Beruflich Dokumente

Kultur Dokumente

Process Costing: © 2009 Pearson Prentice Hall. All Rights Reserved

Hochgeladen von

Anonymous d1eylzUp0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten30 Seitennotes

Originaltitel

costacctg13e_ppt_ch17

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldennotes

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

17 Ansichten30 SeitenProcess Costing: © 2009 Pearson Prentice Hall. All Rights Reserved

Hochgeladen von

Anonymous d1eylzUpnotes

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 30

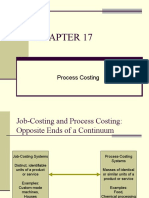

Process Costing

2009 Pearson Prentice Hall. All rights reserved.

Job-Costing Systems Process-Costing

Systems

Distinct, identifiable

units of a product Masses of identical

or service or similar units of a

product or service

Examples:

Custom-made Examples:

machines, Food,

Houses Chemical processing

2009 Pearson Prentice Hall. All rights reserved.

Process-Costing

Process-costing is a system where the unit

cost of a product or service is obtained by

assigning total costs to many identical or

similar units

Each unit receives the same or similar

amounts of direct materials costs, direct

labor costs, and manufacturing overhead

Unit costs are computed by dividing total

costs incurred by the number of units of

output from the production process

2009 Pearson Prentice Hall. All rights reserved.

Process-Costing Assumptions

Direct Materials are added at the beginning of

the production process, or at the start of work

in a subsequent department down the

assembly line

Conversion Costs are added equally along the

production process

2009 Pearson Prentice Hall. All rights reserved.

Five-Step Process-Costing

Allocation

1. Summarize the flow of physical units of

output

2. Compute output in terms of equivalent units

3. Compute cost per equivalent unit

4. Summarize total costs to account for

5. Assign total costs to units completed and to

units in ending Work-in-Process

2009 Pearson Prentice Hall. All rights reserved.

Equivalent Units

A derived amount of output units that:

1. Takes the quantity of each input in units

completed and in unfinished units of work in

process and

2. converts the quantity of input into the

amount of completed output units that could

be produced with that quantity of input

Are calculated separately for each input

(direct materials and conversion cost)

2009 Pearson Prentice Hall. All rights reserved.

Steps 1 & 2 Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Steps 3, 4 & 5, Illustrated

2009 Pearson Prentice Hall. All rights reserved.

General Ledger Cost Flows

Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Weighted-Average

Process-Costing Method

Calculates cost per equivalent unit of all work

done to date (regardless of the accounting

period in which it was done)

Assigns this cost to equivalent units

completed & transferred out of the process,

and to incomplete units in still in-process

2009 Pearson Prentice Hall. All rights reserved.

Weighted-Average

Process-Costing Method

Weighted-average costs is the total of all

costs in the Work-in-Process Account divided

by the total equivalent units of work done to

date

The beginning balance of the Work-in-Process

account (work done in a prior period) is

blended in with current period costs

2009 Pearson Prentice Hall. All rights reserved.

Steps 1 & 2 Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Steps 3, 4 & 5 Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Result of the Process

Two critical figures arise out of Step Five of

the cost allocation process:

1. The amount of the Journal Entry transferring

the allocated cost of units completed and

sent from Work-in-Process Inventory to

Finished Goods Inventory

2. The ending balance of the Work-in-Process

Inventory account that will appear on the

Balance Sheet

2009 Pearson Prentice Hall. All rights reserved.

First-in, First-Out

Process-Costing Method

Assigns the cost of the previous accounting

periods equivalent units in beginning work-

in-process inventory to the first units

completed and transferred out of the

process

Assigns the cost of equivalent units worked

on during the current period first to

complete beginning inventory, next to stat

and complete new units, and lastly to units

in ending work-in-process inventory

2009 Pearson Prentice Hall. All rights reserved.

First-in, First-Out

Process-Costing Method

The beginning balance of the Work-in-Process

account (work done in a prior period) is kept

separate from current period costs

2009 Pearson Prentice Hall. All rights reserved.

Steps 1 & 2, Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Steps 3, 4 & 5, Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Result of the Process (as before)

Two critical figures arise out of Step Five of

the cost allocation process:

1. The amount of the Journal Entry transferring

the allocated cost of units completed and

sent from Work-in-Process Inventory to

Finished Goods Inventory

2. The ending balance of the Work-in-Process

Inventory account that will appear on the

Balance Sheet

2009 Pearson Prentice Hall. All rights reserved.

Standard Costing and

Process Costing

Teams of design and process engineers,

operations personnel, and management

accountants work together to determine

separate standard costs per equivalent unit on

the basis of different technical processing

specifications for each product

Standard costs replace actual costs in

equivalent unit calculations

2009 Pearson Prentice Hall. All rights reserved.

Steps 1 & 2, Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Steps 3, 4 & 5, Illustrated

2009 Pearson Prentice Hall. All rights reserved.

General Ledger Cost Flows

Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Transferred-in Costs

Are costs incurred in previous departments

that are carried forward as the products cost

when it moves to a subsequent process in the

production cycle

Also called Previous Department Costs

Journal entries are made to mirror the

progress in production from department to

department

Transferred-in costs are treated as if they are

a separate type of direct material added at

the beginning of the process

2009 Pearson Prentice Hall. All rights reserved.

Steps 1 & 2, Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Steps 3, 4 & 5, Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Steps 1 & 2, Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Steps 3, 4 & 5, Illustrated

2009 Pearson Prentice Hall. All rights reserved.

Hybrid Costing Systems

A Hybrid-Costing System blends

characteristics from both job-costing and

process-costing systems

Many actual production systems are in fact

hybrids

Examples include manufacturers of

televisions, dishwashers and washing

machines, as well as Adidas

2009 Pearson Prentice Hall. All rights reserved.

2009 Pearson Prentice Hall. All rights reserved.

Das könnte Ihnen auch gefallen

- Process Costing: © 2009 Pearson Prentice Hall. All Rights ReservedDokument33 SeitenProcess Costing: © 2009 Pearson Prentice Hall. All Rights ReservedGesaNoch keine Bewertungen

- Process Costing: © 2012 Pearson Prentice Hall. All Rights ReservedDokument26 SeitenProcess Costing: © 2012 Pearson Prentice Hall. All Rights ReservedayyazmNoch keine Bewertungen

- Process Costing: ReadingsDokument52 SeitenProcess Costing: Readingsمحمود احمدNoch keine Bewertungen

- Managerial Acc 3Dokument52 SeitenManagerial Acc 3emadhamdy2002Noch keine Bewertungen

- Chapter 2 Costing SystemsDokument26 SeitenChapter 2 Costing SystemsfekadeNoch keine Bewertungen

- GE Hca15 PPT ch17Dokument38 SeitenGE Hca15 PPT ch17Tita NurvitaNoch keine Bewertungen

- CH 17Dokument15 SeitenCH 17emmyindraNoch keine Bewertungen

- 20221218145704D6181 - Datar - 17e - Accessible - Fullppt - 18 - Process Costing WeightedDokument27 Seiten20221218145704D6181 - Datar - 17e - Accessible - Fullppt - 18 - Process Costing WeightedMateus AriatamaNoch keine Bewertungen

- Session 10-14 PGDM 2020-21Dokument44 SeitenSession 10-14 PGDM 2020-21Krishnapriya NairNoch keine Bewertungen

- Management AccountingDokument246 SeitenManagement AccountingsaraNoch keine Bewertungen

- Chapter 16 Cost InformationDokument37 SeitenChapter 16 Cost InformationvalerieNoch keine Bewertungen

- Process CostingDokument4 SeitenProcess CostingVidia ProjNoch keine Bewertungen

- Cost Accounting 2 Fourth Year Second Semester 2020-2021 Chapter (17) Part (Dr. Badr Nabeeh) (1&2)Dokument17 SeitenCost Accounting 2 Fourth Year Second Semester 2020-2021 Chapter (17) Part (Dr. Badr Nabeeh) (1&2)محمود احمدNoch keine Bewertungen

- Chapter_4_Process_Costing_Rework_Scrap_Spoilage_Joint_Product_2015Dokument17 SeitenChapter_4_Process_Costing_Rework_Scrap_Spoilage_Joint_Product_2015Amha SeyoumNoch keine Bewertungen

- Cac NotesDokument14 SeitenCac Notescoco credo100% (1)

- AF313 - Lecture 3.1 Process CostingDokument23 SeitenAF313 - Lecture 3.1 Process Costings11186706Noch keine Bewertungen

- Process CostingDokument38 SeitenProcess CostingQurat SaboorNoch keine Bewertungen

- Process Costing SystemDokument15 SeitenProcess Costing SystemAmmad SheikhNoch keine Bewertungen

- Process Costing System ExplainedDokument41 SeitenProcess Costing System ExplainedGenanew AbebeNoch keine Bewertungen

- 5-th Material - Process Costing I (Template)Dokument28 Seiten5-th Material - Process Costing I (Template)KAELA TAFFINA NUGRAHANoch keine Bewertungen

- ch05 dngnDokument22 Seitench05 dngnĐàm Ngọc Giang NamNoch keine Bewertungen

- Understanding Process Costing SystemsDokument13 SeitenUnderstanding Process Costing SystemsMulumebet EshetuNoch keine Bewertungen

- Chapter 17 Final + Class Problems - pdf-1Dokument43 SeitenChapter 17 Final + Class Problems - pdf-1محمود احمدNoch keine Bewertungen

- CH 17-Process CostingDokument11 SeitenCH 17-Process CostingSagar Bhikamchand GugaliyaNoch keine Bewertungen

- Process CostingDokument3 SeitenProcess Costingmasof007Noch keine Bewertungen

- Chapter 3 Job CostingDokument9 SeitenChapter 3 Job CostingMuzey KassaNoch keine Bewertungen

- تكاليف Ch17Dokument14 Seitenتكاليف Ch17alsaqarhamzaNoch keine Bewertungen

- Cost Accounting Chapter 10Dokument66 SeitenCost Accounting Chapter 10Reshyl HicaleNoch keine Bewertungen

- Job Order CostingDokument6 SeitenJob Order CostingJomar Teneza100% (1)

- 4 5892982197136132975Dokument15 Seiten4 5892982197136132975Habte AbeNoch keine Bewertungen

- Process CostingDokument3 SeitenProcess CostingEllah MaeNoch keine Bewertungen

- O Equivalent Units (Number of Partially Completed Units in Ending WIP Inventory) The PercentageDokument3 SeitenO Equivalent Units (Number of Partially Completed Units in Ending WIP Inventory) The Percentagetjn8240Noch keine Bewertungen

- Process Costing 2Dokument23 SeitenProcess Costing 2Alyssa DimangadapNoch keine Bewertungen

- COSACC Assignment 3Dokument2 SeitenCOSACC Assignment 3Kenneth Jim HipolitoNoch keine Bewertungen

- Process CostingDokument15 SeitenProcess CostingyebegashetNoch keine Bewertungen

- Acctg201 JobOrderCostingLectureNotesDokument20 SeitenAcctg201 JobOrderCostingLectureNotesaaron manacapNoch keine Bewertungen

- Class - 6Dokument35 SeitenClass - 6harsheen kaurNoch keine Bewertungen

- COST ACCOUNTING FUNDAMENTALSDokument6 SeitenCOST ACCOUNTING FUNDAMENTALSAyraaahNoch keine Bewertungen

- Process CostingDokument20 SeitenProcess CostingkirosNoch keine Bewertungen

- Job-Process Costing SystemsDokument25 SeitenJob-Process Costing Systemsliyneh mebrahituNoch keine Bewertungen

- Process Costing vs. Job CostingDokument11 SeitenProcess Costing vs. Job CostingRhea Royce CabuhatNoch keine Bewertungen

- Chapter 3: Process Costing: Cost & Management Accounting I/ Lecture Note On Process CostingDokument12 SeitenChapter 3: Process Costing: Cost & Management Accounting I/ Lecture Note On Process CostingFear Part 2Noch keine Bewertungen

- Chapter Three Process Costing: Learning ObjectivesDokument9 SeitenChapter Three Process Costing: Learning ObjectivesAkkamaNoch keine Bewertungen

- Process Costing ModuleDokument6 SeitenProcess Costing ModuleClaire BarbaNoch keine Bewertungen

- ACCY918 T3 2023 Wk3 Process Costing Lecture NoteDokument82 SeitenACCY918 T3 2023 Wk3 Process Costing Lecture NoteNIRAJ SharmaNoch keine Bewertungen

- Process Costing and Hybrid Product-Costing Systems: Answers To Review QuestionsDokument60 SeitenProcess Costing and Hybrid Product-Costing Systems: Answers To Review QuestionsMISRET 2018 IEI JSCNoch keine Bewertungen

- CHAPTER 5 Product and Service Costing: A Process Systems ApproachDokument30 SeitenCHAPTER 5 Product and Service Costing: A Process Systems ApproachMudassar HassanNoch keine Bewertungen

- Zahid AssignmentDokument5 SeitenZahid AssignmentJinnath JumurNoch keine Bewertungen

- POMA Chapter 4 Process CostingDokument17 SeitenPOMA Chapter 4 Process CostingzainabmossadiqNoch keine Bewertungen

- Chapter 10 PPT Agm-1Dokument13 SeitenChapter 10 PPT Agm-1Paulina DocenaNoch keine Bewertungen

- Process costing allocates indirect costs to productsDokument4 SeitenProcess costing allocates indirect costs to productsHarish PrajapatNoch keine Bewertungen

- 4 Cost Management System IMPROVED - by FSCDokument31 Seiten4 Cost Management System IMPROVED - by FSCAryan jhaNoch keine Bewertungen

- Process Costing Systems: Job vs Process CostingDokument10 SeitenProcess Costing Systems: Job vs Process CostingMegan CruzNoch keine Bewertungen

- UEU Akuntansi Biaya Pertemuan 8910Dokument84 SeitenUEU Akuntansi Biaya Pertemuan 8910hardyputra46Noch keine Bewertungen

- Financial Tools Week 5 Block BDokument9 SeitenFinancial Tools Week 5 Block BBelen González BouzaNoch keine Bewertungen

- Process CostingDokument14 SeitenProcess CostingfitsumNoch keine Bewertungen

- MANAGERIAL-ACCOUNTINGDokument16 SeitenMANAGERIAL-ACCOUNTINGLinh ChiNoch keine Bewertungen

- Process Costing FIFO CRDokument21 SeitenProcess Costing FIFO CRMiyangNoch keine Bewertungen

- Cost Management: A Case for Business Process Re-engineeringVon EverandCost Management: A Case for Business Process Re-engineeringNoch keine Bewertungen

- Manual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDokument106 SeitenManual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDante Renee Mendoza DelgadoNoch keine Bewertungen

- (App Note) How To Design A Programmable Gain Instrumentation AmplifierDokument7 Seiten(App Note) How To Design A Programmable Gain Instrumentation AmplifierIoan TudosaNoch keine Bewertungen

- Form 1 ADokument2 SeitenForm 1 ARohit Jain100% (1)

- Where On Earth Can Go Next?: AppleDokument100 SeitenWhere On Earth Can Go Next?: Applepetrushevski_designeNoch keine Bewertungen

- Mama Leone's Profitability AnalysisDokument6 SeitenMama Leone's Profitability AnalysisLuc TranNoch keine Bewertungen

- Scholars of Hadith Methodology in Dealing With The Two Sahihs: The Criticized Ahadith As A Model. Ammar Ahmad Al-HaririDokument37 SeitenScholars of Hadith Methodology in Dealing With The Two Sahihs: The Criticized Ahadith As A Model. Ammar Ahmad Al-HaririSalah KhanNoch keine Bewertungen

- Av1 OnDokument7 SeitenAv1 OnLê Hà Thanh TrúcNoch keine Bewertungen

- Delhi Public School: Class: XI Subject: Assignment No. 3Dokument1 SeiteDelhi Public School: Class: XI Subject: Assignment No. 3Aman Kumar BhagatNoch keine Bewertungen

- Fda PDFDokument2 SeitenFda PDFVictorNoch keine Bewertungen

- MKT-case StudyDokument7 SeitenMKT-case StudyJoe Thampi KuruppumadhomNoch keine Bewertungen

- Executive Education Portfolio Soft Copy-INSEADDokument58 SeitenExecutive Education Portfolio Soft Copy-INSEADОля КусраеваNoch keine Bewertungen

- BMXNRPDokument60 SeitenBMXNRPSivaprasad KcNoch keine Bewertungen

- Crash Cart - General Checklist For Medical Supplies On Crash CartsDokument3 SeitenCrash Cart - General Checklist For Medical Supplies On Crash CartsYassen ManiriNoch keine Bewertungen

- Startups Helping - India Go GreenDokument13 SeitenStartups Helping - India Go Greensimran kNoch keine Bewertungen

- Nature and Scope of Marketing Marketing ManagementDokument51 SeitenNature and Scope of Marketing Marketing ManagementFeker H. MariamNoch keine Bewertungen

- HP 5973 Quick ReferenceDokument28 SeitenHP 5973 Quick ReferenceDavid ruizNoch keine Bewertungen

- EQ - Module - Cantilever MethodDokument17 SeitenEQ - Module - Cantilever MethodAndrea MalateNoch keine Bewertungen

- Donaldson 004117 PDFDokument6 SeitenDonaldson 004117 PDFNSNoch keine Bewertungen

- Assessing Eyes NCM 103 ChecklistDokument7 SeitenAssessing Eyes NCM 103 ChecklistNicole NipasNoch keine Bewertungen

- Choose the Best WordDokument7 SeitenChoose the Best WordJohnny JohnnieeNoch keine Bewertungen

- Useful Coaching Questions: Questions To Create A State Change Questions To Ask When Something Goes WrongDokument2 SeitenUseful Coaching Questions: Questions To Create A State Change Questions To Ask When Something Goes WrongAntonioNoch keine Bewertungen

- Summer Internship Project-NishantDokument80 SeitenSummer Internship Project-Nishantnishant singhNoch keine Bewertungen

- Grade 10 - Mock Test - English - Feb - 2023Dokument12 SeitenGrade 10 - Mock Test - English - Feb - 2023rohanNoch keine Bewertungen

- Module 4-Answer KeyDokument100 SeitenModule 4-Answer KeyAna Marie Suganob82% (22)

- LLoyd's Register Marine - Global Marine Safety TrendsDokument23 SeitenLLoyd's Register Marine - Global Marine Safety Trendssuvabrata_das01100% (1)

- Indian Institute OF Management, BangaloreDokument20 SeitenIndian Institute OF Management, BangaloreGagandeep SinghNoch keine Bewertungen

- C ClutchesDokument131 SeitenC ClutchesjonarosNoch keine Bewertungen

- January 2013 Igcse Timetable 22-06-2012Dokument2 SeitenJanuary 2013 Igcse Timetable 22-06-2012Rizwanur RahmanNoch keine Bewertungen

- Test SessionDokument2 SeitenTest SessionMuhammad Fiaz AslamNoch keine Bewertungen

- ArtigoPublicado ABR 14360Dokument14 SeitenArtigoPublicado ABR 14360Sultonmurod ZokhidovNoch keine Bewertungen