Beruflich Dokumente

Kultur Dokumente

The Electrical Output of Pressure Transducers: Millivolt, Voltage, and 4-20mA

Hochgeladen von

siksac1230 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten11 Seitengrsc

Originaltitel

Pressure Guages

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldengrsc

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten11 SeitenThe Electrical Output of Pressure Transducers: Millivolt, Voltage, and 4-20mA

Hochgeladen von

siksac123grsc

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 11

Pressure

Transducer

Converts pressure into an analog electrical signal, which is

achieved by the physical deformation of strain gages which are

bonded into the diaphragm of the pressure transducer and wired

into a wheatstone bridge configuration. Pressure applied to the

pressure transducer produces a deflection of the diaphragm which

introduces strain to the gages. The strain will produce an

electrical resistance change proportional to the pressure. One of

the most common is the strain-gage base transducer.

11/18/15

The Electrical Output of Pressure

Transducers

Pressure transducers are generally available with three

types of electrical output

Millivolt

Volt and

4-20mA

Millivolt Output Pressure

Transducers

Are normally the most economical.

The output is nominally around 30mV.

The actual output is directly proportional to the input

power or excitation. If the excitation fluctuates, the

output changes.

Because the output signal is so low, the transducer

should not be located in an electrically noisy

environment.

The distances between the transducer and the readout

instrument should also be kept relatively short.

Voltage Output Pressure

Transducers

Include integral signal conditioning which provide a

much higher output than a millivolt transducer.

The output is normally 0-5Vdc or 0-10Vdc.

Because they have a higher level output these

transducers are not as susceptible to electrical noise as

millivolt transducers and can therefore be used in

much more industrial environments.

4-20 mA Output Pressure

Transducers

Since a 4-20mA signal is least affected by electrical

noise and resistance & are best used for long

distances.

It is not uncommon to use these transducers in

applications where the lead wire must be 1000 feet or

more

Styles of Pressure Transducers

PC Board Mountable Pressure Transducers

are generally compact economical pressure

transducers designed to mount on an electrical PC

board and be integrated into other products

General Purpose Transducers

General purpose pressure transducers are the most

common since they are designed to fit the broadest set of

applications

Heavy Duty/Industrial Pressure

Transducers

Feature a much more rugged enclosure than other

transducers.

They are designed to accommodate heavy industrial

environments.

4-20mA output provides much greater immunity to electrical

noise in industrial environments .

High Stability/High Accuracy

Pressure Transducers

An accuracy of 0.25% of full scale or higher.

High stability and high accuracy can offer errors as low

as 0.05% of full scale

Although more expensive than general purpose

transducers, they may be the only option if high precision

is required.

Flush Diaphragm Pressure

Transducers

With flush diaphragm pressure transducers, the

diaphragm is flush to the process. This eliminates a

cavity above the diaphragm that could collect fluid

matter from the process.

Those applications include monitoring the pressure of

foods or liquids that have very high viscosity

Special Purpose Transducers

These include pressure transducers specially designed for

pressure measurement in very high or low temperatures,

submersible pressure transducers, barometric pressure

transducers and pressure transducers with digital

communications output or wireless outputs.

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Organic Pigments - The Basics - SII - Dec 2008Dokument298 SeitenOrganic Pigments - The Basics - SII - Dec 2008Prince Jannisari100% (1)

- 2018 STAAR Gr5 Science TestDokument7 Seiten2018 STAAR Gr5 Science TestEngineerKhandaker Abid RahmanNoch keine Bewertungen

- Transmitter and Smart TransmitterDokument57 SeitenTransmitter and Smart TransmitterBHAGSEN PARVATNoch keine Bewertungen

- What Is Pressure TransducerDokument54 SeitenWhat Is Pressure TransducerMuhammad Ukasha100% (1)

- TransmittersDokument15 SeitenTransmittersAarkayChandru100% (1)

- Review of a simple adjustable power supply using linear and switching componentsDokument4 SeitenReview of a simple adjustable power supply using linear and switching componentsramesh ranjitNoch keine Bewertungen

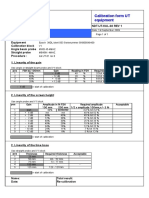

- Calibration Sheet Ultrasonic Test EquipmentDokument1 SeiteCalibration Sheet Ultrasonic Test EquipmentjohnNoch keine Bewertungen

- Hendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFDokument930 SeitenHendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFÂn HồngNoch keine Bewertungen

- Potential and Current TransformersDokument12 SeitenPotential and Current TransformersSyed Muhammad Munavvar Hussain80% (10)

- Types of Pressure Transducers and Gauges: Diaphragm, Bourdon Tube, Strain GaugeDokument23 SeitenTypes of Pressure Transducers and Gauges: Diaphragm, Bourdon Tube, Strain GaugesafvanshaikhNoch keine Bewertungen

- Transformer types and applicationsDokument20 SeitenTransformer types and applicationsnabeel hassan ali100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentVon EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentBewertung: 4.5 von 5 Sternen4.5/5 (3)

- 9 InsulatorDokument39 Seiten9 InsulatorLeo KhkNoch keine Bewertungen

- Voltage Regulator Catalog enDokument16 SeitenVoltage Regulator Catalog ensunny_2502Noch keine Bewertungen

- Difference Between Vacuum Circuit Breaker & Vacuum ContactorDokument2 SeitenDifference Between Vacuum Circuit Breaker & Vacuum ContactorMohan K67% (3)

- Malaviya National Institute of Technology, Jaipur: Submitted To-Dr. Shiv Om MeenaDokument15 SeitenMalaviya National Institute of Technology, Jaipur: Submitted To-Dr. Shiv Om MeenaMukund BiyaniNoch keine Bewertungen

- Instrumentation and Power Training: Pressure InstrumentsDokument27 SeitenInstrumentation and Power Training: Pressure InstrumentsAfzal AsifNoch keine Bewertungen

- Chemical Engineering - 2010-04 (April)Dokument100 SeitenChemical Engineering - 2010-04 (April)Staszek BanachNoch keine Bewertungen

- Sampling TechniquesDokument17 SeitenSampling TechniquesDebjyoti SanyalNoch keine Bewertungen

- Chapter 8 EXERGYDokument37 SeitenChapter 8 EXERGYzabidullahNoch keine Bewertungen

- Lightening Arrester: Substation Equipment and Its FunctionDokument8 SeitenLightening Arrester: Substation Equipment and Its FunctionSunny KatariaNoch keine Bewertungen

- Pressure TransducersDokument12 SeitenPressure Transducersamit kumarNoch keine Bewertungen

- Pressure GuagesDokument6 SeitenPressure GuageselrajilNoch keine Bewertungen

- The Do S and Don Ts of Pressure TransducersDokument5 SeitenThe Do S and Don Ts of Pressure TransducersShankar PediredlaNoch keine Bewertungen

- Distinguishing Between The Ashcroft Transmitters and Ashcroft Transducers.20140405.054518Dokument2 SeitenDistinguishing Between The Ashcroft Transmitters and Ashcroft Transducers.20140405.054518subway1sodaNoch keine Bewertungen

- Pertemuan-12 Transmisi SinyalDokument23 SeitenPertemuan-12 Transmisi SinyalDery DewantaraNoch keine Bewertungen

- Pressure Measuring Instruments: Dr. Fahad Rehman CUI, Lahore CampusDokument69 SeitenPressure Measuring Instruments: Dr. Fahad Rehman CUI, Lahore CampusAhmed Mustafa100% (1)

- Pressure Transducers Group 1Dokument28 SeitenPressure Transducers Group 1Marjorie BandibasNoch keine Bewertungen

- What Is The Difference Between A Pressure Transducer and A TransmitterDokument2 SeitenWhat Is The Difference Between A Pressure Transducer and A TransmittermalimilojeNoch keine Bewertungen

- Pressure Transducer Selection GuideDokument5 SeitenPressure Transducer Selection Guidegeninho3Noch keine Bewertungen

- Passive Tuned Harmonic FiltersDokument4 SeitenPassive Tuned Harmonic FiltersRajendra Prasad Shukla100% (1)

- CMicrotek 50 Nano Ampere Current Probe - UCP1x0 - Probe - FlierDokument2 SeitenCMicrotek 50 Nano Ampere Current Probe - UCP1x0 - Probe - FliernicefireworkNoch keine Bewertungen

- Flow TransmittersDokument22 SeitenFlow TransmittersArwismal RizkyNoch keine Bewertungen

- What Is A Pressure Transmitter ?: Differential Pressure Pressure Measuring InstrumentDokument11 SeitenWhat Is A Pressure Transmitter ?: Differential Pressure Pressure Measuring InstrumentPriNoch keine Bewertungen

- Current TransformerDokument6 SeitenCurrent TransformerGourav KumarNoch keine Bewertungen

- BM235-Manual-EEVblog Revision 18 August 2017Dokument33 SeitenBM235-Manual-EEVblog Revision 18 August 2017Sergio austraNoch keine Bewertungen

- Supplemental Guide: Pressure Switch ProductsDokument12 SeitenSupplemental Guide: Pressure Switch Productsing_vic1Noch keine Bewertungen

- Electronic Pressure SensorsDokument5 SeitenElectronic Pressure Sensorsmcbmcb159Noch keine Bewertungen

- 4-20ma Current LoopsDokument7 Seiten4-20ma Current LoopsRavi BiradarNoch keine Bewertungen

- Control TransformerDokument3 SeitenControl TransformerlehuanNoch keine Bewertungen

- Dixell Fan Speed Controller Setup and Wiring GuideDokument2 SeitenDixell Fan Speed Controller Setup and Wiring GuidedbricchiNoch keine Bewertungen

- NI Tutorial 6940 enDokument6 SeitenNI Tutorial 6940 enOleksandr HusievNoch keine Bewertungen

- Sub Station Eq Circuit-BDokument13 SeitenSub Station Eq Circuit-BChandra Prakash JainNoch keine Bewertungen

- TAPCON230Dokument6 SeitenTAPCON230Rafat ThongNoch keine Bewertungen

- MR Transformer 14 ENG VBack2 SCRDokument14 SeitenMR Transformer 14 ENG VBack2 SCRRafat ThongNoch keine Bewertungen

- College of Oil and Gas Engineering Chemical and Refining Dep EngDokument11 SeitenCollege of Oil and Gas Engineering Chemical and Refining Dep EngMohammad G NaserNoch keine Bewertungen

- UntitledDokument7 SeitenUntitledAnonymous iQMKqMqqWNoch keine Bewertungen

- H.T. Transformer With Built in H.T. Automatic Voltage Stabilizer (Transformer With Built in AVR)Dokument11 SeitenH.T. Transformer With Built in H.T. Automatic Voltage Stabilizer (Transformer With Built in AVR)gpsamNoch keine Bewertungen

- NI Tutorial 5448Dokument4 SeitenNI Tutorial 5448Fane PelinNoch keine Bewertungen

- 5988 5511enDokument8 Seiten5988 5511enthangaraj_icNoch keine Bewertungen

- Notes StudyDokument48 SeitenNotes StudySureshraja9977Noch keine Bewertungen

- (I) Resistive, (Ii) Inductive, (Iii) Capacitive, (Iv) Piezo-Electric TransducersDokument4 Seiten(I) Resistive, (Ii) Inductive, (Iii) Capacitive, (Iv) Piezo-Electric Transducersamritsaikias4Noch keine Bewertungen

- Selecting and Using Transducers For The Measurement of Electric Power, Voltage, and CurrentDokument34 SeitenSelecting and Using Transducers For The Measurement of Electric Power, Voltage, and CurrentPAUL BALLARTANoch keine Bewertungen

- DC Regulated Power Supply (Transformer)Dokument21 SeitenDC Regulated Power Supply (Transformer)Regie BuenaflorNoch keine Bewertungen

- Industrial Rectifier BrochureDokument12 SeitenIndustrial Rectifier Brochure666667Noch keine Bewertungen

- GE-Instrument Transformer InstallationDokument5 SeitenGE-Instrument Transformer InstallationmiveyNoch keine Bewertungen

- Digital Micro-Ohm Meter Model 53C Specifications and Operation GuideDokument6 SeitenDigital Micro-Ohm Meter Model 53C Specifications and Operation Guideilesh22Noch keine Bewertungen

- SBOA169ADokument3 SeitenSBOA169Abookreader1968Noch keine Bewertungen

- 132 KV SubstationDokument12 Seiten132 KV SubstationAnonymous HyOfbJ6Noch keine Bewertungen

- Transformer FAQsDokument1 SeiteTransformer FAQsamitdhamija100% (1)

- XV105D Fan Speed Controller: General Warning 1.1 Please Read Before Using This Manual 5 Direct and Inverse ActionDokument2 SeitenXV105D Fan Speed Controller: General Warning 1.1 Please Read Before Using This Manual 5 Direct and Inverse ActionJennifer Eszter SárközyNoch keine Bewertungen

- Power AssignmentDokument8 SeitenPower AssignmentHaseeb AdilNoch keine Bewertungen

- Harmonic Mitigating Transformers InformationDokument3 SeitenHarmonic Mitigating Transformers InformationJoseph B Delos ReyesNoch keine Bewertungen

- BSNL TTA Sample Paper 10Dokument11 SeitenBSNL TTA Sample Paper 10konsamNoch keine Bewertungen

- Logical DeductionDokument8 SeitenLogical Deductionsiksac123Noch keine Bewertungen

- Sitting Arrangement (Part - 1)Dokument6 SeitenSitting Arrangement (Part - 1)siksac123Noch keine Bewertungen

- PercentageDokument16 SeitenPercentageSindhu GunaNoch keine Bewertungen

- Sentence CompletionDokument7 SeitenSentence Completionsiksac123Noch keine Bewertungen

- Lko/Kku Jgs Ges"Kk Uke Ls Feyrh&Tqyrh QTHZ Lko/Kku Jgs Ges"Kk Djs Uke Ls Feyrh&Tqyrh QTHZ Website LsDokument1 SeiteLko/Kku Jgs Ges"Kk Uke Ls Feyrh&Tqyrh QTHZ Lko/Kku Jgs Ges"Kk Djs Uke Ls Feyrh&Tqyrh QTHZ Website Lssiksac123Noch keine Bewertungen

- 5 - EconomyDokument15 Seiten5 - EconomyRaja SekharNoch keine Bewertungen

- Minor ProjectDokument23 SeitenMinor Projectsiksac123Noch keine Bewertungen

- Interview QuestionsDokument4 SeitenInterview QuestionsRamakant SharmaNoch keine Bewertungen

- Wireless and Mobile CommunicationsDokument23 SeitenWireless and Mobile CommunicationsRavikumaar RayalaNoch keine Bewertungen

- AnalogyOdd One OutSeriesDokument7 SeitenAnalogyOdd One OutSeriessiksac123Noch keine Bewertungen

- RTDDokument10 SeitenRTDsiksac123Noch keine Bewertungen

- Level SensorsDokument15 SeitenLevel SensorselrajilNoch keine Bewertungen

- Date Sheet M.Tech. 3rd Sem Jan-16 PDFDokument2 SeitenDate Sheet M.Tech. 3rd Sem Jan-16 PDFsiksac123Noch keine Bewertungen

- Load CellsDokument9 SeitenLoad Cellssiksac123Noch keine Bewertungen

- Alternating Current - Wikipedia, The Free EncyclopediaDokument9 SeitenAlternating Current - Wikipedia, The Free Encyclopediasiksac123Noch keine Bewertungen

- NetwokingDokument11 SeitenNetwokingsiksac123Noch keine Bewertungen

- AC Motor - Wikipedia, The Free EncyclopediaDokument11 SeitenAC Motor - Wikipedia, The Free Encyclopediasiksac123Noch keine Bewertungen

- Programming Examples: in This Chapter. - .Dokument14 SeitenProgramming Examples: in This Chapter. - .siksac123Noch keine Bewertungen

- Alternating Current - Wikipedia, The Free EncyclopediaDokument9 SeitenAlternating Current - Wikipedia, The Free Encyclopediasiksac123Noch keine Bewertungen

- Sine Wave - Wikipedia, The Free EncyclopediaDokument4 SeitenSine Wave - Wikipedia, The Free Encyclopediasiksac123Noch keine Bewertungen

- Biomedical InstrumentationDokument10 SeitenBiomedical InstrumentationintelinsideocNoch keine Bewertungen

- The Boolean Embassy - Rss LAD 3 - ANLG - ALARM - Total Rungs in File 5Dokument3 SeitenThe Boolean Embassy - Rss LAD 3 - ANLG - ALARM - Total Rungs in File 5Min AdhikariNoch keine Bewertungen

- Electrical Resistance and Conductance - Wikipedia, The Free EncyclopediaDokument10 SeitenElectrical Resistance and Conductance - Wikipedia, The Free Encyclopediasiksac123Noch keine Bewertungen

- Sine Wave - Wikipedia, The Free EncyclopediaDokument4 SeitenSine Wave - Wikipedia, The Free Encyclopediasiksac123Noch keine Bewertungen

- 3Dokument5 Seiten3siksac123Noch keine Bewertungen

- 3Dokument5 Seiten3siksac123Noch keine Bewertungen

- Design of Fuzzy ControllersDokument27 SeitenDesign of Fuzzy ControllerssayedmhNoch keine Bewertungen

- RRB Section Engineer Question Paper 1Dokument34 SeitenRRB Section Engineer Question Paper 1Ganesh BabuNoch keine Bewertungen

- Chromatography Guide: Key Terms and Definitions for Adsorption ChromatographyDokument35 SeitenChromatography Guide: Key Terms and Definitions for Adsorption ChromatographyafdillenburgNoch keine Bewertungen

- Oxidative WearDokument17 SeitenOxidative WearManish Kumar SinghNoch keine Bewertungen

- Grade 12 Chemistry Activity SheetsDokument6 SeitenGrade 12 Chemistry Activity SheetsKrizlyn MondalaNoch keine Bewertungen

- SPM 4551 2006 Biology k2 BerjawapanDokument15 SeitenSPM 4551 2006 Biology k2 Berjawapanpss smk selandarNoch keine Bewertungen

- Fresher Course Chemistry Practice ProblemsDokument2 SeitenFresher Course Chemistry Practice ProblemsHarsh Agarwal0% (1)

- What Is The Major Function of The Coating On An Arc Welding ElectrodeDokument7 SeitenWhat Is The Major Function of The Coating On An Arc Welding ElectrodeElham Jaraine Garcia Lpt100% (4)

- Chemical StabilizationDokument63 SeitenChemical Stabilizationanahita_63100% (1)

- Everything StarsDokument166 SeitenEverything StarsBilly The KidNoch keine Bewertungen

- How To Process and Print Black-and-White FilmDokument6 SeitenHow To Process and Print Black-and-White FilmPepParamosNoch keine Bewertungen

- b28113433 PDFDokument202 Seitenb28113433 PDFJuthika GogoiNoch keine Bewertungen

- MBW Report SF6 Gas Analysis PDFDokument6 SeitenMBW Report SF6 Gas Analysis PDFNaveenNavabNoch keine Bewertungen

- Specification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelDokument4 SeitenSpecification For Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelmalsttarNoch keine Bewertungen

- Ap T68 06 PDFDokument98 SeitenAp T68 06 PDFTauseef HassanNoch keine Bewertungen

- Insulation Resistance Test and Oil Test of Distribution TransformerDokument6 SeitenInsulation Resistance Test and Oil Test of Distribution TransformerBash MatNoch keine Bewertungen

- Scaffold in Tissue EngDokument13 SeitenScaffold in Tissue EngOluwasegun ModupeNoch keine Bewertungen

- P Block Short NotesDokument22 SeitenP Block Short Notesthapliyaldivyanshu274Noch keine Bewertungen

- Different Forms of Corrosion - Intergranular Corrosion - Weld DecayDokument2 SeitenDifferent Forms of Corrosion - Intergranular Corrosion - Weld DecayHarry NuryantoNoch keine Bewertungen

- Distillation Column Tray Selection & Sizing - 1 - Separation TechnologiesDokument18 SeitenDistillation Column Tray Selection & Sizing - 1 - Separation TechnologiesOmesh Borole100% (1)

- Super Day-Tone 3030 MSDSDokument4 SeitenSuper Day-Tone 3030 MSDSeslam sokaNoch keine Bewertungen

- Flowserve Lined Flush BottomDokument32 SeitenFlowserve Lined Flush BottomDevdatt WaghuleNoch keine Bewertungen

- Introduction to Rearrangement Reactions (40Dokument14 SeitenIntroduction to Rearrangement Reactions (40Chandra ReddyNoch keine Bewertungen

- 5-1-14 Recueil Methodes Vol 1 en 2012Dokument488 Seiten5-1-14 Recueil Methodes Vol 1 en 2012James Quynh NguyenNoch keine Bewertungen

- Design For Environment PDFDokument20 SeitenDesign For Environment PDFAnonymous 7bsvkAEloNoch keine Bewertungen