Beruflich Dokumente

Kultur Dokumente

007d Schneider Electric Reclosers Loop Automation Classic Intelligent 1 - 1

Hochgeladen von

César Bolaños QuirósOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

007d Schneider Electric Reclosers Loop Automation Classic Intelligent 1 - 1

Hochgeladen von

César Bolaños QuirósCopyright:

Verfügbare Formate

Automated Overhead

Schneider Electric

Reclosers & Sectionalisers

Loop Automation

Classic & Intelligent

2014

2

Reclosing & Sectionalising - REVIEW

Classic Loop Automation

Intelligent Loop Automation

Intelligent Loop Automation+ Overload Control

Intelligent Loop Automation+ Multi-tie

Index

3

REVIEW

Reclosing & Sectionalising

Index

4

Definition

Reclosing used to quickly

restore power and limit outages

for transient (self-clearing) faults

Sectionalising used to

isolate sections of the network

for permanent faults

Up to 70% of faults

are transient

Index

5

Comparison

Recloser Sectionaliser

Protection Detection

Multiple trips Single Trip

Fault Breaker NOT Fault Breaker

Transient Fault Permanent Fault

ADVC Controller / RTU

Measure Current & Voltage

Programmable Relay

Index

6

N-Series ACR U-Series ACR

W-Series ACR RL-Series LBS

Switchgear Range

Range 15kV to 38kV

SF

6

insulation

Integrated CT/CVT

Vacuum Interrupters

316 Stainless Steel

Range 15kV to 27kV

Solid Dielectric

Integrated CT/CVT

Vacuum Interrupters

316 Stainless Steel

24kV Single Phase

Solid Dielectric

Integrated CT/CVT

Vacuum Interrupter

316 Stainless Steel

Range 15kV to 38kV

SF

6

insulation

Integrated CT/CVT

Puffer Interrupters

316 Stainless Steel

Common control cabinet for all switchgear ADVC

10,000 mechanical operations

3-phase

3-phase

3-phase

single-phase

Index

7

Controller Cubicles

304 stainless steel

Compact option

1 Accessory Tray

2-point locking

316 stainless steel

2 Accessory Trays

Optional 12Ah batteries

3-point locking

Cubicle height 960mm

Cubicle width 450mm

Cubicle depth 302mm

Cubicle height 730mm

Cubicle width 420mm

Cubicle depth 302mm

Index

8

Operator Interfaces

4-line display

Menu-driven

4 Quick Action keys

Auto On / Off

20 status lamps

12 Quick Action keys

Fully configurable

Auto On / Off

Index

9

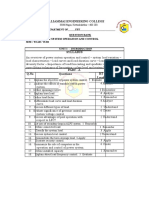

Protection & Detection

Element

Protection

RECLOSER

Detection

SECTIONALISER

Phase Overcurrent YES YES

Earth Fault YES YES

Sensitive Earth Fault YES YES

Negative Phase Sequence YES YES

Inrush Restraint YES YES

Cold Load Pickup YES YES

High Current Lockout YES X

Under/Over Voltage YES X

Loss of Phase YES X

Under/Over Frequency YES X

Index

10

DNP3 balanced (both master and slave can initiate communications)

IEC 60870-5-101/4 can operate as balanced or unbalanced

MODBUS unbalanced (only master can initiate communications)

MITS unbalanced

Communications & SCADA

Port Label Port Type

Comment

RS232 Port A/B RS-232

No handshaking support

RS232 Port C/D RS-232

Handshaking supported

10Base-T Ethernet

Simultaneous SCADA & WSOS5

V23 V23 FSK

UHF radio communications

RS485 RS485

Long distance or multi-drop

USB USB

Local WSOS5 only

Index

11

Wave 1

- Classic Loop Automation -

Quick Win Solution

Reliable (No Comms)

Easy to test and Install

Embedded in the reclosers

offer at no extra cost

Customers on the healthy

circuit can see some

disruption

Relies on grading multiple

reclosers which may not

always be achievable

> Simple logic scheme based

solely on loss of voltage

Wave 2 (2013)

- Intelligent Loop Automation -

Quick Win Solution

Reliable (single comms)

Easy to test and Install

Embedded in the reclosers

offer at no extra cost

> Same Logic + Single

downstream message between

devices to open the down

stream device to prevent

closing on to fault (using

Modbus TCP/IP)

+ Sectionaliser

+ P2P communication

Quick Win Solution

Further intelligence

Easy to test and Install

Embedded in the reclosers

offer at no extra cost

> Enhanced logic calculating

receiving circuit load to

prevent overloading of

alternate source

Wave 3 (Q2 2014)

- Intelligent Loop Automation -

+ Overload Control

> Enhanced logic supporting

connection to multiple ties

Wave 4 (Q4 2014)

- Intelligent Loop Automation -

+ Multiple Tie

More complex loops (3

sources 2 ties)

Reliable (low communications

requirements)

Easy to test and install

Embedded in the reclosers

offer at no extra cost

Q2 2014

Loop Automation 4 types

2013

INTELLIGENT+OVERLOAD

3

INTELLIGENT+MULTI-TIE

4 INTELLIGENT

2

CLASSIC

1

Index

12

HV / MV

Substation

Normal

Open Point

CB

1 Yellow

2 Blue

5 Pink

3 Green

6 Aqua

4 Red

FAULT

1 Y

2 B

3 G

4 R

5 P

6 A

TTL

1 Y

6

2 B

6

3 G

6

4 R

6

5 P

6

6 A

6

Outages for each feeder segment

ALL customers / segments

are affected by ALL faults

Total Segment Outages

36

Typical Feeder: no reclosers

Index

Outage total based on 1 permanent

fault for each feeder segment

13

HV / MV

Substation

Normal

Open Point

1 Yellow

2 Blue

5 Pink

3 Green

6 Aqua

4 Red

R R

CB

FAULT

1 Y

2 B

3 G

4 R

5 P

6 A

TTL

1 Y

2

2 B

2

3 G

4

4 R

4

5 P

6

6 A

6

Outages for each line segment

Customers closer to the source

are affected by fewer faults

Total Segment Outages

24

Typical Feeder: minimum reclosers

Index

Outage total based on 1 permanent

fault for each feeder segment

14

1 Yellow

2 Blue

HV / MV

Substation

5 Pink

3 Green

6 Aqua

Normal

Open Point

4 Red

R R

R

R

R

CB

FAULT

1 Y

2 B

3 G

4 R

5 P

6 A

TTL

1 Y

1

2 B

2

3 G

2

4 R

3

5 P

3

6 A

4

Outages for each line segment

Customers on the main line are

protected from branch faults

Total Segment Outages

15

Typical Feeder: reclosers on branches

Index

Outage total based on 1 permanent

fault for each feeder segment

15

HV / MV

Substation

Normal

Open Point

3 Green 1 Yellow

2 Blue

5 Pink

6 Aqua

4 Red

Remote Controlled

Or Automated

CB

R R

R

R

R

FAULT

1 Y

2 B

3 G

4 R

5 P

6 A

TTL

1 Y

1

2 B

2

3 G

1

4 R

2

5 P

1

6 A

2

Outages for each line segment

Automation / SCADA allows

supply from alternate source

Total Segment Outages

9

Typical Feeder: automated reclosers

Index

Outage total based on 1 permanent

fault for each feeder segment

16

+ SCADA/Automation

Total Segment Outages

9

On main & branch

Total Segment Outages

15

On main line

Total Segment Outages

24

No switchgear

Total Segment Outages

36

FAULT

1 Y

2 B

3 G

4 R

5 P

6 A

TTL

1 Y

1

2 B

2

3 G

1

4 R

2

5 P

1

6 A

2

FAULT

1 Y

2 B

3 G

4 R

5 P

6 A

TTL

1 Y

1

2 B

2

3 G

2

4 R

3

5 P

3

6 A

4

FAULT

1 Y

2 B

3 G

4 R

5 P

6 A

TTL

1 Y

2

2 B

2

3 G

4

4 R

4

5 P

6

6 A

6

FAULT

1 Y

2 B

3 G

4 R

5 P

6 A

TTL

1 Y

6

2 B

6

3 G

6

4 R

6

5 P

6

6 A

6

Benefits: reclosers & automation

Index

17

CLASSIC LOOP AUTOMATION

No communications required

Available for Reclosers & Sectionalisers

Loop Automation

CLASSIC

1

Wave 1

Index

18

Features & Benefits

Features Details Messages

Automatic supply

from alternate

source

When active & configured,

unfaulted sections are quickly

re-energised

No communications

Benefits

1. No communications required

2. No operator intervention

3. Included in the offer at no cost

4. Fast restoration of unfaulted sections

5. SAIDI and SAIFI statistics improved

CLASSIC 1 Wave 1

Index

19

Elements & Rules

Element Type Position Status Normally

Feeder ACR Closest to substation Required Closed

Midpoint ACR Between Feeder & Tie Optional Closed

Tie ACR/LBS Between Feeder lines Required Open

Feeder

Midpoint

Tie

Rule Element Action Conditions when ...

A (1) Feeder Opens (Lockout) Supply is lost

B (2) Midpoint Changes Protection Group* Supply is lost

(2) Midpoint Changes to Single Shot Supply is lost

C (3) Tie Closes Supply is lost on 1 side

(4) Midpoint Opens (Single Shot -Lockout) Fault Detected

Feeder

Midpoint

Tie

Midpoint

Midpoint

* From A to B direction changed

CLASSIC

1

Wave 1

# Loop Auto turned off when

LA actions completed

#

#

#

Index

20

Substation CBs

10km

15km

10km

7.5km

Midpoint 4

Midpoint 3

2D

Feeder 2

2B

10km

2A

1A

Midpoint 2

7.5km

1D

1B

7.5km

1C

5km

B

2C

Classic Loop Automation with Timer-Controlled Tie

Fault between substation CB and Feeder device

Picks up, trips from

protection & goes to lockout.

The feeder device trips and goes to

lockout.

Midpoint 1

Loop Automation Activation Delay

timers start due to a loss of supply.

Midpoint devices change protection group in anticipation

of the change in the direction of the power flow and go to

Single Shot (no auto-reclose) mode.

The tie device also changes protection group depending

on which side the power was lost (source or load), goes to

Single Shot (no auto-reclose) mode and closes .

B+SS

Feeder 1

Tie

Fault isolated

Power restored to unfaulted sections in less than 1 minute

No operator intervention

Closed

Tripped

Switchgear

Live

Dead

Line

B+SS

B

Classic

CLASSIC

1

Wave 1

Index

21

INTELLIGENT LOOP AUTOMATION

Peer to peer IP communications

Downstream messaging TRIP / CLOSE / CLOSE BLOCK

Loop Automation

INTELLIGENT

2

Wave 2

Index

22

Features & Benefits

New Feature Details Messages

Peer to peer

MODBUS over IP

communications

Tie can be Timer or

Message controlled

Each switch can

message the adjacent

downstream device or

the tie

FEED to MID = TRIP

MID to MID = TRIP

FEED TO TIE = CLOSE or

CLOSE BLOCK

MID TO TIE = CLOSE or

CLOSE BLOCK

Additional Benefits

1. Reduced grading requirements

2. Closing alternate supply onto fault

prevented, avoiding possible upstream trip

if elements are misgraded

INTELLIGENT 2 Wave 2

Index

23

Substation CBs

10km

15km

10km

7.5km

Midpoint 4

Midpoint 3

2D

Feeder 2

2B

10km

2A

1A

Midpoint 2

7.5km

1D

1B

7.5km

Feeder 1

2C

1C

5km

B

Intelligent Loop Auto with Comms-Controlled Tie

Fault between Feeder and Midpoint devices

Loop Automation Activation Delay

timers start due to a loss of supply.

The downstream device changes protection

group in anticipation of the change in the

direction of the power flow, goes to Single

Shot (no auto-reclose) mode and trips.

The tie device also changes protection group

depending on which side the power was lost (source or

load), goes to Single Shot (no auto-reclose) mode and

closes upon receiving a close request.

Picks up, executes trip/reclose sequence & goes

to lockout. It will then send a trip request to its

downstream device using Modbus P2P

communications.

Fault isolated

Power restored to unfaulted sections in less than 1 minute

No operator intervention

Alternate source prevented from Closing onto fault

Closed

Tripped

Switchgear

Live

Dead

Line

Modbus Trip Request

Other midpoint devices change protection group and

go to Single Shot (no auto-reclose) mode.

Tie

Modbus Close Request

Midpoint 1

B+SS

B

B+SS

INTELLIGENT

2

Wave 2

Intelligent

Index

24

INTELLIGENT LOOP AUTOMATION

Peer to peer IP communications

Downstream messaging TRIP / CLOSE / CLOSE BLOCK

Loop Automation

INTELLIGENT+OVERLOAD 3 Wave 3

Index

25

Features & Benefits

New

Feature

Details Messages

Overload

Control

All elements regularly advise

phase currents to tie tie will

only close after fault if the

unfaulted alternate source has

sufficient overhead

Loop Auto OLC ON =

send settings to TIE

PING message =

3 phase currents to TIE

Additional Benefits

1. Tie will only close onto unfaulted network if

sufficient overhead exists to prevent

overload

INTELLIGENT 3 Wave 3

Index

26

OLC messaging

INTELLIGENT 3 Wave 3

Ping messages from all elements to TIE

Midpoint

Tie

Sources

Closed

Open

Switchgear State

Feeder

Feeder

>

3 phase currents

Device settings

>

>

TIE closes only when available

OVERHEAD exceeds faulted LOAD

During Loop Automation, TIE uses received data to

calculate LOAD & OVERHEAD

Index

27

INTELLIGENT LOOP AUTOMATION

Peer to peer IP communications

Downstream messaging TRIP / CLOSE / CLOSE BLOCK

Overload control available

Loop Automation

INTELLIGENT+MULTI-TIE 4 Wave 4

Index

28

Features & Benefits

New Feature Details Messages

Multi-tie support Additional logic to support

interconnected networks:

up to 3 sources / 2 ties

TBA

Additional Benefits

1. More complex networks can be supported

Wave 4

INTELLIGENT+MULTI-TIE 4

Index

29

Creation Configuration

Monitoring Validation

WSOS5 Loop Automation Tool

Index

This completes the presentation

Thank you for your attention.

2014

31

Das könnte Ihnen auch gefallen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Switching in Electrical Transmission and Distribution SystemsVon EverandSwitching in Electrical Transmission and Distribution SystemsNoch keine Bewertungen

- Knowledge is "Real Power": Introduction to Power QualityVon EverandKnowledge is "Real Power": Introduction to Power QualityNoch keine Bewertungen

- Paper On Automatic Reclosing Transmission Lines Applications and Its ConsiderationsDokument8 SeitenPaper On Automatic Reclosing Transmission Lines Applications and Its ConsiderationsGagan GillNoch keine Bewertungen

- Review of Power System BlackoutDokument6 SeitenReview of Power System BlackoutPradeep SinghNoch keine Bewertungen

- Substation Switching SchemeDokument13 SeitenSubstation Switching Schememehrbloor@gmail.comNoch keine Bewertungen

- Adaptive Relaying For Power System Protection: Department of Electrical and Electronics EngineeringDokument12 SeitenAdaptive Relaying For Power System Protection: Department of Electrical and Electronics EngineeringJayanth BhargavNoch keine Bewertungen

- Auto ReclosersDokument23 SeitenAuto ReclosersSingam Sridhar100% (1)

- Radial Feeder ProtectionDokument6 SeitenRadial Feeder ProtectionSrivalli ReddyNoch keine Bewertungen

- 3 Distribution System DesignDokument15 Seiten3 Distribution System DesignAHMED YOUSEFNoch keine Bewertungen

- Real-Time Simulation Technology for Modern Power ElectronicsVon EverandReal-Time Simulation Technology for Modern Power ElectronicsNoch keine Bewertungen

- Earth Fault Protection Principles and Techniques in Solidly Grounded SystemsDokument27 SeitenEarth Fault Protection Principles and Techniques in Solidly Grounded SystemsSuresh Chandra PadhyNoch keine Bewertungen

- 12.1 Overcurrent Protection Part 2 Quiz PDFDokument10 Seiten12.1 Overcurrent Protection Part 2 Quiz PDFfaycelNoch keine Bewertungen

- High Voltage and Power System Stability Interview Questions - Engineering TutorialDokument4 SeitenHigh Voltage and Power System Stability Interview Questions - Engineering TutorialPabitra Kumar PatraNoch keine Bewertungen

- Back Up Impedance ProtectionDokument3 SeitenBack Up Impedance ProtectionNeelakandan MasilamaniNoch keine Bewertungen

- NERC Protection System Protection Fundamentals Public 060210Dokument55 SeitenNERC Protection System Protection Fundamentals Public 060210srinivasaphanikiranNoch keine Bewertungen

- High Low Impedance Busbar ProtectionDokument92 SeitenHigh Low Impedance Busbar Protectionsugeng100% (1)

- Distance Protection of Series Compensated Transmission LineDokument9 SeitenDistance Protection of Series Compensated Transmission Lineyand_carlosNoch keine Bewertungen

- Power System Protection PDFDokument12 SeitenPower System Protection PDFBala MNoch keine Bewertungen

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsVon EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNoch keine Bewertungen

- NSD 50&mcdDokument25 SeitenNSD 50&mcdkrishnamanikandanNoch keine Bewertungen

- Advc Operational GuideDokument184 SeitenAdvc Operational GuidegovindarulNoch keine Bewertungen

- On FACTSDokument33 SeitenOn FACTSAravind Babu100% (1)

- Intoduction To 400Kv Switchyard: Single Line Diagram of 400kV SubstationDokument3 SeitenIntoduction To 400Kv Switchyard: Single Line Diagram of 400kV SubstationPratik LahaneNoch keine Bewertungen

- Symmetrical ComponentsDokument147 SeitenSymmetrical ComponentsRavikant TarareNoch keine Bewertungen

- GSM Based Fault Monitoring SystemDokument23 SeitenGSM Based Fault Monitoring SystemSanjana Singh100% (1)

- Contingency Analysis of Power Systems PDFDokument4 SeitenContingency Analysis of Power Systems PDFbenitogaldos19gmail.comNoch keine Bewertungen

- Floating Neutral Impact in Power DistributionDokument9 SeitenFloating Neutral Impact in Power DistributionSugeng SumarnoNoch keine Bewertungen

- Volume V - Batteries and ChargersDokument168 SeitenVolume V - Batteries and ChargersSunil G ParakkalNoch keine Bewertungen

- Everything You Need to Know About Battery Systems at 220kV SubstationsDokument20 SeitenEverything You Need to Know About Battery Systems at 220kV SubstationsManu JosephNoch keine Bewertungen

- ABB Busbar Protection REB670 2.0 ANSIDokument498 SeitenABB Busbar Protection REB670 2.0 ANSIksg9731Noch keine Bewertungen

- Relay Coordination 1 PDFDokument5 SeitenRelay Coordination 1 PDFNikhil SainiNoch keine Bewertungen

- 500 KV TRANSMISSION LINE DESIGN AND FAULT ANALYSISDokument96 Seiten500 KV TRANSMISSION LINE DESIGN AND FAULT ANALYSISkariboo karibooxNoch keine Bewertungen

- Intro To PSCAD PowerPoint Rev1.1Dokument13 SeitenIntro To PSCAD PowerPoint Rev1.1Arumugam RajendranNoch keine Bewertungen

- EE1402 Power System Protection and SwitchgearDokument8 SeitenEE1402 Power System Protection and Switchgearmoonsoon_j100% (1)

- M.E.Electrical Power System - 2 PDFDokument32 SeitenM.E.Electrical Power System - 2 PDFAnonymous 9VcxlFErfNoch keine Bewertungen

- A Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyDokument67 SeitenA Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyGunjan VarshneyNoch keine Bewertungen

- 2020-10-22 Planning Guidline For MV ProtectionDokument62 Seiten2020-10-22 Planning Guidline For MV ProtectionThilina Rajapaksha100% (1)

- Power System Protection & Recent Trends by JDM - LatestDokument152 SeitenPower System Protection & Recent Trends by JDM - Latestraajesh692% (12)

- Substation Automation Basics - The Next GenerationDokument8 SeitenSubstation Automation Basics - The Next GenerationAlly RaxaNoch keine Bewertungen

- Kishenpur Grid Station CompleteDokument39 SeitenKishenpur Grid Station CompletepunitkapoorNoch keine Bewertungen

- Auto RecloserDokument16 SeitenAuto RecloserMohammedHaythamNoch keine Bewertungen

- Ferroresenance Phenomena of A Station Service Transformer During Black Start and Its Investigatio1Dokument4 SeitenFerroresenance Phenomena of A Station Service Transformer During Black Start and Its Investigatio1pongpumNoch keine Bewertungen

- EE-455 Electrical PowerSystem Protection - F2013Dokument48 SeitenEE-455 Electrical PowerSystem Protection - F2013Vinícius Mota SilvaNoch keine Bewertungen

- Midway Report: Project Semester: Study of 220KV Substation and SLDCDokument15 SeitenMidway Report: Project Semester: Study of 220KV Substation and SLDCdamanpreet singhNoch keine Bewertungen

- Transformer Inrush Currents and Protection 2603 003 A00Dokument4 SeitenTransformer Inrush Currents and Protection 2603 003 A00Joshi DhvanitNoch keine Bewertungen

- Voltage and Frequency ControlDokument12 SeitenVoltage and Frequency ControlKhawarAminNoch keine Bewertungen

- Computer Methods in Power Systems Analysis with MATLABVon EverandComputer Methods in Power Systems Analysis with MATLABNoch keine Bewertungen

- Three Winding or Tertiary Winding TransformerDokument7 SeitenThree Winding or Tertiary Winding TransformergopalakrishnanNoch keine Bewertungen

- Course PC3, Dubai Applic Ation of Prote Ctive Relayi NG To Distri Bution and Sub-Trans Missi On Syste MsDokument41 SeitenCourse PC3, Dubai Applic Ation of Prote Ctive Relayi NG To Distri Bution and Sub-Trans Missi On Syste MsMahmoud Al-QudahNoch keine Bewertungen

- A Report On Summer Training AT 400 KV Substation Panki: SYAD SAMEER AHMAD (1804528209)Dokument18 SeitenA Report On Summer Training AT 400 KV Substation Panki: SYAD SAMEER AHMAD (1804528209)Nitin SinghNoch keine Bewertungen

- Muhammad Abdul Fareh Khan 2k19Dokument5 SeitenMuhammad Abdul Fareh Khan 2k19Fareh KhanNoch keine Bewertungen

- EE6603-Power System Operation and ControlDokument23 SeitenEE6603-Power System Operation and ControlJegan8586100% (1)

- Substations - Volume X - GroundingDokument52 SeitenSubstations - Volume X - GroundingAbdul Wadood GharsheenNoch keine Bewertungen

- Auto ReclosingDokument6 SeitenAuto ReclosingJayLord UtaNoch keine Bewertungen

- Upgrading The ProtectionDokument4 SeitenUpgrading The ProtectionMukesh KumarNoch keine Bewertungen

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsVon EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNoch keine Bewertungen

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringVon EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNoch keine Bewertungen

- Current Transformers How To Specify Them PDFDokument36 SeitenCurrent Transformers How To Specify Them PDFargari19Noch keine Bewertungen

- White Paper: DIRTY DOZEN: The 12 Most Common Mistakes of Specifying Circuit Protection For EquipmentDokument8 SeitenWhite Paper: DIRTY DOZEN: The 12 Most Common Mistakes of Specifying Circuit Protection For EquipmentCésar Bolaños QuirósNoch keine Bewertungen

- Aspiro1u Ds PDFDokument5 SeitenAspiro1u Ds PDFCésar Bolaños QuirósNoch keine Bewertungen

- Modulo de Transfer en CIA Automatic A Siemens Atc 5300Dokument50 SeitenModulo de Transfer en CIA Automatic A Siemens Atc 5300Feli ZambranoNoch keine Bewertungen

- SVAN955Dokument2 SeitenSVAN955César Bolaños QuirósNoch keine Bewertungen

- Instalación de PararrayosDokument68 SeitenInstalación de PararrayosCésar Bolaños QuirósNoch keine Bewertungen

- Principles of Electrical GroundingDokument43 SeitenPrinciples of Electrical GroundingSaber HussainiNoch keine Bewertungen

- CPC 100 Firmware Upgrade 4 20 SR2 ENUDokument16 SeitenCPC 100 Firmware Upgrade 4 20 SR2 ENUCésar Bolaños Quirós100% (2)

- Instalación de PararrayosDokument68 SeitenInstalación de PararrayosCésar Bolaños QuirósNoch keine Bewertungen

- Understanding Ground Fault and Leakage CurrentDokument2 SeitenUnderstanding Ground Fault and Leakage CurrentFrancis OwusuNoch keine Bewertungen

- Sa02607001e PDFDokument24 SeitenSa02607001e PDFGayashan KulathungaNoch keine Bewertungen

- Power Quality Standard Assessment LimitsDokument1 SeitePower Quality Standard Assessment Limitscool_saklshpurNoch keine Bewertungen

- Flexible AC Current Probe AFLEX 3000 Users Manual: Global RepresentativeDokument15 SeitenFlexible AC Current Probe AFLEX 3000 Users Manual: Global RepresentativeCésar Bolaños QuirósNoch keine Bewertungen

- Instructions Dashboard Scenic 2Dokument6 SeitenInstructions Dashboard Scenic 2César Bolaños QuirósNoch keine Bewertungen

- Visa SP BrochureDokument2 SeitenVisa SP BrochureCésar Bolaños QuirósNoch keine Bewertungen

- U07 Power Factor Testing of Electrical InsulationDokument11 SeitenU07 Power Factor Testing of Electrical InsulationCésar Bolaños QuirósNoch keine Bewertungen

- 10 Dumb Things Smart People Do When Testing ElectricityDokument2 Seiten10 Dumb Things Smart People Do When Testing ElectricityAN.ADAMMSNoch keine Bewertungen

- Metal Clad Vs Metal EnclosedDokument1 SeiteMetal Clad Vs Metal EnclosedsofyanshahNoch keine Bewertungen

- Current Transformers How To Specify Them PDFDokument36 SeitenCurrent Transformers How To Specify Them PDFargari19Noch keine Bewertungen

- AcuCT R Split Core UL DatasheetDokument2 SeitenAcuCT R Split Core UL DatasheetCésar Bolaños QuirósNoch keine Bewertungen

- Loop Automation Manual - WEB PDFDokument80 SeitenLoop Automation Manual - WEB PDFCésar Bolaños QuirósNoch keine Bewertungen

- Rheolube 368: Test Method Typical Value Lubricant PropertiesDokument1 SeiteRheolube 368: Test Method Typical Value Lubricant PropertiesCésar Bolaños QuirósNoch keine Bewertungen

- Factordepotencia - Reporte de RolandoDokument18 SeitenFactordepotencia - Reporte de RolandoCésar Bolaños QuirósNoch keine Bewertungen

- Ur5iv2 GuideDokument32 SeitenUr5iv2 GuideCésar Bolaños QuirósNoch keine Bewertungen

- PVANGLESDokument3 SeitenPVANGLESCésar Bolaños QuirósNoch keine Bewertungen

- Digitrip 520Dokument40 SeitenDigitrip 520HACNoch keine Bewertungen

- History of Veterinary MedicineDokument25 SeitenHistory of Veterinary MedicineAli AsadullahNoch keine Bewertungen

- War, Rivalry An State Building in Latin AmericaDokument16 SeitenWar, Rivalry An State Building in Latin AmericaPablo Andrés Garrido GonzálezNoch keine Bewertungen

- Health Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4Dokument7 SeitenHealth Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4John Wilfred PegranNoch keine Bewertungen

- Electronics Foundations - Basic CircuitsDokument20 SeitenElectronics Foundations - Basic Circuitsccorp0089Noch keine Bewertungen

- Ce125-2500 Open FrameDokument48 SeitenCe125-2500 Open FrameRomão OliveiraNoch keine Bewertungen

- Template - Time in ManufacturingDokument2 SeitenTemplate - Time in ManufacturingVero RoaNoch keine Bewertungen

- EMarketer Time Spent With Media SnapshotDokument13 SeitenEMarketer Time Spent With Media SnapshotWei ShingNoch keine Bewertungen

- Barry Wylant: Design Thinking and The Experience of InnovationDokument13 SeitenBarry Wylant: Design Thinking and The Experience of InnovationVanesa JuarezNoch keine Bewertungen

- Powers of Central Govt under Environment Protection ActDokument13 SeitenPowers of Central Govt under Environment Protection Actsirajudeen INoch keine Bewertungen

- 50 Ways To Balance MagicDokument11 Seiten50 Ways To Balance MagicRodolfo AlencarNoch keine Bewertungen

- D2DDokument2 SeitenD2Dgurjit20Noch keine Bewertungen

- EDIBLE VACCINES: A COST-EFFECTIVE SOLUTIONDokument21 SeitenEDIBLE VACCINES: A COST-EFFECTIVE SOLUTIONPritish SareenNoch keine Bewertungen

- The Seven Kings of Revelation 17Dokument9 SeitenThe Seven Kings of Revelation 17rojelio100% (1)

- Explanation of Four Ahadeeth From Imaam Al-Bukhaaree's Al-Adab-Ul-MufradDokument4 SeitenExplanation of Four Ahadeeth From Imaam Al-Bukhaaree's Al-Adab-Ul-MufradMountainofknowledgeNoch keine Bewertungen

- SIM7020 Series - HTTP (S) - Application Note - V1.04Dokument15 SeitenSIM7020 Series - HTTP (S) - Application Note - V1.04Vinicius BarozziNoch keine Bewertungen

- Ownership and Governance of State Owned Enterprises A Compendium of National Practices 2021Dokument104 SeitenOwnership and Governance of State Owned Enterprises A Compendium of National Practices 2021Ary Surya PurnamaNoch keine Bewertungen

- Department of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityDokument2 SeitenDepartment of Education Doña Asuncion Lee Integrated School: Division of Mabalacat CityRica Tano50% (2)

- Active Disturbance Rejection Control For Nonlinear SystemsDokument8 SeitenActive Disturbance Rejection Control For Nonlinear SystemsTrần Việt CườngNoch keine Bewertungen

- CA-Endevor Quick EditDokument31 SeitenCA-Endevor Quick Editmariela mmascelloniNoch keine Bewertungen

- Teaching Support Untuk Managemen HRDokument102 SeitenTeaching Support Untuk Managemen HRFernando FmchpNoch keine Bewertungen

- F&B Data Analyst Portfolio ProjectDokument12 SeitenF&B Data Analyst Portfolio ProjectTom HollandNoch keine Bewertungen

- Matrices Class 12 Maths Important Questions Chapter 3 - Learn CBSEDokument41 SeitenMatrices Class 12 Maths Important Questions Chapter 3 - Learn CBSEkhateeb ul islam qadriNoch keine Bewertungen

- Nataraja Stotram - A Hymn Without 'CharaNa' and 'ShRi~NgaDokument8 SeitenNataraja Stotram - A Hymn Without 'CharaNa' and 'ShRi~NgaSiva Krishna100% (1)

- SSRN Id26238Dokument21 SeitenSSRN Id26238Ayame KusuragiNoch keine Bewertungen

- Handout CalmAlphaDokument2 SeitenHandout CalmAlphaDave SnowdenNoch keine Bewertungen

- Defining Public RelationsDokument4 SeitenDefining Public RelationsKARTAVYA SINGHNoch keine Bewertungen

- Preparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimDokument9 SeitenPreparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimslightlyguiltyNoch keine Bewertungen

- Measures of CentralityDokument13 SeitenMeasures of CentralityPRAGASM PROGNoch keine Bewertungen

- Re: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesDokument1 SeiteRe: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesMayada OsmanNoch keine Bewertungen