Beruflich Dokumente

Kultur Dokumente

A Batch

Hochgeladen von

Venkitesh0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

13 Ansichten71 SeitenOriginaltitel

11112015 A batch.pptx

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

13 Ansichten71 SeitenA Batch

Hochgeladen von

VenkiteshCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 71

Air conditioning systems

Based on the fluid media used in thermal

distribution system.

All air systems

All water systems

Air is used as the media transporting

energy from conditioned space to a/c plant.

Air is processed at A/C plant and is

conveyed through the ducts using blowers

and fans to the conditioned space.

This air extracts the required amount of

heat from/to the conditioned space and is

sent back to the A/C plant for further

-reprocessing

All water system- 2 pipe system

Fluid used in thermal distribution system is water.

Water transports energy between conditioned

space and the plant.

Cold water is circulated when cooling is required.

Hot water is circulated when heating is required.

Provision must be there for supplying required

amount of treated outdoor air to the a/c space

since only water is circulated.

Depending of no: of pipes used

Double pipe & four pipe system

2 pipe system is used either for heating /cooling

application only and cant be used for

simultaneous heating/cooling.

All Air Systems

Advantages:

Greatest potential for energy conservation

by utilizing outdoor air.

Able to provide good room air distribution

under all conditions of load.

By using high quality controls, temperature

and relative humidity can be well

maintained.

Disadvantages:

Occupy more space and reduce available

floor space in the building.

All Water system

Advantages:

Thermal distribution system requires less

space compared to all air systems.

Individual room control is possible.

Disadvantages:

Requires high maintenance compared to

all air systems

Draining of condensate water can be

messy and also may create health problems

if water stagnates in the drain tray.

Control of humidity, particularly during

summer is very difficult.

Psychrometry Properties

Dry bulb temperature (DBT): Temperature of

the moist air as measured by a standard

thermometer.

Saturated vapour pressure: saturated partial

pressure of water vapour at DBT.

Relative humidity: normally expressed as

percentage.

Humidity Ratio: mass of water associated with

each kg of dry air.

Enthalpy: Sum of enthalpy of dry air and

enthalpy of water vapour.

Specific volume: no: of cubic metres of moist

air per kilogram of dry air.

Psychrometric chart

Gives graphical representation of

important properties of moist air.

DBT, WBT, Moisture content, RH,

specific enthalpy, and specific volume.

If any 2 properties are known, then the

other 4 can be found from the chart.

Used extensively air-conditioning

applications.

X axis give DBT whereas Y axis gives

humidity ratio in gram of water vapour

per kg of dry air.

Psychrometric processes

Sensible heating/cooling : Refers to

heating/cooling without phase change. (without

increase/decrease of moisture content).

Cooling with dehumidification: reducing of

air temperature along with removal of water

vapour air.

Humidification: Addition of moisture to air.

Evaporative cooling: Needed in hot/dry

climates

It has an arrangement of spraying liquid water

in to air .due to less humidity of air, some

amount of water will evaporate and

consequently temperature will reduce.

Introduction to Automobiles

It is a self propelled vehicle used for

transportation of passengers and goods

upon the ground.

Types of engines used in automobiles:

1. According to type of fuel

1. Petrol engines

2. Diesel engines

3. Gas engines

2. According to the method of igniting the

fuel

1. Spark ignition engines.

2. Compression ignition engines.

3. According to no: of strokes/cycle

Four stroke cycle engines

Cycle is completed in four strokes of the piston

Two stroke engines

Cycle is completed in 2 strokes of the piston.

4. According to the cycle of operation

Otto cycle engines

Diesel cycle engines

Dual combustion cycle engines

5. According to the speed of engines

Slow speed/medium speed/high speed

engines (up to 350 rpm/350-1000/above

1000 rpm)

6. According to the cooling system

Air-cooled engines Uses circulation of air

Water cooled engines Water circulation to hot

engine parts

Evaporative cooled engines Evaporation of liquid

like propylene glycol is used for cooling.

7. According to the method of fuel supply system

Carburettor engines uses carburettor for supplying

air-fuel mixture to the cylinder

Air-Injection Engines Delivers fuel at high pressure

to cylinder using compressed air.

Air less or solid injection engines Delivers fuel at

high pressures to the cylinder using mechanical

pumps.

8. According to the number of cylinders

Single cylinder engines: Consists of only ONE

cylinder

Multi cylinder engines: Consists of multiple

cylinders.

9. According to the arrangement of cylinders:

Vertical engines Axis of cylinder is vertical.

Horizontal engines Axis of cylinder is

horizontal

Radial engines Radially placed around a

common crankshaft

V type multi-cylinder engines: Two cylinders

are placed forming a V-shape.

10. According to the Valve mechanism:

Overhead valve engines: Valve is place

at the top of the cylinder

Side valve engines: Valve is placed at

the side of the cylinder.

Rotary valve engines: Valves are

opened and closed by a rotating

member.

Types of Automobiles

1. Classification based on Purpose

a. Passenger vehicle : Which carries

passengers : Car, Jeep, Bus, auto rickshaw

b. Good vehicle: Which carries

materials/goods.

2. Capacity:

c. Light motor vehicle: able to carry light

things and are also less in size and weight.

d. Heavy motor vehicle: Can carry very

heavy materials and posses large mass

and gross vehicle weight exceeds 12000

kg. Eg: bus, Lorry etc..

3. According to the fuel used:

Petrol vehicles : Car, Jeep, Motorcycle, Scooter

Diesel Vehicles : Car, Jeep, Truck, bus, Tractor

etc.

Electric vehicle: Electric Cars, Electric buses

Gas Vehicles: CNG vehicles.

4. Based on type of transmission:

Automatic transmission vehicles: Vehicles

capable of changing gear automatically while

moving.

Manual gear changing vehicles

Semi-automatic transmission : allows manual

gear changes and uses a clutch but facilitates

the gear changes without a clutch pedal.

5. Drive of the vehicle:

Rear wheel drive: Rear wheel are driven

by the engines.

Front wheel drive: Front wheels are driven

by the engine.

All wheel drive: All the wheels are driven

by the engine.

Layout of an automobile

Chassis- Part of the body which

supports its body, engine and

transmission system.

Transmission system: consists of clutch,

gear box, propeller shaft, axle and

differential.

It transmits power from the engine to

the wheels.

Clutch is used to couple/decouple the

engine and transmission.

Gear box contain gearing arrangement

to get different speeds. Used to get

more than one speed ratios.

Propeller shaft is a long shaft used to connect

the output shaft of the gear box to the rear axle.

Differential has three functions

1. Transfer power from propeller shaft to the wheels.

2. Allow wheels to rotate at different speeds while

turning.

3. To turn the direction of drive through 90 0 to the

rear wheels

. The steering wheel is mechanically linked to

the wheels to provide the steering control.

. Brakes: They are attached to the four wheels

and are of 2 types: 1. Drum brakes 2. Disc brakes

Suspension system: For preventing the

transmission of shock from uneven road surfaces to

the vehicle and to support the vehicle on the axle.

Various systems in IC engines

The components related and needed for a

particular function of the IC engine are

grouped together and is called a system

Various systems are:

Air intake system

Exhaust system, fuel system

Ignition system

Lubrication system

Cooling system

Engine starting system

Air Intake system

Purpose is to supply clean air to the engine.

An air filter is fitted to remove dust from air

before supplying to the engine.

In SI engine, intake system consists of inlet

manifold, a throttle, intake valves and a

carburettor to add fuel.

Carburettor is a device which atomizes the fuel

an mixed with air and is carried to engine cylinder

through inlet manifold.

In CI engine, air intake is uncontrolled with a

very little restriction to the flow of air. Where the

air intake is directly connected to inlet manifold.

A turbocharger in CI engines enhances the air

intake even more.

Exhaust system

After completion of combustion process, the

exhaust gases have to be removed from the

engine cylinder to admit fresh fuel air charge of

the next cycle.

Exhaust gases passes through the exhaust

valves and pass through exhaust manifold.

From exhaust manifold, gases pass through the

emission control system which may contain

thermal converters and a muffler, after which gas

Fuel system in IC engines

Fuels are to be pressurized before

injecting in to the cylinder.

Fuel is supplied using fuel pump.

Carburettor is a device used for atomizing

fuel, vaporizing it and mixing it with air in

correct proportion to produce

homogeneous mixture to suit changing

condition of the engine.

Fuel Pump

Air injection are divided in to two:

Air injection system and solid injection system

Fuel is pumped along with the air to the cylinder

in air injection.

Whereas in solid injection, fuel is raised to

extreme pressures by mechanical pumps and

deliver it to combustion chambers using fuel

injectors without compressed air.

Solid injection consists of pressurizing unit and

injector(atomizing unit).

Fuel is supplied to the cylinder either by gravity

or using fuel pump.

Engine starting system

Consists of electric starter motor, and starter

solenoid.

Powerful Starter motor spins the engine a few

revolutions when ignition key is turned on, so that

combustion process can start.

It requires a powerful motor to spin a cold engine

and to overcome friction, open and close valves

with the cam shaft and all other things directly

attached to the engine.

Hundreds of amperes of electricity flows to the

motor as a large amount of energy is needed for

this.

Solenoid switch controls this much large amount of

current.

Ignition system of IC engine

In petrol engines, it requires a spark plug to

produce spark to initiate combustion.

A high electric discharge is produced between 2

electrodes at the spark plug., by the ignition

system.

Voltage required to produce this high discharge is

10000-20000 V.

In battery ignition systems, a battery is the source of

energy.

In magneto ignition system, energy source is a set of

rotating magnets in fixed coils or rotating coils in fixed

magnets.

The current produced by the magnets flow to the coils.

This system is mainly used in 2 wheelers, kick start

engines

Lubrication system in IC engine

If moving parts are allowed to rub each

other, it will cause friction and heat,

resulting in excess wear.

This can be reduced by placing a film of

lubricating oil between the moving parts so

that they ride on the oil film.

Power required to overcome friction will also

be reduced and results in reduced wear and

tear.

Main parts to be lubricated in an IC engine

are crankshaft, bearing, crank pin, piston,

cylinder walls, cams, valve stems, gears etc.

Cooling system in IC engine

Due to combustion of fuel inside the cylinder, intense

heat is generated.

Only 30% of heat is converted in to work while,

remaining 40% is carried away by the exhaust gases

to the atmosphere.

The remaining 30% is left unattended will be absorbed

by the engine cylinder, piston and cylinder valves etc.

Overheating of the engine components may cause

thermal stresses, seizure of piston, decomposition of

lube oil, reduced volumetric efficiency etc.

An efficient cooling system in an engine is capable of

removing 30% of the heat generated in the

combustion chamber.

Capable of removing heat at a faster rate when engine

is hot.

In Air-cooling system, the heat is dissipated

directly in to the atmosphere directly by

conduction through the cylinder walls.

It works by making the object to be cooled to

have a larger surface area or increased flow of

air over its surface or both.

In water cooling system, water is circulated

through water jackets around each of the

combustion chambers.

The water is kept continuously by a pump which

is driven by a v belt from the pulley on the

engine crank shaft.

After passing through the engine cylinder, the

water is passed through the radiator. In the

radiator, the water is cooled by air drawn

through the radiator by a fan.

Fundamentals of Aerodynamics

Aerodynamics is concerned with motion of

air and bodies moving through air.

The forces acting on bodies moving through

air are termed as aerodynamic forces.

By Archimedes principle, an aircraft will be

buoyed up by a force equal to weight of the

air displaced by it.

The buoyancy force will act upwards

vertically.

The net-force W-Fb will be acting irrespective

of whether aircraft is in rest or in motion.

Aircraft is flying in still air with a constant

velocity V.

Here the motion of air is solely due to the

motion of air craft.

Motion of aircraft is maintained by a force T

exerted by the engines

By Newtons first law of motion, the resultant

force acting on the aircraft must be zero,

when it is at steady flight.

There must be an additional force Fad such

that vectorial sum of forces acting on the

aircraft is zero.

T+(W-Fb) + Fad = 0

Fad is called aerodynamic force.

Lift and drag

Resolution of aerodynamic force in to two.

At right angles to V and opposite to V

The force component normal to V is called

Lift, L and opposite to V is called drag, D

If is the angle between L and D

L = Fad x cos

D = Fad x sin

tan = D/L

is the guide angle.

Lift is the component of aerodynamic

force perpendicular to direction of

motion. (opposite to downward force of

weight).

Drag is the component of force opposite

to the direction of motion

Drag opposes thrust and acts rearward

parallel to the relative wind.

Thrust opposes or overcomes the force

of drag.

Aircraft engines

Modern aircraft engine have the ability to

actuate massive stream and thus to

produce high thrust.

Turbojet engine.

Turboprop engine.

Turbofan engine.

Ramjet engine.

Module V- Theory of Mechanisms & Machines

Used to understand the relationships between

geometry and motion of parts of machine or

mechanism and forces which produce these motion.

Essential for the design of a machine.

Kinematics: It is the branch which deals with

geometric relationships and relative motion

between parts like position, displacement, rotation

speed etc..

Dynamics: Which deals with study of forces acting

on various parts of machine.

Forces can be either static or dynamic due to inertia

of the parts of the machine.

Static deals with stationary systems

Dynamics deals with systems that change with time.

Analysis and synthesis

Synthesis (Design) is the process of prescribing

the sizes, shapes, material compositions, and

arrangement of parts so that the resulting

machine will perform the prescribed task.

Application of largest collection of scientific

methods falls under analysis.

Evaluation and rating of things already

conceived.

A machine is a combination of resistant bodies

so arranged that by their means the mechanical

forces of nature can be compelled to do the

work accompanied by certain determinate

motions

A mechanism is defined as an assemblage of

resistant bodies connected by movable joints

to form a closed kinematic chain with one link

fixed and having purpose of transforming

motion.

A machine is an arrangement for doing

work/applying power where as mechanism is

transmitting power to achieve the desired

motion.

The connection between links of the

mechanism is called a pair (kinematic pair).

The purpose of a link is to hold a constant

spatial relationship between elements of its

pairs.

Structure is an assemblage of no: of resistant

When several links are movable connected

together by joints they are said to form a

kinematic chain.

Links containing only 2 pairs of element

connections are called binary joints.

Recognizing the type of relative motion

and assigning some variable parameters

for measuring or calculating motion are

called degree of freedom.

Lower pairs are having surface contact

between the pair elements whereas higher

pairs have point contact between the

elemental surfaces.

Planar, Spherical & Spatial mechanisms

A planar mechanism is one in which all particles

describe plane curves in space and all these

curves lie in parallel planes.

Loci of all points are plane curves parallel to a

common plane.

The motion transformation of any such

mechanism is called coplanar.

Slider crank mechanism, four bar mechanism are

examples of planar mechanisms.

Planar mechanisms using only lower pairs are

called planar linkages.

It requires that all the axes of revolutionary and

prismatic pairs should be normal to he plane of

motion.

Spherical mechanism

Is one in which all the moving links perform

concentric spherical motions about a common

stationary point called spherical center.

Motion of all particles can be described by

their radial projections on the surface of a

sphere with properly chosen center.

Hooks universal joint is the most familiar

example of spherical mechanism.

They are constituted of revolutionary pairs.

Spatial mechanism &Mobility

A rigid body is said to undergo spatial motion if its

motion is not planar or spherical.

Spatial mechanisms include no restrictions on the

relative motions of the particles.

The motion transformation is not necessarily coplanar

nor it must be concentric.

Have particles with loci of double curvature.

Screw pair is an example for spatial mechanism

Mobility is the no: of degrees of freedom of a

mechanism.

The number of input parameters which must be

independently controlled in order to bring the device

in to a particular position.

Calculation of mobility of a mechanism directly from

the count of no: of links and the no: and types of

joints.

For a n-link planar mechanism, has 3 x (n-1)

degrees of freedom before any joints are

connected.

When we use J1 to denote the no: of single DOF

pairs and J2 to represent no: of 2 DOF pairs,

resulting mobility m of a planar n-link mechanism

is given by the following:

m = 3 x (n-1) - 2J1 J2 (Kutzbach criterion)

Inversion of a Mechanism

Method of obtaining different mechanism by fixing

up different links is called inversion of mechanism.

Relative motions are not changed in inversion but

the absolute motion (one w.r.to Fixed link).

Part of the mechanism which initially moves w.r.to

the frame is called driver whereas part to which

the motion is transmitted is called follower.

Grashoffs law for 4 bar linkage states that the

sum of the shortest and longest linkages cannot

be greater than the remaining 2 link lengths, if

there is to be continuous relative motion between

these two.

In the following figure the following equation

applies:

s+l = p+q

Mechanical advantage of a linkage is the ration of

the output torque exerted by the driven link to

the necessary input torque required at the driver.

(Ratio of load to effort)

Ideal mechanical advantage is M.A =

FB /FA = vA /vB

Mechanical Design &Types

Formulate a plan for the satisfaction of a specific

need or a problem is done in design.

Design is an innovative, highly iterative decision

making process.

Adaptive design: Designers work is concerned

with adaptation of existing designs. Requires no

special skill/knowledge.

Development design: needs considerable

scientific training and design ability in order to

modify the existing designs into a new idea by

adopting new material or different method of

manufacture.

New Design: this type of design need lot of

research, technical ability and creative thinking.

Rational design : This types of design depends

upon mathematical formulae of principle of

mechanics.

Empirical Design: This type of design depends

upon empirical formula based on practice & past

experience.

Industrial Design: Depends upon the production

aspects to manufacture any machine component in

the industry.

Optimum design: Best design for the given

objective function under specified constraints.

System design: Design of any complex mechanical

system like a motor car.

Element design: Design of any element of the

mechanical system like piston, crankshaft,

connecting rod etc.

Design process:

1. Recognition of need

2. Definition of problem

3. Synthesis

4. Analysis and optimization

5. Evaluation

6. Presentation

Types of Loads

Static load : is a stationary force, moment or

torque acting on the member.

Dynamic load: which varies in magnitude or

in direction or in both with respect to time.

Cyclic load: Which when applied, varies in

magnitude in a repetitive cyclic manner, either

completely reversing itself from tension to

compression or oscillating about some mean value.

Eg: weights of machinery, load acting on pressure

vessel etc.

Impact load: Is a load which is applied suddenly in

to a member usually at a high velocity and at a

constant magnitude. Punch press, drop forge are

examples of machines subjected to impact loads.

Factor of safety:

It is the ratio of maximum load carrying

capability of the component to the design

loading.

Purpose is to safeguard against unexpectedly

high loads, material defects and process defects.

FOS = Failure Load/working Load

Working load is the load used in the design to

determine the dimensions of the component.

Failure load is the load at which the failure of the

material occurs.

Low FOS for high quality and consistent

materials, quality manufacturing and inspection

methods.

Material strength basis

Nature of load basis: Static, impact or cyclic

loading

Possible misuse: Designer must consider any

possible foreseeable use and misuse of the

component.

Complexity of stress analysis: Actual stress in

not known.

Environment: Temperature, Weather, radiation,

chemicals

Standards & Codes:

A standard is a set of specifications for parts,

materials or processes intended to achieve

uniformity, efficiency, and a specified quality.

Limit multitude of variations that can arise

from the arbitrary creation of parts.

A code is a set of specifications for the

analysis, design, manufacture and

construction of something.

The purpose of code is to achieve a specified

degree of safety, efficiency and performance

or quality.

Absolute safety is impossible to obtain in

practice.

Economics of Design:

Observe that nothing can be said in an absolute

sense concerning costs.

Increasing cost of materials and labour.

Cost of processing materials trend to decrease

because of automated machines/tools.

Increased cost based on location. (Labour, tax

variations etc.).

Reliability:

Primary focus is on Failures and their prevention.

It is the probability that a unit performs its

intended function adequately for a given period

of time under stated operating conditions o

environment.

Reliability R = 1 Pf

where Pf is the probability of failure is the

number of instances of failure per total

number of possible instances.

0<R<1

R = 0.9, means there is 90% chance that the

part will do intended function without failure.

If a mechanical system fails when any one

component fails, then the system is said to be

a series system.

If reliability of a component is i is Ri in a series

system of n components, then the reliability of

the system is expressed as

R = Ri

Module VI- Engineering Materials

For an engineer materials means structural

material that is used to produce various products.

Various kinds of materials used for industry,

housing, agriculture, transportation, etc. To meet

the plant requirement.

An appropriate selection of material adds to

economy, working and life of the final part of the

component.

The selection of a material for a process depends

on;

Operating parameters.

Manufacturing processes.

Functional requirements.

Cost considerations are known.

Properties of Engg. /Materials

Physical properties: describes the state of the

material, which is observable or measurable.

Eg: Colour, texture, density, MP, BP etc.

Chemical properties: chemical properties are the

measure of reactivity of a material in the presence of

another substance or environment which imposes in

the material composition.

Eg: Corrosion rate, oxidation rate,

Mechanical properties:

Tensile strength: this enables the material to resist the

application of a tensile force. the internal structure of the

material provides the internal resistance.

Hardness: Degree of resistance to indentation , scratching,

abrasion and wear.

Ductility : Property of a metal by virtue of which it can be

drawn in to wires/elongated before rupture take place.

Impact strength: energy required per unit c/s area

to fracture a specimen. response to shock loading.

Wear resistance: Ability of a material to resist

friction wear under particular conditions.(Maintain its

physical dimensions, when sliding or rolling contact

with a second member.

Corrosion resistance: those metals and alloys

which can withstand the corrosive action of medium.

Density: important factor of a material where weight

and mass are critical parameters.

Thermal properties: which are functions of

temperature, plays a vital role in the selection of

material for engg. applications

Eg: Thermal conductivity, specific heat, latent heat.

Classification of engg. materials

Metals & Alloys:

Metals are good electrical and thermal conductors.

At ordinary temperature, metals re usually solid.

To some extent metals are ductile.

Most of the metals form alloys.

May be magnetic or non-magnetic.

2 or more metals are melted together to form a

new metal whose properties are quite different

from those of original metals, is called an alloy.

Eg: steel is an alloy of iron, carbon, and other

alloying elements.

Brass is an alloy of copper and zinc.

Classification of engg. Materials ..(Contd.)

Ferrous metals:

Iron is the principal constituent and contains

significant amount of non-ferrous metals.

On the basis of carbon content, they are

classified as Steel and iron.

% of carbon in steel is up to 2.14.

% of carbon in iron is above 2.14.

Cast irons are manufactured by casting

technique owing to the brittle nature due to the

presence of iron carbide.

Cast irons serve mostly structural components

Lathe bed, sliding guides in machinery,

automobile motor casings etc.

Classification of engg. Materials..(Contd.)

Plain carbon steels is a metal alloy, where

there elements are present in quantities too

small to affect the properties

Mild steel - % of carbon is from 0.15-0.25

Moderately strong and have good weldability

Gears, valves, boiler plats etc.

Medium carbon steel

carbon % from 0.3 -0.6%

High strength and less weldability.

High carbon steels

Carbon % from 0.65-1.5

Getting harder and tougher by heat treatment.

Poor weldability.

Alloy steel:

Class of steel in which one or more elements

other than carbon are intentionally added to

impart some physical properties.

Common elements added are molybdenum,

manganese, nickel, silicon, boron, chromium

and vanadium etc.

Low alloy steels are category of ferrous

materials exhibiting superior mechanical

properties than plain carbon steels.

Total alloy content from 2.07 up to levels just

below that of SS.

Used for surgical instruments, ball bearing etc.

Non-Ferrous Metals:

These substances are composed of metals

other than iron.

Aluminium, tin, zinc, copper, nickel etc.

Ceramics:

These are non metallic solids made of inorganic

compounds such as oxides, nitrides, borides

and carbides.

They are fabricated by first shaping the powder

with or without application of pressure in to a

compact which is subsequently subjected to

high temperature treatment called sintering.

Used in the manufacture of porcelain, pottery,

cement etc.

Organic materials:

These materials originate from plants and animals.

Consists of carbon chemically combined with

hydrogen oxygen and other non-metallic

substances.

Common organic materials are plastics and

synthetic rubbers.

Formed by polymerization.

Have low specific gravity and good strength.

Thermosetting plastics are formed in to shape

under heat and pressure which results in a

permanently hard product.

Thermoplastics are those plastics which remain soft

at elevated temperature and become hard on

cooling.

Composites:

A composite material is defined as a material which is

composed of 2 or more materials at a microscopic

scale.

The constituent materials have different properties.

They can be natural or artificial made materials

Naturally occurring composites are wood, granite etc.

Semiconductors:

They are solid materials either non-metallic or

compounds which allow electrons to pass through

them so that they conduct electricity in much the

same way as metals.

They occupy an intermediate position between

conductor and insulator.

They usually have high resistivity, hardness and

brittileness.

Advanced materials:

Advanced materials refer to all new materials

and their development to the existing

materials to obtain superior, unique, and high

performance in one or more properties.

Amorphous and metallic glasses, nano

materials and nano composites, bio materials,

and smart or so called intelligent materials are

some type of advanced materials.

Nano structured materials:

Are those materials whose structural elements

(clusters, crystallites or molecules have

dimensions in the range of 1-100 nm)

Nano particles, nano crystals etc are examples.

Das könnte Ihnen auch gefallen

- Diesel Engine Power PlantsDokument58 SeitenDiesel Engine Power PlantsVadiraj PatilNoch keine Bewertungen

- AutomotiveDokument259 SeitenAutomotiveNavasca RandeeNoch keine Bewertungen

- Location Risk Assessment Form-Part A: Basic Information & Hazard ListDokument3 SeitenLocation Risk Assessment Form-Part A: Basic Information & Hazard Listapi-330049796Noch keine Bewertungen

- Mbeya Institute of Science and Technology: Power Plants Lecture No 6 Diesel Engine Power PlantsDokument68 SeitenMbeya Institute of Science and Technology: Power Plants Lecture No 6 Diesel Engine Power PlantsNyandaMadili MalashiNoch keine Bewertungen

- Diesel Power Plant PresentationDokument13 SeitenDiesel Power Plant PresentationAljomar Bas JularbalNoch keine Bewertungen

- DG SetDokument103 SeitenDG Setlvsaru67% (3)

- Fuel Supply System in Petrol EnginesDokument54 SeitenFuel Supply System in Petrol EnginesKLUniveristy86% (14)

- Valve Timing DiagramDokument43 SeitenValve Timing Diagramѕυdeѕн ĸNoch keine Bewertungen

- DieselPower PlantDokument12 SeitenDieselPower PlantJC ElarmoNoch keine Bewertungen

- Florafelt Vertical Garden GuideDokument27 SeitenFlorafelt Vertical Garden Guidelarguedas100% (1)

- Thermal Power Plants: 17 Mechanical by Engr. Ans Ahmed Department of Mechanical EngineeringDokument47 SeitenThermal Power Plants: 17 Mechanical by Engr. Ans Ahmed Department of Mechanical EngineeringAzhar Ali100% (1)

- Diesel Power PlantDokument28 SeitenDiesel Power PlantIrvs SaiNoch keine Bewertungen

- Tarnish & CorrosionDokument48 SeitenTarnish & CorrosionmujtabaNoch keine Bewertungen

- Comparison of Diesel and Petrol EnginesVon EverandComparison of Diesel and Petrol EnginesBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Diesel EngineDokument33 SeitenDiesel EngineCherry ObiasNoch keine Bewertungen

- Engine TerminologyDokument13 SeitenEngine Terminologyhotbuddy723Noch keine Bewertungen

- Spark Sensor FM 1-8 - EngDokument86 SeitenSpark Sensor FM 1-8 - EngBarosz0% (1)

- Diesel PPDokument58 SeitenDiesel PPManvendra Pratap Singh Bisht100% (1)

- UNIT 2 Diesel Power PlantDokument27 SeitenUNIT 2 Diesel Power Plantkavinraj vNoch keine Bewertungen

- Jansons Institute of Technology: Jit0141 Power Plant EngineeringDokument45 SeitenJansons Institute of Technology: Jit0141 Power Plant Engineeringanuj1166Noch keine Bewertungen

- Diesel Pwer Plant by Kalpit RautDokument21 SeitenDiesel Pwer Plant by Kalpit RautKalpit RautNoch keine Bewertungen

- Uice001-Basic Civil and Mechanical Engineering Unit-IV Module-IIIDokument28 SeitenUice001-Basic Civil and Mechanical Engineering Unit-IV Module-IIIBoovendra VarmanNoch keine Bewertungen

- Cooling SystemDokument18 SeitenCooling SystemElFear P. NayawiNoch keine Bewertungen

- Energy Science Part 2Dokument16 SeitenEnergy Science Part 2Lav BajpaiNoch keine Bewertungen

- B 9fuel200313 w21Dokument70 SeitenB 9fuel200313 w21Muhammad Ishaq KhanNoch keine Bewertungen

- IC EnginesfinalDokument136 SeitenIC EnginesfinalVarsha SreekumarNoch keine Bewertungen

- Diesel Powerpoint PDFDokument19 SeitenDiesel Powerpoint PDFfranzNoch keine Bewertungen

- Cooling and Lubrication SystemsDokument14 SeitenCooling and Lubrication SystemsBalvinderNoch keine Bewertungen

- 1-Ic EngineDokument66 Seiten1-Ic EngineTOBIN THOMAS ME100% (1)

- IC Engines and Reciprocating Machines Chapter 1: Thermodynamic Cycles and Performance of IC EnginesDokument71 SeitenIC Engines and Reciprocating Machines Chapter 1: Thermodynamic Cycles and Performance of IC EnginesYohanis AgumaseNoch keine Bewertungen

- Unit-4 Automobile EngineeringDokument52 SeitenUnit-4 Automobile EngineeringShubham GuptaNoch keine Bewertungen

- Government Polytechnic College, Jodhpur FinalDokument21 SeitenGovernment Polytechnic College, Jodhpur Finalgovind jodhpurNoch keine Bewertungen

- Engine and TransmissionDokument26 SeitenEngine and TransmissionWFilmy STARNoch keine Bewertungen

- UnitII UpdatedDokument53 SeitenUnitII UpdatedChandraSekharKondaveetiNoch keine Bewertungen

- Gas Turbine Engine: - Fuel SystemDokument45 SeitenGas Turbine Engine: - Fuel SystemMoin KhanNoch keine Bewertungen

- Lecture 3Dokument23 SeitenLecture 3khalid mustafaNoch keine Bewertungen

- Natural Heat Flow Increases Entropy - Converting Heat To Work Decreases EntropyDokument5 SeitenNatural Heat Flow Increases Entropy - Converting Heat To Work Decreases EntropyDuraimurugannNoch keine Bewertungen

- Unit-I Vehicle Structure and EnginesDokument31 SeitenUnit-I Vehicle Structure and EnginesSirajAyeshaNoch keine Bewertungen

- AUTOMOBILEDokument14 SeitenAUTOMOBILEDaniel PeprahNoch keine Bewertungen

- Diesel Power PlantDokument9 SeitenDiesel Power PlantNishanth NishNoch keine Bewertungen

- Parts of An Automobile and The FunctionDokument11 SeitenParts of An Automobile and The Functionrajronson6938100% (8)

- Unit 2 Diesel Power PlantDokument31 SeitenUnit 2 Diesel Power PlantMadhura TuljapurkarNoch keine Bewertungen

- Unit II - Electronically Controlled Fuel InjectionDokument38 SeitenUnit II - Electronically Controlled Fuel InjectiondrkbalaNoch keine Bewertungen

- Seminar On "Diesel Power Plant": BY Gautam DangiDokument14 SeitenSeminar On "Diesel Power Plant": BY Gautam DangiGautam DangiNoch keine Bewertungen

- Microsoft Word - Diesel EngineDokument3 SeitenMicrosoft Word - Diesel EngineprasadNoch keine Bewertungen

- jjgZ5k5ZlQ40WE5g 7831693292330431Dokument29 SeitenjjgZ5k5ZlQ40WE5g 7831693292330431Mersal BalaNoch keine Bewertungen

- UNIT-1 Hydraulic and Pneumatic DrivesDokument56 SeitenUNIT-1 Hydraulic and Pneumatic DrivesChetuNoch keine Bewertungen

- Diesel Power Plant PDFDokument12 SeitenDiesel Power Plant PDFZaul tatingNoch keine Bewertungen

- Internal Combustion Engine Chapter 1Dokument31 SeitenInternal Combustion Engine Chapter 1norazwanizaNoch keine Bewertungen

- Diesel Fa19Dokument35 SeitenDiesel Fa19Muhammad JunaidNoch keine Bewertungen

- IC Engine - 1Dokument17 SeitenIC Engine - 121-Syed Ihtasham Javaid ShahNoch keine Bewertungen

- Combustion PDFDokument79 SeitenCombustion PDFKranthi ReddyNoch keine Bewertungen

- DIESEL PPDokument62 SeitenDIESEL PPjaz squaredNoch keine Bewertungen

- Fuel Systems: BY Kalakanda Alfred SunnyDokument21 SeitenFuel Systems: BY Kalakanda Alfred SunnyalfredsunnyNoch keine Bewertungen

- Thermal 1unit3Dokument178 SeitenThermal 1unit3NAGU2009Noch keine Bewertungen

- Cooling System: Prepared By: Glen AbeganDokument52 SeitenCooling System: Prepared By: Glen AbeganJade AbeganNoch keine Bewertungen

- Unit 2 - IceDokument30 SeitenUnit 2 - IceSugumar MuthusamyNoch keine Bewertungen

- Layout Diesel Engine Power PlantDokument6 SeitenLayout Diesel Engine Power PlantJyotismoy SarmaNoch keine Bewertungen

- Diesel Power Plant Operation and Efficiency: Submitted To:-Submitted By: - Mahesh Chandra JoshiDokument14 SeitenDiesel Power Plant Operation and Efficiency: Submitted To:-Submitted By: - Mahesh Chandra JoshiMahesh JoshiNoch keine Bewertungen

- Qip Ice 01 IntroductionDokument40 SeitenQip Ice 01 IntroductionTiffany Powell100% (1)

- Fuel MeteringDokument31 SeitenFuel Meteringrabbi35_me10Noch keine Bewertungen

- Aemr-Unit 1-Piston EngineDokument85 SeitenAemr-Unit 1-Piston Engineuthira100% (1)

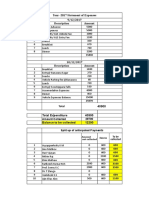

- Tour - 2017 Statement of Expenses: 9/12/2017 Description AmountDokument2 SeitenTour - 2017 Statement of Expenses: 9/12/2017 Description AmountVenkiteshNoch keine Bewertungen

- EE 394V New Topics in Energy Systems Distributed Generation TechnologiesDokument32 SeitenEE 394V New Topics in Energy Systems Distributed Generation TechnologiesVenkiteshNoch keine Bewertungen

- Heat TreatmentDokument21 SeitenHeat TreatmentVenkiteshNoch keine Bewertungen

- MASS PRODUCTION OF LiAl ALLOYS BY THE STEPDokument28 SeitenMASS PRODUCTION OF LiAl ALLOYS BY THE STEPVenkiteshNoch keine Bewertungen

- Hosur Road, (1K.M. Before Electronic City), Bangalore - 560 100Dokument10 SeitenHosur Road, (1K.M. Before Electronic City), Bangalore - 560 100VenkiteshNoch keine Bewertungen

- Icgt Series IIDokument1 SeiteIcgt Series IIVenkiteshNoch keine Bewertungen

- ME09 801 Refrigeration and Air ConditioningDokument9 SeitenME09 801 Refrigeration and Air ConditioningVenkiteshNoch keine Bewertungen

- 20 eDokument57 Seiten20 eakanksha vermaNoch keine Bewertungen

- Done By: Neha Jain Priya Upadhyay Saanchi AroraDokument13 SeitenDone By: Neha Jain Priya Upadhyay Saanchi AroraPriya UpadhyayNoch keine Bewertungen

- Ster RadDokument4 SeitenSter RadKlos BettoNoch keine Bewertungen

- Predicting Defoamer Performance in Coating FormulationsDokument10 SeitenPredicting Defoamer Performance in Coating Formulationsyok patchnakanNoch keine Bewertungen

- Worksheet - Experiment 9 MilkDokument2 SeitenWorksheet - Experiment 9 MilkYuraNoch keine Bewertungen

- Module06 NewDokument206 SeitenModule06 NewMiltiadis Zabelas0% (1)

- RTV106 TdsDokument6 SeitenRTV106 TdsAlice AnistonNoch keine Bewertungen

- Poster Concrete (SMY1B) 270612FINALDokument1 SeitePoster Concrete (SMY1B) 270612FINALIsalfi JahroNoch keine Bewertungen

- Unit 1, 2 and 8Dokument71 SeitenUnit 1, 2 and 8Noor SaleemNoch keine Bewertungen

- Safety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposureDokument3 SeitenSafety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposurehazopmanNoch keine Bewertungen

- 2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDokument6 Seiten2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDursunNoch keine Bewertungen

- Standard Reduction PotentialsDokument1 SeiteStandard Reduction PotentialsCamiloNoch keine Bewertungen

- Hardness Temperature in MetalsDokument6 SeitenHardness Temperature in MetalsStevenJacomeNoch keine Bewertungen

- Forensic Assignment Muhammad Asghar Roll No. 2357Dokument5 SeitenForensic Assignment Muhammad Asghar Roll No. 2357Faisal AwanNoch keine Bewertungen

- Hot-Dip Galvanizing Vs Continuous Sheet GalvanizingDokument2 SeitenHot-Dip Galvanizing Vs Continuous Sheet GalvanizingSreedhar Patnaik.M100% (1)

- Guidelines For The Establishment of Pharmaceutical Retail BusinessDokument19 SeitenGuidelines For The Establishment of Pharmaceutical Retail BusinessFranc100% (1)

- The Determination of Benzalkonium Chloride in Eye-Drops by Difference SpectrophotometryDokument8 SeitenThe Determination of Benzalkonium Chloride in Eye-Drops by Difference SpectrophotometryAngga FgNoch keine Bewertungen

- Protein Structure Function and Uses WorksheetDokument3 SeitenProtein Structure Function and Uses WorksheetAngelon UdaniNoch keine Bewertungen

- Seperator Design, K C Foong PDFDokument7 SeitenSeperator Design, K C Foong PDFpomaukNoch keine Bewertungen

- Studi Kasus Kerusakan Silinder Liner Engine PC PDFDokument46 SeitenStudi Kasus Kerusakan Silinder Liner Engine PC PDFApril KukuhNoch keine Bewertungen

- HealthDokument183 SeitenHealthJonaNoch keine Bewertungen

- Asme A13 - 1Dokument13 SeitenAsme A13 - 1Jaroslaw KoniecznyNoch keine Bewertungen

- Effects of Caffeine and Aspirin On Daphnia MagnaDokument2 SeitenEffects of Caffeine and Aspirin On Daphnia MagnazoujasonNoch keine Bewertungen

- Chemical Equilibrium (Reversible Reactions)Dokument22 SeitenChemical Equilibrium (Reversible Reactions)Anthony AbesadoNoch keine Bewertungen

- bw-G1030 USDokument24 Seitenbw-G1030 USEuojrNoch keine Bewertungen

- Gerflor Catalog SPM 2019 348 EnrichDokument152 SeitenGerflor Catalog SPM 2019 348 EnrichsuhaamuhammadNoch keine Bewertungen