Beruflich Dokumente

Kultur Dokumente

06 Heating Cooling

Hochgeladen von

recaiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

06 Heating Cooling

Hochgeladen von

recaiCopyright:

Verfügbare Formate

Grinding with Ball Mill Systems

Mill Ventilation

Heating & Cooling - Possibilities

Cooling in Separator

Mill Ventilation

Heating

HGRS

Cement

Coolers

Water

Injection

Tikaria_Mill

Workshop

2

SEPT-07

Heating and Cooling Units

Mill Ventilation

Water Injection

Heating

HGRS

Tikaria_Mill

Workshop

3

SEPT-07

Mill Ventilation - Objectives

Avoid the consequences of too high grinding

temperatures inside the mill (115 130 [C]):

HGRS

Material coating on balls and liners resulting in a

performance loss of 5 10 [%]

Cement false setting gypsum dehydration

Lump formation in the silos

Tikaria_Mill

Workshop

4

SEPT-07

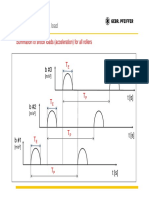

Mill Ventilation - Guidelines

False air

Filter dimensioned for 1.5 [m/s]

airspeed above the ball charge

Optimum mill ventilation is a

compromise between :

Fan

Material level in the first chamber

Mill outlet temperature

Filter dew point (T >25 30 [C])

Product fineness at the filter

Mill fresh air

False air

False air reduces the cooling

capacity of the mill tube

HGRS

Tikaria_Mill

Workshop

5

SEPT-07

Additional ventilation cooling possibilities

False air

Separator fresh air

Fan

Clinker

Mill fresh air

False air

Water

HGRS

Tikaria_Mill

Workshop

Cooler

6

SEPT-07

Separator fresh air

Separator fresh air

A single pass separator with 0.7 [m3/kg cement] can cool down

the cement at the mill outlet 30 40 [C].

The mill tube is cooled down through the lower temperature

separator rejects

A cyclone air separator only achieves marginal cooling of the

cement (5 10 [C])

HGRS

Tikaria_Mill

Workshop

7

SEPT-07

Heating and Cooling - Units

Mill Ventilation

Water Injection

Heating

HGRS

Tikaria_Mill

Workshop

8

SEPT-07

Water injection - Guidelines

1 [m3/h] water = 15000 30000 [m3/h] air in heat dissipation

Water acts like a grinding aid (mill capacity increase)

Water increases the air dew point (watch out starts & stops) must

maintain air temperature 25 to 30 oC higher than dew point in filter

Not more than 1.0 1.5 [%] water injection on total mill feed basis

Water

HGRS

Tikaria_Mill

Workshop

9

SEPT-07

Water injection - Systems

Water in 1st chamber only if mill feed > 100 [C] and oriented towards

the ball charge

If water is required in both chambers: 1/3 in the 1st chamber & 2/3 in

the 2nd chamber, starting in 2nd

HGRS

Tikaria_Mill

Workshop

10

SEPT-07

Water injection - Devices

HGRS

Tikaria_Mill

Workshop

11

SEPT-07

Standard Installation

HGRS

Tikaria_Mill

Workshop

12

SEPT-07

Water injection Control scheme

HGRS

Tikaria_Mill

Workshop

13

SEPT-07

Heating and Cooling - Units

Mill Ventilation

Water Injection

Heating

HGRS

Tikaria_Mill

Workshop

14

SEPT-07

Fresh feed moisture and mill performance

[t/h] dry

Clinker temperature &

proportion

Hot gas generator

maximum capacity

100

90

[%] H2O in fresh feed

HGRS

Tikaria_Mill

Workshop

15

SEPT-07

Dying wet components without hot gas

+/-

+/-

> 90 - 95 [C]

+

HGRS

Tikaria_Mill

Workshop

16

SEPT-07

Drying wet components with hot gas

+/-

+/-

+

> 90 - 95 [C]

+

HGRS

Tikaria_Mill

Workshop

17

SEPT-07

Drying wet components with hot gas

False air

Hot gas

+

Water steam

False air

Fan gas

= Fan gas

False air

Water

steam

Hot gas

False air

HGRS

Tikaria_Mill

Workshop

18

SEPT-07

Hot gas generator

Fuel type

Nozzle adapted to the

operating range

Control

Hot gas generator type

(start/stop sequences)

HGRS

Tikaria_Mill

Workshop

19

SEPT-07

Drying wet components in a drying chamber

Parameters to play with in a drying chamber:

HGRS

Gas flow path

Material trajectory

Material retention time

Tikaria_Mill

Workshop

20

SEPT-07

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Superior Performance Through Innovative Technology - VEGA IndustriesDokument72 SeitenSuperior Performance Through Innovative Technology - VEGA IndustriesNael50% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Gebr. Pfeiffer Brochure Passion For Grinding enDokument28 SeitenGebr. Pfeiffer Brochure Passion For Grinding enRollerJonnyNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Heat AnalysisDokument33 SeitenHeat AnalysisirfanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- 01 Polycom Design-OverviewDokument72 Seiten01 Polycom Design-OverviewJesus Manuel Juarez Mamani100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- High Pressure Grinding RollsDokument42 SeitenHigh Pressure Grinding RollsSebastian100% (1)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Ball Charge ManagementDokument14 SeitenBall Charge ManagementrecaiNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Roller Mill FundamentalsDokument11 SeitenRoller Mill Fundamentalshidrastar123100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Mps MillDokument4 SeitenMps MillRahul RoyNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- OK Mill Symposuim Indonesia2Dokument69 SeitenOK Mill Symposuim Indonesia2Joko Dewoto100% (3)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Heat Balance GrindingDokument13 SeitenHeat Balance GrindingAbhijeet JhankalNoch keine Bewertungen

- NM, NP Raw Mill Semen Padang2Dokument272 SeitenNM, NP Raw Mill Semen Padang2Emel100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shock Load Roller MillDokument1 SeiteShock Load Roller MillrecaiNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Loesche Round Table VICATDokument20 SeitenLoesche Round Table VICATrecaiNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Vertical Mill CalculationsDokument11 SeitenVertical Mill Calculationssaravana kumarNoch keine Bewertungen

- Cement Raw Material Grinding VerticalDokument1 SeiteCement Raw Material Grinding VerticalrecaiNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Mill Ventilation MeasurementDokument5 SeitenMill Ventilation MeasurementBùi Hắc HảiNoch keine Bewertungen

- VRM Operation and OptimizationDokument39 SeitenVRM Operation and OptimizationrecaiNoch keine Bewertungen

- 5 - Energy ConsiderationChristian Pfeiffer Products 20110824Dokument42 Seiten5 - Energy ConsiderationChristian Pfeiffer Products 20110824Bülent BulutNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Vertical Mill PresesntationDokument54 SeitenVertical Mill PresesntationrecaiNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Roller Press FL Smidth PDFDokument27 SeitenRoller Press FL Smidth PDFThaigroup Cement100% (10)

- Bab 2 Raw Mill System DG VRMDokument80 SeitenBab 2 Raw Mill System DG VRMrecai100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Enduron High Pressure Grinding Rolls HPGR Product BrochureDokument27 SeitenEnduron High Pressure Grinding Rolls HPGR Product BrochurerecaiNoch keine Bewertungen

- Rotary Dryer HandbookDokument34 SeitenRotary Dryer Handbook11331490% (10)

- Energies 12 00829Dokument22 SeitenEnergies 12 00829recaiNoch keine Bewertungen

- Grinding Theory SentDokument27 SeitenGrinding Theory SentShakil AhmadNoch keine Bewertungen

- Lubricants: A Practical Approach To Gear Design and Lubrication: A ReviewDokument21 SeitenLubricants: A Practical Approach To Gear Design and Lubrication: A ReviewESTEBANNoch keine Bewertungen

- Reducing Agent of Cr6for Portland CementDokument8 SeitenReducing Agent of Cr6for Portland CementrecaiNoch keine Bewertungen

- FlenderDokument384 SeitenFlenderAnis Kurniawati100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Introduction To Vertical Roller MillDokument35 SeitenIntroduction To Vertical Roller MillrecaiNoch keine Bewertungen

- Purchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ADokument11 SeitenPurchasing Process Models Inspiration For Teac 2019 Journal of Purchasing ASunita ChayalNoch keine Bewertungen

- Aitkensmethod 170829115234Dokument17 SeitenAitkensmethod 170829115234Yumi koshaNoch keine Bewertungen

- Ballsim DirectDokument58 SeitenBallsim DirectDiego GaliciaNoch keine Bewertungen

- Slab Culvert Irc 21 Irc 112Dokument5 SeitenSlab Culvert Irc 21 Irc 112Rupendra palNoch keine Bewertungen

- Basic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYDokument17 SeitenBasic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYPrincess RonsableNoch keine Bewertungen

- Practicality and Efficiency: Presented By: Grace EscabasDokument11 SeitenPracticality and Efficiency: Presented By: Grace EscabasMiaeNoch keine Bewertungen

- Elephant Catalog V13 PDFDokument96 SeitenElephant Catalog V13 PDFsamuelNoch keine Bewertungen

- Thing in Itself Kantian: AnstoßDokument1 SeiteThing in Itself Kantian: Anstoßwhynotbequiet23Noch keine Bewertungen

- Student Camps 2022 - Grade 6 Science Curriculum Based Test BookletDokument58 SeitenStudent Camps 2022 - Grade 6 Science Curriculum Based Test Bookletthank you GodNoch keine Bewertungen

- Best Actor and Actress Adjudication Rubric 41950cb9a3Dokument3 SeitenBest Actor and Actress Adjudication Rubric 41950cb9a3Sarah Jhoy SalongaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Module 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary StressDokument10 SeitenModule 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary Stressفردوس سليمانNoch keine Bewertungen

- Pdlgfu15: PDLGFU15 User's GuideDokument327 SeitenPdlgfu15: PDLGFU15 User's Guidejose antonio carazoNoch keine Bewertungen

- TOEFL - Longman TOEFL-534-540Dokument7 SeitenTOEFL - Longman TOEFL-534-540Diah Agustina RatuNoch keine Bewertungen

- Procedure Issuing EtaDokument5 SeitenProcedure Issuing EtaCarlos FrançaNoch keine Bewertungen

- Asl Scroll Wuxi 2hp - 8hp 2930719180Dokument142 SeitenAsl Scroll Wuxi 2hp - 8hp 2930719180Roy MokNoch keine Bewertungen

- Pre-Placement Training Program: Sample Profiling (All About You)Dokument2 SeitenPre-Placement Training Program: Sample Profiling (All About You)RISHAV RAJ GUPTANoch keine Bewertungen

- 027 03 Dec13 CseDokument647 Seiten027 03 Dec13 CseParth NagarNoch keine Bewertungen

- NC1 AC Contactor, 9 95A: Contactors ContactorsDokument2 SeitenNC1 AC Contactor, 9 95A: Contactors ContactorsYamendra GurungNoch keine Bewertungen

- 78-SAFETY - QUESTIO in PDFDokument21 Seiten78-SAFETY - QUESTIO in PDFIndermohan MehtaNoch keine Bewertungen

- IB Biology Lab Report TemplateDokument6 SeitenIB Biology Lab Report TemplatebigbuddhazNoch keine Bewertungen

- AquaMapPublic v202Dokument26 SeitenAquaMapPublic v202engfeupNoch keine Bewertungen

- Microprocessor Lab ManualDokument36 SeitenMicroprocessor Lab ManualsivagamasundhariNoch keine Bewertungen

- Fashion Design and Product DevelopmentDokument6 SeitenFashion Design and Product DevelopmentYona Tasya AzizieNoch keine Bewertungen

- Bantilan Maureen Lhee RDokument8 SeitenBantilan Maureen Lhee RAlexa Anne Louise BercillaNoch keine Bewertungen

- Cultural Diversity in Vikram Seth's A Suitable Boy'Dokument3 SeitenCultural Diversity in Vikram Seth's A Suitable Boy'Sneha PradhanNoch keine Bewertungen

- I. Company Data 1.1. Company ProfileDokument19 SeitenI. Company Data 1.1. Company ProfileMhy AcajaNoch keine Bewertungen

- FLIGHT Punta Arenas - SantiagoDokument3 SeitenFLIGHT Punta Arenas - SantiagoАртем ПичугинNoch keine Bewertungen

- TSS Training Package Implementation Guidefinal 0Dokument18 SeitenTSS Training Package Implementation Guidefinal 0hanabbecharaNoch keine Bewertungen

- AbstractDokument1 SeiteAbstractJignesh PrajapatiNoch keine Bewertungen