Beruflich Dokumente

Kultur Dokumente

Small Base Moldflow Analysis Report

Hochgeladen von

Sreedhar PugalendhiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Small Base Moldflow Analysis Report

Hochgeladen von

Sreedhar PugalendhiCopyright:

Verfügbare Formate

Moldflow Analysis Report

Cool, Flow & Warp Analysis Of The Small Base Part

AG10-07, 07 JULY 2010

Page 1

Moldflow Analysis Report

Contents

1.

Summary

03

2.

Material Properties

04

3.

Part thickness

05 -06

4.

Processing Condition & Runner Layout

07

5.

Results

08 - 23

AG10-07, 07 JULY 2010

Page 2

Moldflow Analysis Report

Summary

ANALYSIS AIMS

To study the flow and to predict the cycle time of the A1309-2 part.

ANALYSIS APPROACH

The cavity and the cold runner sections are modeled.

A Fusion Cool + Flow + Warp analysis was conducted.

The specified material is PP (grade is specified BP RPP 2009 GK BLK, which is not listed in

the moldflow database, so we used Polypropylene PPC 5660 from TOTAL Petrochemicals) to

run the analysis .

This may effect the actual values obtained in the analysis (e.g. shrinkage values, pressure

requirements), but it can still be used to observe the general trends in the results (e.g. filling

pattern, warpage shape etc).

CONCLUSION

A pressure drop of 15MPa is expected across the system which indicates this material can

easily fill this part.

The overall melt front temperature drop is 1.2 C across the part, which is acceptable.

The weld lines might be visible to the eye due to zero degrees of two melts.

The part is expected to have warpage in X,Y,Z direction. Please refer to the data of the

particular warpage on page 19 to 22.

The hot spots in the slider side are due to the placement of the cooling channel. These areas

need cooling circuit or beryllium insert added to them if possible (refer to page 18).

AG10-07, 07 JULY 2010

Page 3

Moldflow Analysis Report

Material :

PP

Similar Material

Trade Name: Polypropylene PPC 5660

Material Family: PP

Manufacturer : TOTAL Petrochemicals

Recommend processing temperature

Melt : 200C 260C

Characteristics : Amorphous Material

others:

Conductivity : 0.1762 W/m/C (at 230C)

Specific Heat :

2618.6 J/kg/ C (at 230 C)

Melt Density : 0.74577 g/cm^3

Absolute Max Temp : 300 C

Ejection Temperature :

95C

Max Shear Stress :

0.25MPa

Max Shear Rate :

100,000 l/s

Viscosity Plot

AG10-07, 07 JULY 2010

Mold : 20 C 60 C

Viscosity Index : VI(240)0111

Melt mass Flow Rate(MFR)(230C/2.16kg)

7.0g/10min

PVT Plot

Page 4

Moldflow Analysis Report

Part thickness

Use different color to show the thickness.

AG10-07, 07 JULY 2010

Page 5

Moldflow Analysis Report

Part thickness

Use different color to show the thickness.

AG10-07, 07 JULY 2010

Page 6

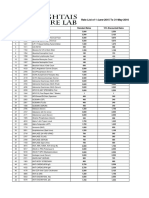

Moldflow Analysis Report

Processing Condition & Runner Layout

The Processing Conditions used was as follows:

Filling Time : Auto, 4.6 sec.

Mold Temperature : 40 C

Melt Temperature : 230 C

Velocity/Pressure switchover at 98.5% volume fill

Packing Pressure : 80% of Max Injection Pressure

Gate size:

7.8mm

AG10-07, 07 JULY 2010

Page 7

Moldflow Analysis Report

Filling Pattern

Fig 1

Fig 3

Fig 2

The last filling area

AG10-07, 07 JULY 2010

Fig 4

Page 8

Moldflow Analysis Report

Filling Time (Flash)

AG10-07, 07 JULY 2010

Page 9

Moldflow Analysis Report

Filling Time (Flash)

AG10-07, 07 JULY 2010

Page 10

Moldflow Analysis Report

Pressure drop

A pressure drop of 15MPa is expected across the system,

this indicated that the material is easy to fill this part.

AG10-07, 07 JULY 2010

Page 11

Moldflow Analysis Report

Temperature at flow front

The plastics material enters the runners at 230 C.

The overall temperature drop is about 1.2C,

which is acceptable.

AG10-07, 07 JULY 2010

Page 12

Moldflow Analysis Report

Weld Lines

The weld lines (color curve) might be visible to the

eye, due to the zero degrees of the two melts.

AG10-07, 07 JULY 2010

Page 13

Moldflow Analysis Report

Air traps

The air traps (pink marks ) location are as show.

AG10-07, 07 JULY 2010

Page 14

Moldflow Analysis Report

Cooling Channels : Temperature Rise

The coolant is specified as water at 25 C, and with turbulent flow in each channels

(Reynold Number = 10,000).

The outlet temperature of each channels exceeds 0.66C, this indicates the cooling

channels are efficient.

Cavity cooling

AG10-07, 07 JULY 2010

Page 15

Moldflow Analysis Report

Cooling Channels : Temperature Rise

The coolant is specified as water at 25 C, and with turbulent flow in each channels

(Reynold Number = 10,000).

The outlet temperature of each channels exceeds 0.8C, this indicates the cooling

channels are efficient.

Core cooling

AG10-07, 07 JULY 2010

Page 16

Moldflow Analysis Report

Cooling Channels : Temperature Rise

Slider cooling

AG10-07, 07 JULY 2010

Page 17

Moldflow Analysis Report

Mould Surface Temperature

Total Cycle time: 105 sec.

( Auto Injection + Packing + Cooling Times = 100 sec. Mold open time = 5 sec.)

Core side

Cavity side

Hot spot

Slider

AG10-07, 07 JULY 2010

Slider

Page 18

Moldflow Analysis Report

Warpage in X direction

AG10-07, 07 JULY 2010

Page 19

Moldflow Analysis Report

Warpage in Y direction

AG10-07, 07 JULY 2010

Page 20

Moldflow Analysis Report

Warpage in Z direction

AG10-07, 07 JULY 2010

Page 21

Moldflow Analysis Report

Warpage in Z direction

Z direction

AG10-07, 07 JULY 2010

Page 22

Moldflow Analysis Report

The conclusions

1) This product was analyzed by using Moldflow software. The

directions of the shrinkage is due to structure of the product.

2)Theres not enough cooling of the slide and core. Suggestions: to

improve this, use the Heat Pipes on the slide area instead and

increase water cooling system on the core area, But these are just

some minor adjustments, the deformation will still be prominent.

3) The large base mold has the same problems.

AG10-07, 07 JULY 2010

Page 23

Moldflow Analysis Report

The End

AG10-07, 07 JULY 2010

Page 24

Das könnte Ihnen auch gefallen

- GÜNTHER Hot Runner TechnologyDokument35 SeitenGÜNTHER Hot Runner TechnologyjazNoch keine Bewertungen

- Plastic Drying PDFDokument3 SeitenPlastic Drying PDFMonica JoynerNoch keine Bewertungen

- Injection Mould With Hot RunnerDokument17 SeitenInjection Mould With Hot RunnerKiran KumarNoch keine Bewertungen

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Von EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Noch keine Bewertungen

- New Injection Molding Machine SY200 I PDFDokument5 SeitenNew Injection Molding Machine SY200 I PDFkamelNoch keine Bewertungen

- Meat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingVon EverandMeat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingNoch keine Bewertungen

- Material - 5. Injection Moulding Technology Part 3 - 3Dokument127 SeitenMaterial - 5. Injection Moulding Technology Part 3 - 3Sachin KumarNoch keine Bewertungen

- MouldDokument16 SeitenMouldetamil87Noch keine Bewertungen

- Moldflow PresentationDokument50 SeitenMoldflow PresentationpatrickNX9420Noch keine Bewertungen

- Multiphase Flow in Polymer ProcessingVon EverandMultiphase Flow in Polymer ProcessingChang HanBewertung: 1 von 5 Sternen1/5 (1)

- PIM 101 Ebook-1Dokument33 SeitenPIM 101 Ebook-1agniflameNoch keine Bewertungen

- Thermoforming of Single and Multilayer Laminates: Plastic Films Technologies, Testing, and ApplicationsVon EverandThermoforming of Single and Multilayer Laminates: Plastic Films Technologies, Testing, and ApplicationsNoch keine Bewertungen

- دورة تشغيل ماكينات البلاستيكDokument28 Seitenدورة تشغيل ماكينات البلاستيكfadyNoch keine Bewertungen

- InTech-Modelling and Simulation For Micro Injection Molding ProcessDokument16 SeitenInTech-Modelling and Simulation For Micro Injection Molding ProcessPankaj SattawatNoch keine Bewertungen

- Injection Mold Design Engineering Complete Self-Assessment GuideVon EverandInjection Mold Design Engineering Complete Self-Assessment GuideNoch keine Bewertungen

- Different Types of Blow MoldingDokument11 SeitenDifferent Types of Blow MoldingParvateshNoch keine Bewertungen

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Von EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Noch keine Bewertungen

- Setting Process ConditionDokument11 SeitenSetting Process Conditioneitan-dalia4971Noch keine Bewertungen

- Investigate of Parameter Setting in Plastic Injection MoldingDokument28 SeitenInvestigate of Parameter Setting in Plastic Injection MoldingKristine de ClaroNoch keine Bewertungen

- Injection MoldingDokument42 SeitenInjection Moldinglovilove01Noch keine Bewertungen

- Injection MouldingDokument7 SeitenInjection MouldingAzizol WahabNoch keine Bewertungen

- Top12-Results From MoldflowDokument30 SeitenTop12-Results From Moldflowpawang422100% (1)

- ARBURG-Examples of Multi Component Mould Designs GB PDFDokument40 SeitenARBURG-Examples of Multi Component Mould Designs GB PDFkfaravNoch keine Bewertungen

- Injection Molding Troubleshooting Flash BurnmarksDokument60 SeitenInjection Molding Troubleshooting Flash Burnmarkswawawa1100% (1)

- Introduction Injection MoldingDokument39 SeitenIntroduction Injection Moldingmaran.suguNoch keine Bewertungen

- Injection Molded Part Problems & Solutions With: SkillbuilderDokument2 SeitenInjection Molded Part Problems & Solutions With: SkillbuilderradzNoch keine Bewertungen

- Two Plate Three PlateDokument15 SeitenTwo Plate Three PlateHarshvardhan KharatNoch keine Bewertungen

- Plastic Injection Molding Write UpDokument16 SeitenPlastic Injection Molding Write UpVishal MahajanNoch keine Bewertungen

- Cold Runner eDokument7 SeitenCold Runner eKodhansNoch keine Bewertungen

- Week 5 Processing 3Dokument33 SeitenWeek 5 Processing 3cipan karungNoch keine Bewertungen

- 8 Optimizing The Molding ParametersDokument54 Seiten8 Optimizing The Molding ParametersEdith Chavez LindosNoch keine Bewertungen

- ASB Blow MoldingDokument52 SeitenASB Blow MoldingManuelCaballeroNoch keine Bewertungen

- BM1 ProcessDokument55 SeitenBM1 Processeduardo_umNoch keine Bewertungen

- Injection Molding Defect OzDokument12 SeitenInjection Molding Defect Oztopkaya100% (1)

- Setting Process ConditionsDokument10 SeitenSetting Process ConditionszaldsonNoch keine Bewertungen

- About Rotational MoldingDokument7 SeitenAbout Rotational MoldingPatel DarshanNoch keine Bewertungen

- Explain Basic Injection Molding Machine ProcessDokument9 SeitenExplain Basic Injection Molding Machine ProcessNazriNoch keine Bewertungen

- How To Select Plastic Injection Moulding MachineDokument48 SeitenHow To Select Plastic Injection Moulding MachineDiego Sáchica60% (5)

- Design For InjectionDokument38 SeitenDesign For Injectionnurwinantoindra100% (1)

- Optimization of Plastics Injection Molding ProcessDokument11 SeitenOptimization of Plastics Injection Molding Processfaishal hafizhNoch keine Bewertungen

- 70D Manual BookDokument43 Seiten70D Manual BookgeorgioNoch keine Bewertungen

- Injection Molding ProcessDokument3 SeitenInjection Molding ProcessSteven ChengNoch keine Bewertungen

- Injection Molding Methods Design Optimization Simulation of Plastic Toy Building Block by Mold Flow AnalysisDokument10 SeitenInjection Molding Methods Design Optimization Simulation of Plastic Toy Building Block by Mold Flow AnalysisIAEME PublicationNoch keine Bewertungen

- C Polybridge Calculator V25 Feb 09 Office 2003Dokument58 SeitenC Polybridge Calculator V25 Feb 09 Office 2003KodhansNoch keine Bewertungen

- Mde Injection Molding Troubleshooting GuideDokument11 SeitenMde Injection Molding Troubleshooting GuideNader ElenanyNoch keine Bewertungen

- Plastic Injection Molding TERMS and GLOSSARYDokument9 SeitenPlastic Injection Molding TERMS and GLOSSARYDanny Martinez100% (1)

- Microinjection Molding of Thermoplastic Polymers: A ReviewDokument14 SeitenMicroinjection Molding of Thermoplastic Polymers: A ReviewMario Allesina JuniorNoch keine Bewertungen

- Plastic InjectionDokument39 SeitenPlastic InjectionRishav KumarNoch keine Bewertungen

- 7 Factors To Be Considered in Injection Molding Process Cannot Be Ignored. (158) DocxDokument8 Seiten7 Factors To Be Considered in Injection Molding Process Cannot Be Ignored. (158) DocxGiap NguyenNoch keine Bewertungen

- Injection Molding Without The DryingDokument3 SeitenInjection Molding Without The DryingHalloy1Noch keine Bewertungen

- Hot Runner TechnologyDokument3 SeitenHot Runner Technologysuveesh nvNoch keine Bewertungen

- Design of Plunger Screws Ofinjection Molding MachineDokument28 SeitenDesign of Plunger Screws Ofinjection Molding MachineSushmaNoch keine Bewertungen

- Microsystem - Presentation - MICRO MOULDINGDokument70 SeitenMicrosystem - Presentation - MICRO MOULDINGrameshNoch keine Bewertungen

- Defects in Injection MouldingDokument14 SeitenDefects in Injection Mouldinghajarpaiman100% (1)

- OVA and OVFDokument3 SeitenOVA and OVFSreedhar PugalendhiNoch keine Bewertungen

- 0000 EN DN TOF Timer Off Delay Timer Time Base Preset Accum TOFDokument1 Seite0000 EN DN TOF Timer Off Delay Timer Time Base Preset Accum TOFSreedhar PugalendhiNoch keine Bewertungen

- 12 1 What Is A Force? 1 - ? F 1 M e S 2 S F: Ma? Define AcceDokument12 Seiten12 1 What Is A Force? 1 - ? F 1 M e S 2 S F: Ma? Define AcceSreedhar PugalendhiNoch keine Bewertungen

- DocumentDokument3 SeitenDocumentSreedhar PugalendhiNoch keine Bewertungen

- Visi MouldDokument2 SeitenVisi MouldSreedhar PugalendhiNoch keine Bewertungen

- Catalog Switches OnlyDokument4 SeitenCatalog Switches OnlySreedhar PugalendhiNoch keine Bewertungen

- Lab 0 - Introduction To Laboratory: ObjectiveDokument2 SeitenLab 0 - Introduction To Laboratory: ObjectiveSreedhar PugalendhiNoch keine Bewertungen

- ) Appendh A-Typical Graphlc Symbols Lor Electrlcal Dlagrams WLTH Baslc Devlce Deslgnatlons SwrtchesDokument2 Seiten) Appendh A-Typical Graphlc Symbols Lor Electrlcal Dlagrams WLTH Baslc Devlce Deslgnatlons SwrtchesSreedhar PugalendhiNoch keine Bewertungen

- Implementation of 5S' Technique in A Manufacturing Organization: A Case StudyDokument13 SeitenImplementation of 5S' Technique in A Manufacturing Organization: A Case StudySreedhar PugalendhiNoch keine Bewertungen

- Molding Process PDFDokument7 SeitenMolding Process PDFSreedhar PugalendhiNoch keine Bewertungen

- DJF Module 3Dokument104 SeitenDJF Module 3jestin100% (1)

- Injection Molding Design GuidelinesDokument13 SeitenInjection Molding Design GuidelinesSreedhar PugalendhiNoch keine Bewertungen

- 42 PressesDokument3 Seiten42 PressesSreedhar PugalendhiNoch keine Bewertungen

- D D P I M A C: Esign and Evelopment of Lastic Njection Oldfor UTO OmponentDokument7 SeitenD D P I M A C: Esign and Evelopment of Lastic Njection Oldfor UTO OmponentSreedhar PugalendhiNoch keine Bewertungen

- TNM Sites May 2023Dokument24 SeitenTNM Sites May 2023Joseph ChikuseNoch keine Bewertungen

- MEAMTA2-Assignment 2Dokument5 SeitenMEAMTA2-Assignment 2pfukanisibuyi7Noch keine Bewertungen

- A Team - Group - ESG Handbook 2021 July 2021Dokument69 SeitenA Team - Group - ESG Handbook 2021 July 2021Prajwala JankarNoch keine Bewertungen

- Fundamental and Technical Analysis of Iron and Steel SIP PROJECTDokument34 SeitenFundamental and Technical Analysis of Iron and Steel SIP PROJECThaveuever910Noch keine Bewertungen

- DHI-ITALE-060AA-P: White Strobe LampDokument2 SeitenDHI-ITALE-060AA-P: White Strobe LampXlabs MedanNoch keine Bewertungen

- CF1900SS-DF Example Spec - Rev1Dokument1 SeiteCF1900SS-DF Example Spec - Rev1parsiti unnesNoch keine Bewertungen

- VK-53 (ВК-53) Erecting Cut-Out Switch: Maintenance ManualDokument76 SeitenVK-53 (ВК-53) Erecting Cut-Out Switch: Maintenance ManualhaileNoch keine Bewertungen

- Rate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesDokument25 SeitenRate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesMirza BabarNoch keine Bewertungen

- Labangon Elementary School Diagbostic Test in Epp/Tle 6 Directions: Multiple Choice. Choose The Correct The Letter of The Correct AnswerDokument4 SeitenLabangon Elementary School Diagbostic Test in Epp/Tle 6 Directions: Multiple Choice. Choose The Correct The Letter of The Correct AnswerJulianFlorenzFalconeNoch keine Bewertungen

- A Lesson About SpringDokument7 SeitenA Lesson About SpringKatjaNoch keine Bewertungen

- Apti 2Dokument17 SeitenApti 2Arunkumar MurugappanNoch keine Bewertungen

- Manual Placa Mae Ga 945gcmx-s2 6.6Dokument72 SeitenManual Placa Mae Ga 945gcmx-s2 6.6luisb3toNoch keine Bewertungen

- List INN 08february2012 PDFDokument128 SeitenList INN 08february2012 PDFMarisaNoch keine Bewertungen

- Nervous SystemDokument40 SeitenNervous SystemJaneNoch keine Bewertungen

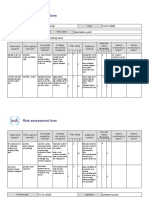

- Risk Assessment Project Iosh - MsDokument2 SeitenRisk Assessment Project Iosh - MsSanjeev Kumar75% (32)

- Brochure E-AIR T400-900 WEG APP 2958 1020 02 ENDokument3 SeitenBrochure E-AIR T400-900 WEG APP 2958 1020 02 ENDaniel BravoNoch keine Bewertungen

- Vet CareplanexampleDokument6 SeitenVet CareplanexampleAnonymous eJZ5HcNoch keine Bewertungen

- Maths Class Xii Sample Paper Test 02 For Board Exam 2023Dokument6 SeitenMaths Class Xii Sample Paper Test 02 For Board Exam 2023Priyanshu KasanaNoch keine Bewertungen

- Catálogo DP InglêsDokument20 SeitenCatálogo DP Inglêsjf2003Noch keine Bewertungen

- 365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusDokument10 Seiten365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusER Aditya DasNoch keine Bewertungen

- Ford6000cd Rear ConnectorDokument2 SeitenFord6000cd Rear ConnectorAnonymous WcYW9AeNoch keine Bewertungen

- Water Treatment Lecture 4Dokument34 SeitenWater Treatment Lecture 4pramudita nadiahNoch keine Bewertungen

- P&S U V PracticeDokument4 SeitenP&S U V PracticeHari KrushnaNoch keine Bewertungen

- Elevator ControlDokument3 SeitenElevator ControlNATHANNoch keine Bewertungen

- Layout - Foundation Drawing - Air BlowerDokument2 SeitenLayout - Foundation Drawing - Air BlowerBabel THIAMNoch keine Bewertungen

- Cleavage in MammalsDokument51 SeitenCleavage in MammalsIrfan Azram100% (4)

- ABB Photovoltaic DisconnectorsDokument6 SeitenABB Photovoltaic DisconnectorsBog PenNoch keine Bewertungen

- FutbolistaDokument18 SeitenFutbolistaKaren Osses50% (2)

- Paracetamol BPDokument4 SeitenParacetamol BPjaimurugeshNoch keine Bewertungen

- F115a'12 Fl115a'12: (68VB) (68WB)Dokument96 SeitenF115a'12 Fl115a'12: (68VB) (68WB)AlexDiazNoch keine Bewertungen