Beruflich Dokumente

Kultur Dokumente

Bruker S1 V1-2 Overview New Functions

Hochgeladen von

Ayleen Núñez CalderónCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bruker S1 V1-2 Overview New Functions

Hochgeladen von

Ayleen Núñez CalderónCopyright:

Verfügbare Formate

S1 TITAN

Bruker S1 Software

Version 1.2

27.11.15

Innovation with Integrity

Application Scientist by Territory

North America

South America

Therese Howe

Asia

Jun Choi

China Jiyan Gu

Others Erkki Puusaari

EMEA

Scandinavia - Erkki Puusaari

Others Philippe Meynard

Version 1.2 Added Features

Extensive changes to Grade ID

Boot time progress bar

First result time faster

Timeout now under Supervisor control

Computer/Display Sleep mode disabled

Limit sets by material type

New color scheme

All applications have set defaults in application files

Bottom Button row moved up for easier access

Happy Trigger Test disabled for benchtop stand use

GPS Via Bluetooth for Dual XGPS150

V1.2 Grade ID Changes

Change Grade ID algorithm to include N*STD

Beam 1/Beam 2 definitions

Display elements <LOD

Nominal chemistry processing

Tramp/Residual Processing

Grade Match Number >9.99 shown as EXACT

Improved control of multiple grade display

Version 1.2 Bugs Fixed

Results Display stalling fixed

Results Display does not blank

SMARTGrade timing fixed (note: min time 3 sec)

IR Proximity sensor is global and survives a reboot

Remote Control is enabled by default

Numeric input starting with decimal point

Display N in +/- column header

Language list alphabetized

Corrected operation and display of Use Default Settings checkbox

Faster Data Display

Application Alloy and SMART Grade - in phase 1 the first data

packet is processed and then discarded

Application Alloy and SMART Grade - in phase 2 the second data

packet is processed (as opposed to the third in V1.1)

This results in first grade and assay in about 2.2 sec vs. 3.2 sec in

V1.1

This is controlled at the factory level and can be modified by changes

in the application file

Application Auxiliary Alloy uses the V1.1 timing

NOTE: Application upgrades are separate from the Software Upgrade

Timeout Setting

Auto Logout timing is now set by

the supervisor

Instrument goes to Log-in Screen

after the set number of minutes

Zero prevents auto logout

This screen is Utilities => System

Setup

Sleep mode has been disabled

7

Limit Sets by Material

IEC 62321 require different limit

values for Metals, Polymer, Composite

Software links material type to

calibration within Restricted Materials

Application

Metals => Metals

Polymer => Plastic Low /Plastic High

Composite => Mid Density

Selecting IEC Limits sets the proper

limits for IEC 62321

Note: IEC Limits cannot be changed

Limit Sets by Material

For use with applications other than

Restricted Materials select

Unknown and edit the list as

before

Materials Metals, Polymer,

Composite will have no effect in

other Applications

Applications defaults

Each application has its own set of

settings ex. Data acquisition timing,

Measurement timing, display settings

etc.

These defaults are set when loading

Applications

Your Applications engineer will

ensure that the defaults are set

properly when your unit is updated

10

Display Settings

Add <LOD Check box

When checked any element

analyzed which has an assay

<N*STD will be reported as

<LOD on screen

STD Display Limit

Sets N*STD for Grade ID and

Limit testing

Can be set from 1 to 5

Grade ID Settings

11

Grade ID calculation

Now includes +/- N*STD

Note: N is now displayed in

column header

Range definitions expanded to

include uncertainty

Yellow colored elements do not

reduce Grade Match Number

12

Enable LOD Display

When enabled all elements

analyzed are listed

Elements with assay first

with appropriate coloring

Elements with assay <LOD

(e.g. N*STD) are listed in

order at the end of the

screen

Note: all elements are reported

as <LOD in results.csv

regardless of setting of flag

13

Enable LOD Display

Known Bug

When <LOD

not enabled,

Assay at

<LOD will not

be displayed

even if

defined in the

Grade

Definition

14

Grade ID Settings

Use Color Coding

Enable Tramp\Residual Element

Processing

Enable Nominal Chemistry

Display Multiple Alloy Grades

Match Quality Threshold

Multiple Grade Threshold

15

Tramp/Residual Element

Add Tramp/Residual processing

Grade Library defines class

When assay is >Tramp limit it is

displayed as >TR with assay and

limit and is colored red the

assay is considered in the Match

Number

Table on instrument defines

Tramp level by class

When assay is <Tramp limit it is

displayed as <TR with assay and

limit the assay is NOT

considered in the Match Number

16

Tramp/Residual Element

NOTE: Tramp/Residual

processing has the potential of

changing the Grade ID,

especially when low

concentrations define the

difference ex. 304/321

IF you have trouble with Grade

ID, please try running w/o

Tramp/Residual Enabled and

send the report both ways

17

Nominal Chemistry

On Phase 1

When enabled

When flag set in Grade Library

The average of the light

elements is calculated from

grade definition

The total is subtracted from

100

The remaining assay is

normalized to that value

Average of light elements

definition displayed with blue

background

18

Display Multiple Grades

When enabled will list up to

three grades which match

closely

Multiple Grade Threshold

determines how close the

grades must be to be listed

Recommended practice for

aluminum alloys as there are

many close grades with lots of

overlaps

19

Match Quality Threshold

Value determines what Grade

Match Number will be displayed

Default is 5

Any Grade Match Number <5

will result in No Match being

displayed

20

Grade Library

New Grade Library Format

Alloy Base used in grade processing

Tramp/Residual Class link to limits in Tramp/Residual lib

Alloy ID Text displayed in Grade Line

Nominal Use nominal processing for this alloy

Beam 1 Use this definition for Phase 1

Beam 2 Use this definition for Phase 2

Phase 1 Time SMART Grade time for Phase 1

Phase 2 Time SMART Grade time for Phase 2

First Grade Time SMART Grade time for first Grade display

Balance Element used in S1 Sync

Then Min/Max by element

21

Grade Library

Nominal Use nominal processing for this alloy

Used mainly in copper/nickel and titanium alloys

Not used for aluminum alloys

Beam 1 Use this definition for Phase 1

Beam 2 Use this definition for Phase 2

Most alloys are set for both phases

Many grades which are distinguished by light elements are

disabled for beam 1

In aluminum alloys several combined grades are defined for

beam 1

To remove alloy from Standardlib simply set both Beam 1 and Beam

2 to N

22

SMART Grade Library

SMART Grade

Phase 1 Time SMART Grade time for Phase 1

Phase 2 Time SMART Grade time for Phase 2

First Grade Time SMART Grade time for first Grade display

Values are set empirically by comparing chemistries of close alloys

Alloys which differ by Mg require longer phase 2 measurements; ex.

Mg>1% add 10 sec to Phase 2; Mg < 1% add 15-20 sec to phase 2

Alloys which contain light elements require Phase 2; ex. Ti alloys

take 5 sec on Phase 2

23

SMART Grade Library

Same format for both Standard and SMART Grade Libraries

Standardlib and SMART GRADE contain the same alloys with the

same definitions

In next release the difference will be transparent to the user

24

Changes in Results.csv

Method name stored (not Auto)

<LOD for all elements at that level (e.g. elements in calibration

where assay is <LOD e.g. <N*STD)

N*STD (Note: N is not specified to be changed in V1.3)

Gain Check Pass

Note: it is unlikely that a Pass will be seen in this column as such

a failure will stop the analyzer

25

Request for Feedback

This release represents MAJOR changes in the way Grade ID is

processed and displayed

We have done significant testing

I am sure that there are errors in the way it works

We have designed it the way that makes the most sense to us

I am sure that there are different ways to display the data in a more

meaningful way

26

Feedback Mechanism

Use the Bruker XRF Sales Forum

Under the General Forum find Software

Threads are established for each software product

One is Known Bugs

One is Bug Reports

PLEASE!! Send as much information as possible include *.pdz along

with measurement conditions or any other information you feel is

warranted.

27

GPS active

28

27. November 201

Copyright Bruker Corporation. All rights reserved

29

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Project Management Excel Templates - Action Item and Roadmap TemplatesDokument2 SeitenProject Management Excel Templates - Action Item and Roadmap TemplatesMurali MNoch keine Bewertungen

- 2.4. E-Commerce Payment Systems and Security IssuesDokument68 Seiten2.4. E-Commerce Payment Systems and Security IssuesNency ThummarNoch keine Bewertungen

- JMobile Training Day1 v16Dokument142 SeitenJMobile Training Day1 v16Vegard SømliøyNoch keine Bewertungen

- Smart Card ReadersDokument16 SeitenSmart Card ReadersNareshNvNoch keine Bewertungen

- DATA SCIENCE With DA, ML, DL, AI Using Python & R PDFDokument10 SeitenDATA SCIENCE With DA, ML, DL, AI Using Python & R PDFSaikumar ReddyNoch keine Bewertungen

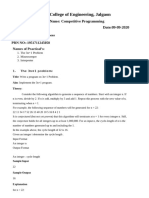

- Compititive Programming - I ManualDokument79 SeitenCompititive Programming - I ManualArun ChaudhariNoch keine Bewertungen

- Computer Science Revision NotesDokument26 SeitenComputer Science Revision Notesfiercesasha8808Noch keine Bewertungen

- Lib Burst GeneratedDokument8 SeitenLib Burst Generated関谷大成Noch keine Bewertungen

- Lenguaje EnsambladorDokument115 SeitenLenguaje EnsambladorFidel SalavarriaNoch keine Bewertungen

- Role of Mis in PlanningDokument3 SeitenRole of Mis in PlanningJjjo ChitimbeNoch keine Bewertungen

- 74 Ls 175Dokument8 Seiten74 Ls 175AndrescronqueNoch keine Bewertungen

- Space Vector PWM For PMSM Simulation UsiDokument4 SeitenSpace Vector PWM For PMSM Simulation UsiVictor IkechukwuNoch keine Bewertungen

- Real-Time De-Identification of Healthcare Data Using Ephemeral PseudonymsDokument5 SeitenReal-Time De-Identification of Healthcare Data Using Ephemeral PseudonymsInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- 4.melsec Q Process ControlDokument13 Seiten4.melsec Q Process ControlLeader OneNoch keine Bewertungen

- How Real (Floating Point) and 32-Bit Data Is Encoded in Modbus RTU Messages - Chipkin Automation SystemsDokument8 SeitenHow Real (Floating Point) and 32-Bit Data Is Encoded in Modbus RTU Messages - Chipkin Automation SystemsMochamad EffendiNoch keine Bewertungen

- Ravikant ManiDokument9 SeitenRavikant ManiDave JonesNoch keine Bewertungen

- Panasonic 3DO FZ-10 Service Manual (E, For UK)Dokument40 SeitenPanasonic 3DO FZ-10 Service Manual (E, For UK)AlessandroNoch keine Bewertungen

- Final Report The Platform Game MakerDokument69 SeitenFinal Report The Platform Game MakerMt SptNoch keine Bewertungen

- Philips Tpn15.2ela Chassis 312278519972 PDFDokument71 SeitenPhilips Tpn15.2ela Chassis 312278519972 PDFВячеслав Шевчук0% (1)

- RepDokument41 SeitenReppriyarajagopal_kNoch keine Bewertungen

- cs4410 Prelim1 Soln PDFDokument4 Seitencs4410 Prelim1 Soln PDFSherin OmranNoch keine Bewertungen

- Project ReportDokument29 SeitenProject ReportSathishkumarNoch keine Bewertungen

- ReleaseNote FileList of B1400CEAE 2009 X64 V2.01A LDokument7 SeitenReleaseNote FileList of B1400CEAE 2009 X64 V2.01A LMorosan AndreeaNoch keine Bewertungen

- 8051 BasicsDokument22 Seiten8051 BasicsviswapraveenNoch keine Bewertungen

- Gastritis: Free TemplatesDokument57 SeitenGastritis: Free TemplatesJonathanNoch keine Bewertungen

- Feroz Khan - ResumeDokument4 SeitenFeroz Khan - ResumeFeroz KhanNoch keine Bewertungen

- Curriculum Vitae: Ananto Danang WibowoDokument1 SeiteCurriculum Vitae: Ananto Danang WibowoDanangNoch keine Bewertungen

- Creating and Modifying Database TablesDokument71 SeitenCreating and Modifying Database TablesManal TaoufikiNoch keine Bewertungen

- BAdi2 For MM02Dokument14 SeitenBAdi2 For MM02raju221756_843567682100% (1)