Beruflich Dokumente

Kultur Dokumente

Eddy Current Inspection Application

Hochgeladen von

Restu Putra0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

120 Ansichten13 Seiteneddy current inspection

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldeneddy current inspection

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

120 Ansichten13 SeitenEddy Current Inspection Application

Hochgeladen von

Restu Putraeddy current inspection

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 13

Material Thickness Measurement

By Restu Putra & Ahmad Irsyad

Defective coating lead to rust

Determine coating thickness

Measuring corrosion thinning in aircraft

Measurement of Thin Conductive Sheet, Strip

and Foil

Cross-sectional Dimensions of Cylindrical

Tubes and Rods

Example of flaw on the surface of aircrafts

wing

1. Selection of the probe (surface probes, pencil

probes, sliding probes) depends on type of material

inspect

2. Switch on instrument and select suitable

frequencies

3. Reference calibration standard which composition

and geometry are the same with material inspect

4. Place the inspection probe at the surface of

specimen to be inspected and scan the probe over

the surface of specimen

5. Monitor the signal to detect the amount of

impedance changes

6. Material thickness determined by the impedance

change in the form of digital reading.

Select probe

Select frequency

Record the result

Place the probe at the

surface of specimen

Used to do spot check

Scanner used to inspect small areas

Determine if corrosion thinning is present in

buried layers for multi-layered areas

Determine thickness changes down to about

three percent of the skin thickness

To measure thickness of hot sheet, strip and foil in

rolling mills

To measure the amount of metal thinning due to

corrosion on fuselage skins of aircraft

Thickness variations exhibit the same type of current

signal response as a subsurface defects

Depth of penetration of the eddy current must cover

the entire range of thickness

Measuring thickness of very thin protective coatings

of ferromagnetic metals on ferromagnetic metal

bases

Measurement can be made using a single-coil probe,

transformer probe or preferable reflection type

Measure with OD coils or internal axial coils

Measuring eccentricities of the diameters of

tubes and rods and thickness of tube walls

Detection and assessment of corrosion for

external and internal

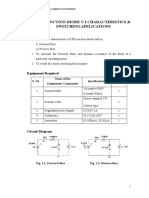

Conducting Material

Non-Conducting Material

The coil wounded on an insulated core

excited by an alternating current supply

The alternating field produced as a results

generates eddy current in the test piece

The opposition created by the magnetic field

of eddy current against the magnetic field of

coil, reduces the inductance of the coil

So, higher the thickness of the test piece,

higher will be the eddy current, lower would

be the inductance of the coil.

Thickness measurement is done by

depositing it on a metal backing

If the thickness of the test piece is large, the

eddy current transducer head and the metal

backing are separated by a larger distance

and therefore the eddy currents are small and

consequently the inductance of the coil is

large

Das könnte Ihnen auch gefallen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Disclosure To Promote The Right To Information: IS 11521 (1985) : Cargo Handling Nets (TXD 9: Cordage)Dokument16 SeitenDisclosure To Promote The Right To Information: IS 11521 (1985) : Cargo Handling Nets (TXD 9: Cordage)Ganesh ModiNoch keine Bewertungen

- Part A16: Determination of Natural Spreading Rate by Brush ApplicationDokument8 SeitenPart A16: Determination of Natural Spreading Rate by Brush ApplicationAsif Maqbool Hakeem100% (1)

- Industrial Radiography A Complete Guide - 2021 EditionVon EverandIndustrial Radiography A Complete Guide - 2021 EditionNoch keine Bewertungen

- Cold Pilger Rolling - Part Two - KEY To METALS ArticleDokument2 SeitenCold Pilger Rolling - Part Two - KEY To METALS Articlekumarpankaj030Noch keine Bewertungen

- Non-Destructive Testing MethodsDokument30 SeitenNon-Destructive Testing MethodsshuklahouseNoch keine Bewertungen

- The ABCs of Eddy Current Weld InspectionDokument4 SeitenThe ABCs of Eddy Current Weld Inspectionpadmgovi23Noch keine Bewertungen

- CP120B & CP160B: Portable X-Ray GeneratorDokument2 SeitenCP120B & CP160B: Portable X-Ray GeneratorKirke Andrew Wrubel MoreiraNoch keine Bewertungen

- Holiday Detection in Pipeline Coatings: Standard Test Methods ForDokument4 SeitenHoliday Detection in Pipeline Coatings: Standard Test Methods ForAlejandro ValdesNoch keine Bewertungen

- NDT and Eddy Current TestingDokument8 SeitenNDT and Eddy Current TestingTonyo AyshiyuNoch keine Bewertungen

- Cold Pilger Rolling - Part One - KEY To METALS ArticleDokument3 SeitenCold Pilger Rolling - Part One - KEY To METALS Articlekumarpankaj030Noch keine Bewertungen

- Nuclear UT - ISO - CD - 20890-1-2017Dokument39 SeitenNuclear UT - ISO - CD - 20890-1-2017Anonymous 5qPKvmuTWCNoch keine Bewertungen

- Epoch 650 BrochureDokument8 SeitenEpoch 650 BrochureVincent Ellie JaramillaNoch keine Bewertungen

- PT 2Dokument91 SeitenPT 2safeer ahmadNoch keine Bewertungen

- X Ray TestingDokument24 SeitenX Ray Testingapi-27176519100% (6)

- Mordec-Catalogue 2011 MayDokument83 SeitenMordec-Catalogue 2011 Maykiiru88100% (1)

- Answer All The Four Questions BelowDokument2 SeitenAnswer All The Four Questions BelowSamerNoch keine Bewertungen

- En 10029Dokument5 SeitenEn 10029PHAMTOAINoch keine Bewertungen

- DAC Block Details PDFDokument2 SeitenDAC Block Details PDFShrikant UtekarNoch keine Bewertungen

- Examination of Tube and BundleDokument8 SeitenExamination of Tube and BundleiraprobotNoch keine Bewertungen

- Chapter 4bDokument33 SeitenChapter 4bAhmed shabanNoch keine Bewertungen

- Answer All The Four Questions BelowDokument2 SeitenAnswer All The Four Questions BelowSamerNoch keine Bewertungen

- RR C 271FDokument45 SeitenRR C 271Fm_naderasliNoch keine Bewertungen

- Emergency Responder Fact Sheet - TransportationDokument2 SeitenEmergency Responder Fact Sheet - TransportationS Pushya Mitra100% (1)

- 15 - Nde Rev 011Dokument32 Seiten15 - Nde Rev 011Adnan RanaNoch keine Bewertungen

- Catalog Tevi - Van Leeuwend-Slatina PDFDokument62 SeitenCatalog Tevi - Van Leeuwend-Slatina PDFBara SebastianNoch keine Bewertungen

- Basic Principles of Ultrasonic TestingDokument101 SeitenBasic Principles of Ultrasonic TestingJohn Eric OliverNoch keine Bewertungen

- 9ni Cryogenic Materials PDFDokument5 Seiten9ni Cryogenic Materials PDFyogie4061100% (1)

- Investmech - Structural Integrity (ASME VIII - Part UG - Rules For The Design of Pressure Vessels) R0.0Dokument33 SeitenInvestmech - Structural Integrity (ASME VIII - Part UG - Rules For The Design of Pressure Vessels) R0.0CAC-39.01Noch keine Bewertungen

- 6-Overview of Radiation Practices IndusrialDokument59 Seiten6-Overview of Radiation Practices Indusrialkirandevi1981Noch keine Bewertungen

- Basic Principles of Ultrasonic TestingDokument98 SeitenBasic Principles of Ultrasonic TestingSaikat HalderNoch keine Bewertungen

- Ultrasonidos Manual PDFDokument78 SeitenUltrasonidos Manual PDFJose Luis Gonzalez Perez100% (1)

- M-121 Aluminium Structural Material Rev1Dokument17 SeitenM-121 Aluminium Structural Material Rev1vlong3003100% (1)

- Welding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedDokument4 SeitenWelding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedSurendra KamalNoch keine Bewertungen

- E2700-09 Standard Practice For Contact Ultrasonic Testing of Welds Using Phased ArraysDokument9 SeitenE2700-09 Standard Practice For Contact Ultrasonic Testing of Welds Using Phased Arrayskenvn100% (1)

- IQI (Penetrameter) Selection in Industrial Radiography TestingDokument3 SeitenIQI (Penetrameter) Selection in Industrial Radiography TestingGomathyselvi100% (1)

- EN 1090 White Paper17 119019 PDFDokument24 SeitenEN 1090 White Paper17 119019 PDFZaza PokumbaNoch keine Bewertungen

- Velocity Chart of Preset MaterialsDokument1 SeiteVelocity Chart of Preset MaterialskimikononNoch keine Bewertungen

- 1100 Gorman RT-UT Presentation For CTMS Oct 07Dokument29 Seiten1100 Gorman RT-UT Presentation For CTMS Oct 07Sagar NaduvinamaniNoch keine Bewertungen

- Partial List of ISO SpecificationsDokument4 SeitenPartial List of ISO Specificationsskynyrd75Noch keine Bewertungen

- WIS5 NoneDestructiveTestingDokument45 SeitenWIS5 NoneDestructiveTestingalfa_macasaetNoch keine Bewertungen

- General Principles of Radiography BSEN 444 PDFDokument17 SeitenGeneral Principles of Radiography BSEN 444 PDFThe Normal HeartNoch keine Bewertungen

- Bgas PaintingDokument96 SeitenBgas PaintingYoNoch keine Bewertungen

- Difference Between TOFD Vs PAUT: Mohd Siraj/Knowledge Resource/free To Share With AnybodyDokument18 SeitenDifference Between TOFD Vs PAUT: Mohd Siraj/Knowledge Resource/free To Share With AnybodyRahul DubeyNoch keine Bewertungen

- Guided Wave Testing of Water Loaded StructuresDokument5 SeitenGuided Wave Testing of Water Loaded StructuresMahade Hasan DipuNoch keine Bewertungen

- Project Proposal Wind MillDokument8 SeitenProject Proposal Wind MillAbdul BasitNoch keine Bewertungen

- Planar Flaw Height Sizing by Ultrasonics: Standard Guide ForDokument22 SeitenPlanar Flaw Height Sizing by Ultrasonics: Standard Guide ForAnonymous gQTQ8cbUNoch keine Bewertungen

- List of StandardsDokument6 SeitenList of StandardsShahazad ShaikNoch keine Bewertungen

- NDT Training Syllabus PDFDokument8 SeitenNDT Training Syllabus PDFNkwor AndersonNoch keine Bewertungen

- Form Qw-482 Format For Welding Procedure Specification (WPS) (See QW-200,1, Section Ix, ASME Boiler and Pressure Vessel Code)Dokument4 SeitenForm Qw-482 Format For Welding Procedure Specification (WPS) (See QW-200,1, Section Ix, ASME Boiler and Pressure Vessel Code)Rajkumar ArikumarNoch keine Bewertungen

- Inspection and Certification of Boilers and Unfired Pressure Vessels-BDokument66 SeitenInspection and Certification of Boilers and Unfired Pressure Vessels-BAjay SharmaNoch keine Bewertungen

- ASME SECTION VIII Ultrasonido CriteriosDokument1 SeiteASME SECTION VIII Ultrasonido CriteriosLorena Jimenez100% (1)

- Filmbadge and TLD ManualDokument2 SeitenFilmbadge and TLD ManualAldrin Cabrera100% (1)

- Regulatory Guide: June, 2019 PNRA-RG-904.06 (Rev.0)Dokument40 SeitenRegulatory Guide: June, 2019 PNRA-RG-904.06 (Rev.0)Shahbaz AhmadNoch keine Bewertungen

- Bs en Iso 17637 PreviewDokument8 SeitenBs en Iso 17637 PreviewUlviyye ElesgerovaNoch keine Bewertungen

- Radiography: J K Singh Lecturer/EMDokument33 SeitenRadiography: J K Singh Lecturer/EMmanoj kumarNoch keine Bewertungen

- Introduction To Eddy Current TestingDokument4 SeitenIntroduction To Eddy Current TestingyatheendravarmaNoch keine Bewertungen

- Ultrasonic Thickness GagingDokument4 SeitenUltrasonic Thickness Gagingcal2_uniNoch keine Bewertungen

- Ultrasonic Thickness Measurement PrincipleDokument5 SeitenUltrasonic Thickness Measurement PrincipleM Hamza NadeemNoch keine Bewertungen

- 55 T Lifting PlanDokument5 Seiten55 T Lifting PlanRestu Putra100% (1)

- Mohd Fauzi CSCSDokument1 SeiteMohd Fauzi CSCSRestu PutraNoch keine Bewertungen

- Caution. Work in Progress: All Visitor Must Report To The Site Office Unauthorised Access Strictly ProhibitedDokument1 SeiteCaution. Work in Progress: All Visitor Must Report To The Site Office Unauthorised Access Strictly ProhibitedRestu PutraNoch keine Bewertungen

- Safety ScoreboardDokument1 SeiteSafety ScoreboardRestu PutraNoch keine Bewertungen

- Roleofengineersinsd 090901163407 Phpapp02Dokument45 SeitenRoleofengineersinsd 090901163407 Phpapp02Restu PutraNoch keine Bewertungen

- Radiographic TestingDokument47 SeitenRadiographic TestingsmrndrdasNoch keine Bewertungen

- Assignment 5: Operational ManagementDokument3 SeitenAssignment 5: Operational ManagementRestu PutraNoch keine Bewertungen

- The Concepts and Specification of Maintainance Ramp For Military VehicleDokument5 SeitenThe Concepts and Specification of Maintainance Ramp For Military VehicleRestu PutraNoch keine Bewertungen

- The Pelton Wheel ExperimentDokument18 SeitenThe Pelton Wheel ExperimentRestu PutraNoch keine Bewertungen

- Surfer10Guide PDFDokument60 SeitenSurfer10Guide PDFRestu PutraNoch keine Bewertungen

- Tanaka, Murakami, Ooka - Effects of Strain Path Shapes On Non-Proportional Cyclic PlasticityDokument17 SeitenTanaka, Murakami, Ooka - Effects of Strain Path Shapes On Non-Proportional Cyclic PlasticityDavid C HouserNoch keine Bewertungen

- Riluzole For SCZDokument11 SeitenRiluzole For SCZHana Rizka AnandaNoch keine Bewertungen

- 8085 and 8051 PresentationDokument54 Seiten8085 and 8051 PresentationJitendra Chuugh100% (3)

- Mathematical Model of Transportation ProblemDokument14 SeitenMathematical Model of Transportation ProblemwasimghghNoch keine Bewertungen

- Binary Dependent VarDokument5 SeitenBinary Dependent VarManali PawarNoch keine Bewertungen

- Anatomia Del Pie en Insuficiencia VenosaDokument13 SeitenAnatomia Del Pie en Insuficiencia VenosaDinOritha AtiLanoNoch keine Bewertungen

- Wärtsilä NOXDokument35 SeitenWärtsilä NOXDeepesh MerchantNoch keine Bewertungen

- Silver Nanoparticles DataDokument6 SeitenSilver Nanoparticles DataSanwithz SittiNoch keine Bewertungen

- PPT11 12 Ic 2.3 PPT1112 Id 2.4 Realized That The Methods of Philosophy LeadDokument47 SeitenPPT11 12 Ic 2.3 PPT1112 Id 2.4 Realized That The Methods of Philosophy LeadShayne Pagwagan100% (1)

- REvision Test - 1Dokument2 SeitenREvision Test - 1JagendraNoch keine Bewertungen

- Vulgare Mill.) Terhadap Bakteri Staphylococcus Aureus ATCC 25923Dokument8 SeitenVulgare Mill.) Terhadap Bakteri Staphylococcus Aureus ATCC 25923MUHAMMAD RIZKY HUSULUDINNoch keine Bewertungen

- Commercial Unit Coolers Cubic Series Type: S3HC 59 E 65 N. Units: 1Dokument2 SeitenCommercial Unit Coolers Cubic Series Type: S3HC 59 E 65 N. Units: 1hamzehNoch keine Bewertungen

- RHE07 07c 08 Data SheetDokument7 SeitenRHE07 07c 08 Data SheetAnkitNoch keine Bewertungen

- Guideline For Typical Appliance Ratings To Assist in Sizing of PV Solar SystemsDokument8 SeitenGuideline For Typical Appliance Ratings To Assist in Sizing of PV Solar SystemspriteshjNoch keine Bewertungen

- GD33-12 12V33AH: GD SERIES-Deep Cycle BatteryDokument2 SeitenGD33-12 12V33AH: GD SERIES-Deep Cycle BatteryMarcel BaqueNoch keine Bewertungen

- CNS TechnicianDokument2 SeitenCNS TechnicianSohailNoch keine Bewertungen

- Semiconductor Devices and Circuits LaboratoryDokument53 SeitenSemiconductor Devices and Circuits LaboratoryKaryampudi RushendrababuNoch keine Bewertungen

- Automatic Bug BountyDokument80 SeitenAutomatic Bug BountyAlbert Luzx100% (1)

- Alternator E1S13S A/4: Three-Phase Synchronous Alternator With Brushes and Compound - 4 PolesDokument7 SeitenAlternator E1S13S A/4: Three-Phase Synchronous Alternator With Brushes and Compound - 4 PolesmasanmartinfNoch keine Bewertungen

- LG Rp29fa40Dokument15 SeitenLG Rp29fa40palomoqro100% (1)

- Characterization and Manufacture of Braided Composites For Large Commercial Aircraft StructuresDokument44 SeitenCharacterization and Manufacture of Braided Composites For Large Commercial Aircraft StructuresnicolasNoch keine Bewertungen

- Chapter 01 Properties of SolutionDokument70 SeitenChapter 01 Properties of SolutionYo Liang SikNoch keine Bewertungen

- FireEdge FE400 PLC Interface Tech NoteDokument2 SeitenFireEdge FE400 PLC Interface Tech NoteTuyên VũNoch keine Bewertungen

- CCNA 4 - Chapter 2 QuzDokument1 SeiteCCNA 4 - Chapter 2 Quzchobiipiggy26Noch keine Bewertungen

- On The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignDokument8 SeitenOn The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignJiyang WangNoch keine Bewertungen

- The Effect of Backrest Roller On Warp Tension in Modern LoomDokument11 SeitenThe Effect of Backrest Roller On Warp Tension in Modern LoomRavi KumarNoch keine Bewertungen

- Data Kebutuhan Consumable Suparma 2018Dokument5 SeitenData Kebutuhan Consumable Suparma 2018IGUHNoch keine Bewertungen

- Schwarzer Schmarsow - The Emergence of Architectural Space August Schmarsows Theory of RaumgestaltungDokument15 SeitenSchwarzer Schmarsow - The Emergence of Architectural Space August Schmarsows Theory of RaumgestaltungDimitra BilliaNoch keine Bewertungen

- Engineering MeasurementsDokument77 SeitenEngineering MeasurementsFemi Prince0% (1)

- ADO and SQL SERVERDokument493 SeitenADO and SQL SERVERKristian CevallosNoch keine Bewertungen