Beruflich Dokumente

Kultur Dokumente

Power Flex 7000

Hochgeladen von

Felipe Rene AucailleOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Power Flex 7000

Hochgeladen von

Felipe Rene AucailleCopyright:

Verfügbare Formate

Next Generation

MV Drive

2

PowerFlex 7000 Overview

General purpose stand alone MV drive

Controls speed, torque, direction, starting, stopping of induction or

synchronous motors

Global product

IEC / NEMA / UL / CSA

2400-6600 Volts

Focus on high reliability, ease of use, lower total cost of

ownership

Target audience

Industrial / commercial users

Consultants

OEMs

3

Benefits of MV Drives

Reduce costs

energy savings on fans, pumps, compressors

reduced maintenance costs on mechanical equipment

increase life of mechanical equipment

Improved process control

increase productivity

flexibility

environmental compliance

Starting large motors on weak systems

eliminate voltage flicker

reduce inrush current

higher starting torque than reduced voltage

4

Target Industries / Applications

Petrochemical

Pipeline pumps

Gas compressors

Brine pumps

Mixers / extruders

Electrical submersible pumps

Induced Draft Fans

Boiler feed water pumps

Cement

Kiln induced draft fans

Forced draft fans

Cooler baghouse fans

Preheat tower fans

Raw mill induced draft fans

Kiln gas fans

Cooler exhaust fans

Seperator fans

Baghouse fans

Forest Products

Fan pumps

Induced draft fans

Boiler feed water pumps

Pulpers

Refiners

Kiln drives

Line shafts

Water / Waste Water

Raw sewage pumps

Bio-roughing tower pumps

Treatment pumps

Freshwater pumps

Miscellaneous

Test stands

Wind tunnels

Agitators

Rubber mixers

Mining & Metals

Slurry pumps

Ventilation fans

De-scaling pumps

Conveyors

Baghouse fans

Cyclone feed pumps

Electric Power

Feed water pumps

Induced draft fans

Forced draft fans

Baghouse fans

Effluent pumps

Compressors

5

Product Power Ratings

0

500

1000

1500

2000

2500

3000

3500

4000

2300 3300 4160 6600

HP

kWatts

Motor Voltage

V

F

D

P

o

w

e

r

R

a

t

i

n

g

6

Advanced CSI-PWM Technology

Simple, reliable power

structure

easy to series devices

Fuseless

Low component count

Inherent regeneration

SGCT inverter switch

SCR or SGCT rectifier switch

M

SGCT Inverter

7

Symmetrical Gate Commutated Thyristor (SGCT)

Modified GTO with integrated gate

drive

Gate drive close to the device creates

low inductance path

more efficient and uniform gating

Low conduction & switching losses

Low failure rate

100 failures per billion hours operation

Double sided cooling

8

SGCT blocks voltage in forward &

reverse directions up to 6500V, current

flow in 1 direction only

Non-Punch-Through structure

Symmetrical pnp transistor in the wafer

Significant advantages

Simplification or elimination of snubber components

operation at a higher switching frequency, hence

reducing the size of passive components (by 50%) and

improving performance of the drive

reduction of component count, hence improving

reliability, cost, and size of the drive.

SGCT

Symmetrical Gate Commutated Thyristor (SGCT)

9

High Reliability

0

5

10

15

20

25

30

35

40

MV SGCT

PowerFlex

Drive

MV IGBT

Drive

MV IGCT

Drive

LV IGBT

Drive

6

18

36

12

Inverter Power Device Component Count

Best Components X Fewest Components = Highest Reliability

10

MV Drive Topology Comparison

PowerFlex 7000 PWM

SGCT inverter switch

Low component count

Simple power structure

VSI-PWM 3 Level

IGCT or MV IGBT inverter

switch

Medium component count

Power structure complex due

to series and parallel diodes

required for 3 level

VSI-PWM Multi-Level (Series Cell)

LV IGBT inverter switch

Very high component count.

Very Complex power structure and

transformer configuration

Simple

Complex

Very Complex

11

Patented* Power Cage

Houses main power

components

Compact, modular package

Common design for rectifier

& inverter modules

12

Easy to Service

Front access

Component replacement in

less than 5 minutes

no special tools required

13

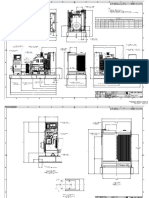

PowerFlex 7000 MV Drive

Control Boards

Identical line and machine side control boards used for

asynchronous and synchronous drives.

Floating point Digital Signal Processors (DSP).

Field Programmable Gate Arrays (FPGA) used

for advanced logic.

External I/O with 24 digital inputs and

24 digital outputs.

Operator interface terminal with 16-line, 40-

character LCD display for easy set-up,

monitoring and

troubleshooting.

Robust AC/DC power

supplies with

optional redundancy.

Low voltage swing out tub for access to

cable connection assembly and motor filter

capacitor

Rugged DC link inductor limits fault

current and eliminates nuisance trips.

A compact enclosure saves on valuable

floor space. Rear access not required

6.5 kV SGCT power semiconductors

reduce parts count and increase reliability.

Integral cooling fan provides efficient

heat transfer from power components.

PowerCage modules on the rectifier and inverter reduce manufacturing time

and allow easy access to main power components for quick replacement.

6-Pulse, 18-Pulse, or PWM rectifiers available as standard

for greater flexibility in meeting power quality needs.

Common gate drive power supply module

reduces parts count and lowers overall cost

14

MV SGCT MV GTO MV IGBT MV IGCT LV IGBT

Conduction Losses Low Low High Low Medium

Switching Losses Low Low Medium Low Low

Switching Frequency High Low High High High

PIV Rating (Volts) 6500 6500 3300 6500 1700

Gate Drive Integrated Separate Synch. with IGBT Integrated Synch. with IGBT

Failure Rate Low Low High Low Low

Failure Mode No-rupture, no-arc No-rupture, no-arc rupture, arc No-rupture, no-arc rupture, arc

Cooling Double sided Double sided single sided Double sided single sided

Thermal Stress Low Low High Low High

Parts Count Low Medium Medium-High Medium Very High

MV Power Semiconductor Comparison

SGCT- The Ideal Switch for MV Drives

Symmetrical Gate Commutated Thyristor (SGCT)

15

6 Pulse Rectifier with Optional Filter

18 Pulse Rectifier

PWM Rectifier with AC Line Reactor

Lower Harmonics without Increasing Complexity

6 pulse rectifier with optional filter

most economical

ideal when VFD is small percentage of total plant load

available with transformer or AC line reactor

elimination of transformer on new motor applications

highest efficiency, smallest footprint, low total cost of ownership

18 pulse rectifier

Meets IEEE 519-1992 Harmonic Guidelines

Low complexity & component count compared to other 18 pulse

solutions

series rectifiers

only 3 secondary windings on transformer

Most common solution

PWM rectifier

Meets IEEE 519-1992 Harmonic Guidelines

Near unity PF on variable torque loads

Optimum drive performance

Available with transformer or line reactor

elimination of transformer on new motor applications

highest efficiency, smallest footprint, low total cost of ownership

16

Line Friendly

18 Pulse and PWM rectifier

meet IEEE 519 Harmonic

Guidelines without filters or

additional complexity

Typically, no harmonic

analysis required

Specify 18 pulse minimum

some competitor use 12 pulse

only with high impedance(12-

14%) transformer

low harmonics, poor efficiency

Typical input waveforms (18 Pulse

Rectifier)

@ full load, full speed

Line current 4.6% THD (top)

Line voltage 2.0% THD (bottom)

4160V, 933kW, 60 Hz

17

Motor Friendly

Near sinusoidal current and voltage

@ all speeds and loads

no additional motor heating or voltage stress to

insulation compared to sine wave operation

Compatible with standard motors

induction or synchronous motors

no de-rating

inverter duty motor not required

new or retrofit applications

Virtually unlimited motor cable

distance

stable operation up to 15 Km

no capacitive coupling or dv/dt issues

Typical motor waveforms @ full load, full

speed

4160V, 933 kW, 60 Hz

Top - Motor Voltage

Bottom - Motor Current

18

Typical Drive & System Efficiency*

6 Pulse 6 Pulse 18 Pulse PWM Rectifier PWM Rectifier

VFD 0.98 0.98 0.98 0.975 0.975

Rectifier Duty Transformer 0.985 0.985 0.985

Line Reactor 0.995 0.995

System Efficiency 0.9653 0.9751 0.9653 0.9701 0.9604

* Efficiency at full load, full speed

19

Control Enhancements

Common control boards

for inverter / rectifier

for induction / synchronous drive

for 6- / 18-pulse / PWM rectifiers

Floating point digital signal

processors (DSP)

provides high speed internal processing

capabilities resulting in a higher degree of

speed response to variations in the end

process

Field programmable gate

arrays ( FPGA)

result in higher speed handling of diagnostics

and fault handling routines previously handled

by software

20

Remote I/O

DeviceNet

ControlNet

DPI protocol

SCANPort /DPI

connectivity

Embedded Communication Options

21

Control Enhancements

Common control boards for inverter / rectifier

common for induction / synchronous drive

common for 6 pulse / 18 pulse / PWM rectifiers

floating point Digital Signal Processors (DSP)

Field Programmable Gate Arrays ( FPGA) used for advanced logic

PWM gating

protection

digital I/O

synchronous transfer

Drive Identity Module will capture order data from business systems

provides info to firmware about specific order hardware (hp, voltage, rectifier type, dc link,

capa, etc)

Rugged AC/DC power supplies with optional redundancy

3 phase control power

208-480 Volts for cooling fans supplied by customer

208-230 Volts for AC/DC from fan power with step-down transformer (if required)

5 cycle ride-through is standard

optional extended ride-through with UPS

Commonality with Mequon standard drives

22

User Friendly Operator Interface

Modified PV550 terminal with unique

bootcode and functionality for

PowerFlex 7000

16 line, 40 character LCD display

Start-up wizard

prompts user through set-up,

operation and trouble shooting

Bar type LCD metering

speed

load

voltage

Auto tuning

Test modes

Trending

23

Specifications

Design Standards CSA, UL, IEC, IEEE, NEMA, ANSI

Inverter Type PWM

Power Rating 373-3000 kW (500-4000 hp)

Motor Type Asynchronous, Synchronous

Input Voltage

Tolerance

+ / - 10 % of Nominal Line Voltage

Input Frequency 50 / 60 Hz, +/- 10%

Output Voltage Rating 0 2300, 0 3300, 0 4160, 0 6,600

Output Frequency 0 75 Hz

Output Waveform Near Sinusoidal Current & Voltage

Rectifier Designs 6 / 18 Pulse, PWM- Active Front End

Input Protection Metal Oxide Varistors

Efficiency > 98.0%

Availability > 99.9%

Modulation Technique Pulse Width Modulation (PWM) /

Selective Harmonic Elimination (SHE)

Control Method

Sensorless Direct Vector

(Full Vector Control Optional)

Tuning Method Automatic Self Tuning Control

Overload Capability 110 % - 1 Minute / 150% - 1 Minute

Speed Regulation 0.5% Open Loop

0.1% with Shaft Encoder

Operator Interface 40 Character / 16 Line LCD

Control Power 208-480V 3 Phase, 50/60 Hz

Analog Inputs (1) Isolated, (3) Non-isolated

4 20 Ma / 0 10 V

Control I/O 24 Digital Inputs / 24 Digital Outputs

Communication

Interface.

RS 232, Remote I/O, DeviceNet, ControlNet

Enclosure

IEC Type IP42 (NEMA 1with gasket)

Ambient Temp. 0 40 Deg. C

Cooling Forced Air

Relative Humidity 95% Non condensing

Altitude 1000 M above sea level

without de rating

Paint Powder Epoxy

Analog Outputs (1) Isolated, (7) Non-isolated

4 20 Ma / 0 10 V

Inverter Switch SGCT

24

Availability

Available for sale

January 2000:

Release for Shipment

July 2000:

6 and 18 pulse configurations

Induction motor drive

October 2000

PWM configurations

Synchronous motor drive

25

High reliability

Greater ease of use

Lower total cost of ownership

Summary

Das könnte Ihnen auch gefallen

- Functional Test Sheet - CBDokument2 SeitenFunctional Test Sheet - CBaslam shaikhNoch keine Bewertungen

- Honeywell Ceiling Speaker 2015Dokument2 SeitenHoneywell Ceiling Speaker 2015ocduran42004Noch keine Bewertungen

- Electrical SpecificationsDokument4 SeitenElectrical Specificationsjoe rommel riveraNoch keine Bewertungen

- Motors Efficiency Standards & Regulations LAFERTDokument6 SeitenMotors Efficiency Standards & Regulations LAFERTRoberto Becerra RiveraNoch keine Bewertungen

- Phelps Dodge - TF Wires PDFDokument1 SeitePhelps Dodge - TF Wires PDFJason AbalajenNoch keine Bewertungen

- AC Fire Pump Systems-4 Color Brochure (English)Dokument8 SeitenAC Fire Pump Systems-4 Color Brochure (English)Biggie ColdAngelNoch keine Bewertungen

- Submittal 16080.003.A - NETA Test FormsDokument34 SeitenSubmittal 16080.003.A - NETA Test Formsirish sedilllNoch keine Bewertungen

- Basic Electrical System DesignDokument17 SeitenBasic Electrical System DesignPrincess Tin PalerNoch keine Bewertungen

- Planning of Optimal Power SystemsDokument9 SeitenPlanning of Optimal Power Systemsaliscribd46Noch keine Bewertungen

- BoxesDokument1 SeiteBoxesctoujagueNoch keine Bewertungen

- Meralco Metering2 PDFDokument10 SeitenMeralco Metering2 PDFLe'Novo FernandezNoch keine Bewertungen

- Catalog: NGR-TSD-NBX (2021) : Dimensions in (MM)Dokument1 SeiteCatalog: NGR-TSD-NBX (2021) : Dimensions in (MM)rosempb14100% (1)

- Iguzzini The Product Book EN - 2021 PDFDokument962 SeitenIguzzini The Product Book EN - 2021 PDFSangeeta SikariaNoch keine Bewertungen

- Electronics PermitDokument2 SeitenElectronics Permitkenneth sarmientoNoch keine Bewertungen

- IdentificationDokument1 SeiteIdentificationctoujagueNoch keine Bewertungen

- DOORSDokument39 SeitenDOORSAizle MariñoNoch keine Bewertungen

- FA QCDD Exam Questions KIC by TrekaDokument7 SeitenFA QCDD Exam Questions KIC by TrekaSHERIF KHATTABNoch keine Bewertungen

- Decision,+ERC+Case+No +2014-118+RCDokument35 SeitenDecision,+ERC+Case+No +2014-118+RCDyna EnadNoch keine Bewertungen

- PriceList Firefly Conventional 4 SLA Price List JAN 2018Dokument6 SeitenPriceList Firefly Conventional 4 SLA Price List JAN 2018Anonymous YAtUrXpI75Noch keine Bewertungen

- Transphil 25-150 KvaDokument1 SeiteTransphil 25-150 KvaRomeoNoch keine Bewertungen

- Bank Transformers in Open DeltaDokument11 SeitenBank Transformers in Open DeltaAndré Conhak LinsNoch keine Bewertungen

- Boston Bay Exhaust & Ventilating FansDokument4 SeitenBoston Bay Exhaust & Ventilating FansGem EscalanteNoch keine Bewertungen

- 8 6 4 Details of Conduit Encased in ConcreteDokument1 Seite8 6 4 Details of Conduit Encased in Concretenoor bashaNoch keine Bewertungen

- Main Certificate Compliance TemplateDokument1 SeiteMain Certificate Compliance TemplateBikila RusiNoch keine Bewertungen

- Masterpact NW08-63 User ManualDokument54 SeitenMasterpact NW08-63 User ManualCRIS SEDANTONoch keine Bewertungen

- Transformer VaultDokument7 SeitenTransformer VaultMia Monica Fojas LoyolaNoch keine Bewertungen

- Trina 550W Tallmax DE18Dokument2 SeitenTrina 550W Tallmax DE18WussbugNoch keine Bewertungen

- Silay Patag PDF Page 1 - 9 PDFDokument10 SeitenSilay Patag PDF Page 1 - 9 PDFRalph Emmanuel MercadoNoch keine Bewertungen

- Pad Mounted TransformerDokument14 SeitenPad Mounted Transformeraryans143sNoch keine Bewertungen

- Solar Energy S Torage Series: Anern Patent Design Exclusive ManufactureDokument19 SeitenSolar Energy S Torage Series: Anern Patent Design Exclusive ManufactureHabibNoch keine Bewertungen

- Load Schedule (1 & 3 Phase)Dokument5 SeitenLoad Schedule (1 & 3 Phase)electricalengineerNoch keine Bewertungen

- 2023 CCAC Pricelist - February 1, 2023Dokument8 Seiten2023 CCAC Pricelist - February 1, 2023Raylie PaguioNoch keine Bewertungen

- Battery Capacity Tester: Instruction ManualDokument24 SeitenBattery Capacity Tester: Instruction ManualEngr. Rik2xNoch keine Bewertungen

- The Unique Surf Ace-Deep Well Pump C Ombination:: Ensive Deep Well Pumping Solutions Easy T o Install and Mainta in !!Dokument6 SeitenThe Unique Surf Ace-Deep Well Pump C Ombination:: Ensive Deep Well Pumping Solutions Easy T o Install and Mainta in !!Kasim ButkovicNoch keine Bewertungen

- AMP Photo ListDokument10 SeitenAMP Photo ListBudi Jaya Equipment100% (1)

- Weighcom Company ProfileDokument11 SeitenWeighcom Company ProfileWeighcom Electrical in Kampala 0750614536Noch keine Bewertungen

- Laguna Gym Schedule of LoadDokument1 SeiteLaguna Gym Schedule of LoadjanmczealNoch keine Bewertungen

- Compressed Air Equipment Catalog: Our Wide-Ranging Lineup Meets Your NeedsDokument100 SeitenCompressed Air Equipment Catalog: Our Wide-Ranging Lineup Meets Your NeedsFOTOPLES Digital Printing100% (1)

- Order Code Sel 351 PDFDokument2 SeitenOrder Code Sel 351 PDFMohammed shamaaNoch keine Bewertungen

- Schneider Powerline Plus Brochure 2012Dokument12 SeitenSchneider Powerline Plus Brochure 2012Anonymous 4kBfjffrNoch keine Bewertungen

- A057E143 - Plano de GEDokument4 SeitenA057E143 - Plano de GECarlos E. Culquicondor InfanteNoch keine Bewertungen

- Royu Wires Devices Price List March 2016Dokument6 SeitenRoyu Wires Devices Price List March 2016AlrwinNoch keine Bewertungen

- RC ColumnsDokument9 SeitenRC ColumnsACES JEEL CENDA�A100% (1)

- Service Application Process: Jason B. Elamparo Mark C. ManjaresDokument37 SeitenService Application Process: Jason B. Elamparo Mark C. Manjaresjopaypagas0% (1)

- Engineering DataDokument10 SeitenEngineering Dataskjha61Noch keine Bewertungen

- Schneider ElectricDokument8 SeitenSchneider ElectricLanz ValdezNoch keine Bewertungen

- NEADokument22 SeitenNEALowell Valiente100% (1)

- PEC 2017 Short Circuit Calculation SampleDokument8 SeitenPEC 2017 Short Circuit Calculation SamplemarvinNoch keine Bewertungen

- RFQ For EarthingDokument4 SeitenRFQ For EarthingNUpurNoch keine Bewertungen

- Door Phones PDFDokument12 SeitenDoor Phones PDFEPCOMUSANoch keine Bewertungen

- 5 - 04 Fundation, Rigid and Resilient Mounted Gen-SetDokument11 Seiten5 - 04 Fundation, Rigid and Resilient Mounted Gen-SetHelder Norberto SilvaNoch keine Bewertungen

- Land Use and Zoning District / City / Municipal: Vicinity Map ScaleDokument18 SeitenLand Use and Zoning District / City / Municipal: Vicinity Map ScaleGeraldine Araneta GalingNoch keine Bewertungen

- Product Manual - Wires - Duraflex-10Dokument1 SeiteProduct Manual - Wires - Duraflex-10Yvan Glendell Mangune100% (1)

- Purlins Analysis and DesignDokument6 SeitenPurlins Analysis and DesignJestoni Gonzales TortolaNoch keine Bewertungen

- 2016 AEE Solar Catalog PDFDokument266 Seiten2016 AEE Solar Catalog PDFveracity50% (2)

- G8000MM - Brochure 120408 PDFDokument6 SeitenG8000MM - Brochure 120408 PDFogautierNoch keine Bewertungen

- VSG Sinamics V 1 0Dokument56 SeitenVSG Sinamics V 1 0milad miriNoch keine Bewertungen

- SS8 CPGKDokument4 SeitenSS8 CPGKRoozbeh BahmanyarNoch keine Bewertungen

- MatrixDokument37 SeitenMatrixmssurajNoch keine Bewertungen

- Analog Smart Motor Drive ApplicationDokument55 SeitenAnalog Smart Motor Drive ApplicationPankaj D PatelNoch keine Bewertungen

- c1Dokument19 Seitenc1vgnagaNoch keine Bewertungen

- 6-DZ F-12 12V 12ah Vrla Gel Battery: Features & BenefitsDokument2 Seiten6-DZ F-12 12V 12ah Vrla Gel Battery: Features & BenefitsAnonymous AJlmqhTmUqNoch keine Bewertungen

- Manual FW230 PDFDokument16 SeitenManual FW230 PDFaze20100% (1)

- Design A 60hz Notch Filter With The Uaf42 (Sbfa012)Dokument3 SeitenDesign A 60hz Notch Filter With The Uaf42 (Sbfa012)rafaelchristNoch keine Bewertungen

- PLCCDokument27 SeitenPLCC400kv100% (1)

- Popular Connector Pin Assignments For Data Communication: © 1998 National Semiconductor Corporation AN011940Dokument10 SeitenPopular Connector Pin Assignments For Data Communication: © 1998 National Semiconductor Corporation AN011940Enrique RoblesNoch keine Bewertungen

- Cable Impedance Calculations Open Electrical PDFDokument4 SeitenCable Impedance Calculations Open Electrical PDFblaagicaNoch keine Bewertungen

- Em Project SquidDokument31 SeitenEm Project SquidOng Yern Yee100% (1)

- CH 24Dokument13 SeitenCH 24HayaAhmaadSossoNoch keine Bewertungen

- Circuit Board Layout Guidelines For Class-D AmplifiersDokument4 SeitenCircuit Board Layout Guidelines For Class-D AmplifiersXavi AlonsoNoch keine Bewertungen

- Eee424 1 DC-DCDokument184 SeitenEee424 1 DC-DCM.Feridun HızNoch keine Bewertungen

- DatasheetDokument5 SeitenDatasheetPradeep KumarNoch keine Bewertungen

- Converter, Inverter, Brake: SKIIP 12NAB126V1Dokument4 SeitenConverter, Inverter, Brake: SKIIP 12NAB126V1vishadkapadiaNoch keine Bewertungen

- Express Calculation and Science: Information Technology (Centre of Excellence)Dokument143 SeitenExpress Calculation and Science: Information Technology (Centre of Excellence)Vasim MansuriNoch keine Bewertungen

- Package Dimensions: Power Brushless Motor Predriver IC For OA ApplicationsDokument12 SeitenPackage Dimensions: Power Brushless Motor Predriver IC For OA ApplicationsHojas VientoNoch keine Bewertungen

- BipolarDokument25 SeitenBipolarpakdeno100% (1)

- 78d33 DatasheetDokument4 Seiten78d33 DatasheetJorge AdrianNoch keine Bewertungen

- Al - SiDokument7 SeitenAl - SiNipun KadurupokunaNoch keine Bewertungen

- NTE52Dokument4 SeitenNTE52amanuel waleluNoch keine Bewertungen

- Ec 2254 Linear Integrated Circuits 3 0 0 3Dokument2 SeitenEc 2254 Linear Integrated Circuits 3 0 0 3priyajegaNoch keine Bewertungen

- Synthesis and Characterization of Selenium Doped Zinc Oxide (Zno-Se) NanoparticlesDokument6 SeitenSynthesis and Characterization of Selenium Doped Zinc Oxide (Zno-Se) NanoparticlesKrishna DontarajuNoch keine Bewertungen

- Taurus TSUPREM-4 Reference ManualDokument893 SeitenTaurus TSUPREM-4 Reference ManualRaisul IslamNoch keine Bewertungen

- 171 CatalogDokument156 Seiten171 Catalogchente_b100% (1)

- Contactor - Wikipedia, The Free EncyclopediaDokument6 SeitenContactor - Wikipedia, The Free EncyclopediaAbhishek RoyNoch keine Bewertungen

- I. Project Background and DescriptionDokument18 SeitenI. Project Background and DescriptionBelle Boholts Busis100% (1)

- Is Now Part ofDokument9 SeitenIs Now Part ofviyikitoNoch keine Bewertungen

- Ard Based Elevator Control SystemDokument7 SeitenArd Based Elevator Control SystemIRJIENoch keine Bewertungen

- An 1030Dokument8 SeitenAn 1030kuazuNoch keine Bewertungen

- Zinc Oxide Varistors - A Review.: American Ceramic Society Bulletin April 1986Dokument43 SeitenZinc Oxide Varistors - A Review.: American Ceramic Society Bulletin April 1986Nguyen Trung HuyNoch keine Bewertungen

- Mosfet'S: From Microelectronic Circuits Text by Sedra and Smith Oxford PublishingDokument29 SeitenMosfet'S: From Microelectronic Circuits Text by Sedra and Smith Oxford PublishingKomay Abo ShakraNoch keine Bewertungen