine Bewertungen

- Copy of Pharmacognosy-and-Plant-ChemistryDokument25 SeitenCopy of Pharmacognosy-and-Plant-ChemistryDecemae FuentesNoch keine Bewertungen

- Product UserManual Pulsarlube V EnglishDokument2 SeitenProduct UserManual Pulsarlube V EnglishTiago LimaNoch keine Bewertungen

- API Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationDokument4 SeitenAPI Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationFabioSalaNoch keine Bewertungen

- In The Name of GodDokument34 SeitenIn The Name of GodFariha NormanNoch keine Bewertungen

- Case Studies of The EntrepreneursDokument14 SeitenCase Studies of The EntrepreneursSneha DobariaNoch keine Bewertungen

- BC34.1 E9 Determination of Acid Value of FatsDokument3 SeitenBC34.1 E9 Determination of Acid Value of FatsGlenn Vincent Tumimbang96% (26)

- Stainless Steel 1.4404 316lDokument3 SeitenStainless Steel 1.4404 316lDilipSinghNoch keine Bewertungen

- Toksikologi PDFDokument134 SeitenToksikologi PDFPurwani Ni NyomanNoch keine Bewertungen

- E53-07 (Reapproved 2013) PDFDokument4 SeitenE53-07 (Reapproved 2013) PDFearth metallurgical services pvt.ltd.Noch keine Bewertungen

- 01 Well Cementing - Day 1 PDFDokument131 Seiten01 Well Cementing - Day 1 PDFام فاطمة البطاط100% (1)

- 6 9500 F Axera 7 240 PDFDokument4 Seiten6 9500 F Axera 7 240 PDFsegomezpNoch keine Bewertungen

- Differential Thermal Analysis (Dta)Dokument21 SeitenDifferential Thermal Analysis (Dta)Shaise Jacob100% (6)

- Ladder Inspection Form: Company Name: Ladder Reference Number: Inspector Dept. DateDokument2 SeitenLadder Inspection Form: Company Name: Ladder Reference Number: Inspector Dept. DatesantoshjayantiNoch keine Bewertungen

- Types of Insulation Used On Rotating Machines, Their Insulation Life, and Deterioration CausesDokument14 SeitenTypes of Insulation Used On Rotating Machines, Their Insulation Life, and Deterioration CausessantoshkumarNoch keine Bewertungen

- EXPERIMENT A2: Determination of The Formula of A HydrateDokument5 SeitenEXPERIMENT A2: Determination of The Formula of A HydrateTessi SeokoloNoch keine Bewertungen

- I) Introduction To Polymer Nanocomposites For Food Packaging Applications II) Overview On An European Activity in The FieldDokument39 SeitenI) Introduction To Polymer Nanocomposites For Food Packaging Applications II) Overview On An European Activity in The FieldNormanBatesNoch keine Bewertungen

- Kartu Stock Obat: Apotek EmpangDokument17 SeitenKartu Stock Obat: Apotek EmpangKlinik EmpangNoch keine Bewertungen