Beruflich Dokumente

Kultur Dokumente

TRONXY P802MA Installation Guide v.04

Hochgeladen von

pisterCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TRONXY P802MA Installation Guide v.04

Hochgeladen von

pisterCopyright:

Verfügbare Formate

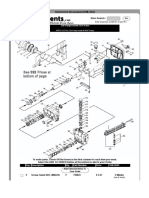

TRONXY 3D PRINTER

P802MA

INSTALLATION GUIDE

V.04

Classification Of Screws

M3 nuts 60pcs

M3*20mm Round

head screws 58pcs

M2.5*10mm black

screws 2pcs

M8 nuts 12pcs

M3*10mm inner

hexagon screws

17pcs

M3*30mm Flathead screws 7pcs

M8 Cushion ring

12pcs

M3*14mm Flathead screws 4pcs

Plastic Pillars 4pcs

Classification Of Screws

M4*15mm Round

head cross screws

12pcs

M3*30mm Flat

head screws 4pcs

Thumb nuts*4

Compression

springs*4

M3*20mm Round

head screws 4pcs

tep 1 Assemble Y-axis Motor

Fit the synchronous pulley on the motor, Locking

with M3*2mm jackscrew.

As the picture, Put Y-axis motor on <Y-axis motor

support> , locking with Four M3*10mm

screws.

Synchronous

pulley

Y-axis motor

M3*2mm

jackscrew

M3*10mm

inner hexagon

screws*4

Y-axis motor

support

p 2 Assemble Y-axis Limit switch

Put the Y-axis limit switch and the holder

together ,locking with two M3*20mm Round

head screws & nuts. As picture

M3*20mm

Round head

screws

Y-axis limit

switch

Y-axis limit

switch holder

(Acrylic)

M3 nuts

p 3 Assemble Base Frame Holder_Back

As the picture, put two of the

Sliding rod Restriction in front of

the base frame holder (back).

locking with two M3*20mm Round

head screws & nuts.

Sliding rod

Restriction

*2

M3*20m

m

screws

M3

nuts

Put the limit switch and holder

assembly on the base frame holder,

locking with one M3*20mm Round

head screw & nut.

Put Y-axis motor holder on base

frame holder ,locking with one

M3*20mm Round head screw &

nut.

Put Y-axis motor assembly on

base frame holder, locking with

three M3*20mm Round head

screws & nuts.

Y-axis limit

switch

assembly

Base frame

holder_Bac

k

Y-axis

motor

holder

Y-axis motor

assembly

p 4 Assemble Base Frame Holder_Front

As the picture, put two of the Sliding rod

Restriction in front of the base frame

holder _front. locking with two

M3*20mm Round head screws & nuts.

Put Y-axis belt pulley wheel assembly

behind the base frame holder, Locking with

two M3*20mm Round head screws &

nuts.

Base Frame

Holder_Front

Y-axis belt

pulley wheel

assembly

M3*20mm

Round head

Screws & nuts

Sliding rod

Restriction

*2

ep 5 Assemble Heat Bed Frame

Firstly fixed the Bed Frame and

M3 nuts fixed parts together

with M3*20mm. As picture below.

As the picture, put Aluminium

plate and heat bed together,

locking with four M3*30mm

screws & nuts.

Put three bearings under the

bed frame, locking with twelve

M4*15 Round head cross

screws.

Put four compression spring

between heat bed and the bed

frame. Next Top four thumb nuts

under the bed frame.

Thumb

nuts*4

Belt

clip

M3*20mm

Round

head cross

screws

Compressi

on

springs*4

M4*15mm

Round head

cross screws

*12

Bed

frame

M3*30m

m

screws*4

Bearing

*3

M3 nuts

Fixed

part

Aluminium

plate

Heat bed

M3

nuts

Step 6 Assemble Extruder (with Auto lev

Heat

sink

Metal

Block

U-Metal

plate

Motor &

Hotend

Cooler Fan

M3*22mm

cross

screws

Install Cooler Fan and Heat sink on the

Metal Block use 2pcs M3*22mm cross

screws .

Put Fan and Position Sensor Holder to the

U-Metal plate, and locking with 2pcs

M3*20mm and 1pcs M3*10mm Cross

screws ,as picture

Put the Position Sensor on the holder

Fan

,locking with 2pcs M3*22mm cross screws.

M3*10mm

cross

screws

M3*25mm

cross

screws

M3 Nuts

Position Sensor

Holder (Acrylic)

M3*22mm

cross

screws

Position

Sensor

ep 7 Assemble Z-axis motor

coupli

ng

Put two Z-axis motor

support(side) in two sides of the

motor, Cover the Z-axis motor

support(top) on the top, locking

with M3*20mm Round head

screws & nuts.

Z-axis motor

support(top)

M3*20mm

Round head

screws

M3*10mm

The cable of Z-axis motor is back of

the Z-axis motor support. Locking Zaxis motor with four M3*10mm

Inner hexagon screws.

Inner hexagon

Z-axis

screws

motor

support(sid

e)

Put the coupling on the motor,

locking with the jackscrews.

Another Z-axis motor is the same

assembly.

Z-axis

motor

Step 8 Assemble Z-axis

M3*20mm

Round head

screws

As the picture, Put the two Z-axis

motors assembly on the left and right

side of the Bottom plate, locking with

three M3*20mm screws & nuts.

Z-axis motor

assembly

Bottom

plate

M3

nuts

ep 9 Assemble Side plate

As the picture, Put the two Side

plate on the left and right side of

the Bottom plate , locking with

four M3*20mm screws & nuts.

Side plate

M3*20mm

Round head

screws

p 10 Assemble Top plate & Junction Plate

As the picture, Put the Top plate on

Side Plate, locking with four

M3*20mm screws & nuts.

Put the two Junction Plate on the

top of the Side plate ,locking with

four M3*20 screws & nuts.

Put two sliding rod restriction on

the top of left and right sides.

Locking with one M3*20mm Round

head screw & nut each.

Sliding

rod

restrictio

n

Junction Plate

Top

plate

M3*20mm

Round head

screws

ep 11 Install LCD display

Put the LCD display on the top of

the Top plate ,locking with three

M3*25mm flat_head screws

&nuts

LCD

display

assembly

M3

nuts

M3*25mm

Flat head

screws

Framewor

k (top

half)

ep 12 Install Power supply

Put Power supply on the right of

the side plate , locking with three

M3*14mm Flat_head screws

and nuts.

Side plate

Power

supply

M3*14mm

Flat_head

screw

p 13 Install PCBA Control Board

Install Control Board as picture ,

locking with Four M3*30mm Flat

head screws + 4pcs Plastic pillars

+ 4pcs M3 nuts

Plastic

Pillars*4

M3

Nuts*8

Control

Board

M3*30mm

Flat_head

Screws *4

Side

plate

p 14 Install Base frame holder_Back

Put the Base frame holder_back

back of Side plate, locking with

four M3*20mm Round head

screw

Base frame

holder_back

M3*16mm

Round head

screws*4

p 15 Install Base Frame Holder_Front

Through the Frame Holder_Front &

Back by two M8*400mm screw

arbors, locking with twelve M8 Nuts

& cushion ring.

M8

nuts

M8 cushion

ring

M8*400m

m screw

arbors

Base

frame

holder_fron

ep 16 Instal Platform Assembly

As the picture , through the

platform on the base by two of

M8*380mm Sliding rod. Fix both

end by Sliding rod restriction

Attention: Put the 1pcs

bearing on the hotbed on the

left side , and put the hotbed

wires on back side .

Platform

assembl

y

M8*380mm

sliding

rod*2

The 1pcs

bearing are

on this side

Sliding

rod

Restrictio

n

ep 17 Instal Y-axis Timing belt

As the picture, Lock one end of

the timing belt in belt clip ,

the other end through the Yaxis motor and belt pulley

wheel on the base frame

holder. Then tense the belt and

lock in the other belt clip with

M3*20mm Round head

screws & nuts.

Synchronous

pulley

Timing

belt

Belt

clip*2

M3*20mm

Round

head

screws

&nuts

Acrylic Bed

frame

Y-axis belt

pulley wheel

assembly

p 18 Instal X-axis Motor & Pulley mount

Put X-axis motor on X-axis

motor mount. Locking with three

M3*10mm Inner hexagon

screws.

Through the X-axis motor mount

& pulley mount by M8*380mm

sliding rod & M8*345mm screw

arbor. As picture

Limit the top of sliding rod with

sliding rod restriction,X-axis

connect

the bottom of screw arbors

with

Motor

couplings , locking jackscrew

mount in

coupling.

X-axis

Motor

Sliding

rod

restrictio

n

M8*380m

m Sliding

rod

M8*345m

m screw

arbor

Couplin

g

X-axis

Pulley

mount

tep 19 Assemble X-axis

Through the X-axis motor

mount & Pulley mount and

Extruder assembly using two

M8*443mm sliding rods, as the

picture.

Put X-axis limit switch on the Xaxis motor mount, locking with

two M2.5*10mm screws (small

X-axis

black screw)

motor

mount

Extruder

assembly

M8*443mm

sliding rod

X-axis

limit

switch

X-axis

pulley

mount

ep 20 Instal X-axis Timing Belt

Tighten one end of the Timing

Belt to the Belt clip with Nylon

cable ties. The other end through

the X-axis pulley & motor ,then

tighten another end of the belt to Nylon cable

ties

the another Belt clip with Nylon

cable ties . as picture below

X-axis timing

belt

Belt clip

Nylon cable

ties

p 21 Control Board Wiring Diagram

The method of connecting wire is as picture

!

NOTE!:ThewiresconnectedtoPOWE

RSUPPLYandHETBEDmustbeAWG1

4or thicker one.

PS: For auto level 3D printer, there only 2pcs

limit switches , one for X-axis and one for Yaxis, the Position sensor is for Z stop and auto

leveling .

The red

wire is

upturned

p 22 AC Power Connector Wiring Diagram

Connect Power cable as the picture (Right)

Note: There are different voltages in different

country. Please select the appropriate voltage by

switch before power on. As the picture below.

Step 23 Assemble Filament Feed

Separately put two Steel Pipe

holder on two Filament support

frame, locking with four

M3*20mm Round head screws

& nuts.

Steel

Pipe

Filament

spool

Filament

support

frame

Steel

Pipe

holder

Connect the two Filament

support frames with two Fixed

links , locking with four M3*20mm

Round head screws & nuts

M3 nuts

M3*20mm

Round head

screws

Fixed

Link

nstallation Finished

Das könnte Ihnen auch gefallen

- TRONXY P802EA Installation Guide v.03Dokument29 SeitenTRONXY P802EA Installation Guide v.03Jessica Ross100% (1)

- ZONESTAR P802M Installation Guide v.02Dokument28 SeitenZONESTAR P802M Installation Guide v.02Jose Miguel Cañete HidalgoNoch keine Bewertungen

- CSTAR P802M Installation Guide v.04Dokument28 SeitenCSTAR P802M Installation Guide v.04Hector GarciaNoch keine Bewertungen

- Tronxy x1 Assembly GuideDokument26 SeitenTronxy x1 Assembly GuideВайсер Евгений100% (1)

- Tronxy X3A Assemble Guide v.02Dokument29 SeitenTronxy X3A Assemble Guide v.02ramblicasNoch keine Bewertungen

- How To Build A MendelMax 1.5 3D PrinterDokument124 SeitenHow To Build A MendelMax 1.5 3D PrinterFr0styanNoch keine Bewertungen

- Tronxy X3 Assemble Guide V.03Dokument30 SeitenTronxy X3 Assemble Guide V.03everestoNoch keine Bewertungen

- Ultimaker 2 Assembly Manual V1.1Dokument69 SeitenUltimaker 2 Assembly Manual V1.1petrkalousNoch keine Bewertungen

- MicroCube Assembly GuideDokument22 SeitenMicroCube Assembly GuideAlexandruNoch keine Bewertungen

- 2417 Assembly Guide - EnglishDokument53 Seiten2417 Assembly Guide - EnglishJose LunaNoch keine Bewertungen

- Tronxy X5 Assemble English User ManualDokument16 SeitenTronxy X5 Assemble English User ManualPhil Hall0% (1)

- MSS404G Installation Guide Line 20161112 英文版安装说明Dokument12 SeitenMSS404G Installation Guide Line 20161112 英文版安装说明Karen PillasaguaNoch keine Bewertungen

- Sidecar Mount For Intruder 800 or Volusia 800Dokument2 SeitenSidecar Mount For Intruder 800 or Volusia 800dneprmt1Noch keine Bewertungen

- Ecksbot Electronics InstructionsDokument78 SeitenEcksbot Electronics InstructionsjohnNoch keine Bewertungen

- ARB 3438100 FittingDokument7 SeitenARB 3438100 FittingthailanNoch keine Bewertungen

- Ibiza 6l FMIC Mount InstructionsDokument18 SeitenIbiza 6l FMIC Mount Instructionsvagelis vlaxopouliotisNoch keine Bewertungen

- 04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation InstructionsDokument10 Seiten04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation Instructionstrimoca_234178616Noch keine Bewertungen

- Compact Pet Filament MachineDokument13 SeitenCompact Pet Filament Machineaex853120Noch keine Bewertungen

- G768 Car ModelDokument2 SeitenG768 Car ModelVaibhav GaurNoch keine Bewertungen

- Running Boards For OutlanderDokument8 SeitenRunning Boards For OutlanderionutNoch keine Bewertungen

- Cambelt and Water Pump Change MultiplaDokument12 SeitenCambelt and Water Pump Change Multiplaa1037699Noch keine Bewertungen

- FMINTPOLODokument24 SeitenFMINTPOLOClaudiu PunkkNoch keine Bewertungen

- Installation Guide - R8 V8 V10 ExhaustDokument22 SeitenInstallation Guide - R8 V8 V10 ExhaustNishan HunsrajNoch keine Bewertungen

- DMYCO3dp-001 Installation Guide v.07Dokument26 SeitenDMYCO3dp-001 Installation Guide v.07Saed CattywampusNoch keine Bewertungen

- Yosh R55 InstallDokument6 SeitenYosh R55 Installsnoop43Noch keine Bewertungen

- Mantua Model 1987 PDFDokument39 SeitenMantua Model 1987 PDFvintagerccar100% (1)

- Prusa Mendel Iteration 2 Documentation: Thingdoc November 16, 2011Dokument13 SeitenPrusa Mendel Iteration 2 Documentation: Thingdoc November 16, 2011Mr. KNoch keine Bewertungen

- Reprap Prusa Mendel Build Manual - 2Dokument14 SeitenReprap Prusa Mendel Build Manual - 2Laxmikanth ReddyNoch keine Bewertungen

- BMW E60 Engine Seals NotebookDokument24 SeitenBMW E60 Engine Seals NotebookPeter McCracken100% (6)

- Build Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda DecalsDokument16 SeitenBuild Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda Decalsfer freeNoch keine Bewertungen

- Prusa I3 Build Document by 3D Printer CzarDokument29 SeitenPrusa I3 Build Document by 3D Printer CzarlasersmartNoch keine Bewertungen

- Body - Headlight Conversion, Vac To Electric Elite & EclatDokument3 SeitenBody - Headlight Conversion, Vac To Electric Elite & EclatbrynerNoch keine Bewertungen

- TRONXY P802EA Installation Guide V.03 PDFDokument29 SeitenTRONXY P802EA Installation Guide V.03 PDFSalas Meneses JavierNoch keine Bewertungen

- Clock One Build InstructionsDokument12 SeitenClock One Build Instructionsroddick1988Noch keine Bewertungen

- Manual - AR2 Robot Arm AssemblyDokument53 SeitenManual - AR2 Robot Arm AssemblyNelson Rey Laura0% (1)

- Civil 3D Tutorial - RoadDokument4 SeitenCivil 3D Tutorial - RoadKasman NtiNoch keine Bewertungen

- Owner's Manual: Lat MachineDokument16 SeitenOwner's Manual: Lat MachineThughu GhuNoch keine Bewertungen

- Step by Step DIY Windmill PlansDokument10 SeitenStep by Step DIY Windmill Planskeratoconos100% (2)

- 5330 New Carriage Drive Motor ReplacementDokument15 Seiten5330 New Carriage Drive Motor ReplacementBrenda ClayNoch keine Bewertungen

- General Tightening TorquesDokument16 SeitenGeneral Tightening TorquesLars MyrvoldNoch keine Bewertungen

- SKRRFrontbrake FrameDokument3 SeitenSKRRFrontbrake Framesacomani_123Noch keine Bewertungen

- 07K Manifold IEIMVB1 IEIMVB2 Install GuideDokument18 Seiten07K Manifold IEIMVB1 IEIMVB2 Install GuideEmmanuel HernandezNoch keine Bewertungen

- PTP6 Assembly GuideDokument11 SeitenPTP6 Assembly GuidecristiandarvilleNoch keine Bewertungen

- Technical Note: Installing New Y CouplingDokument9 SeitenTechnical Note: Installing New Y CouplingmanishinsightNoch keine Bewertungen

- M-Jet ManualDokument17 SeitenM-Jet Manualh2oo2hNoch keine Bewertungen

- Kit WJ 639pDokument8 SeitenKit WJ 639pjp_xtremNoch keine Bewertungen

- 1 - Frame Assemble PDFDokument69 Seiten1 - Frame Assemble PDFEJ CFNoch keine Bewertungen

- How To Retrofit ESP in A VW MK4 Golf/JettaDokument17 SeitenHow To Retrofit ESP in A VW MK4 Golf/Jettakd7iwp100% (2)

- Y6 DIY Assembly Instructions WEBDokument12 SeitenY6 DIY Assembly Instructions WEBAmru ZulNoch keine Bewertungen

- Kossel Mini Building GuideDokument43 SeitenKossel Mini Building GuideMustafa Liqa-Madiq IV AzoulayeNoch keine Bewertungen

- Assembled By: Jonathan K Instruction ManualDokument44 SeitenAssembled By: Jonathan K Instruction ManualmatteoNoch keine Bewertungen

- Contitech: Installation Tips - Changing Timing Belts: Press ReleaseDokument6 SeitenContitech: Installation Tips - Changing Timing Belts: Press Releasecabral_bhNoch keine Bewertungen

- Small Robot Arm Mechanical AssemblDokument26 SeitenSmall Robot Arm Mechanical AssemblAlexander CanalesNoch keine Bewertungen

- Folgertech Prusa I3 Build Manual v1.1Dokument74 SeitenFolgertech Prusa I3 Build Manual v1.1DonutdealerdNoch keine Bewertungen

- CNC Router 2417 Installation InstructionsDokument53 SeitenCNC Router 2417 Installation InstructionsUranianNoch keine Bewertungen

- DUCATI 48T 10911 Mounting InstructionsDokument6 SeitenDUCATI 48T 10911 Mounting InstructionsBike Build RacingNoch keine Bewertungen

- Prusa I3 Build Document by 3D Printer Czar PDFDokument29 SeitenPrusa I3 Build Document by 3D Printer Czar PDFlasersmartNoch keine Bewertungen

- ND074组装教程文档 MANUAL ROBOTICARMDokument29 SeitenND074组装教程文档 MANUAL ROBOTICARMroboticsengineer.anttNoch keine Bewertungen

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsVon EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNoch keine Bewertungen

- Manual Motor Doosan L136TDokument91 SeitenManual Motor Doosan L136TCarlos Eugenio Lovera Velasquez100% (4)

- Engine Lubrication SystemDokument6 SeitenEngine Lubrication SystemWaqar Younas NumberdarNoch keine Bewertungen

- mf31 1 160810203506 PDFDokument200 Seitenmf31 1 160810203506 PDFagrodostavaNoch keine Bewertungen

- 1564473186374-Question Bank SrDME DSLDokument43 Seiten1564473186374-Question Bank SrDME DSLVishal SinghNoch keine Bewertungen

- B2 Engine Mechanical: To IndexDokument58 SeitenB2 Engine Mechanical: To IndexKwun Hok ChongNoch keine Bewertungen

- NSK Ball ScrewsDokument307 SeitenNSK Ball ScrewsmostafaNoch keine Bewertungen

- SRV540 Tech SheetsDokument190 SeitenSRV540 Tech Sheetsesso123456100% (3)

- S 220 BobcatDokument403 SeitenS 220 BobcatGustavo100% (4)

- Description: Recommended Rates For Spare Parts of Cummins Make 125 Kva D.G.Set S.L. Qty RATES /unit (RS.)Dokument2 SeitenDescription: Recommended Rates For Spare Parts of Cummins Make 125 Kva D.G.Set S.L. Qty RATES /unit (RS.)kewalpal singhNoch keine Bewertungen

- Rock DrillDokument16 SeitenRock DrillESRANoch keine Bewertungen

- 7.2 Log de Recepción de Materiales 1860 OkDokument10 Seiten7.2 Log de Recepción de Materiales 1860 OkAndrea VilcaNoch keine Bewertungen

- GD755 5R - Cen00449 02 PDFDokument16 SeitenGD755 5R - Cen00449 02 PDFlesantiago100% (1)

- Honda BF75D-90D ManualDokument159 SeitenHonda BF75D-90D ManualAkper AliyevNoch keine Bewertungen

- 1st Quarter Pre Test in Technology and Livelihood Education EIM 10Dokument4 Seiten1st Quarter Pre Test in Technology and Livelihood Education EIM 10Citrus National High SchoolNoch keine Bewertungen

- Higer Warranty BookDokument42 SeitenHiger Warranty BookNaingminn HtoonNoch keine Bewertungen

- Tractors SameDokument82 SeitenTractors Sameomni_parts100% (1)

- DTS Univ QPDokument29 SeitenDTS Univ QPAnand NagarajanNoch keine Bewertungen

- Tecumseh Model Tvs90 43000b Parts ListDokument9 SeitenTecumseh Model Tvs90 43000b Parts ListSandra SpeedNoch keine Bewertungen

- NEMA Straight Blade Reference ChartDokument5 SeitenNEMA Straight Blade Reference ChartMateen AhmedNoch keine Bewertungen

- PreloadDokument3 SeitenPreloadvenky364Noch keine Bewertungen

- Honda Rvt1000r Rc51 2000 Parts Manual and MicrofichesDokument10 SeitenHonda Rvt1000r Rc51 2000 Parts Manual and MicrofichesGuadalupe100% (46)

- LONKING CDM855E Wheel Loader Parts Book Catalogue (Manual de Partes)Dokument217 SeitenLONKING CDM855E Wheel Loader Parts Book Catalogue (Manual de Partes)Emmanuel Garcia OzanNoch keine Bewertungen

- Homelite Service Guide String Trimmers ST01369-12012-21-1998Dokument44 SeitenHomelite Service Guide String Trimmers ST01369-12012-21-1998William.Parris3256Noch keine Bewertungen

- S02 Rock Drill, Flushing HeadDokument15 SeitenS02 Rock Drill, Flushing HeadAlexanderNoch keine Bewertungen

- 10 Structure, Function and Maintenance Standard 1 ParteDokument78 Seiten10 Structure, Function and Maintenance Standard 1 ParteAugusto OliveiraNoch keine Bewertungen

- TMG E1341Dokument31 SeitenTMG E1341dwinanto.lrsNoch keine Bewertungen

- Machinery Canada - DC Swiss Taps AluminumDokument35 SeitenMachinery Canada - DC Swiss Taps AluminummachineCanNoch keine Bewertungen

- All Motor, &electrical Equipment in StorDokument8 SeitenAll Motor, &electrical Equipment in StorMd. Saddam HossainNoch keine Bewertungen

- 03 Screw Jacks MERKUR P081-088Dokument8 Seiten03 Screw Jacks MERKUR P081-088Shubham AvhaleNoch keine Bewertungen

- Parts For Cat Pump Model # 3535Dokument4 SeitenParts For Cat Pump Model # 3535Alassane NiangNoch keine Bewertungen