Beruflich Dokumente

Kultur Dokumente

Class

Hochgeladen von

Brian Freeman0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

10 Ansichten11 Seitenclass

Originaltitel

Class PPT

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenclass

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

10 Ansichten11 SeitenClass

Hochgeladen von

Brian Freemanclass

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 11

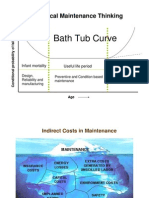

Introduction to cbm

Condition Based Maintenance (CBM) and

Condition Monitoring

CBM is about utilizing the condition monitoring technologies to predict the failure

pattern (s) of a machine.

CBM will not be scheduled based on the time.

CBM will allow the maintenance to be scheduled based on the condition of the

machine.

1

Introduction to cbm (continued)

Vision of CBM:

Attain meaningful set of maintenance schedules (Technical Basis of Maintenance

TBoM)

Attain improved operating performance

Ensure safety and environmental protection

Attain reduced maintenance costs

Attain comprehensive maintenance database (centralized)

Attain clearer view of resource requirements

Attain lasting benefits and can be applied across all or just selected machine

2

Introduction to cbm (continued)

Methodology of CBM:

The strategy of CBM uses a two level approach by overlaying techniques and

technologies on monitored components

Level One (Short term):

Identify and reduce machine failures across site

Use technologies to troubleshoot and examine poor performing assets

Energy usage examinations

3

Introduction to cbm (continued)

Methodology of CBM:

The strategy of CBM uses a two level approach by overlaying techniques and

technologies on monitored components

Level Two (Medium term to Long term):

Reduce maintenance exam tasks, extend maintenance exam and overhaul periodicities

(TBoM integration)

Use technologies to reduce maintenance costs

Effective utilization of work force

Increased knowledge of machine performance and condition

Feedback into TBoM

Introduction to cbm (continued)

Portable Vibration Analysis

What does it monitor?

Imbalance problems

Misalignment problems

Bearing problems

Electrical defects

Introduction to cbm (continued)

Portable Vibration Analysis

Where does it monitor?

Cranes

Air Compressor motors

Brake resistor/Traction cooling fans

Alternators

Turbocharger

Gearboxes

Electrical motors

Cooling system pumps

Lubrication oil system pumps

Fuel pumps

Diesel engine

Axle boxes

Introduction to cbm (continued)

Portable Ultrasonic Analysis

What does it monitor?

Air leak problems

Electrical problems

Mechanical problems

Introduction to cbm (continued)

Portable Ultrasonic Analysis

Where does it monitor? Leak detection in

Valves

Air supply lines

Brake resistor/Traction cooling fans

Flexible hoses

Pneumatic systems

Pressurized systems

Vacuum system problems

Compressor

Steam traps

Electrical Arcing detection

Mechanical Bearing defects, lack of lubrication and over lubricatoin

8

Introduction to cbm (continued)

Portable Thermography Analysis

What does it monitor?

Electrical problems

Mechanical problems

Pipework problems

Introduction to cbm (continued)

Portable Thermography Analysis

What kind of problems?

Electrical

High resistance connection

Corroded/hot connections

Earths returns higher loading

Relay problems

Internal fuse damage

Internal breaker fault

Cracking insulation

Overload or unbalanced load

Busbar faults

Couplings

Cooling jackets

10

Introduction to cbm (continued)

Oil and Grease Analysis

Three dimension analysis:

Wear Ferrous and Nonferrous

Contamination Dust, Water and Fuel

Chemistry Oil and Additive

11

Das könnte Ihnen auch gefallen

- Automated InspectionDokument31 SeitenAutomated InspectionVijay Kumar100% (8)

- O&M TransformerDokument47 SeitenO&M TransformerAshish PatelNoch keine Bewertungen

- Trouble Shooting For InternDokument9 SeitenTrouble Shooting For InternSANMINoch keine Bewertungen

- 03 - Advance Maintenance StartegiesDokument105 Seiten03 - Advance Maintenance StartegiesMuhammad Amru Yazid100% (1)

- Predictive Maintenance - Training CourseDokument130 SeitenPredictive Maintenance - Training CourseWaleed Tahawy100% (5)

- CENT Condition Monitoring PresentationDokument28 SeitenCENT Condition Monitoring PresentationmkpqNoch keine Bewertungen

- Slides - Key Steps To Implementing Condition-Based MaintenanceDokument13 SeitenSlides - Key Steps To Implementing Condition-Based MaintenanceGeraldo Rossoni Sisquini100% (1)

- Section No.: 7 / Title: Condition Based MaintenanceDokument5 SeitenSection No.: 7 / Title: Condition Based Maintenancekrishna_14893Noch keine Bewertungen

- Tutorial 7Dokument3 SeitenTutorial 7ermmm123Noch keine Bewertungen

- ) Maintenance Management (EM 664Dokument15 Seiten) Maintenance Management (EM 664rafiq5002Noch keine Bewertungen

- CNC Machines and Automation: Problems in CNC MachineDokument21 SeitenCNC Machines and Automation: Problems in CNC Machinerahul bhattNoch keine Bewertungen

- 02SRCE104 Slides Module1Dokument49 Seiten02SRCE104 Slides Module1elsonmilan761Noch keine Bewertungen

- Automated InspectionDokument31 SeitenAutomated InspectionelkhawadNoch keine Bewertungen

- Automated Inspection CimsDokument30 SeitenAutomated Inspection CimsGomish SharmaNoch keine Bewertungen

- Condition Monitoring TataDokument24 SeitenCondition Monitoring TataNicolas Pérez MoralesNoch keine Bewertungen

- 2019-01-25 - ACR Webinar On DBT QC For MPsDokument54 Seiten2019-01-25 - ACR Webinar On DBT QC For MPsGeorgiana KokonaNoch keine Bewertungen

- The - Multi - Technology - Approach Rev 1Dokument8 SeitenThe - Multi - Technology - Approach Rev 1RM HaroonNoch keine Bewertungen

- O and M of HV CKT BreakerDokument46 SeitenO and M of HV CKT Breakerraqib safari100% (1)

- Condition Based MaintenanceDokument5 SeitenCondition Based MaintenanceSaumya KharyaNoch keine Bewertungen

- CMMDokument90 SeitenCMMA S100% (1)

- 07 Guezennec FC Workshop OSU YGDokument20 Seiten07 Guezennec FC Workshop OSU YGaymanaymanNoch keine Bewertungen

- Maintenance and Reliability - Theory: John E. Skog P.E. WGA3-06 Tutorial June 2006 Rio de JaneiroDokument59 SeitenMaintenance and Reliability - Theory: John E. Skog P.E. WGA3-06 Tutorial June 2006 Rio de JaneiroDXLopesNoch keine Bewertungen

- Automotive Electrical & ElectronicsDokument50 SeitenAutomotive Electrical & ElectronicsleninkishgmailcomNoch keine Bewertungen

- Application of ASME PTCs To Geothermal Perf Testing (Oct 2010)Dokument18 SeitenApplication of ASME PTCs To Geothermal Perf Testing (Oct 2010)mrizalygani99Noch keine Bewertungen

- Condition Monitoring - Theory and PracticeDokument26 SeitenCondition Monitoring - Theory and PracticejoaogularNoch keine Bewertungen

- Rose - Josh API MPMS Chapters 5 and 6 FinalDokument50 SeitenRose - Josh API MPMS Chapters 5 and 6 Finalgechaves10% (1)

- Chapter 1Dokument34 SeitenChapter 1Abdelrahman KassmNoch keine Bewertungen

- Application of ASME Performance Test Codes To Geothermal Plant Performance TestingDokument18 SeitenApplication of ASME Performance Test Codes To Geothermal Plant Performance Testingmrizalygani99Noch keine Bewertungen

- L1 - Introduction To ControlDokument28 SeitenL1 - Introduction To ControlOmer Ahmed100% (1)

- Kat F Temperature Rise OptionsDokument8 SeitenKat F Temperature Rise OptionsRudanekNoch keine Bewertungen

- 1 Arun KumarDokument23 Seiten1 Arun KumarrafieeNoch keine Bewertungen

- Thermo Cem SDokument30 SeitenThermo Cem SfahshaikNoch keine Bewertungen

- Automated Inspection: Unit ViDokument45 SeitenAutomated Inspection: Unit ViAnonymous surAitMpaNoch keine Bewertungen

- Uniten Arsepe 08 L16Dokument56 SeitenUniten Arsepe 08 L16Walid SonjiNoch keine Bewertungen

- CIGRE-Ciclo de Vida de InterruptoresDokument8 SeitenCIGRE-Ciclo de Vida de InterruptoresRoland AvlsNoch keine Bewertungen

- Diesel Emissions Mechanics Maintenance ManualDokument58 SeitenDiesel Emissions Mechanics Maintenance Manualrafaelcardena73100% (2)

- 1,2 - Well Planning Objective & Rig Sizing and SelectionDokument30 Seiten1,2 - Well Planning Objective & Rig Sizing and SelectionYassir Hindi100% (1)

- Maintenance Genesis: Presented By: Group 2 (Batch 18B)Dokument44 SeitenMaintenance Genesis: Presented By: Group 2 (Batch 18B)Ankur PrabhakarNoch keine Bewertungen

- Unit II - Electronic Ignition SystemDokument17 SeitenUnit II - Electronic Ignition SystemdrkbalaNoch keine Bewertungen

- Pres - Sachin MohanDokument1 SeitePres - Sachin MohanManel MontesinosNoch keine Bewertungen

- Introducation To Linear Control SystemsDokument23 SeitenIntroducation To Linear Control SystemsJahan ZaibNoch keine Bewertungen

- Dan Dettmers - Understanding RAGAGEPDokument58 SeitenDan Dettmers - Understanding RAGAGEPRASHEED YUSUF100% (1)

- CML Optimization Ryan SittonDokument53 SeitenCML Optimization Ryan Sittongopidhan100% (4)

- Maintenance Engineering: Reliability Centered Maintenance (RCM)Dokument28 SeitenMaintenance Engineering: Reliability Centered Maintenance (RCM)Muhammad KamranNoch keine Bewertungen

- Controle de Motores - ADokument284 SeitenControle de Motores - ARenan MirandaNoch keine Bewertungen

- Bearing Defect Inspection Based On Machine Vision: Guided By: Dr. T.D JohnDokument36 SeitenBearing Defect Inspection Based On Machine Vision: Guided By: Dr. T.D Johnvarun kuamr100% (1)

- SEC StandardDokument432 SeitenSEC Standardsathiyaseelan100% (3)

- Maintenance Management (3), 2021Dokument21 SeitenMaintenance Management (3), 2021Vidisha TripathiNoch keine Bewertungen

- IEC - Panel RegulationDokument20 SeitenIEC - Panel RegulationAsith SavindaNoch keine Bewertungen

- How To Proceed With TroubleshootingDokument9 SeitenHow To Proceed With TroubleshootingdiemnganNoch keine Bewertungen

- Pass Marks: - 40: Detail Syllabus For Automobile EngineerDokument7 SeitenPass Marks: - 40: Detail Syllabus For Automobile EngineerSaurav AdhikariNoch keine Bewertungen

- 6 Arb ObdDokument43 Seiten6 Arb ObdGIUSEPPENoch keine Bewertungen

- Pump MaintenanceDokument155 SeitenPump Maintenancemohamed abd eldayem100% (2)

- 15HE38E-Condition Monitoring of High Votage Power Apparatus Unit I - IndroductionDokument3 Seiten15HE38E-Condition Monitoring of High Votage Power Apparatus Unit I - IndroductionjananiNoch keine Bewertungen

- MaintenanceDokument8 SeitenMaintenanceDanish IqbalNoch keine Bewertungen

- Common Rail Direct InjectionDokument60 SeitenCommon Rail Direct InjectionSapari VelNoch keine Bewertungen

- Automotive Computer ControlledDokument54 SeitenAutomotive Computer ControlledtselothaiilemariamNoch keine Bewertungen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Matlab SimulinkDokument42 SeitenMatlab SimulinkBrian FreemanNoch keine Bewertungen

- Analog Input: Device SpecificationsDokument14 SeitenAnalog Input: Device SpecificationsBrian FreemanNoch keine Bewertungen

- The First Window That Pops Up Is The Library: BrowserDokument26 SeitenThe First Window That Pops Up Is The Library: BrowserBrian FreemanNoch keine Bewertungen

- 10 1 1 124 9636 PDFDokument11 Seiten10 1 1 124 9636 PDFBrian FreemanNoch keine Bewertungen

- Typical Performance Graphs: Figure 1. Settling Error Versus Time For Different Source ImpedancesDokument13 SeitenTypical Performance Graphs: Figure 1. Settling Error Versus Time For Different Source ImpedancesBrian FreemanNoch keine Bewertungen

- Tentative Course List July 2017Dokument15 SeitenTentative Course List July 2017Brian FreemanNoch keine Bewertungen

- What Is Manufacturing?Dokument3 SeitenWhat Is Manufacturing?Brian FreemanNoch keine Bewertungen

- Mechanical Handbook PDFDokument4 SeitenMechanical Handbook PDFBrian FreemanNoch keine Bewertungen

- A New Piezodriven Precision Micropositioning Stage Utilizing Flexure HingesDokument1 SeiteA New Piezodriven Precision Micropositioning Stage Utilizing Flexure HingesBrian FreemanNoch keine Bewertungen

- Emp 006Dokument2 SeitenEmp 006Brian FreemanNoch keine Bewertungen

- Adaptive Control For Piezo-Actuated Nano-Positioner: Xinkai ChenDokument6 SeitenAdaptive Control For Piezo-Actuated Nano-Positioner: Xinkai ChenBrian FreemanNoch keine Bewertungen

- Amirkabir University of Technology, Tehran, Iran University of BirminghamDokument6 SeitenAmirkabir University of Technology, Tehran, Iran University of BirminghamBrian FreemanNoch keine Bewertungen

- Full 62625Dokument10 SeitenFull 62625Brian FreemanNoch keine Bewertungen

- Fabrication of Actuator For Nanopositioning Using Laser Micro-MachiningDokument4 SeitenFabrication of Actuator For Nanopositioning Using Laser Micro-MachiningBrian FreemanNoch keine Bewertungen

- 3 Sighting Through (Bore Sighting)Dokument1 Seite3 Sighting Through (Bore Sighting)Brian FreemanNoch keine Bewertungen

- Shaft Alignment Guide - E-Jan05Dokument12 SeitenShaft Alignment Guide - E-Jan05Brian FreemanNoch keine Bewertungen

- 1 Propulsion Shaft Alignment: SectionDokument5 Seiten1 Propulsion Shaft Alignment: SectionBrian FreemanNoch keine Bewertungen

- SSC Je Mechanical Papers JQmV4Dokument4 SeitenSSC Je Mechanical Papers JQmV4Brian Freeman50% (2)

- Project 1 PDFDokument70 SeitenProject 1 PDFBrian Freeman100% (3)

- Shaft Alignment Guide - E-Jan05Dokument21 SeitenShaft Alignment Guide - E-Jan05Brian FreemanNoch keine Bewertungen

- Chapters Page No.: AcknowledgementDokument7 SeitenChapters Page No.: AcknowledgementBrian FreemanNoch keine Bewertungen

- V470 Compt Wise Equips From HODokument2 SeitenV470 Compt Wise Equips From HOBrian FreemanNoch keine Bewertungen

- ProjectDokument20 SeitenProjectBrian FreemanNoch keine Bewertungen

- Ship Design & Construction - SNAMEDokument9 SeitenShip Design & Construction - SNAMEBrian FreemanNoch keine Bewertungen

- 103 PipenetDokument23 Seiten103 PipenetLucious LightNoch keine Bewertungen

- A Natural Gas Fired Duplex Stirling For Domestic RefrigeratiDokument11 SeitenA Natural Gas Fired Duplex Stirling For Domestic RefrigeratiditoNoch keine Bewertungen

- Spekteknis Portable Residual Stress AnalyzerR1Dokument2 SeitenSpekteknis Portable Residual Stress AnalyzerR1RYHAN PRATAMANoch keine Bewertungen

- Grade 8 Science Matter Questions or ResearchDokument2 SeitenGrade 8 Science Matter Questions or Researchleon08jayNoch keine Bewertungen

- Metric Tolerance Chart PDFDokument6 SeitenMetric Tolerance Chart PDFSinan Yıldırım100% (1)

- 1st Monthly ExamDokument8 Seiten1st Monthly ExamRaven AvoNoch keine Bewertungen

- Thermoplastic Composites1Dokument90 SeitenThermoplastic Composites1NounaNoch keine Bewertungen

- Fluid Mechanics Theory and DesignDokument158 SeitenFluid Mechanics Theory and DesignWONG TSNoch keine Bewertungen

- Advanced Micro & Nano Systems: Dhiman Mallick Department of Electrical Engineering, IIT DelhiDokument24 SeitenAdvanced Micro & Nano Systems: Dhiman Mallick Department of Electrical Engineering, IIT DelhisajanNoch keine Bewertungen

- Reservoir SimDokument39 SeitenReservoir SimsereptNoch keine Bewertungen

- Alumina Matrix in RefractoriesDokument5 SeitenAlumina Matrix in RefractoriesSans SenNoch keine Bewertungen

- High Field MRIDokument66 SeitenHigh Field MRIMilena RakinNoch keine Bewertungen

- CHEM 10.01 I Mod 2 AssessementDokument1 SeiteCHEM 10.01 I Mod 2 AssessementAntonio Luis BanzonNoch keine Bewertungen

- DNV Rudder, Steering Gear, Anchoring, Mooring PDFDokument50 SeitenDNV Rudder, Steering Gear, Anchoring, Mooring PDFDian Arina100% (1)

- Theromodynamics 1Dokument14 SeitenTheromodynamics 1UPSC GEOGRAPHYNoch keine Bewertungen

- Marine Lubricating OilDokument15 SeitenMarine Lubricating OilAbdallah Mansour100% (2)

- Gen Relativity Modules 6 7 8Dokument6 SeitenGen Relativity Modules 6 7 8Joshua BermoyNoch keine Bewertungen

- Porous Carriers 2021 BROCHURE 1Dokument15 SeitenPorous Carriers 2021 BROCHURE 1anshul2106Noch keine Bewertungen

- Chapter 2 - Work, Energy and Power - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatDokument85 SeitenChapter 2 - Work, Energy and Power - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatskjNoch keine Bewertungen

- General Ser Vice Ball Valves: GB SeriesDokument13 SeitenGeneral Ser Vice Ball Valves: GB SeriesRyan DuhonNoch keine Bewertungen

- Maxifloor MFT 323 SL Epoxy CoatingDokument2 SeitenMaxifloor MFT 323 SL Epoxy CoatinganggaNoch keine Bewertungen

- 546 - PHE-02 - ENG D18 - Compressed PDFDokument4 Seiten546 - PHE-02 - ENG D18 - Compressed PDFDominator GamingNoch keine Bewertungen

- Slab Moment of ResistanceDokument4 SeitenSlab Moment of ResistanceSyed KashifNoch keine Bewertungen

- Structural Design and Analysis of FPSO Topside Module SupportsDokument10 SeitenStructural Design and Analysis of FPSO Topside Module Supportscaic351b100% (1)

- Smart Fibres Technology Introduction PDFDokument5 SeitenSmart Fibres Technology Introduction PDFKavya ShivakumarNoch keine Bewertungen

- Analysis of Building With Soft Storey During EarthquakeDokument5 SeitenAnalysis of Building With Soft Storey During EarthquakeKausalya PurushothamanNoch keine Bewertungen

- Welded Joint, Welded ConnectionsDokument45 SeitenWelded Joint, Welded ConnectionsRaju Sharma67% (12)

- System Dynamics and Response 1st Edition Kelly Solutions ManualDokument27 SeitenSystem Dynamics and Response 1st Edition Kelly Solutions Manualsusanschroederoqdrkxtafn100% (14)

- IND0078Dokument5 SeitenIND0078rajit kumarNoch keine Bewertungen