Beruflich Dokumente

Kultur Dokumente

DWX-50 Spindle Replacement - 1

Hochgeladen von

gina50%(2)50% fanden dieses Dokument nützlich (2 Abstimmungen)

1K Ansichten22 SeitenDWX 50

Originaltitel

DWX-50 Spindle Replacement_1 (2)

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDWX 50

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

50%(2)50% fanden dieses Dokument nützlich (2 Abstimmungen)

1K Ansichten22 SeitenDWX-50 Spindle Replacement - 1

Hochgeladen von

ginaDWX 50

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 22

DWX Spindle Replacement Procedure

Here are the necessary tools

needed to perform this

replacement (show image of tools

, feeler gauge, & spindle,

optional magnetic) I recommend

watching this first before

attempting adjustments

Before we begin lets turn off the

power switch in the rear, then

unplug the power cord and turn

off your compressor.

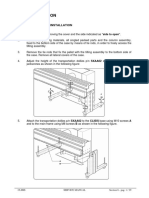

Now lets open both the front top

and bottom cover & gently move

the carriage the right side &

remove the air tube from the

spindle unit cover by loosening

the screw

Remove the spindle unit cover

with your 2.5mm hex key

Now disconnect the connector of

the spindle and ATC motor

[1] On the left side of the

ATC motor remove the 3

screws to dismount the

ATC motor using your

3.0mm hex key

[2] Once removed do not

lay the ATC motor unit with

the spring facing

downward. Once its bent,

the spring does not

[1] Next loosen the screws

securing the motor base in place

then we can remove the spring.

[2] Next we can remove the

spindle motor with the motor

base.

[1] Remove the spindle belt, then

with your 2.5mm hex key [2] then

remove the spindle unit by

loosening the two screws and

remove the spindle unit by

pulling it up. fix the new spindle

unit by tightening the screws

With your new spindle belt

place it at the top of the

spindle motor shaft make

sure that the white line on

the outside.

Using your 2.5mm hex Temporally

fix the spindle motor with the

motor base the motor w/base

should move smoothly(show

movement of motor moving

smoothly

Now fix the pulley belt

and hook the spring,

by rotating the pulley,

align the spindle belt

to each center of the

spindle unit and the

pulley.

[1] Insert your ATC motor

unit [2] then by using your

3.0mm hex key, fix the ATC

motor unit by gently

pushing it to the front of

the machine

[1] Fix the spindle motor with the

motor base completely and [2]

connect the connectors of the

spindle and ATC motor

once we have everything

connected plug in your AC cord

and then turn the power SW

connect your PC to the DWX-50

and open the DWX50PIT.exe

15mm

Now we are going to check verify the

operation of the collet, so click on the

[SP/ATC]>[ATC Operation]>[Open/Close

Collet] and open the collet and put the

4mm diameter tool through the collet

manually and check whether you can

slide the collet manually and check

whether you can slide the tool in

15mm. Then, click the [Open/Close

Collet] and grasp the tool manually

and check whether the tool is grasped

correctly. Next click the [Open/Close

Collet] and remove the tool from the

collect.

We are now going to check the clearance

between the spring of the ATC motor unit

and the spindle unit with the feeler gauge,

the thickness must be 0.5mm to 0.8mm if

not, adjust the position by loosening the

fixing screws of the spring

Click SP/ATC]>[ATC Operation]>[Leaf

Spring Position]>[Move]. Now we are

going to check for two things:

1. There should be a space between

the top of the Spindle unit and the

bottom of the ATC motor unit shown

in the figure.

2. The Spring contacts with the

Spindle Unit shown in the figure.

Since we replaced a new spindle we are

now going to clear the spindle time,

Click [Info]>[Clear Spindle Time]>[Unit

Time] and clear

the Spindle unit operation time.

Lets go ahead and place the

spindle unit cover back on.

Now move the spindle head to

the right side put the air tube

through the spindle unit cover

and fix the air tube by tightening

the screw.

Go ahead and start up your VPanel we are going

to perform a spindle Run In which will basically

warm up your new spindle this will take up to

1hour maximum to complete.

Lastly we will need to perform the [Correct

magazine] & [Correct rotary axis] operations on

the VPanel

Das könnte Ihnen auch gefallen

- Singer Quantum Stylist 9960: Pocket Guide: Buttons, Dials, Settings, Stitches, and FeetVon EverandSinger Quantum Stylist 9960: Pocket Guide: Buttons, Dials, Settings, Stitches, and FeetNoch keine Bewertungen

- Akira Em-2900dq GeneratorDokument7 SeitenAkira Em-2900dq Generatorrahmat teaNoch keine Bewertungen

- Technical Data: SUPERIX RL180N USER MANUAL - UM - 18005 - 0698 MECALL SRL 1998 All Rights ReservedDokument14 SeitenTechnical Data: SUPERIX RL180N USER MANUAL - UM - 18005 - 0698 MECALL SRL 1998 All Rights ReservedRaklo YukhninNoch keine Bewertungen

- Clisis 6Dokument29 SeitenClisis 6fortroniNoch keine Bewertungen

- Eccocee Ssa340Dokument76 SeitenEccocee Ssa340atilio.agirre100% (1)

- LG RD - jt91 DLP ProjectorDokument34 SeitenLG RD - jt91 DLP ProjectorMalay K GhoshNoch keine Bewertungen

- Toshiba PDFDokument22 SeitenToshiba PDFSohail AhmedNoch keine Bewertungen

- 5 - B - Dxap2001j Alineacion Tubo RXDokument10 Seiten5 - B - Dxap2001j Alineacion Tubo RXSEASBINoch keine Bewertungen

- Manual de Operaciones MakoDokument94 SeitenManual de Operaciones MakoHugo Samuel López VasquezNoch keine Bewertungen

- EMShape ManualDokument14 SeitenEMShape ManualJaime0% (1)

- Tera Term ManualDokument10 SeitenTera Term ManualMeryem LaouidiNoch keine Bewertungen

- Fenix PN10 ManualDokument47 SeitenFenix PN10 ManualKovács TamásNoch keine Bewertungen

- Conversational Automatic Programming Function Ii For Lathe Operator's Manual (B-61804e-2 - 05) PDFDokument798 SeitenConversational Automatic Programming Function Ii For Lathe Operator's Manual (B-61804e-2 - 05) PDFdmlukinyandex.ru0% (1)

- Printbar Replacement GuideDokument16 SeitenPrintbar Replacement GuideAlberto Fernández VázquezNoch keine Bewertungen

- Storz MP200 User ManualDokument72 SeitenStorz MP200 User ManualGuan JiangNoch keine Bewertungen

- ST6000 Inboard Service ManualDokument214 SeitenST6000 Inboard Service ManualmanateehunterNoch keine Bewertungen

- Efs Brochure 11-2010Dokument36 SeitenEfs Brochure 11-2010Anonymous Wu6FDjbNoch keine Bewertungen

- Kodak 101-102 SDokument20 SeitenKodak 101-102 Sspaske_Noch keine Bewertungen

- a850HK1 SM 20170109Dokument114 Seitena850HK1 SM 20170109Braulio Soto AlfaroNoch keine Bewertungen

- Omega Air-Rdp - en - 950376 - 06-2020 - A4Dokument8 SeitenOmega Air-Rdp - en - 950376 - 06-2020 - A4Taufan JustvandsNoch keine Bewertungen

- LG Hecto Service ManualDokument98 SeitenLG Hecto Service ManualKSnakeWNoch keine Bewertungen

- Eswl SalesDokument24 SeitenEswl Salesapi-538691317Noch keine Bewertungen

- TXL PLUS AL 4 8 KWDokument12 SeitenTXL PLUS AL 4 8 KWNgoc Hung VuNoch keine Bewertungen

- DI-166 Service Manual v1.18Dokument31 SeitenDI-166 Service Manual v1.18Juan Cristóbal CarvalloNoch keine Bewertungen

- SERVICE MANUAL TUBE SEALER Model SE250Dokument38 SeitenSERVICE MANUAL TUBE SEALER Model SE250silictronic100% (1)

- Programat P500/G2: Operating InstructionsDokument40 SeitenProgramat P500/G2: Operating InstructionsMario Arturo RendonNoch keine Bewertungen

- Drager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementDokument24 SeitenDrager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementAmirNoch keine Bewertungen

- Drager Cato Ventilator - Service ManualDokument20 SeitenDrager Cato Ventilator - Service ManualEdwin Salazar OrtizNoch keine Bewertungen

- Centroid cnc12 Oak Allin1dc Lathe Operator Manual v4.14Dokument269 SeitenCentroid cnc12 Oak Allin1dc Lathe Operator Manual v4.14Cesar Augusto MontejoNoch keine Bewertungen

- No. 2J308-036EN I: Toshiba Medical Systems Corporation 2010-2012 All Rights ReservedDokument1.195 SeitenNo. 2J308-036EN I: Toshiba Medical Systems Corporation 2010-2012 All Rights ReservedHoai ThuongNoch keine Bewertungen

- Installation Manual of Aj12 Us Dental ChairDokument28 SeitenInstallation Manual of Aj12 Us Dental ChairDr.Ahmed AlsadiNoch keine Bewertungen

- Ver.4.5 Upgrade of Pro A5Dokument14 SeitenVer.4.5 Upgrade of Pro A5Rama Tenis CopecNoch keine Bewertungen

- Sparcengine™Ultra™Axi: Oem Technical Reference Manual July 1 9 9 8Dokument181 SeitenSparcengine™Ultra™Axi: Oem Technical Reference Manual July 1 9 9 8Jaxon Mosfet100% (1)

- 3.24 980MD EnglishDokument348 Seiten3.24 980MD EnglishAbraham Tellez Flores100% (1)

- User Manual of NK105 G2 Handle Controller RicocncDokument89 SeitenUser Manual of NK105 G2 Handle Controller RicocncHertzog BurgerNoch keine Bewertungen

- Firepower FP-70A Service ManualDokument48 SeitenFirepower FP-70A Service Manualrtgeorge100% (1)

- BK 5000 Ultrasound System - Quick User ManualDokument12 SeitenBK 5000 Ultrasound System - Quick User ManualIñaki GonzálezNoch keine Bewertungen

- Whirlpool Awo D 41100Dokument29 SeitenWhirlpool Awo D 41100Teodora OnciuNoch keine Bewertungen

- Linvatec LIS8430 Xenon Light Source - User and Service Manual PDFDokument93 SeitenLinvatec LIS8430 Xenon Light Source - User and Service Manual PDFkarimNoch keine Bewertungen

- 269-663300 Rev 03 - PVE - VikingQuest V21.1 User - English - 01-31-2020 - CE2797Dokument84 Seiten269-663300 Rev 03 - PVE - VikingQuest V21.1 User - English - 01-31-2020 - CE2797AhmmedNoch keine Bewertungen

- Haier Medical and LB T C LTD Laboratory Co., LTD: DW-40L Series Service Manual For Low Temperature RefrigeratorDokument21 SeitenHaier Medical and LB T C LTD Laboratory Co., LTD: DW-40L Series Service Manual For Low Temperature RefrigeratorHectorNoch keine Bewertungen

- Technical Manual PAC Light Commercial Binnen-Buitendelen Compleet PDFDokument115 SeitenTechnical Manual PAC Light Commercial Binnen-Buitendelen Compleet PDFBobi GorgievskiNoch keine Bewertungen

- Panamatic Optima 2 ExportDokument59 SeitenPanamatic Optima 2 ExportmichelRamirez100% (3)

- Avair AV-508Dokument2 SeitenAvair AV-508Nenad PetrovicNoch keine Bewertungen

- Brochure UNIBASE 30Dokument6 SeitenBrochure UNIBASE 30MaferNoch keine Bewertungen

- Chromophare Surgical and Examination Light: Pre-Installation InformationDokument23 SeitenChromophare Surgical and Examination Light: Pre-Installation InformationCesar AlfaroNoch keine Bewertungen

- MTC Operation ManualDokument32 SeitenMTC Operation ManualXcd SteflerNoch keine Bewertungen

- 128X64 DOTS Graphic LCD Module User'S ManualDokument11 Seiten128X64 DOTS Graphic LCD Module User'S ManualalphaeletricaNoch keine Bewertungen

- Somatom: Hiq/ Plus/ ArDokument18 SeitenSomatom: Hiq/ Plus/ ArHernan PerezNoch keine Bewertungen

- VITA VITA Vacumat VITA Vacumat 50 BA en V00 Screen enDokument8 SeitenVITA VITA Vacumat VITA Vacumat 50 BA en V00 Screen enanas100% (1)

- Digora Optime Classic User GuideDokument46 SeitenDigora Optime Classic User GuideRichard Gomez100% (1)

- Eba ManualDokument46 SeitenEba Manualddrak1964Noch keine Bewertungen

- SL-2 Calibration ProceduresDokument17 SeitenSL-2 Calibration ProceduresManuelDavilaRojasNoch keine Bewertungen

- PX 520 en DM Printc (2009.07)Dokument2 SeitenPX 520 en DM Printc (2009.07)monitex_tw0% (1)

- DSP NK105 Operating Instruction DSP Control System DSP Operate ManualDokument7 SeitenDSP NK105 Operating Instruction DSP Control System DSP Operate ManualMd. Atiqur Rahman TalukdarNoch keine Bewertungen

- As 1115-1985 Numerical Control of Machines - Axis and Motion NomenclatureDokument6 SeitenAs 1115-1985 Numerical Control of Machines - Axis and Motion NomenclatureSAI Global - APACNoch keine Bewertungen

- M100702E MAI Memory Upgrade For Fanuc 02 PDFDokument22 SeitenM100702E MAI Memory Upgrade For Fanuc 02 PDFSelvedin GudicNoch keine Bewertungen

- 307D Excavator-Before PerationDokument8 Seiten307D Excavator-Before PerationMecatrónico100% (1)

- Helix: Operating Instructions and Parts List Spring Assembler ModelDokument32 SeitenHelix: Operating Instructions and Parts List Spring Assembler ModelPranavNoch keine Bewertungen

- Calibration Procedure UKDokument15 SeitenCalibration Procedure UKartNoch keine Bewertungen

- Ith Bolt Tensioning Cylinders BTC 2014 en WebDokument28 SeitenIth Bolt Tensioning Cylinders BTC 2014 en WebMatiasNoch keine Bewertungen

- Plexo Catalog PDFDokument20 SeitenPlexo Catalog PDFMeylia RodiawatiNoch keine Bewertungen

- Warning Warning: Grigri GrigriDokument24 SeitenWarning Warning: Grigri GrigriEdmilson Espindola Dos SantosNoch keine Bewertungen

- Doosan VMC Maintenance DNM 500Dokument123 SeitenDoosan VMC Maintenance DNM 500sunhuynh100% (2)

- Question Paper Code:: Reg. No.Dokument2 SeitenQuestion Paper Code:: Reg. No.bala muruganNoch keine Bewertungen

- Method Statement FOR Laying of LV Cables: M & E ContractorDokument4 SeitenMethod Statement FOR Laying of LV Cables: M & E ContractorJoe_AverageNoch keine Bewertungen

- Lenovo b470 Laptop SchematicsDokument103 SeitenLenovo b470 Laptop Schematicsantonio velozNoch keine Bewertungen

- Fuse - On: Short Circuit Protection in PV SystemsDokument8 SeitenFuse - On: Short Circuit Protection in PV SystemsDiego MorenoNoch keine Bewertungen

- Garage Inventory ChecklistDokument3 SeitenGarage Inventory ChecklistBALJIT WARISNoch keine Bewertungen

- ERSA Microsoldering Irons: ERSA Minor ERSA Minityp ERSA Tip 260Dokument1 SeiteERSA Microsoldering Irons: ERSA Minor ERSA Minityp ERSA Tip 260Maria KokkinariNoch keine Bewertungen

- Speller Effect Sign DisplayDokument1 SeiteSpeller Effect Sign Displayshrankruk4364Noch keine Bewertungen

- ZF 3-6-191 - 211 - e Repair ManualDokument6 SeitenZF 3-6-191 - 211 - e Repair ManualarthurNoch keine Bewertungen

- SILOS COMPONENTS MORE Kunststoffindustrie ENDokument15 SeitenSILOS COMPONENTS MORE Kunststoffindustrie ENАлександр МихайловичNoch keine Bewertungen

- 6GK50050BA001AB2 Datasheet enDokument2 Seiten6GK50050BA001AB2 Datasheet enLuis BritoNoch keine Bewertungen

- Reachstacker: RS45-27CH, RS45-30CH, RS45-27IH, RS46-33CH, RS46-30IH, RS46-36CH, RS46-33IH (A222)Dokument40 SeitenReachstacker: RS45-27CH, RS45-30CH, RS45-27IH, RS46-33CH, RS46-30IH, RS46-36CH, RS46-33IH (A222)stefan corjucNoch keine Bewertungen

- Fluke Isolator Tester 1555Dokument2 SeitenFluke Isolator Tester 1555adominguezramonNoch keine Bewertungen

- Lp-s070 User Manual AutonicsDokument175 SeitenLp-s070 User Manual AutonicsPatricio DavidNoch keine Bewertungen

- Rechert 3Dokument3 SeitenRechert 3WillNoch keine Bewertungen

- Welger RP12-15S BA - Eng2Dokument50 SeitenWelger RP12-15S BA - Eng2Branko Mikulinjak50% (2)

- Introduction To In-Circuit TestingDokument123 SeitenIntroduction To In-Circuit TestingMed Medy Fehem100% (1)

- Q3 - Module1 G9 CSSDokument9 SeitenQ3 - Module1 G9 CSSAubz Almelia NavarroNoch keine Bewertungen

- Design A Inverter With Nmos Enhancement LoadDokument8 SeitenDesign A Inverter With Nmos Enhancement LoadfuchsialifeNoch keine Bewertungen

- Gamma TecDokument4 SeitenGamma TecmtonellyNoch keine Bewertungen

- InteliVision 18touch - DatasheetDokument4 SeitenInteliVision 18touch - DatasheetMaylen RivasNoch keine Bewertungen

- MS2 IpmDokument101 SeitenMS2 Ipmgionguyen0% (1)

- Data Sheet: SMPS630-GDokument11 SeitenData Sheet: SMPS630-GXuân TrườngNoch keine Bewertungen

- Somfy GlydeaDokument14 SeitenSomfy GlydeaKarth CenaNoch keine Bewertungen

- Manual Presetting Valves LENO™ MSV-O: Data SheetDokument24 SeitenManual Presetting Valves LENO™ MSV-O: Data SheetZoran StanovnikNoch keine Bewertungen

- Huawei Smart PV Solution Anti-PID Module Application Guide 01 - (20151219)Dokument18 SeitenHuawei Smart PV Solution Anti-PID Module Application Guide 01 - (20151219)Jaime Andres Herrera RestrepoNoch keine Bewertungen