Beruflich Dokumente

Kultur Dokumente

Natural Gas in Malaysia

Hochgeladen von

Daniel Wiggins0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

217 Ansichten11 SeitenNatural gas in Malaysia

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenNatural gas in Malaysia

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

217 Ansichten11 SeitenNatural Gas in Malaysia

Hochgeladen von

Daniel WigginsNatural gas in Malaysia

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 11

Natural gas in Malaysia

Natural Gas in Malaysia

Malaysia has the 14th largest gas reserves as at January 2008.

As at January 2008, Malaysia's gas reserves stood at 88.0 trillion standard cubic

feet (tscf) or 14.67 billion barrels of oil equivalent, approximately three times the

size of crude oil reserves of 5.46 billion barrels.

In 2007, Malaysia's production of natural gas averaged 7.01 bscf per day.

As at 31 March 2008, Malaysia had 88 producing fields of which 61 were oil

fields and 27 gas fields.

About 50% of these producing fields are solely operated by PETRONAS's

subsidiary, PETRONAS Carigali.

MALAYSIAN NATURAL GAS RESERVES

Malaysia is ranked 14th in the world in terms of its gas reserves. As at 1 January

2008, the natural gas reserves in Malaysia stood at 88.0 trillion standard cubic feet

(tscf) or 14.67 billion barrels of oil equivalent, approximately three times the size of

crude oil reserves of 5.46 billion barrel. Of this, 33.5 trillion standard cubic feet (tscf)

or 38% is found off the East Coast of Peninsular Malaysia, 41.8 tscf (48%) offshore

Sarawak and the remaining 12.7 tscf (14%) offshore Sabah. At the current rate of

production, Malaysia's gas reserves expected to last another 36 years.

PENINSULAR GAS UTILISATION

PROJECT

In 2007, Malaysia's production of natural gas averaged 7.01 bscf per day.

As at 31 March 2008, Malaysia had 88 producing fields of which 61 were oil fields and

27 gas fields.

About 50% of these producing fields are solely operated by PETRONAS's subsidiary,

PETRONAS Carigali.

The PGU Project, which commenced in 1984, now spans over 1,700km, comprising

main gas transmission pipelines, supply pipelines and laterals.

The system also comprises of six gas-processing

plants with a combined capacity of 2,000 million

standard cubic feet per day (mmscfd), producing

methane, ethane, propane, butane and

condensate.

A typical pipeline may contain a pressure of about

65 atmospheres. The gas moves at about 24km/h

Pipe Lines

PGU, TTM and TAGP

Peninsular Gas Utilisation (PGU) system was operational in

December 1997

Development of the Trans-ASEAN Gas Pipeline (TAGP) system

to ensure the security of energy supply in the region by 2020.

360 km Trans Thailand - Malaysia (TTM) Gas Pipeline system

was linked to the PGU pipeline system to transport gas from

Changlun in the northern part of Peninsular Malaysia to the

Malaysia Thailand Joint Development Area (MTJDA),

an average of 330 million standard cubic feet per day

(mmscfd) of sales gas from Phase 1 of MTJDA is being

transmitted through the PGU system since 20 February 2005.

TTM, MTJDAPGU, TAGP

In July 2005, the Gas Separation Plant owned and operated by Trans Thailand Malaysia (Thailand) Ltd. - 50:50 joint ventures between PETRONAS and the Petroleum

Authority of Thailand - commenced operation.

With this commissioning, additional gas supply from the MTJDA is made available into

the PGU system, hence enhancing the security of gas supply to Peninsular Malaysia in

addition to existing supply from Kertih, Terengganu.

At the same time, the additional gas supply provides a significant fit to the

forthcoming TAGP network.

The supply for Peninsular Malaysia is also complemented by the gas from the

Indonesian West Natuna B and the PM3 fields (Commercial Allocation Arrangement

between PETRONAS Carigali Sendirian Berhad, Talisman and PETROVIETNAM) at the

current average rate of 245 mmscfd and 120 mmscfd respectively.

Enhancing security and sustainability

of gas supply

Production of gas from indigenous sources is expected to decline in a decade, based on

current reserves.

Malaysia imports gas from the neighbouring countries West Natuna B (Indonesia)

and JDA.

to date about 20% of Peninsular Malaysia's gas demand is met by import sources.

This is expected to increase when the volume from West Natuna B and JDA increases

to 250 mmscfd and 390 mmscfd respectively.

Future gas development from domestic reserves will be more challenging. The

future reserve fields have the following characteristics:

High CO2 content ranging from 12% to 40%.

Smaller fields and fields that are scattered far from existing developed fields

High cost of development

PETRONAS also plans to introduce various measures such as

capping the demand (in the short term),

assessing potential import sources and

doubling efforts to monetise gas from high CO2 and small gas fields

CO2 Removal-Cryogenic Process

A process for pretreating a natural gas stream having greater than about 40

mole % carbon dioxide

Step 1: passing the gas stream through a separator zone

at a temperature of from about 30 to about 80 F.

at a pressure of from about 600 psia to about 1200 psia

to remove liquid condensate and

Step 2. passing the gas stream through a stripping zone

at a temperature of from about -20 to about 0 F.

at a pressure of from about 600 psia to about 1200 psia

to remove most of the carbon dioxide content

as liquefied carbon dioxide.

Fuel Mix for Electricity Generation

Coal

Oil

Gas

Hydro

Other

2002

6

9

74

11

2010

36

1

56

7

1

2020

45

1

48

6

1

2030

50

0

45

4

1

Natural Gas Consumption by Sectors

1990 - 2007

Das könnte Ihnen auch gefallen

- Inspectorate Malaysia SDN BHD, JohorDokument3 SeitenInspectorate Malaysia SDN BHD, JohorIan RidzuanNoch keine Bewertungen

- Panduan Mengenai Akta Peraturan Bekalan Gas PDFDokument24 SeitenPanduan Mengenai Akta Peraturan Bekalan Gas PDFDriftKing100% (1)

- Petronas Value Chain and Benchmark CriteriaDokument7 SeitenPetronas Value Chain and Benchmark CriteriaJustin Chan100% (1)

- GT - Turbine Inlet CoolingDokument12 SeitenGT - Turbine Inlet CoolingSharon Lambert100% (1)

- The Maisotsenko CycleDokument10 SeitenThe Maisotsenko Cyclenishith_soni100% (1)

- Renewable Energy MalaysiaDokument8 SeitenRenewable Energy MalaysiaAhmad MuzammilNoch keine Bewertungen

- Complete ReportDokument87 SeitenComplete ReportShalihan Mustafa100% (2)

- Section 2.3 - Gas Supply SchemeDokument30 SeitenSection 2.3 - Gas Supply SchemePDPPPMAT0621 Ruhilin Binti NasserNoch keine Bewertungen

- Hydrogengassafety PDFDokument23 SeitenHydrogengassafety PDFmujolicoNoch keine Bewertungen

- Main Pipe Replacement - Phase Ii - Stage 2: Summary of Packages & List of ConsultantsDokument4 SeitenMain Pipe Replacement - Phase Ii - Stage 2: Summary of Packages & List of ConsultantsJennifer PearsonNoch keine Bewertungen

- Siliporite NK10 Beads Revision 9 - 2017Dokument2 SeitenSiliporite NK10 Beads Revision 9 - 2017JonatanNoch keine Bewertungen

- Performance Galileo Mx521Dokument1 SeitePerformance Galileo Mx521Juan AlarconNoch keine Bewertungen

- Reference For Orifice SelectionDokument1 SeiteReference For Orifice Selectiondeepak_313Noch keine Bewertungen

- Booster GuideDokument28 SeitenBooster GuideRafael.AugustinisNoch keine Bewertungen

- Sceintific Review of HHO KitDokument3 SeitenSceintific Review of HHO KitAsim RiazNoch keine Bewertungen

- ReticulationDokument118 SeitenReticulationIzzul Hazim100% (1)

- Damietta Liquefaction ProjectDokument16 SeitenDamietta Liquefaction ProjectthawdarNoch keine Bewertungen

- Chap 3 Gas Supply ActDokument89 SeitenChap 3 Gas Supply Actkimberly_87100% (1)

- Hac Schedule: Contract No.: PGB/HO/19/2016/0009Dokument4 SeitenHac Schedule: Contract No.: PGB/HO/19/2016/0009Naveen RaoNoch keine Bewertungen

- Life Boat Equipment Requirements, Maintenance, and Servicing.Dokument5 SeitenLife Boat Equipment Requirements, Maintenance, and Servicing.liaraNoch keine Bewertungen

- Flare Reduction Project Family: October 2009Dokument67 SeitenFlare Reduction Project Family: October 2009amirlngNoch keine Bewertungen

- 135 MW Combine Gas Cycle - PakistanDokument88 Seiten135 MW Combine Gas Cycle - Pakistanthawdar100% (1)

- Natural Gas Utilization in Malaysia: by Ir. Ahmad Fauzi Hasan Energy Commission, MalaysiaDokument47 SeitenNatural Gas Utilization in Malaysia: by Ir. Ahmad Fauzi Hasan Energy Commission, Malaysiafaiz_oeNoch keine Bewertungen

- LPG Bottle Filling 1Dokument42 SeitenLPG Bottle Filling 1segunoyes100% (2)

- Pinch Technology AnalysisDokument20 SeitenPinch Technology AnalysisPiyush JainNoch keine Bewertungen

- SOP AmmoniaDokument6 SeitenSOP AmmoniaNakkolopNoch keine Bewertungen

- Methanol Volume 1Dokument64 SeitenMethanol Volume 1Leong CheaNoch keine Bewertungen

- RP 158 PDFDokument40 SeitenRP 158 PDFDeependra SinghNoch keine Bewertungen

- GTG 1409sc Solart60 60hzDokument21 SeitenGTG 1409sc Solart60 60hzKhaldoon AlnashiNoch keine Bewertungen

- Gas Hydrate Tutorial PDFDokument134 SeitenGas Hydrate Tutorial PDFGinoNoch keine Bewertungen

- Ambatovy Site TourDokument41 SeitenAmbatovy Site Tourrabbidhaggis100% (1)

- Flare Reduction Project Family: October 2009Dokument67 SeitenFlare Reduction Project Family: October 2009dragos_n66Noch keine Bewertungen

- Model Yhau-Ce-Je Ex, Exw and Exw3 Series Exhaust Gas Absorption Chiller-HeaterDokument42 SeitenModel Yhau-Ce-Je Ex, Exw and Exw3 Series Exhaust Gas Absorption Chiller-HeaterUmar MajeedNoch keine Bewertungen

- Real-Time Ppt-Level Analysis of CO, CO and CH in Semiconductor UHP GasDokument4 SeitenReal-Time Ppt-Level Analysis of CO, CO and CH in Semiconductor UHP GasTanNoch keine Bewertungen

- Module 2.1 - Basic Flow Assurance PDFDokument13 SeitenModule 2.1 - Basic Flow Assurance PDFAyuku KidaNoch keine Bewertungen

- Hse Assignment 24 JuneDokument13 SeitenHse Assignment 24 JuneJohan Aliff100% (1)

- CSB ReportDokument13 SeitenCSB ReportKarim FigoNoch keine Bewertungen

- Petronas Details RAPID Project Contract AwardsDokument9 SeitenPetronas Details RAPID Project Contract AwardsIzzadAfif1990100% (1)

- LPG Autogas Station: Ss Energy (Presents) Auto Gas Station Installation On Turnkey BasisDokument17 SeitenLPG Autogas Station: Ss Energy (Presents) Auto Gas Station Installation On Turnkey BasisSaeed AwanNoch keine Bewertungen

- Vacuum Booster Application of Bernoulli's PrincipleDokument9 SeitenVacuum Booster Application of Bernoulli's PrincipleDouglas OngomNoch keine Bewertungen

- Method Statement Upvc UndergroundDokument2 SeitenMethod Statement Upvc UndergroundMohammad AbrarNoch keine Bewertungen

- ASTM Materials - CHINA MaterialsDokument29 SeitenASTM Materials - CHINA MaterialsHema HemaNoch keine Bewertungen

- SMBS GradesDokument8 SeitenSMBS GradestinuvalsapaulNoch keine Bewertungen

- 9ha Power Plants PDFDokument2 Seiten9ha Power Plants PDFmead6356Noch keine Bewertungen

- Marine Energy ConversionDokument64 SeitenMarine Energy Conversionsachu chandranNoch keine Bewertungen

- 70 KvaDokument4 Seiten70 KvaLeonardusHSijabatNoch keine Bewertungen

- Ventsorb Ventsorb: Description Specifications Carbon Life EstimateDokument4 SeitenVentsorb Ventsorb: Description Specifications Carbon Life EstimateEvert AlexNoch keine Bewertungen

- LPG T4S-Original Reg-15.02.2019Dokument179 SeitenLPG T4S-Original Reg-15.02.2019Abdul Kareem0% (1)

- Hydrogen Decarbonization Pathways: A Life-Cycle AssessmentDokument24 SeitenHydrogen Decarbonization Pathways: A Life-Cycle AssessmentGabriel DiazNoch keine Bewertungen

- Loading ArmDokument2 SeitenLoading ArmAnonymous iM2totBrNoch keine Bewertungen

- Conversion of Fuel Data To MWHDokument12 SeitenConversion of Fuel Data To MWHdanferreiro8318Noch keine Bewertungen

- Process Safety-Related Standards & RegulationsDokument54 SeitenProcess Safety-Related Standards & RegulationsSebastian Cheah Cheok Fung100% (1)

- LJ Pulsation Dampener PDS en BWDokument2 SeitenLJ Pulsation Dampener PDS en BWmasimaha1379Noch keine Bewertungen

- 5e Template Energy Services RFPDokument40 Seiten5e Template Energy Services RFPrahul84803Noch keine Bewertungen

- Fydp II Group 17 Final Report - 24th August 2011 - 1Dokument166 SeitenFydp II Group 17 Final Report - 24th August 2011 - 1Nur Fardina100% (2)

- 2010 Aquascape Price List FinalDokument13 Seiten2010 Aquascape Price List FinallioairlanggaNoch keine Bewertungen

- Liberalising Gas Supply in MalaysiaDokument20 SeitenLiberalising Gas Supply in MalaysiaMohammad Faizul Zainudin100% (1)

- 1.1 Purpose of The ReportDokument14 Seiten1.1 Purpose of The ReportAnonymous 2trYNDKnNoch keine Bewertungen

- Design: Johan Design Associates, MalaysiaDokument20 SeitenDesign: Johan Design Associates, MalaysiaSyukri ShahNoch keine Bewertungen

- Uk Asset EtapDokument6 SeitenUk Asset EtapJiaqing_189134182Noch keine Bewertungen

- Liquid Pipeline Hydraulics 50Dokument1 SeiteLiquid Pipeline Hydraulics 50Daniel WigginsNoch keine Bewertungen

- Liquid Pipeline Hydraulics 24 PDFDokument1 SeiteLiquid Pipeline Hydraulics 24 PDFDaniel WigginsNoch keine Bewertungen

- SL6Y Spec Sheet PDFDokument1 SeiteSL6Y Spec Sheet PDFDaniel WigginsNoch keine Bewertungen

- Liquid Pipeline Hydraulics 23Dokument1 SeiteLiquid Pipeline Hydraulics 23Daniel WigginsNoch keine Bewertungen

- Plugin Installation Manual EN PDFDokument5 SeitenPlugin Installation Manual EN PDFDaniel WigginsNoch keine Bewertungen

- Liquid Pipeline Hydraulics 24 PDFDokument1 SeiteLiquid Pipeline Hydraulics 24 PDFDaniel WigginsNoch keine Bewertungen

- Ledger Nano X: User ManualDokument47 SeitenLedger Nano X: User ManualFabio Soares ReisNoch keine Bewertungen

- SL6Y Spec Sheet PDFDokument1 SeiteSL6Y Spec Sheet PDFDaniel WigginsNoch keine Bewertungen

- Unifi Wifi TNC PDFDokument6 SeitenUnifi Wifi TNC PDFDaniel WigginsNoch keine Bewertungen

- Automatic LiquidationDokument1 SeiteAutomatic LiquidationDaniel WigginsNoch keine Bewertungen

- Notebooks Nov-28-2018 1543420969947Dokument61 SeitenNotebooks Nov-28-2018 1543420969947Yonas AddamNoch keine Bewertungen

- Form Part17Dokument1 SeiteForm Part17Daniel WigginsNoch keine Bewertungen

- Mod1 PDFDokument41 SeitenMod1 PDFAhmad Budiman100% (2)

- Form Part13Dokument1 SeiteForm Part13Daniel WigginsNoch keine Bewertungen

- Note: - Proof of Net Assets/ Income Is Compulsory.: Intraday Short Selling Declaration by ApplicantDokument1 SeiteNote: - Proof of Net Assets/ Income Is Compulsory.: Intraday Short Selling Declaration by ApplicantDaniel WigginsNoch keine Bewertungen

- Form Part14Dokument1 SeiteForm Part14Daniel WigginsNoch keine Bewertungen

- B) - Terms and Conditions For Discretionary Financing AccountDokument1 SeiteB) - Terms and Conditions For Discretionary Financing AccountDaniel WigginsNoch keine Bewertungen

- Form Part10Dokument1 SeiteForm Part10Daniel WigginsNoch keine Bewertungen

- Consequences of Failing To Provide Personal Data or ConsentDokument1 SeiteConsequences of Failing To Provide Personal Data or ConsentDaniel WigginsNoch keine Bewertungen

- Discretionary Financing Fees (DF Fees)Dokument1 SeiteDiscretionary Financing Fees (DF Fees)Daniel WigginsNoch keine Bewertungen

- Form Part9Dokument1 SeiteForm Part9Daniel WigginsNoch keine Bewertungen

- Declaration For Electronic PaymentDokument1 SeiteDeclaration For Electronic PaymentDaniel WigginsNoch keine Bewertungen

- Covenants and Undertakings To: UOB Kay Hian Securities (M) SDN BHDDokument1 SeiteCovenants and Undertakings To: UOB Kay Hian Securities (M) SDN BHDDaniel WigginsNoch keine Bewertungen

- Declaration For Electronic PaymentDokument1 SeiteDeclaration For Electronic PaymentDaniel WigginsNoch keine Bewertungen

- Malaysia US Others Malaysia US OthersDokument1 SeiteMalaysia US Others Malaysia US OthersDaniel WigginsNoch keine Bewertungen

- Market ScannerDokument1 SeiteMarket ScannerDaniel WigginsNoch keine Bewertungen

- To Be Completed by Self Employed Individual / Income Provider OnlyDokument1 SeiteTo Be Completed by Self Employed Individual / Income Provider OnlyDaniel WigginsNoch keine Bewertungen

- Securities Part4Dokument1 SeiteSecurities Part4Daniel WigginsNoch keine Bewertungen

- Scanner PDFDokument1 SeiteScanner PDFDaniel WigginsNoch keine Bewertungen

- Map Selangor PDFDokument1 SeiteMap Selangor PDFDaniel WigginsNoch keine Bewertungen

- Central Asia Pipelines Are The New Silk RoadDokument3 SeitenCentral Asia Pipelines Are The New Silk Roadstravinsky YuravinochNoch keine Bewertungen

- Methane Hydrate Gulf of Mexico Oil Spill BPDokument133 SeitenMethane Hydrate Gulf of Mexico Oil Spill BPVincent J. CataldiNoch keine Bewertungen

- Hesc103 PDFDokument8 SeitenHesc103 PDFParam SukhwaniNoch keine Bewertungen

- The Unbranched Alkanes: Table 2.1Dokument2 SeitenThe Unbranched Alkanes: Table 2.1FishingtonNoch keine Bewertungen

- List of IOCL Patents As On 31.05.2020Dokument26 SeitenList of IOCL Patents As On 31.05.2020Mustafa AhsanNoch keine Bewertungen

- JPT MagazineDokument148 SeitenJPT MagazineAsahel NuñezNoch keine Bewertungen

- Refining Process - Shell Refining CompanyDokument2 SeitenRefining Process - Shell Refining Companyce10m034Noch keine Bewertungen

- Technodyne Refrigerated Tank Projects - May 18Dokument6 SeitenTechnodyne Refrigerated Tank Projects - May 18AndrzejNoch keine Bewertungen

- Andy N. Sommeng, Director General of Electricity ESDMDokument17 SeitenAndy N. Sommeng, Director General of Electricity ESDMShah Reza DwiputraNoch keine Bewertungen

- LNG AT GLANCE PosterDokument1 SeiteLNG AT GLANCE PosterDhiren PrajapatiNoch keine Bewertungen

- HM 50 Guidelines For Tankcleaning - Products 5th EditionDokument33 SeitenHM 50 Guidelines For Tankcleaning - Products 5th Editionnivasmarine100% (5)

- New Offshore ProjectDokument126 SeitenNew Offshore ProjectMathias OnosemuodeNoch keine Bewertungen

- Lecture For Transportation of Crude OilDokument22 SeitenLecture For Transportation of Crude OilJayChristian Quimson100% (1)

- Methane LEL, UEL.Dokument4 SeitenMethane LEL, UEL.Ovais FarooqNoch keine Bewertungen

- Garp Erp Study NotesDokument71 SeitenGarp Erp Study Notesjohn smith100% (2)

- Major Pipelines in IndiaDokument2 SeitenMajor Pipelines in IndiaAnil Kumar SinghNoch keine Bewertungen

- 6th Grade Reading Comprehension WorksheetsDokument31 Seiten6th Grade Reading Comprehension Worksheetsxw20210522Noch keine Bewertungen

- Calculations, Boilers, CapacitiesDokument1 SeiteCalculations, Boilers, CapacitieswvwintersNoch keine Bewertungen

- Operating Natural Gas Pipelines in India: S. No. Name of The Pipeline Name of EntityDokument2 SeitenOperating Natural Gas Pipelines in India: S. No. Name of The Pipeline Name of Entityrahijain26890Noch keine Bewertungen

- Global Oil and Gas Exploration and Production - Data Monitor 2008Dokument34 SeitenGlobal Oil and Gas Exploration and Production - Data Monitor 2008DanmalmxNoch keine Bewertungen

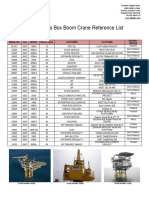

- Nautilus Box Boom Crane Reference ListDokument6 SeitenNautilus Box Boom Crane Reference Listvipin_nair01100% (2)

- Analysis of Natural Gas Demand & SupplyDokument5 SeitenAnalysis of Natural Gas Demand & SupplyHariprasad P SNoch keine Bewertungen

- Heavy OilDokument9 SeitenHeavy OilMeyda AstriaNoch keine Bewertungen

- Table of Geologic Time: Supereon Eon Era Period Epoch/Age YearsDokument7 SeitenTable of Geologic Time: Supereon Eon Era Period Epoch/Age YearsFitriana ApriliaNoch keine Bewertungen

- Oil Report 08142016Dokument10 SeitenOil Report 08142016reagandrNoch keine Bewertungen

- ExxonMobil Ergynet Work XOMDokument36 SeitenExxonMobil Ergynet Work XOMRuslan ZakirovNoch keine Bewertungen

- Oil and GasDokument10 SeitenOil and GassrajeceNoch keine Bewertungen

- Crossref Guia de Ref. Lub KluberDokument29 SeitenCrossref Guia de Ref. Lub Kluberroberto gomezNoch keine Bewertungen

- Explanation Text Lesson For JHS and SHSDokument3 SeitenExplanation Text Lesson For JHS and SHSFilmaNoch keine Bewertungen

- Arabian HeavyDokument2 SeitenArabian HeavyAhmed Mohamed KhalilNoch keine Bewertungen