Beruflich Dokumente

Kultur Dokumente

Fabric Finish

Hochgeladen von

textile028Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fabric Finish

Hochgeladen von

textile028Copyright:

Verfügbare Formate

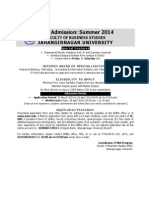

Textile Finishing

Bangladesh University of Business and

Technology (BUBT)

Permanent Campus Plot # 77-78 Road # 9 Rupnagar Mirpur-2,

Dhaka-1216

Name: Mohammad Billal Hossain (mohon)

Program: B.Sc. In Textile Engineering

Id: 10112107028

Intake :2nd

Section -1

Bangladesh University of Business and

Technology (BUBT)

Dept. of Textile Engineering

Finishing

Introduction

Textile finishing is a term commonly applied to different process that the

textile material under go after pretreatment, dyeing or printing for final

embellishment to enhance there attractiveness and sale appeal as well as

for comfort and usefulness.

Objects of finishing:

The aim of finishing is to render textile goods fit for their purpose or

end use. Besides that, finishing can be done for achieving the following

purposesa) To improve fabric attractiveness.

-By modification of fabric appearance (Calendaring, Optical

brightening)

-By altering fabric handle (Softening, Stiffening)

-Control of fabric dimension (Sanforising, Compacting)

b) To improve service ability.

-Protection of fabric (Flame proofing, Water proofing)

-Improved performance (Water repellency, Raising)

-Easy care properties (Resin finish, Crease recovery)

Textile Finishes are classified in several ways:

Classification of Textile Finishing

According to Function

Functional

Finishes

Aesthetic

Finishes

Aesthetic Finishes modify

the appearance and /or hand

or drape of the fabrics.

Functional Finishes improve

the performance properties of

the fabric ; like durability,

strength etc.

Mercerization

Napping And Sueding

Shearing

Softening

Stiffening

Antimicrobial/Antiseptic

Crease resistant

Durable Press

Flame Resistant

Mothproof

Shrinkage Control

Soil Release

Water Proof/Repellant

Classification of Textile Finishing

According to the quality

Temporary

A finish which is not

stable and goes off

after the first wash is

known as temporary

finish and these

finishes disappears

during subsequent

washing and usage.

Calendaring

Embossing

Starching

Softening

Permanent

Semi

Permanent

A Finishing on the

fabric is said to be semi

permanent finish if it is

stable to more than 5 to

10 washes and not

afterwards.

Schreiner

Calendaring

Buckram Finish

If the finishing effect in

the fabric does not

disappear and remains

unaffected through all

the conditions of wear

and washing treatments,

then the finish is said to

be permanent finish.

Sanforising

Resin Finish

Water Proof

Flame Proof

Classification of Textile Finishing

According to type of machinery

Chemical

Finishes

Chemical finishes are

usually applied to fabric by

padding followed by curing

and drying. These are also

called as wet Finishes.

Flame Retardant

Soil Release

Water Proof

Crease Resistance

Softening

Mechanical

Finishes

Mechanical Finishes

usually involved specific

physical treatment to a

fabric surface to cause a

change in fabric

appearance. This is also

known as dry finish.

Calendaring

Raising

Sanforising

Mechanical Finishing

Calendaring

Calendaring is defined as the modification of the surface of a fabric by

the action of heat and pressure. The finish is obtained by passing the

fabric between heated rotating rollers (Smooth or Engraved) when both

speed of rotation and pressure applied are variable.

Objects of Calendaring

To improve the fabric handle

and to impart a smooth silky

touch to the fabric.

To compress the fabric and

reduce its thickness.

To reduce the air

permeability by closing the

threads.

To increase the luster.

To reduce the yarn slippage.

Surface patterning by

embossing.

Mechanical Finishing

Brushing

The process which is used to remove loose threads and short

fibre ends from smooth-surfaced fabrics and is also used to

raise a nap on knits and woven fabrics is called Brushing.

Brushing is frequently applied to fabrics after shearing,

removing the cut fibres that have fallen into the nap.

Mechanical Finishing

Singeing

Singeing is a process applied to both yarns and fabrics to

produce an even surface by burning off projecting fibres,

yarn ends, and fuzz. This is accomplished by passing the

fibre or yarn over a gas flame or heated copper plates at a

speed sufficient to burn away the protruding material

without scorching or burning the yarn or fabric.

Mechanical Finishing

Tentering,

These are final processes applied to set the warp and weft of

woven fabrics at right angles to each other, and to stretch and

set the fabric to its final dimensions. Tentering stretches width

under tension by the use of a tenter frame, consisting of

chains fitted with pins or clips to hold the selvages of the

fabric, and travelling on tracks.

Mechanical Finishing

Raising

1. Napping

Using wire-covered rolls to "dig out" individual fiber ends

to the surface

2. Sueding

Using abrasive-covered rolls (sandpaper, emery cloth, etc.)

to produce shorter pile surface - does cause an apparent shade change.

Special type of raised surface fabric is corduroy

Sueding, sanding- creates softer hand of fabric.

Heat Setting

Heat Setting: Heat setting of synthetic fabrics eliminates the internal tensions

within the fiber generated during manufacture and the new state can be fixed

by rapid cooling.

This heat setting fixes the fabrics in the relaxed state and thus avoids

subsequent shrinkage or creasing of fabric. Presetting of goods make it possible

to use higher temperature for setting without considering the sublimation

properties of dyes and also has a favorable effect on dyeing behavior and

running properties of goods.

SOFT FINISH:

Chemical Finishing

Softening is the complex phenomenon and is composite of surface

smoothness and internal lubrication of the fiber elements of the treated fabric.

There are many softening agent used in industries such as:

Wetting agent

Acetic acid (for neutralization)

Non-ionic polyethylene softener

Slightly cationic softener

Silicon softener

Chemical Finishing

HARD FINISH:

In case of hard finish, it is desirable to make the fabric

stiffer and give them more body by filling certain

chemicals:

Wetting agent

Acetic acid (for neutralization)

Non-ionic polyethylene softener

Slightly cationic softener

Silicon softener

Hardeners

RESIN FINISH:

The resin finish is also know as crease recovery treatments

the objective of resin finish to remove the wrinkles or crease

from the fabric by certain chemicals.

Wetting agent

Acetic acid (for neutralization)

Non-ionic polyethylene softener

Slightly cationic softener

Silicon softener

Resin

Catalyst ( mgcl2)

Chemical Finishing

Mercerization

Mercerization is a treatment for cotton fabric and thread that

gives fabric a lustrous appearance. The process is applied to

materials like cotton or hemp. Mercerization alters the

chemical structure of the cotton fibre. The structure of the

fibre changes from alpha-cellulose to beta-cellulose.

Mercerizing results in the swelling of the cell wall of the

cotton fibre. This causes increases in the surface area and

reflectance, and gives the fiber a softer feel.

Chemical Finishing

Fire Resistant finishes:

Polyester fabrics can be made flame

resistant by treatment with an aqueous

emulsion

of

xylene

soluble

2,3dibromopropyl phosphate in a pad-cure

sequence. A semi-permanent effect can be

produced by treating with a mixture of

ammonium bromide and brominated

phosphoric acid esters.

Anti-microbial finishes:

With the increasing use synthetic fibbers for

carpets and other materials in public places, antimicrobial finishes have assumed importance. Anti

microbial finish Eco-friendly anti microbial

finishing agent for cotton fabrics & Garments.

Das könnte Ihnen auch gefallen

- Cutting Management: Facilitated byDokument11 SeitenCutting Management: Facilitated bytextile028Noch keine Bewertungen

- Finishing Evaluation: Others StatusDokument9 SeitenFinishing Evaluation: Others Statustextile028Noch keine Bewertungen

- Feederstripeautoengineeringstripe 170922050923Dokument6 SeitenFeederstripeautoengineeringstripe 170922050923textile028100% (1)

- QualityDokument7 SeitenQualitytextile028Noch keine Bewertungen

- Productspec 180275arain 002 02 Dress&Dismatic (PVT) Ltd. (Al-Muslimgroup) Imran LCWDokument19 SeitenProductspec 180275arain 002 02 Dress&Dismatic (PVT) Ltd. (Al-Muslimgroup) Imran LCWtextile028Noch keine Bewertungen

- CSMDokument13 SeitenCSMtextile028Noch keine Bewertungen

- Supply Chain Management - 08Dokument4 SeitenSupply Chain Management - 08textile028Noch keine Bewertungen

- Introduction To Work Study George Kanawaty 4edDokument542 SeitenIntroduction To Work Study George Kanawaty 4edtextile028100% (2)

- Types of Knit FabricDokument10 SeitenTypes of Knit Fabrictextile028Noch keine Bewertungen

- 9 MQM Meeting September-17Dokument55 Seiten9 MQM Meeting September-17textile028Noch keine Bewertungen

- Types of FabricsDokument32 SeitenTypes of Fabricstextile028Noch keine Bewertungen

- Kpis For Apparel Manufacturing 171201185847Dokument17 SeitenKpis For Apparel Manufacturing 171201185847textile028100% (1)

- Marker PlaningDokument11 SeitenMarker Planingtextile028100% (1)

- PantoneDokument5 SeitenPantonetextile028Noch keine Bewertungen

- ImsDokument74 SeitenImstextile028Noch keine Bewertungen

- TrishnaDokument43 SeitenTrishnatextile028Noch keine Bewertungen

- Basic Knowlage of MarchandisingDokument10 SeitenBasic Knowlage of Marchandisingtextile028Noch keine Bewertungen

- IE QuestionDokument2 SeitenIE Questiontextile028Noch keine Bewertungen

- Karthika M Dev: Soft (Nift, Pune)Dokument57 SeitenKarthika M Dev: Soft (Nift, Pune)textile028Noch keine Bewertungen

- Main Copy of IADokument126 SeitenMain Copy of IAtextile028Noch keine Bewertungen

- Industrial AttachDokument139 SeitenIndustrial Attachtextile028Noch keine Bewertungen

- AttachmentDokument116 SeitenAttachmenttextile028Noch keine Bewertungen

- 2014 Advertisement PDFDokument1 Seite2014 Advertisement PDFtextile028Noch keine Bewertungen

- Cad/Cam/Cim: Presented by N.N.V. Krishna Kanth I Mba AlietDokument18 SeitenCad/Cam/Cim: Presented by N.N.V. Krishna Kanth I Mba Aliettextile028Noch keine Bewertungen

- Organization of American StatesDokument22 SeitenOrganization of American Statestextile028Noch keine Bewertungen

- Smart Textiles - Technology and Application Fields: Dipl.-Ing. Klaus ScheulenDokument24 SeitenSmart Textiles - Technology and Application Fields: Dipl.-Ing. Klaus Scheulentextile028Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Beauty Idioms Synonyms and Collocations PDFDokument5 SeitenBeauty Idioms Synonyms and Collocations PDFMinaEmadNoch keine Bewertungen

- A Heartbreaking Work of Staggering Genius LessonplanDokument229 SeitenA Heartbreaking Work of Staggering Genius LessonplanMahmoud El SheikhNoch keine Bewertungen

- WorldTex Fashion MediaDokument2 SeitenWorldTex Fashion MediaSayed Pranto AhmadNoch keine Bewertungen

- JCR Vol. 08 No. 02: Symposium On The AtonementDokument245 SeitenJCR Vol. 08 No. 02: Symposium On The AtonementChalcedon Foundation100% (2)

- Future Player's Companion - Tomorrows' Foundation PDFDokument44 SeitenFuture Player's Companion - Tomorrows' Foundation PDFKevin Lee Elam100% (3)

- An Ecofeminist Reading of The Winter's TaleDokument21 SeitenAn Ecofeminist Reading of The Winter's TaleFerna Navarro LatorreNoch keine Bewertungen

- BG 15.15 - Krsna Is Source of Knowledge Remembrance & ForgetfulnessDokument1 SeiteBG 15.15 - Krsna Is Source of Knowledge Remembrance & ForgetfulnessSiddharth Hosangadi - Sridamasakha dasNoch keine Bewertungen

- The Cambridge Encyclopedia of The English Language 2nd EditionDokument265 SeitenThe Cambridge Encyclopedia of The English Language 2nd EditionТамара Волошина95% (20)

- Vidal - Allover India - Network Hospital ListDokument48 SeitenVidal - Allover India - Network Hospital ListSRINIVASARAO JONNALANoch keine Bewertungen

- Egyptian Gods & Mythology - Hollywood SubliminalsDokument10 SeitenEgyptian Gods & Mythology - Hollywood SubliminalsVen GeanciaNoch keine Bewertungen

- Standard 6 Scheme of Work Term 2Dokument25 SeitenStandard 6 Scheme of Work Term 2JOSEPH MWANGINoch keine Bewertungen

- Falling Scales Chapter Two - SAS - CoDDokument39 SeitenFalling Scales Chapter Two - SAS - CoDCWOD100% (1)

- Lab NetworkDokument9 SeitenLab NetworkPro NebyuNoch keine Bewertungen

- St. Croix County Property Transfers For Jan. 4-10, 2021Dokument39 SeitenSt. Croix County Property Transfers For Jan. 4-10, 2021Michael BrunNoch keine Bewertungen

- Empire State of Mind New York by Alicia Keys Worksheet Templates Layouts - 102594Dokument5 SeitenEmpire State of Mind New York by Alicia Keys Worksheet Templates Layouts - 102594Cristina DiezNoch keine Bewertungen

- Plastic Parts & Tooling Surface Finish - VDI 3400Dokument4 SeitenPlastic Parts & Tooling Surface Finish - VDI 3400Selvaraj BalasundramNoch keine Bewertungen

- What Are The Elements of A BiographyDokument3 SeitenWhat Are The Elements of A BiographyEstelle Nica Marie Dunlao100% (2)

- Newbies2#1 Surprisesinkorean:Wow!Ilove Surprises, Too!: LessonnotesDokument6 SeitenNewbies2#1 Surprisesinkorean:Wow!Ilove Surprises, Too!: LessonnotesMaverickNoch keine Bewertungen

- LAM Circular and HDR QuestionsDokument38 SeitenLAM Circular and HDR QuestionszamsiranNoch keine Bewertungen

- Abad Members-List-As-On-1-9-2018 PDFDokument100 SeitenAbad Members-List-As-On-1-9-2018 PDFSameer ShahNoch keine Bewertungen

- Jenna Ellis - Bio Chart OwDokument4 SeitenJenna Ellis - Bio Chart Owapi-481050334Noch keine Bewertungen

- Paleography BibliographyDokument5 SeitenPaleography BibliographyNabil RoufailNoch keine Bewertungen

- Invisible Sun - We Begin at The End (2018!06!25)Dokument20 SeitenInvisible Sun - We Begin at The End (2018!06!25)Ignacio Peralta100% (3)

- Bach - 6f.embellishments VIIDokument8 SeitenBach - 6f.embellishments VIIPailo76Noch keine Bewertungen

- Children's Sabbath 2012Dokument2 SeitenChildren's Sabbath 2012paheadbandNoch keine Bewertungen

- Appendix I - List of Prescribed Books PDFDokument9 SeitenAppendix I - List of Prescribed Books PDFShruthi MuralidharNoch keine Bewertungen

- Goan Social StudyDokument37 SeitenGoan Social StudyKushal RaoNoch keine Bewertungen

- Gre Analogies: A Racket Is Used To Play TennisDokument9 SeitenGre Analogies: A Racket Is Used To Play TennisaslamzohaibNoch keine Bewertungen

- MGH SRM 1 2Dokument473 SeitenMGH SRM 1 2Julia VershininaNoch keine Bewertungen

- Donuts by The Dozen: Word SearchDokument3 SeitenDonuts by The Dozen: Word Searchamornrat kampitthayakulNoch keine Bewertungen