Beruflich Dokumente

Kultur Dokumente

Lab 2 - Microsoft Visio

Hochgeladen von

athieyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lab 2 - Microsoft Visio

Hochgeladen von

athieyCopyright:

Verfügbare Formate

MICROSOFT VISIO

1

INTRODUCTION

The design of complex chemical plants

requires the integration of very large amounts

of diverse information.

Process designers make use of standardized

sets of graphical representations to assist in

the development and transfer of these

information sets.

HOW to develop the information sets?

2

HOW?

3

P&ID

PFD BFD

GENERIC

DIAGRAM

INPUT/

OUTPUT

DIAGRAM

a crude block flow

diagram in which only

feed and product streams

are identified.

Break the process into its basic

elements such as reaction

and separation, and recycle sections

Include the material

balance calculations

complete mass and

energy balance and

preliminary equipment

specs

includes the mechanical

and instrumentation

details

4

LEVELS

OF

DIAGRAM

BLOCK FLOW

DIAGRAM

(BFD)

PROCESS

FLOW

DIAGRAM

(PFD)

Piping and

Instrumentation

Diagram

(P&ID)

often referred

to as Mechanical Flow Diagram

COMPARISON

5

6

Block Flow Diagram

Group of connected blocks of process units

Lines with arrows connect blocks and represent process

streams

Raw materials enter on the left

Products exit on the right

4 kinds of process units:

Mixers

Reactors

Splitters

Separators

Process

Products

Raw Materials

7

Mixer

butter

C

12

H

22

O

11

flour

eggs

NaCl

NaHCO

3

Chocolate chips

Raw chocolate chip

Cookie dough

Baked chocolate chip

Cookies

Reactor (Oven)

Raw chocolate chip

Cookie dough

8

Splitter

4 dozen cookies

75% choc chip

25% peanut butter

3 dozen cookies

75% choc chip

25% peanut butter

1 dozen cookies

75% choc chip

25% peanut butter

Separator

4 dozen cookies

75% choc chip

25% peanut butter

3 dozen cookies

97.5% choc chip

2.8% peanut butter

1 dozen cookies

8.3% choc chip

91.7% peanut butter

BFD

9

10

Flowsheets

The first step in any process design or analysis is

the construction of a flowsheet that shows the

major material flows and processing steps.

common flowsheet symbols

common abbreviations

The flow sheet allows for better visualization and

quantification of the process.

A picture is worth a thousand words.

A process flow sheet is comprised of units,

represented by simple shapes like circles or

rectangles.

11

Some common flowsheet symbols

Pumps are used to increase a fluids pressure so the fluid will flow from high

pressure to low pressure, or used to condense a fluid or increase the speed of

a chemical reaction.

Gas compressor a different unit description is used as the fluid responds

differently than liquid in a pump (ie increase in pressure causes gas to condense)

Gas expander or turbine is similar but with flows reversed.

Valves are needed to control flows between various units.

12

Combiner and splitter:

Avoid crossing streams. If streams must cross,

you need to indicate whether they mix or not.

streams cross

without mixing

Ambiguous

streams combine

and split

13

Example

14

tabulate process

design values for

the components in

different

operating modes,

typical minimum,

normal and

maximum.

PFD

PFD Should NOT include:

15

pipe classes pipe line numbers

minor bypass

lines

isolation and shutoff

valves

maintenance

vents and

drains

relief and safety valves

code class information

SYMBOLS FOR DRAWING PFD

16

PFD 17

18

P&ID

A family of functional one-line diagrams showing hull,

mechanical and electrical (HM&E) systems like piping,

and cable block diagrams.

Show the interconnection of process equipment and

the instrumentation used to control the process.

They are the primary schematic drawings used for

laying out a process control installation in a factory or

plant.

A standard set of symbols may be used to prepare

drawings of processes, for instance the instrument

symbols used may be based on Instrument Society of

America (ISA) Standard S5.1.

19

A P&ID should not include :

Instrument

root valves

control relays

manual

switches

equipment rating

or capacity

primary

instrument

tubing and valves

pressure

temperature and

flow data

elbow, tees and

similar standard

fittings

extensive

explanatory

notes

20

P&ID

21

The P&ID mixes pneumatic / hydraulic elements, electrical

elements and instruments on the same diagram

It uses a set of symbols defined in the ISA S5.1 standard.

Examples of pneumatic / hydraulic symbols:

pipe

valve

binary (or solenoid) valve (on/off)

350 kW

heater

vessel / reactor

pump, also

heat exchanger

analog valve (continuous)

one-way valve (diode)

22

P&ID

23

24

INSTRUMENTATION IDENTIFICATION

V1528

FIC

S

tag name of the

corresponding

variable

function

(here: valve)

mover

(here: solenoid)

The first letter defines the measured or initiating variables such as Analysis (A), Flow (F),

Temperature (T), etc. with succeeding letters defining readout, passive, or output functions such

as Indicator (I), Record (R), Transmit (T), and so forth. *(C for control)

INTRODUCTION TO VISIO

25

10/16/2014

26

10/16/2014

27

General Equipment & Details

10/16/2014

28

Vessel, Pump & Others

EXERCISE 1 : PFD

29

30

Draw a PFD from the following simplified

description of the synthesis of ammonia:

A mixture of hydrogen and nitrogen is fed to a

catalytic reactor where some of the hydrogen and

nitrogen is converted to ammonia. The reactor

effluent is sent to a condenser where all of the

ammonia is condensed. The condensed ammonia is

sent to product storage. The uncondensed hydrogen

and nitrogen are recycled by being mixed with a

fresh feed of the same composition. The resulting

mixture is fed to the reactor.

31

Type of process?

Reactor and condenser are continuous

Storage tank is semi-continuous

Reaction: N

2

+ 3H

2

2NH

3

32

A mixture of hydrogen and nitrogen is fed to a catalytic

reactor where some of the hydrogen and nitrogen is

converted to ammonia. The reactor effluent is sent to a

condenser where all of the ammonia is condensed. The

condensed ammonia is sent to product storage. The

uncondensed hydrogen and nitrogen are recycled by being

mixed with a fresh feed of the same composition. The

resulting mixture is fed to the reactor.

Step 1 is the feed to the reactor:

reactor

feed

N

2

H

2

effluent

NH

3

N

2

H

2

33

A mixture of hydrogen and nitrogen is fed to a catalytic reactor

where some of the hydrogen and nitrogen is converted to

ammonia. The reactor effluent is sent to a condenser where all

of the ammonia is condensed. The condensed ammonia is sent

to product storage. The uncondensed hydrogen and nitrogen

are recycled by being mixed with a fresh feed of the same

composition. The resulting mixture is fed to the reactor.

Step 2 is to purify the product:

reactor

feed

N

2

H

2

effluent

NH

3

N

2

H

2

condenser

NH

3

liquid

34

A mixture of hydrogen and nitrogen is fed to a catalytic reactor

where some of the hydrogen and nitrogen is converted to

ammonia. The reactor effluent is sent to a condenser where all

of the ammonia is condensed. The condensed ammonia is sent

to product storage. The uncondensed hydrogen and nitrogen

are recycled by being mixed with a fresh feed of the same

composition. The resulting mixture is fed to the reactor.

Step 3 is to send product to storage:

reactor

feed

N

2

H

2

effluent

NH

3

N

2

H

2

condenser

NH

3

liquid

Storage

tank

35

A mixture of hydrogen and nitrogen is fed to a catalytic reactor

where some of the hydrogen and nitrogen is converted to

ammonia. The reactor effluent is sent to a condenser where all

of the ammonia is condensed. The condensed ammonia is sent

to product storage. The uncondensed hydrogen and nitrogen

are recycled by being mixed with a fresh feed of the same

composition. The resulting mixture is fed to the reactor.

Step 4 is to recycle unreacted feeds:

reactor

feed

N

2

H

2

effluent

NH

3

N

2

H

2

condenser

NH

3

liquid

Storage

tank

N

2

, H

2

recycle

purge

EXERCISE 2: CREATING A P&ID

37

38

Instrumentation and Control

Instruments are used to sense process variables and

drive control valves.

These are denoted on P&IDs by circles with letters:

Valves are connected by solid lines to the point where

variables are measured, and by dotted lines to the

equipment they control

LC FRC

FRC

39

As 1st letter As 2

nd

letter As 3

rd

letter

A analyzer Alarm Alarm

C - controller controller

F flow - -

I - indicator -

L Level/liquid level -

P Pressure - -

R - Recorder -

T Temperature - -

V - - Valve

D Differential Differential -

r ratio ratio -

Instrumentation symbols

40

First letter describes the variable sensed by the

instrument: Pressure (P), Temperature (T), Flow (F), level

or liquid level (L or LL), composition (A)

The second and third letters describe the action taken:

Record ( R), Indicate (I), Sound an alarm (A), or Control

(C )

Explain the symbols:

LC FRC

41

42 Description

Main pieces of equipment are the column (C1),

accumulator drum (D1), reboiler (E2) and condenser

(E1).

The distillation column (C1) separates the feed stream

according to volatility into overhead and bottoms

products.

The heat exchangers (E1) and (E2) condense the

overhead vapours and partially vaporize the liquid from

the bottom of the column.

The drum (D1) accumulates the condensed liquid and

also accommodates surges in overhead product rate.

Control elements are shown by circles and dashed lines.

43 Control elements

The rate of bottoms withdrawal is controlled by the liquid level in the

bottom of the column. When the level rises the valve is opened to increase

the withdrawal rate and thus lower the level.

The net bottoms flow is controlled by an analyzer (with recorder) which sets

the flow controller on the steam to the reboiler to maintain the bottoms

composition within specified limits.

The net overhead is withdrawn from the drum on level control (ie when the

level in D1 rises the valve is opened). This keeps the level in the tank within

a preset upper and lower limits.

The rate at which reflux is returned to the column is controlled by the

Temperature at a particular point in the column, when this temperature rises

the valve is opened and more reflux flows to the column. This instrument is

an indicator as well as a controller so it sends a signal proportional to the

temperature to a readout instrument in the control room.

The column is feed controlled by an FRC.

Das könnte Ihnen auch gefallen

- 2015-Xii. P&id PDFDokument71 Seiten2015-Xii. P&id PDFFitria Nur HayatiNoch keine Bewertungen

- Mechanical Isolation Methods and ProceduresDokument13 SeitenMechanical Isolation Methods and ProceduresHse RiyazNoch keine Bewertungen

- Minitab DOE Tutorial PDFDokument32 SeitenMinitab DOE Tutorial PDFnmukherjee20100% (3)

- Chapter 1.1 PFD & PIDDokument103 SeitenChapter 1.1 PFD & PIDS JNoch keine Bewertungen

- Jump Start To Crushing and Milling in AspenPlus v8 - DownLoadLy - IrDokument14 SeitenJump Start To Crushing and Milling in AspenPlus v8 - DownLoadLy - IrMarcoiNoch keine Bewertungen

- PFD PrintDokument1 SeitePFD PrintAgung PrabowoNoch keine Bewertungen

- Chemical Process DiagramDokument43 SeitenChemical Process DiagramMark GuevarraNoch keine Bewertungen

- Aspen Plus Model For Entrained Flow Coal Gasifier PDFDokument35 SeitenAspen Plus Model For Entrained Flow Coal Gasifier PDFSumit KaushikNoch keine Bewertungen

- Ekahau Survey Datasheet FinalDokument2 SeitenEkahau Survey Datasheet FinalEdison Alexis León CarreraNoch keine Bewertungen

- Network Engineer (Cisco) : SkillsDokument4 SeitenNetwork Engineer (Cisco) : SkillsAkassh Deep100% (1)

- Simulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactDokument15 SeitenSimulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactVyssionNoch keine Bewertungen

- Refinery and Petrochemical Line Sizing CriteriaDokument9 SeitenRefinery and Petrochemical Line Sizing CriteriaAatish ChandrawarNoch keine Bewertungen

- Cisco ACI and F5 BIG IP Design GuideDokument46 SeitenCisco ACI and F5 BIG IP Design GuideOinotna Rj PisiNoch keine Bewertungen

- Multivariable Predictive Control: Applications in IndustryVon EverandMultivariable Predictive Control: Applications in IndustryNoch keine Bewertungen

- Activated Exchanger Design & Rating Aspen 8.4Dokument12 SeitenActivated Exchanger Design & Rating Aspen 8.4cacardenasmaNoch keine Bewertungen

- AspenPlus Solids JumpStartGuide ParticleScientist 120812 - DownLoadLy - Ir PDFDokument22 SeitenAspenPlus Solids JumpStartGuide ParticleScientist 120812 - DownLoadLy - Ir PDFMarcoiNoch keine Bewertungen

- M2 IGCC HRSG Enhanced Modeling and Simulation in Power Plant DR R R JoshiDokument32 SeitenM2 IGCC HRSG Enhanced Modeling and Simulation in Power Plant DR R R JoshiAkshat RawatNoch keine Bewertungen

- Prisma Access Licensing GuideDokument3 SeitenPrisma Access Licensing GuideRadi Pratama100% (1)

- ColumnA RadFrac ABCDokument5 SeitenColumnA RadFrac ABCGaby HdzNoch keine Bewertungen

- Control of An Isomerization Column/Reactor Process: William L. LuybenDokument8 SeitenControl of An Isomerization Column/Reactor Process: William L. LuybenMirko SusichNoch keine Bewertungen

- Radhanatha SwamiDokument3 SeitenRadhanatha SwamiAchutananda Barada100% (1)

- Gas Liquid AbsorptionDokument9 SeitenGas Liquid AbsorptionShashwat OmarNoch keine Bewertungen

- Instrucalc ViDokument25 SeitenInstrucalc ViNorberto Soto100% (1)

- IPSec VPN LABDokument7 SeitenIPSec VPN LABAparna Garg100% (2)

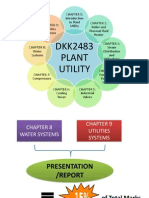

- Plant UtilityDokument4 SeitenPlant Utilityathiey100% (1)

- Terephthalic AcidDokument8 SeitenTerephthalic AcidWali AhsanNoch keine Bewertungen

- 5 Energy Audit of Pumps FansDokument49 Seiten5 Energy Audit of Pumps FansSai SwaroopNoch keine Bewertungen

- Vertical turbine fire pumps for industrial facilitiesDokument5 SeitenVertical turbine fire pumps for industrial facilitiesedwinNoch keine Bewertungen

- UAE University College of Engineering Training and Graduation Project UnitDokument100 SeitenUAE University College of Engineering Training and Graduation Project UnitPortia ShilengeNoch keine Bewertungen

- Thermodynamic Analysis of Superheated Steam and Flue Gas As Drying Agents For Biomass DryersDokument6 SeitenThermodynamic Analysis of Superheated Steam and Flue Gas As Drying Agents For Biomass DryersNaolNoch keine Bewertungen

- Chapter 3 Process SimulationDokument19 SeitenChapter 3 Process SimulationYang Yew Ren100% (1)

- DSTWU - A Shortcut Distillation Model in Aspen Plus® V8.0: 1. Lesson ObjectivesDokument39 SeitenDSTWU - A Shortcut Distillation Model in Aspen Plus® V8.0: 1. Lesson Objectivesnico123456789Noch keine Bewertungen

- ChemSepTutorial MulticomponentDistillationDokument16 SeitenChemSepTutorial MulticomponentDistillationavailme100% (1)

- What Is Network SwitchDokument13 SeitenWhat Is Network SwitchJhec AlbaNoch keine Bewertungen

- PHE Control Mechanism PDFDokument6 SeitenPHE Control Mechanism PDFNaren VmdNoch keine Bewertungen

- Overall Flowsheet Simulation Benzene Cyclohexane TW6Dokument7 SeitenOverall Flowsheet Simulation Benzene Cyclohexane TW6Mitesh ParmarNoch keine Bewertungen

- CSTRDokument11 SeitenCSTRfarahanisiliasNoch keine Bewertungen

- Benefits of The NIST Thermo Data Engine in AspenONE EngineeringDokument12 SeitenBenefits of The NIST Thermo Data Engine in AspenONE EngineeringMohammed MorsyNoch keine Bewertungen

- Aspenhysysoliif2006 RefDokument232 SeitenAspenhysysoliif2006 RefKrishanu SahaNoch keine Bewertungen

- Digital Fuel IndicatorDokument14 SeitenDigital Fuel IndicatorAbhaykumar MaliNoch keine Bewertungen

- Arc Discharge ApplicationDokument15 SeitenArc Discharge ApplicationHong Chun LeeNoch keine Bewertungen

- Formic Acid TechnologyDokument3 SeitenFormic Acid Technologyatharnadim_osNoch keine Bewertungen

- Chemical Process Equipment DesignDokument9 SeitenChemical Process Equipment Designraghu_iictNoch keine Bewertungen

- Methane Syngas Methanol MicroprocessingDokument14 SeitenMethane Syngas Methanol MicroprocessingAtieyNoryhati-dzNoch keine Bewertungen

- Paper Sukanta Azad - 11 PDFDokument6 SeitenPaper Sukanta Azad - 11 PDFAgung SiswahyuNoch keine Bewertungen

- Statistical Process ControlDokument29 SeitenStatistical Process ControlTushar NaikNoch keine Bewertungen

- Computers and Chemical Engineering: Pravin D. Ghuge, Nilesh A. Mali, Sunil S. JoshiDokument13 SeitenComputers and Chemical Engineering: Pravin D. Ghuge, Nilesh A. Mali, Sunil S. JoshiSebastián Castañeda100% (1)

- Chemical Reactor Control OptimizationDokument19 SeitenChemical Reactor Control OptimizationJetulio JetulinoNoch keine Bewertungen

- Lab 4 SimulationDokument8 SeitenLab 4 SimulationaziziNoch keine Bewertungen

- CCNA R&S Practical EbookDokument78 SeitenCCNA R&S Practical EbookParvinderSinghNoch keine Bewertungen

- Problems 2Dokument32 SeitenProblems 2Pritesh Bhakta50% (6)

- Compressor Stage Pressure - Design & OptimizationDokument4 SeitenCompressor Stage Pressure - Design & OptimizationAshwin ChandaranaNoch keine Bewertungen

- Aniline Separation From TolueneDokument41 SeitenAniline Separation From ToluenecaprolactamclNoch keine Bewertungen

- 4470 Project Description 2008Dokument6 Seiten4470 Project Description 2008Edu PavaniNoch keine Bewertungen

- Ethylene Oxide AppDokument2 SeitenEthylene Oxide AppSyifa AnggrainiNoch keine Bewertungen

- AspenPlusProcModelV8 4 GettingStartedDokument95 SeitenAspenPlusProcModelV8 4 GettingStartedJianguo XieNoch keine Bewertungen

- 474 - CHM 703Dokument25 Seiten474 - CHM 703permata100% (1)

- CV of Chemical EngineerDokument3 SeitenCV of Chemical EngineerAmol JdvNoch keine Bewertungen

- Manufacturing process flow diagram for producing Ethyl acetateDokument1 SeiteManufacturing process flow diagram for producing Ethyl acetateElgusta0% (1)

- Lime Neutralization Treatment Plant Cost Estimate PDFDokument9 SeitenLime Neutralization Treatment Plant Cost Estimate PDFWilmer JuarezNoch keine Bewertungen

- Workshop 12Dokument111 SeitenWorkshop 12Manash MudoiNoch keine Bewertungen

- Scale-Up - Right First TimeDokument4 SeitenScale-Up - Right First TimeDoddappa Anekal0% (1)

- Waste Water Treatment by Activated CharcoalDokument15 SeitenWaste Water Treatment by Activated Charcoallokesh singh100% (1)

- Pressure Swing DistillationDokument7 SeitenPressure Swing DistillationgongweejieNoch keine Bewertungen

- Mass Transfer Operations II Rr320801Dokument8 SeitenMass Transfer Operations II Rr320801Nagwa MansyNoch keine Bewertungen

- 4 Description of Chemical ProcessesDokument45 Seiten4 Description of Chemical Processesishhh12Noch keine Bewertungen

- Advancethermodynamics 140912124101 Phpapp01Dokument35 SeitenAdvancethermodynamics 140912124101 Phpapp01Nik Hafiy HafiziNoch keine Bewertungen

- 2015 - 10 - 12 - Calculating Pressure Drop Across FilmDokument15 Seiten2015 - 10 - 12 - Calculating Pressure Drop Across FilmathieyNoch keine Bewertungen

- How To Read A Paper-KeshavDokument3 SeitenHow To Read A Paper-KeshavathieyNoch keine Bewertungen

- Filter Media Replacement: Theory and Practical ExperienceDokument41 SeitenFilter Media Replacement: Theory and Practical ExperienceMuhammad Ammar AkbarNoch keine Bewertungen

- Coiled Tubing BHA Manual PDFDokument12 SeitenCoiled Tubing BHA Manual PDFSantiago Zárate0% (1)

- Polyvalve Poly-Gas Polyvalve For Gas ApplicationsDokument4 SeitenPolyvalve Poly-Gas Polyvalve For Gas ApplicationsVasco FerreiraNoch keine Bewertungen

- Chemical Oxygen Demand (Cod) Test: 1.0 Learning OutcomesDokument5 SeitenChemical Oxygen Demand (Cod) Test: 1.0 Learning OutcomesAnis NurdiniNoch keine Bewertungen

- Sandwich Type Butterfly Valve: I ApplicationDokument2 SeitenSandwich Type Butterfly Valve: I ApplicationFery FebryantoNoch keine Bewertungen

- 29 Static Total PressureDokument24 Seiten29 Static Total Pressuresiva anandNoch keine Bewertungen

- Heat Transfer Conduction Convection RadiationDokument3 SeitenHeat Transfer Conduction Convection RadiationMiftakhulHudaTachulSpentigsUnyilStembaNoch keine Bewertungen

- Bioreactor Engineering module-1: Basic design and construction of a fermentor and its ancillariesDokument23 SeitenBioreactor Engineering module-1: Basic design and construction of a fermentor and its ancillariesssfoodtechNoch keine Bewertungen

- Adaptive Identification of A Pneumatic Pump: Diploma ThesisDokument86 SeitenAdaptive Identification of A Pneumatic Pump: Diploma Thesisandreas vavatsikosNoch keine Bewertungen

- Reaction Areas in AodDokument4 SeitenReaction Areas in AodPrakash MishraNoch keine Bewertungen

- ASTM PIPES CATALOGUEDokument12 SeitenASTM PIPES CATALOGUESanjeev GoelNoch keine Bewertungen

- Calculating Friction Loss in Fire HoseDokument3 SeitenCalculating Friction Loss in Fire HoseRicky SimangunsongNoch keine Bewertungen

- Heat Transfer Assignment ProblemsDokument1 SeiteHeat Transfer Assignment ProblemsIzwan SaifudinNoch keine Bewertungen

- General Aptitude (GA) : Q.1 - Q.5 Multiple Choice Question (MCQ), Carry ONE Mark Each (For Each Wrong Answer: - 1/3)Dokument32 SeitenGeneral Aptitude (GA) : Q.1 - Q.5 Multiple Choice Question (MCQ), Carry ONE Mark Each (For Each Wrong Answer: - 1/3)kartik goyalNoch keine Bewertungen

- Hydraulics of Stepped Spillways PDFDokument6 SeitenHydraulics of Stepped Spillways PDFGuillermo Andres SalvatierraNoch keine Bewertungen

- Single Equilibrium Stages (2) Single Equilibrium StagesDokument16 SeitenSingle Equilibrium Stages (2) Single Equilibrium StagesHajra AamirNoch keine Bewertungen

- Gas LiftDokument2 SeitenGas LiftArmando O GarciaNoch keine Bewertungen

- Discharge Volume and Ditch Sizing at Tie-in Point TI03Dokument13 SeitenDischarge Volume and Ditch Sizing at Tie-in Point TI03Crisger ObordoNoch keine Bewertungen

- FEMA HH Study Quick Guide (Final)Dokument4 SeitenFEMA HH Study Quick Guide (Final)MEL VIRGIL BASTASANoch keine Bewertungen

- Turbine StatorDokument18 SeitenTurbine StatorAli KamranNoch keine Bewertungen

- 2ND Part Lab2Dokument6 Seiten2ND Part Lab2celineNoch keine Bewertungen

- Ethylene Glycol Heat-Transfer FluidDokument4 SeitenEthylene Glycol Heat-Transfer Fluidashif28Noch keine Bewertungen

- Determination of Thermo-Physical Properties of Food Through Transient CoolingDokument5 SeitenDetermination of Thermo-Physical Properties of Food Through Transient CoolingshahamNoch keine Bewertungen

- Syllabus For Chemical Reaction Engineering CourseDokument5 SeitenSyllabus For Chemical Reaction Engineering CourseGwen TennysonNoch keine Bewertungen

- Daftar PustakaDokument3 SeitenDaftar PustakaAjeng WijareniNoch keine Bewertungen

- Assignment 3Dokument3 SeitenAssignment 3Vandit GoyalNoch keine Bewertungen