Beruflich Dokumente

Kultur Dokumente

Updated Stresses in Threads 2

Hochgeladen von

Christopher GarciaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Updated Stresses in Threads 2

Hochgeladen von

Christopher GarciaCopyright:

Verfügbare Formate

ME3180

ME 3180 - Mechanical Engineering Design

Stresses in Threads

Lecture Notes

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Stresses in Threads

When nut engages thread, theoretically all threads in engagement

should share load

In actuality, due to inaccuracies in thread spacing, first pair of threads

takes virtually all load

Conservative approach for calculating bolt stresses is to assume worst

case of one thread-pair taking entire load

Other extreme approach for calculating bolt stresses is to assume that all

of engaged threads share load equally

Better compromise is to assume that true stress lies between these two

extremes, but most likely is closer to one thread-pair assumption.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Stresses in Threads Contd

Power screws and fasteners for high-load applications are usually made

of hardened high-strength steels.

Power screw nuts may also be of hardened material for strength and

wear resistance.

Fastener nuts, on the other hand, are often made of soft materials, and

thus, are typically weaker than screws (i.e. regular fastener and nut).

This promotes local yielding in nut threads when fastener is tightened,

which can improve thread fit and promote load sharing between threads.

Hardened nuts are used on hardened high-strength bolts.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Axial Stress

While power screw can see either tensile or compressive axial load, threaded

fastener sees only axial tensile load

This equation can be used to compute axial tensile stress in screw.

F

At

Eq. 14-2

For power screws loaded in compression, possibility of column buckling must

be investigated. Use screws minor diameter to compute slenderness ratio.

Slenderness ratio is factor that determines if column is short or long.

For short column,

where is radius of gyration.

l d

S r use its compressive

10

If it is short column,

yield strength as limiting

stress (Page 200, Norton), if it is long column, then use buckling to

perform failure analysis.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Shear Stress

Possible shear-failure mode involves stripping of threads:

Out of nut

Off of screw

Possibility of either of these scenarios occurring depends on relative

strengths of nut and screw materials

If nut material is weaker, it may strip its threads at its major diameter

If screw is weaker, it may strip its threads at its minor diameter

If both materials are of equal strength, assembly may strip along pitch

diameter

In order to calculate stresses, we must assume some degree of load

sharing among the threads

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Shear Stress Contd

Since complete failure requires all threads to strip, all of threads can be

considered to share load equally

This is good approach as long as nut or screw (or both) is ductile, allowing

each thread to yield as assembly begins to fail

If both nut and screw are brittle (e.g., high-hardness steels or cast iron)

and thread fit is poor

One can envision each thread taking entire load in turn until it fractures

and passes job to the next thread.

The reality is again somewhere between these extremes.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

Shear Stress Contd

ME3180

Stripping-shear area for each screw thread is area of cylinder of its minor diameter d r:

A d w p

where

p = thread pitch

s

r i

wi = factor that defines percentage of pitch occupied by metal at minor

diameter (see Table 14-5)

This area can be multiplied by number of threads in engagement based on

designers judgment.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Shear Stress Contd

For nut stripping at its major diameter, shear area for one screw thread is:

As dwo p

wo is the factor found in Table 14-5

Shear stress for thread stripping is:

As

Minimum Nut Length If the nut is long enough, the load required to strip the

threads will exceed the load needed to fail the screw in tension. The equations

for both modes of failure can be combined and a minimum nut length computed for

any particular screw size. For any UNS/ISO threads or Acme threads of d 1in, a

nut length of at least 0.5d will have a strip strength in excess of the screws tensile

strength. For larger diameter ACME threads, strip-strength of nut with length 0.6d

will exceed the screws tensile strength. These figures are valid only if the screw and

nut are of the same material, which is usually the case.

Minimum Tapped-Hole Engagement When a screw is threaded into a tapped

hole rather than a nut, a longer thread engagement is needed. For same material

combinations, a thread-engagement length at least equal to the nominal thread

diameter d is recommended. For a steel screw in cast iron, brass or bronze, use

TheGeorge

George

W.aluminum,

WoodruffSchool

School

ofMechanical

Mechanical

Engineering

1.5d. For The

steel

screws W.

in

use

2d of

of

minimum

thread-engagement

length.

Woodruff

Engineering

ME3180

Torsional Stress

Torsional stress will develop when:

Nut is tightened on screw

Torque is transmitted through power screw

Torque that twists screw is dependent on friction at screw-nut interface

If screw and nut are well lubricated, less of applied torque is transmitted to

screw, and more is absorbed between nut and clamped surface

If nut is rusted to screw, all applied torque will twist screw, which is why rusty

bolts usually shear even when you attempt to loosen nut

For power screw, if thrust collar has low friction, all applied torque at nut will

create torsional stress in screw (since little torque is taken to ground through lowfriction collar).

In order to accommodate worst case of high thread friction, use total applied

torque in equation for torsional stress in round section (page 183, Norton)

Tr 16T

for this calculation: dr = minor

diameter

J

d r3

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Types of Screws/Fasteners

Fasteners can be classified in different ways: by their intended use, by

thread type, by head style, and by their strength.

These fasteners are available in variety of materials including steel,

stainless steel, aluminum, brass, bronze, and plastics.

Classification by Intended Use

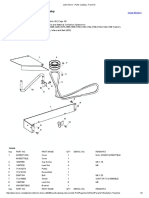

Bolts and Machine screws:

Same fastener may take on different name for particular application.

Bolt is fastener with head and straight threaded shank intended to be used

with nut to clamp assembly together. See Fig 14-10a

However, same fastener is called machine screw or cap screw when it is

threaded into tapped hole rather than used with nut. See Fig. 14-10b

Studs:

Headless fastener, threaded on both ends and intended to be semipermanently threaded into one-half of assembly. See Fig. 14-10c

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

FIGURE 14-10

Bolt and Nut, Machine Screw and Stud

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Types of Screws/Fasteners

Classification by Thread Type

All fasteners intended to make their own hole or make their own threads are

called tapping screws, as in self-tapping, thread-forming, thread cutting,

and self-drilling screws. See Fig. 14-11

These are used in sheet metal or plastic

Classification by Head Style

Slotted Screw:

Many different types of head styles are made, including: straight-slot,

cross-slot (Phillips), hexagonal, hexagonal socket and others. Head shape

can be round, flat (recessed), filister, pan,etc. See Fig. 14-12

Socket-Head Cap Screw:

Typically made of high-strength, hardened steel, stainless steel or other

metals, and are used extensively in machinery. See Fig. 14-13

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

FIGURE 14-13

Various Styles of Socket-Head Cap Screws

Courtesy of Cordova Bolt Inc., Buena Park, Calif.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Nuts and Washers

Nuts: Please read up on nuts on pp 897 Norton. See Fig. 14-14, & Fig. 1415 on next slide

Washers:

Plain washer is doughnut -shaped part that serves to increase area of

contact between bolt head or nut and clamped part. See Fig. 10.

Hardened -steel washers are used where bolt compression load on

clamped part needs to be distributed over larger area than bolt head or

nut provides

Any plain washer also prevents marring of part surface by nut when it

is tightened

Softer washer will yield in bending rather than effectively distribute

load

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

FIGURE 14-14

Various Styles of Standard Nuts

Courtesy of Cordova Bolt Inc.,

Buena Park, Calif., 90621

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Nuts and Fasteners Contd

Lock Washers:

Help prevent spontaneous loosening of standard nuts (as opposed to

lock nuts)

Can be used under nut of bolt or under head of machine screw. See Fig.

14-16

SEMS:

Are combinations of nuts and captive lock washers that remain with

nut

Their main advantage is to ensure that lock washer will not be left out

at assembly or reassembly. See Fig. 14-17

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

FIGURE 14-16

Types of Lock Washers

Courtesy of Cordova Bolt Inc.,

Buena Park, Calif., 90621

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Bolts and Fasteners

Strengths of Standard Bolts and Machine Screws

Bolts and screws are selected based on their proof strength Sp.

Proof strength is quotient of proof load and tensile-stress area

Proof Load Fp is maximum load (force) that bolt can withstand without

acquiring permanent set.

Preloaded Fastener in Tension

Primary application of bolts and nuts is to clamp parts together, such that

applied loads put bolt(s) in tension. See Fig. 14-21

Joints are preloaded by tightening bolts with sufficient torques to create

tensile loads that approach their proof strengths.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Fasteners Contd

For statically loaded assemblies, preload that generates bolt stress as high

as 90% of proof strength is sometimes used.

For dynamically loaded assemblies (fatigue loading) preload that generates

bolt stress as high as 75% or more of proof strengths is commonly used.

If bolts are suitably sized for applied loads, these high preloads increase

reliability of the bolts.

Reasons for this are subtle and require an understanding of how

elasticities of bolts and clamped members interact when bolt is tightened and

when external load is later applied.

Clamped members have spring constant .

Bolt, being elastic, will stretch when tightened.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Spring Constants of Bolt

Fig. 14.23 shows bolt clamping cylinder of known cross section and length.

We want to examine loads, deflections, and stresses in both bolt and cylinder under

preload and after an external load is applied.

To examine above parameters, we must determine spring constants of bolt and

members.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Spring Constants of Bolt

Bolt:

For bolt of diameter d and axially loaded thread length lt within its clamped zone of length l as

shown in Fig. 14-21, spring constant is

14.11a

1

lt

l lt

lt

ls

Kwhere:

At Eb

Ab Eb

At Eb

Ab Eb

b

Ab is total cross-sectional area and At is tensile stressed area of bolt, and

ls is length of unthreaded shank.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Spring Constants of Bolt Contd

LT lth

1

(2d ) in

4

1

(2d ) in

2

(2d 6) mm

LT lth (2d 12) mm

(2d 25) mm

L 6 in

Table 8.7 (Shigley)

L 6 in

L 125 , d 48 mm

125 L 200 mm

L 200 mm

Table 8.7 (Shigley)

Bolts shorter than standard thread lengths are threaded as close to head as possible

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Determining Joint Stiffness Factor Contd

Fig. 14-30 shows results of finite element analysis (FEA) study of stress

distribution in two-part joint-sandwich clamped together with single,

preloaded bolt.

Stress distribution around bolt resembles truncated-cone (or cone-frusta)

barrel shape, as shown in Fig. 14-30a.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

FIGURE 17.19

Lines of equal compressive stress in joint. Bolt loaded

to 100 kip. (Reprinted from [20], courtesy Marcel Dekker

Inc.)

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

Spring Constants of Members

(Cylindrical Model)

ME3180

Members:

For cylindrical material geometry shown in Fig. 14-23 (ignoring flanges), material

spring constant becomes:

14.11b

l

l

4l

4l

1

Km

Am1 E1

Am 2 E2

D 2 eff 1E1

D 2 eff 2 E2

where:

Am are effective areas of clamped materials and D eff are effective diameter

of those areas

14.11c

If both clamped materials are same

Deff2

14.11d

D2 d 2

Am Em

Km

l

If Am can be defined as solid cylinder with effective diameter Deff equation 14.11d

becomes

2

D

Am Em

eff Em

Km

or K m

l

4l Engineering

TheGeorge

GeorgeW.

W.Woodruff

Woodruff

SchoolofofMechanical

Mechanical

Engineering

The

School

ME3180

External Load on Bolted Connection

Let us consider what happens when external tensile load P is applied to bolted

connection in Fig. 14-23.

Assume clamping force which we call preload Fi, has been correctly applied

by tightening nut before P is applied.

Fi = preload

P = external tensile load

Pb = portion of P taken by bolt

Pm = portion of P taken by members

Fb = Pb + Fi = resultant bolt load

Fm = Fi - Pm = resultant load on members

Fm < 0

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

External Load on Bolted Connection Contd

These results are valid as long as some clamping load remains in the members.

P = Pb + P m

14.12a

The load P causes connection to stretch, or elongate.

K

Pb b Pm

Km

Pb = CP, where

Kb

Pb

P

Km Kb

14.13b

14.13c

Kb

C

Km Kb

C is called joints stiffness constant or joint

constant.

C is typically less than 1, and if K b is small compared to Km, C will be small

fraction. This confirms that bolt will see only portion of the applied load P.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

External Load on Bolted Connection Contd

Pm 0.8P. Also members can take even greater percentage of P, if grip is

longer. See Table 8.12 (Shigley)

Km

Pm

P (1 C)P

Kb Km

Fm Fi (1 C)P

14.13d

14.14a

Fb Fi CP

14.14b

Load Po required to separate the joint can be found from equation 14.14a by

F

setting Fm = 0.

Po i

1 C

14.14c

Safety factor (or load factor) guarding against joint separation is

Po

Fi

N

P P(1 C)

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

14.14d

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

External Load on Bolted Connection Contd

Tensile stress in bolt can be found by dividing F b = CP + Fi by At.

CP Fi

At At

section 8.9 in Shigley

Limiting value of b is the proof strength Sp. Thus with introduction of load

factor, above equation becomes:

CnP Fi

Sp

At At

Sp A t Fi

CP

Any value of load factor (factor of safety), n 1, ensures that

b Sp

This implies that bolt will not fail.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

External Load on Bolted Connection Contd

From Shigley

0.75 Fp for reused connections also used for dynamic loading

Fi

0.90 Fp for permanent connections also used for static loading

Fp = AtSp

For other materials not in Tables 14.6 and 14.7, use Sp = 0.85Sy

Where Sy is yield strength of that material.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

FIGURE 14-19

Head Marks for SAE Bolts

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

FIGURE 14-20

Head Marks-Metric Bolts

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Joints-Member Stiffness

(Cone Frusta Model)

Both stiffness of members and fasteners must be known in order to

learn what happens when assembled connection is subjected to external

tensile loading.

More than two members could be included in grip of fastener. All

together these act like compressive springs in series, and hence total

spring rate of members is

1

1 1 1

1

km k1 k2 k3

ki

(Equ.8-18 Shigley)

If one of members is soft gasket, its stiffness relative to other

members is usually so small that for all practical purposes others can be

neglected and only gasket stiffness is used.

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

Joints-Member Stiffness (cont.)

Figure 8-15 illustrates general cone geometry using half-apex angle .

Angle = 45 has been used, but Little reports that this overestimates

3

clamping stiffness. In this book we shall use = 30 except in cases in

which material is insufficient to allow frusta to exit.

Thus spring rate or stiffness of this frustum is

P

Ed tan

k

ln (2t tan D d )( D d )

(2t tan D d )( D d )

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

(8-19)

ME3180

Joints-Member Stiffness (cont.)

With = 30, this becomes

0.5774 Ed

(1.155t D d )( D d )

ln

(1.155t D d )( D d )

(8-20)

Equations (8-20), or (8-19), must be solved separately for each

frustum in the joint. Then individual stiffnesses are assembled to obtain

using Eq.(8-18).

If members of joint have same Youngs modulus E with symmetrical

frusta back to back, then they act as two identical springs in series.

From Eq.(8-18) we learn that =/2

. Using grip as l=2t and d w as

m

diameter of washer face, we find spring rate of members to be

Ed tan

km

(l tan d w d )(d w d )

2 ln

(l tan d w d )(d w d )

(8-21)

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

Joints-Member Stiffness (cont.)

ME3180

Diameter of washer face is about 50 percent greater than fastener

diameter for standard hexagon-head bolts and cap screws. Thus we can

simplify Eq.(8-21) by letting d W =1.5d . If we also use = 30, the Eq.

(8-21) can be written as

km

2 ln

0.5774 Ed

0.5774l 0.5d

0.5774l 2.5d

(822)

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

ME3180

TheGeorge

GeorgeW.

W.Woodruff

WoodruffSchool

SchoolofofMechanical

MechanicalEngineering

Engineering

The

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Welded Beams BrochureDokument9 SeitenWelded Beams BrochureChristopher GarciaNoch keine Bewertungen

- Smootharc MMA 130 Operating ManualDokument36 SeitenSmootharc MMA 130 Operating ManualChristopher GarciaNoch keine Bewertungen

- Lightforce Has Arrived: Lightforce Durability and Power, Now Available in A Compact Utility LightDokument2 SeitenLightforce Has Arrived: Lightforce Durability and Power, Now Available in A Compact Utility LightChristopher GarciaNoch keine Bewertungen

- 1984 Surf Roughness PGDokument8 Seiten1984 Surf Roughness PGHussn YazdanNoch keine Bewertungen

- PHD Pajaczkowski Piotr PDFDokument162 SeitenPHD Pajaczkowski Piotr PDFChristopher GarciaNoch keine Bewertungen

- 896 1886Dokument7 Seiten896 1886Christopher GarciaNoch keine Bewertungen

- DTC 1209Dokument4 SeitenDTC 1209Christopher GarciaNoch keine Bewertungen

- ZOOM Software Measurement and Graph TypesDokument6 SeitenZOOM Software Measurement and Graph TypesChristopher GarciaNoch keine Bewertungen

- 17670Dokument3 Seiten17670Christopher GarciaNoch keine Bewertungen

- CST09 PDFDokument18 SeitenCST09 PDFChristopher Garcia100% (1)

- G2 Vibration Spectrum: 2x Dominantmayhinttomisalignment, However Timewaveform BelowindicatesunbalancesymptomDokument3 SeitenG2 Vibration Spectrum: 2x Dominantmayhinttomisalignment, However Timewaveform BelowindicatesunbalancesymptomChristopher GarciaNoch keine Bewertungen

- 18.environmental Impact AssessementDokument401 Seiten18.environmental Impact AssessementChristopher Garcia100% (1)

- Riva Brochure Install 2015Dokument36 SeitenRiva Brochure Install 2015Christopher GarciaNoch keine Bewertungen

- Euro Energy Low SAPS 5W 30-3-2015Dokument2 SeitenEuro Energy Low SAPS 5W 30-3-2015Christopher GarciaNoch keine Bewertungen

- BP Chart For AdultsDokument2 SeitenBP Chart For AdultssultanudNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Metric STD ThreadDokument4 SeitenMetric STD ThreadmayurNoch keine Bewertungen

- Drive Train - MT55 PDFDokument4 SeitenDrive Train - MT55 PDFIliyan VasilevNoch keine Bewertungen

- YUKEN Hydraulic Equipment (PG 618)Dokument1 SeiteYUKEN Hydraulic Equipment (PG 618)yogi fransbeenNoch keine Bewertungen

- Juk LBH-1700Dokument56 SeitenJuk LBH-1700RHoskaNoch keine Bewertungen

- Metric Thread Size Chart: Product TableDokument5 SeitenMetric Thread Size Chart: Product TableAan KurniawanNoch keine Bewertungen

- MDPLT7 PRB5Dokument3 SeitenMDPLT7 PRB5Crystian Kobee EmpeynadoNoch keine Bewertungen

- Shuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001Dokument1 SeiteShuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001ABAID ULLAHNoch keine Bewertungen

- BN - 3803 Hexalobular Socket Countersunk Flat Head Screws Fully ThreadedDokument2 SeitenBN - 3803 Hexalobular Socket Countersunk Flat Head Screws Fully ThreadedMSD ENGRNoch keine Bewertungen

- Screw Jack Drawing - Akash Savita PDFDokument1 SeiteScrew Jack Drawing - Akash Savita PDFEpicNewtonNoch keine Bewertungen

- Threading Tools: F79 To F101Dokument24 SeitenThreading Tools: F79 To F101Peter KlassenNoch keine Bewertungen

- Single Convoluted Design: Enidine GoodyearDokument3 SeitenSingle Convoluted Design: Enidine GoodyearMichael AkhramovichNoch keine Bewertungen

- 1420 Turnbuckle M12 HDGDokument2 Seiten1420 Turnbuckle M12 HDGqualityNoch keine Bewertungen

- SL1970 018 PDFDokument5 SeitenSL1970 018 PDFBas Van TilburgNoch keine Bewertungen

- John Deere - Parts Catalog - Frame 5 - 60D Power Flow ComponentsDokument2 SeitenJohn Deere - Parts Catalog - Frame 5 - 60D Power Flow ComponentsTrent DobrzynNoch keine Bewertungen

- 02 Crown Block DrawingDokument20 Seiten02 Crown Block DrawingramiNoch keine Bewertungen

- Hex Socket Head Screws Is 2269Dokument17 SeitenHex Socket Head Screws Is 2269Rajasekaran MuruganNoch keine Bewertungen

- Iso 965-2 General Purpose Metric Screw Thread TolerancesDokument12 SeitenIso 965-2 General Purpose Metric Screw Thread TolerancesLuis AparcanaNoch keine Bewertungen

- Design of Machine Element-1Dokument23 SeitenDesign of Machine Element-1rutvikvavale0375Noch keine Bewertungen

- Sheettracs: Secure Thin Sheet FasteningDokument6 SeitenSheettracs: Secure Thin Sheet Fastening김상철Noch keine Bewertungen

- Engine & Attaching Parts - 553Dokument3 SeitenEngine & Attaching Parts - 553Cristian Fernando Tarifa MartinezNoch keine Bewertungen

- Partlist - Paddy Seperator 400D-TDokument14 SeitenPartlist - Paddy Seperator 400D-TGENIUS1507100% (1)

- Carrusel RHS17 Actualizado, Simba 1254Dokument44 SeitenCarrusel RHS17 Actualizado, Simba 1254Pancho ArriazaNoch keine Bewertungen

- Ans I Thread SizesDokument3 SeitenAns I Thread SizesPasinduNoch keine Bewertungen

- Dehaye CatalogDokument544 SeitenDehaye CatalogRogier van der HeideNoch keine Bewertungen

- Auto Clips and Fasteners 2014.original PDFDokument1 SeiteAuto Clips and Fasteners 2014.original PDFdletica_1Noch keine Bewertungen

- Retail Price List 06-09-2011 PAK SUZUKIDokument581 SeitenRetail Price List 06-09-2011 PAK SUZUKImartial20Noch keine Bewertungen

- Creo Basic UdfDokument612 SeitenCreo Basic Udfneeraj kumarNoch keine Bewertungen

- Soal Latihan-2 - Machinist's JackDokument3 SeitenSoal Latihan-2 - Machinist's JackRahmat Agung100% (1)

- Xcelite Catalog 5506Dokument100 SeitenXcelite Catalog 5506Ruben MontelongoNoch keine Bewertungen

- 10186590Dokument74 Seiten10186590qualidadesiderNoch keine Bewertungen