Beruflich Dokumente

Kultur Dokumente

Pmi Program Review: Raymond de Weever May 4, 2009

Hochgeladen von

Raymond de Weever0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten9 SeitenPMI program started in June 2004 Twelve (12) process units were PMI'd. Out of 36,811 locations, 3,641 were identified as non-conformances. 1,384 were identified as low grade (3.8%)

Originalbeschreibung:

Originaltitel

PMI012809.ppt

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenPMI program started in June 2004 Twelve (12) process units were PMI'd. Out of 36,811 locations, 3,641 were identified as non-conformances. 1,384 were identified as low grade (3.8%)

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten9 SeitenPmi Program Review: Raymond de Weever May 4, 2009

Hochgeladen von

Raymond de WeeverPMI program started in June 2004 Twelve (12) process units were PMI'd. Out of 36,811 locations, 3,641 were identified as non-conformances. 1,384 were identified as low grade (3.8%)

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 9

PMI PROGRAM REVIEW

Raymond de Weever

May 4, 2009.

Refinery Wide PMI program

PMI program started in June 2004

Twelve (12) process units were PMId:

D1AR, D2AR, D3AR

V3AR

DC1AR, DC2AR

C5AR, C6AR, C7AR

H1AR, H2AR, H3AR

Total locations inspected: 36,811

Out of the 36,811 locations, 3,641 were identified

as non-conformances. This is 9.9% of the total

number of locations that were PMIed. 1,384 were

identified as low grade (3.8%).

Refinery Wide PMI program

The main driver was to confirm the appropriate

material in the following services:

High Temperature Sulfidic Corrosion

High Temperature Hydrogen Attack (HTHA)

That covers 99% of application issues

PMI program was completed in December

2006

Refinery Wide PMI program

The other concern is the correct grade of S.S.

piping

PMI will not identify Carbon content, therefore effort

would be meaningless

With visual inspection stainless steel is easy to

identify vs. carbon steel and alloys, therefore

minimizing the chance of having a complete wrong

material

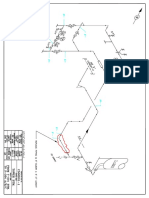

Refinery Wide PMI program

Refinery Wide PMI program

Current Status:

D1AR:

Except for thirty-four (34) Inconel small bore welds, there is

no other material issues

D2AR:

All low grade non-conformances were removed and repaired

D3AR:

Three (3) non-conformances are monitored (UT, RT). These

non-conformances consist of piping, blinds, flanges and

welds. Address non-conformances in next TA

H1AR:

All low grade non-conformances were addressed in 2006

H2AR:

All low grade non-conformances were addressed in 2007 TA

H3AR:

All low grade non-conformances were removed and repaired

Refinery Wide PMI program

Current Status:

DC1AR:

Sixteen (16) out of one-hundred-thirty-six (136) low grade nonconformances remained to be addressed. These consist of pipings,

welds, blinds and valves. The non-conformances are monitored

(UT, RT)

DC2AR:

All low grade non-conformances were removed and repaired

C5AR:

All low grade non-conformances (5) were submitted for removal

and repair during the 2010 TA

V3AR:

Ten (10) low grade non-conformances remained to be addressed.

Nine (9) have been addressed during the refurbishment. The nonconformances consist of piping, welds, blinds, valves and are

monitored (UT, RT)

C6AR:

All low grade non-conformances were removed and repaired

Refinery Wide PMI program

Starting 2004 Valero Inspection was requesting/

performing 100% PMI of all alloy material

However, as per Valero Specs,

heat numbers were used in order to identify correct

material

Only 10% of welds were to be PMId

Valero Engineering Spec has been modified in

June 2007 to require 100 % PMI of all alloy piping,

welds and components during pre-fab and

installation, in order to eliminate discrepancies.

Refinery Wide PMI program

Re-check all Inco welds on small bore piping for

correct metallurgy

UT/RT low grade materials to determine condition

once a year. Frequency will be increased

depending on findings

Develop a procedure (SP/SOP) to address a check

and balance in order to assure that all PMI issued

are properly identified and repaired during the

TAs

Include step in PSSR checklist requesting

Reliability Engineering & Inspection Managers

sign-off confirming PMI scope completion

Das könnte Ihnen auch gefallen

- Reliability, Maintainability and Risk: Practical Methods for Engineers including Reliability Centred Maintenance and Safety-Related SystemsVon EverandReliability, Maintainability and Risk: Practical Methods for Engineers including Reliability Centred Maintenance and Safety-Related SystemsBewertung: 4.5 von 5 Sternen4.5/5 (5)

- A Refinery Approach To Address Corrosion Under Insulation & External CorrosionDokument35 SeitenA Refinery Approach To Address Corrosion Under Insulation & External CorrosionIshan ShahNoch keine Bewertungen

- Mitigation of External Corrosion On Buried Pipeline SystemsDokument27 SeitenMitigation of External Corrosion On Buried Pipeline Systemshitm357Noch keine Bewertungen

- Sabp A 036Dokument40 SeitenSabp A 036RJSQ100% (2)

- IRIS - Finfans Inspection Report PDFDokument14 SeitenIRIS - Finfans Inspection Report PDFnaoufel1706Noch keine Bewertungen

- Safety and Health in Chemical IndustriesDokument18 SeitenSafety and Health in Chemical IndustriesPratik BhosaleNoch keine Bewertungen

- Completion Equipment Reliability Database Well Master SPE63112-PaperDokument7 SeitenCompletion Equipment Reliability Database Well Master SPE63112-PapervjourNoch keine Bewertungen

- 055 - Guidelines For NDT of GRP Pipe Systems and TanksDokument96 Seiten055 - Guidelines For NDT of GRP Pipe Systems and Tanksabdulwahabbaba67% (3)

- Dahlgren Division Naval Surface Warfare Center: NSWCDD/TR-12/68Dokument68 SeitenDahlgren Division Naval Surface Warfare Center: NSWCDD/TR-12/68skr2010Noch keine Bewertungen

- CP 9710 FR 01Dokument60 SeitenCP 9710 FR 01كشكووولNoch keine Bewertungen

- Riopipeline2019 1124 Worlds First Remote Deepwater PDFDokument10 SeitenRiopipeline2019 1124 Worlds First Remote Deepwater PDFMarcelo Varejão CasarinNoch keine Bewertungen

- Thermal Response of Vessels and Pipework Exposed To FireDokument141 SeitenThermal Response of Vessels and Pipework Exposed To FireAli AbbasovNoch keine Bewertungen

- Safety and Health in Chemical IndustriesDokument18 SeitenSafety and Health in Chemical IndustriesMubarak AhmadNoch keine Bewertungen

- Mitigation of Internal Corrosion in Oilfield Water PipelinesDokument28 SeitenMitigation of Internal Corrosion in Oilfield Water Pipelineshitm357Noch keine Bewertungen

- Inspect Electric9Dokument7 SeitenInspect Electric9Anonymous Wu6FDjbNoch keine Bewertungen

- An Analysis of International Tranformer Failure, Part 1Dokument4 SeitenAn Analysis of International Tranformer Failure, Part 1kfaliNoch keine Bewertungen

- Project Report On MS Pipe and TubeDokument9 SeitenProject Report On MS Pipe and TubeEIRI Board of Consultants and PublishersNoch keine Bewertungen

- Infrared Thermography at RefineriesDokument2 SeitenInfrared Thermography at Refineriesayviwurbayviwurb100% (1)

- D Cem1000 1001 Ops ADokument76 SeitenD Cem1000 1001 Ops Aawiverma789Noch keine Bewertungen

- Yim018x AnnualbookASTM StandardDokument14 SeitenYim018x AnnualbookASTM StandardMohammed Gabr AgamyNoch keine Bewertungen

- Iso Astm StandardDokument4 SeitenIso Astm StandardroellyNoch keine Bewertungen

- Instrumentation Design BasisDokument49 SeitenInstrumentation Design BasisJayesh Sangani100% (3)

- NBSP Indorama NBSP 2009 NBSP DraftDokument133 SeitenNBSP Indorama NBSP 2009 NBSP Draftkirandevi1981Noch keine Bewertungen

- Best Practice For The Assessment of Defects in Dents and Gouges PDFDokument26 SeitenBest Practice For The Assessment of Defects in Dents and Gouges PDFSharbel WgNoch keine Bewertungen

- Importance of Inspection For CorrosionDokument23 SeitenImportance of Inspection For CorrosionabyNoch keine Bewertungen

- Hydrostatic Test Procedure: Salalah Ammonia ProjectDokument6 SeitenHydrostatic Test Procedure: Salalah Ammonia ProjectAbdelkhak KhallaNoch keine Bewertungen

- Implementing A Corrosion Under Insulation ProgramDokument4 SeitenImplementing A Corrosion Under Insulation ProgramChelsea Skinner100% (1)

- Oin Ops Chem 003 Recommendations On Online InstrumentsDokument9 SeitenOin Ops Chem 003 Recommendations On Online InstrumentsraniNoch keine Bewertungen

- 2 Basics of Functional Safety in Process Industry A Practical Approach To IEC 61511 EN61511 SILDokument33 Seiten2 Basics of Functional Safety in Process Industry A Practical Approach To IEC 61511 EN61511 SIL최재호Noch keine Bewertungen

- University of Aberdeen - 15 - 5) Leak Sealing Technologies For The Oil & Gas IndustryDokument4 SeitenUniversity of Aberdeen - 15 - 5) Leak Sealing Technologies For The Oil & Gas IndustryAnonymous IUFzAW9wHGNoch keine Bewertungen

- Technical OfferDokument125 SeitenTechnical OfferPragathees WaranNoch keine Bewertungen

- Riopipeline2019 1117 Ibp1117 19 Versao Final para e PDFDokument8 SeitenRiopipeline2019 1117 Ibp1117 19 Versao Final para e PDFMarcelo Varejão CasarinNoch keine Bewertungen

- Distribution TransformersDokument17 SeitenDistribution Transformersvenkateswaran.M venkateswaran.MNoch keine Bewertungen

- Corrosion Under InsulationDokument4 SeitenCorrosion Under InsulationChem.EnggNoch keine Bewertungen

- General Requirements For Purchasing Valves (Project Standards and Specifications)Dokument5 SeitenGeneral Requirements For Purchasing Valves (Project Standards and Specifications)Azze DdineNoch keine Bewertungen

- QG 4935 - Discipline Inspectors E&I InspectionDokument4 SeitenQG 4935 - Discipline Inspectors E&I InspectionCao Mạnh CườngNoch keine Bewertungen

- Codigos y NormasDokument13 SeitenCodigos y NormasMaría MarquinaNoch keine Bewertungen

- CNG Tank SafetyDokument34 SeitenCNG Tank SafetyIan sajahNoch keine Bewertungen

- AFIC Company Profile 2021Dokument20 SeitenAFIC Company Profile 2021mohsenNoch keine Bewertungen

- Analysis of Large Reverse Osmosis MembranesDokument197 SeitenAnalysis of Large Reverse Osmosis MembranesYoussefNoch keine Bewertungen

- Riopipeline2019 1084 201906031458ibp1084 19 Combine PDFDokument9 SeitenRiopipeline2019 1084 201906031458ibp1084 19 Combine PDFMarcelo Varejão CasarinNoch keine Bewertungen

- Applitek - Detector in Vinyl Process PDFDokument24 SeitenApplitek - Detector in Vinyl Process PDFwiboonwiNoch keine Bewertungen

- Pressurized Water Reactor Steam Generator Lay-Up (Corrosion Evaluation)Dokument98 SeitenPressurized Water Reactor Steam Generator Lay-Up (Corrosion Evaluation)kangsungjinNoch keine Bewertungen

- PNABU386Dokument224 SeitenPNABU386Andrei HorhoianuNoch keine Bewertungen

- XVI Paper 25Dokument12 SeitenXVI Paper 25Costas AggelidisNoch keine Bewertungen

- Sewage and Graywater Flow Through Treatment Systems: Standard Specification ForDokument16 SeitenSewage and Graywater Flow Through Treatment Systems: Standard Specification ForDarwin DarmawanNoch keine Bewertungen

- Luwendran MoodleyDokument7 SeitenLuwendran MoodleyDante FilhoNoch keine Bewertungen

- Aramco-Candidate QuestionDokument5 SeitenAramco-Candidate Questionnafis2u100% (1)

- The Development of Corrosion Control Document (CCD) in Refinery: Crude Distillation Unit (CDU) ProcessDokument6 SeitenThe Development of Corrosion Control Document (CCD) in Refinery: Crude Distillation Unit (CDU) Processnktiah1207Noch keine Bewertungen

- Managing Ili ProjectsDokument13 SeitenManaging Ili ProjectsuncleflowerNoch keine Bewertungen

- VSFSGDokument1 SeiteVSFSGFtg WwfdfNoch keine Bewertungen

- Risk and Reliability MethodsDokument45 SeitenRisk and Reliability MethodsNatraji100% (1)

- IRIS - Boiler Tubes Inspection ReportDokument11 SeitenIRIS - Boiler Tubes Inspection Reportkoib789Noch keine Bewertungen

- Oil and Gas Pipelines: Integrity and Safety HandbookVon EverandOil and Gas Pipelines: Integrity and Safety HandbookNoch keine Bewertungen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesVon EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesBewertung: 5 von 5 Sternen5/5 (2)

- RELEASE: A Model with Data to Predict Aerosol Rainout in Accidental ReleasesVon EverandRELEASE: A Model with Data to Predict Aerosol Rainout in Accidental ReleasesNoch keine Bewertungen

- Pocket Guide to Preventing Process Plant Materials Mix-upsVon EverandPocket Guide to Preventing Process Plant Materials Mix-upsNoch keine Bewertungen

- Arubapay June2Dokument1 SeiteArubapay June2Raymond de WeeverNoch keine Bewertungen

- V-9901&V-9902 - Equity Cracks Report Dated Oct 06 PDFDokument3 SeitenV-9901&V-9902 - Equity Cracks Report Dated Oct 06 PDFRaymond de WeeverNoch keine Bewertungen

- Decision MakingDokument2 SeitenDecision MakingRaymond de WeeverNoch keine Bewertungen

- VAR Refinery Temporary Leak Repair Data For The April PSM Metrics Rev.BDokument85 SeitenVAR Refinery Temporary Leak Repair Data For The April PSM Metrics Rev.BRaymond de WeeverNoch keine Bewertungen

- Hotel BracelonaDokument3 SeitenHotel BracelonaRaymond de WeeverNoch keine Bewertungen

- SFAR1 2007 TA - Becht Engineering Report PDFDokument2 SeitenSFAR1 2007 TA - Becht Engineering Report PDFRaymond de WeeverNoch keine Bewertungen

- Chile Exchange FormsDokument2 SeitenChile Exchange FormsRaymond de WeeverNoch keine Bewertungen

- Poinsettia PavilionDokument13 SeitenPoinsettia PavilionRaymond de WeeverNoch keine Bewertungen

- Algebra ChicagoDokument1 SeiteAlgebra ChicagoRaymond de WeeverNoch keine Bewertungen

- 500 For SaudiEngDokument1 Seite500 For SaudiEngRaymond de WeeverNoch keine Bewertungen

- Arends Inspection ServicesDokument1 SeiteArends Inspection ServicesRaymond de WeeverNoch keine Bewertungen

- Family de Weever 7719-3 Pelicanstreet P.O. Box 5492 Saudi Aramco Najmah Compound Eastern ProvinceDokument1 SeiteFamily de Weever 7719-3 Pelicanstreet P.O. Box 5492 Saudi Aramco Najmah Compound Eastern ProvinceRaymond de WeeverNoch keine Bewertungen

- Dear BhanDokument1 SeiteDear BhanRaymond de WeeverNoch keine Bewertungen

- Viator ZagrebDokument5 SeitenViator ZagrebRaymond de WeeverNoch keine Bewertungen

- Singapore: A Unique Blend of Rich Cultures and The Modern WorldDokument10 SeitenSingapore: A Unique Blend of Rich Cultures and The Modern WorldRaymond de WeeverNoch keine Bewertungen

- API 571 Special Material ProblemsDokument6 SeitenAPI 571 Special Material ProblemsRaymond de Weever100% (1)

- Post T&i 2000 Hpb-8Dokument4 SeitenPost T&i 2000 Hpb-8Raymond de WeeverNoch keine Bewertungen

- ChinaDokument18 SeitenChinaRaymond de WeeverNoch keine Bewertungen

- VietnamDokument19 SeitenVietnamRaymond de WeeverNoch keine Bewertungen

- Czech RepublicDokument8 SeitenCzech RepublicRaymond de WeeverNoch keine Bewertungen

- NBIC and IR2 CertsDokument2 SeitenNBIC and IR2 CertsRaymond de WeeverNoch keine Bewertungen

- Poinsettia PavilionDokument13 SeitenPoinsettia PavilionRaymond de WeeverNoch keine Bewertungen

- Viator ZagrebDokument5 SeitenViator ZagrebRaymond de WeeverNoch keine Bewertungen

- Ireland: The Emerald IsleDokument8 SeitenIreland: The Emerald IsleRaymond de WeeverNoch keine Bewertungen

- HBP-9 SIS For EconomizerDokument11 SeitenHBP-9 SIS For EconomizerRaymond de WeeverNoch keine Bewertungen

- ResumeDokument3 SeitenResumeRaymond de WeeverNoch keine Bewertungen

- TS Chart - 04 - 01 - 2010Dokument1 SeiteTS Chart - 04 - 01 - 2010Raymond de WeeverNoch keine Bewertungen

- c5vb TML Due ScopeDokument2 Seitenc5vb TML Due ScopeRaymond de WeeverNoch keine Bewertungen

- VRC 43Dokument17 SeitenVRC 43Raymond de WeeverNoch keine Bewertungen

- C506D01-1 Model PDFDokument1 SeiteC506D01-1 Model PDFRaymond de WeeverNoch keine Bewertungen

- 4 Project Description: 4.1 Baiji RefineryDokument123 Seiten4 Project Description: 4.1 Baiji Refineryduraid ahmadNoch keine Bewertungen

- C-20 Petroleum Rules ActDokument13 SeitenC-20 Petroleum Rules Actnike_y2kNoch keine Bewertungen

- Past Paper Mutliple ChoiceDokument36 SeitenPast Paper Mutliple Choicevj4ktcskfdNoch keine Bewertungen

- Country Analysis Brief: Venezuela: Last Updated: November 25, 2015Dokument12 SeitenCountry Analysis Brief: Venezuela: Last Updated: November 25, 2015Anonymous HJZffHvTNoch keine Bewertungen

- Sabp A 001Dokument22 SeitenSabp A 001kuse2456Noch keine Bewertungen

- High Temperature CorrosionDokument9 SeitenHigh Temperature CorrosionnishilgeorgeNoch keine Bewertungen

- The Design of Onshore Civil WorksDokument8 SeitenThe Design of Onshore Civil Workskkkelvin50% (2)

- Syah Hafiz SIT Report PPM PDFDokument44 SeitenSyah Hafiz SIT Report PPM PDFchiang95Noch keine Bewertungen

- Nap Acid Paper FinalDokument18 SeitenNap Acid Paper Finalpapaya123Noch keine Bewertungen

- Global Ethylene Capacity Poised For Major Expansion - Oil & Gas JournalDokument9 SeitenGlobal Ethylene Capacity Poised For Major Expansion - Oil & Gas JournalcarlosapemNoch keine Bewertungen

- Unit 1 - Chemical Engineer and Chemical Engineering ProfessionDokument14 SeitenUnit 1 - Chemical Engineer and Chemical Engineering Professionvibbhavdchandan17Noch keine Bewertungen

- Australian Petroleum Statistics: Issue 258, January 2018Dokument40 SeitenAustralian Petroleum Statistics: Issue 258, January 2018Alia ShabbirNoch keine Bewertungen

- Condensate StabilizerDokument16 SeitenCondensate Stabilizern73686861Noch keine Bewertungen

- Whatever Is Updated and RevisedDokument14 SeitenWhatever Is Updated and RevisedWan Ah-LunNoch keine Bewertungen

- IndiaDokument11 SeitenIndiaMd Riz ZamaNoch keine Bewertungen

- General Specification For Material Inweth S ServiceDokument10 SeitenGeneral Specification For Material Inweth S Servicetomas budrysNoch keine Bewertungen

- Filtration in HydrotreatingDokument2 SeitenFiltration in Hydrotreatingck196548400% (1)

- Emergency Response & Disaster Management Plan and Best Practices at NRLDokument41 SeitenEmergency Response & Disaster Management Plan and Best Practices at NRLVinod ChaudhariNoch keine Bewertungen

- SIB Petrochemical 2018 ZZ V4Dokument15 SeitenSIB Petrochemical 2018 ZZ V4jane2127Noch keine Bewertungen

- TechnipFMC Wins A Large Contract For Vietnam-S Largest Olefins PlantDokument2 SeitenTechnipFMC Wins A Large Contract For Vietnam-S Largest Olefins Plantmuhammad ilyasNoch keine Bewertungen

- SMPS5103 Process Safety Management - Vapr2020Dokument243 SeitenSMPS5103 Process Safety Management - Vapr2020Manjit100% (1)

- FCC FundamentalsDokument68 SeitenFCC Fundamentalsvenkatraman1985100% (1)

- OIL REFINING PROCESSES Ver1 PDFDokument97 SeitenOIL REFINING PROCESSES Ver1 PDFHiếu NguyễnNoch keine Bewertungen

- Crude Oil Transport PDFDokument12 SeitenCrude Oil Transport PDFManuel GimenezNoch keine Bewertungen

- D6074 PDFDokument8 SeitenD6074 PDFCorina StanculescuNoch keine Bewertungen

- Refinery and Petrochemical Processing DistillationDokument18 SeitenRefinery and Petrochemical Processing Distillationrashid1986@hotmailNoch keine Bewertungen

- Technipfmc Ripple Tray Brochure Final Web 2019Dokument8 SeitenTechnipfmc Ripple Tray Brochure Final Web 2019Minh Quý LêNoch keine Bewertungen

- High TAN CrudesDokument7 SeitenHigh TAN Crudesmanassk100% (1)

- Delayed CokingDokument41 SeitenDelayed CokingtotpityiNoch keine Bewertungen

- Comparative Study of Financial Statements of Company, Oil and Gas.Dokument105 SeitenComparative Study of Financial Statements of Company, Oil and Gas.Ray Brijesh AjayNoch keine Bewertungen