Beruflich Dokumente

Kultur Dokumente

Topic 1 Iron Making

Hochgeladen von

Saqeeb Adnan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

57 Ansichten17 Seitenslide of usama sir

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenslide of usama sir

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

57 Ansichten17 SeitenTopic 1 Iron Making

Hochgeladen von

Saqeeb Adnanslide of usama sir

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 17

he Blast Furna

What is a Blast Furnace?

The purpose of a blast furnace is to

reduce and convert iron oxides into

liquid iron called "hot metal".

The blast furnace is a huge, steel stack

lined with refractory brick.

Iron ore, coke and limestone are put

into the top, and preheated air is

blown into the bottom.

Why does Iron have to be extracted

in a Blast Furnace???

Iron can be extracted by the blast furnace because it

can be displaced by carbon.

This is more efficient method than electrolysis

because it is more cost effective

The fact that iron-oxide can be reduced by carbon

along with the abundance of iron-oxide in earths crust

(4th most abundant element), makes iron so

economical

The Method

Three substances are needed to enable to extraction of iron from its ore. The combined

mixture is called the charge.

Iron ore, haematite - Fe2O3 often contains impurities such as sand (SiO2)

Limestone (calcium carbonate).

Coke - mainly carbon

The charge is placed in the blast furnace. The blast furnace is around 30 metres high and

lined with fireproof bricks. Hot air is blasted through the bottom.

Principle reactions of iron-making

Oxygen in the air reacts with coke to give carbon dioxide:

C(s) + O 2(g) CO2(g)

The limestone breaks down to form carbon dioxide:

CaCO3(s) CO2 (g) + CaO(s)

Carbon dioxide produced in 1 + 2 react with more coke to produce

carbon monoxide:

CO2(g) + C(s) 2CO(g)

The carbon monoxide reduces the iron in the ore to give molten iron:

3CO(g) + Fe2O3(s) 2Fe(l) + 3CO2(g)

The limestone from 2, reacts with the sand to form slag (calcium silicate):

CaO(s) + SiO(s) CaSiO3(l)

Other slag forming reactions also occur

IRON MAKING IS THUS A REDUCTIVE PROCESS

Sections of a blast furnace

Main sections are (from bottom to top)

Hearth

Bosch

Stack

Charging is done through the top

The tuyeres through which hot air is blasted are

situated at the joining of bosch and hearth

A slaghole and a taphole is provided at the

hearth

Outline of operation

The burden is charged in layers

One layer comprises coke and the other one is iron ore+flux

and so on

A bed of coke is maintained in the tuyere region all the time

The hot air blasted through the tuyeres, reacts with the coke,

burning them, and produces carbon monoxide

This zone experiences the highest temperature (1800-2000 C)

because combustion takes place here

The hot gases generated rise through the furnace and gives

up its sensible heat to the charge that is filling the stack

column

Outline of operation

As the gas rises its temperature drops because its heat is

taken away by the charge.

A temperature gradient is created, and so the temperature is

highest at the tuyere region and lowest at the top

The alternately charged burden thus, experiences different

temperatures depending on where it is located in the

furnace

The level of the entire burden periodically drops as metal

and slag are tapped from the bottom

This means that burden charged at the top (where T is low)

gradually experiences higher T as it drops periodically

Outline of operation

When it drops sufficiently and the temperature is suitable, iron-oxide

reduction begins

As it drops further the ore is eventually fully reduced to metallic iron and

thereafter picks up some extra carbon (carburization this also lowers the

melting point of solid iron)

At some point the temperature is high enough to cause melting and the

metallic drops trickle through the bed of coke and so does the liquid slag,

which has formed by now

The molten liquids finally settle at the hearth where slag and metal forms

separate layers due to their specific gravity being different

The coke that was charged from the top does not take part in any significant

reaction until it reaches the tuyere region

Here it joins the coke bed already present and serves to replenish it, which is

continually burning

Detailed reactions (see figure on next page)

Logical order of reactions (Note: these reactions DO NOT occur

in the same place. They occur in different parts but reaction

products of one reaction may take part in another one)

1. Burning of coke

2. Reduction, carburization and melting of iron oxides by gas

produced in 1

3. Decomposition of limestone by heat generated from 1

4. Slag formation by reactants made available from 2 and 3

5. Slag dissociation (reverse of 4)

6. Reduction reactions made possible because of 5

7. Impurity pick up due to reactions in 6

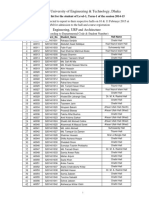

1. Iron ore + limestone sinter

2. Coke

3. Elevator

4. Feedstock inlet

5. Layer of coke

6. Layer of sinter pellets of ore and limestone

7. Hot blast (around 1200 C)

8. Removal of slag

9. Tapping of molten pig iron

About the stoves

Something that increases the thermal efficiency of the furnace greatly is the use of gas

coming out of the furnace itself (Blast burnace gas-BFG)

This gas contains some percentages of unburnt CO (~20%), and so can be used as a fuel

This gas is burnt inside the cowper stoves (which works like regenerators) heating them

up

Once heating is complete, BFG is shut off and fresh air is then passed through the hot

stoves

This heated air is then sent to the furnace which we have referred to as the hot blast

before

When the T of the stove drops too much fresh air is shut off and fuel is passed again

Thus one stove cannot continuously supply hot air, because it works in a cyclic heating-

cooling operation

In fact three or more stoves are generally required because the time it takes to heat up

one stove is not the same as the time it takes to cool it

So two stoves would be inadequate and a third would be needed

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Getting Started With OneDriveDokument5 SeitenGetting Started With OneDriveShivam GuptaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Project To Design and Build A Simple Heat ExchangerDokument6 SeitenProject To Design and Build A Simple Heat ExchangerSaqeeb AdnanNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Complex PDF 2Dokument67 SeitenComplex PDF 2Saqeeb AdnanNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- All MembersDokument20 SeitenAll MembersSaqeeb AdnanNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- EJAZ's IC Jahurul Sir NoteDokument182 SeitenEJAZ's IC Jahurul Sir NoteSaqeeb AdnanNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Lecture1-Interactive Computing With MATLABDokument104 SeitenLecture1-Interactive Computing With MATLABSaqeeb AdnanNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Hamid Sir (SM)Dokument134 SeitenHamid Sir (SM)Saqeeb AdnanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- FIFA15MW - Readme - How To InstallDokument18 SeitenFIFA15MW - Readme - How To InstallSaqeeb AdnanNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- EEEDokument48 SeitenEEESaqeeb AdnanNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hall Distribution 2014-15Dokument20 SeitenHall Distribution 2014-15Saqeeb AdnanNoch keine Bewertungen

- ListDokument1 SeiteListSaqeeb AdnanNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- MOM Lab ProblemsDokument51 SeitenMOM Lab ProblemsSaqeeb AdnanNoch keine Bewertungen

- M & I-AnupSir - Tain 21-12-16Dokument39 SeitenM & I-AnupSir - Tain 21-12-16Saqeeb AdnanNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Solid WorksDokument6 SeitenSolid WorksSaqeeb AdnanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- AVR Trainer Kit ManualDokument40 SeitenAVR Trainer Kit ManualSaqeeb Adnan100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Chapter 4Dokument12 SeitenChapter 4Saqeeb AdnanNoch keine Bewertungen

- Numerical IntegrationDokument20 SeitenNumerical IntegrationSaqeeb AdnanNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- RobomanDokument3 SeitenRobomanSaqeeb AdnanNoch keine Bewertungen

- ICC Cricket World Cup, 2011: Date Venue Match TeamsDokument3 SeitenICC Cricket World Cup, 2011: Date Venue Match TeamsSaqeeb AdnanNoch keine Bewertungen

- E Business - Module 1Dokument75 SeitenE Business - Module 1Kannan V KumarNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Kübra Şendoğan CVDokument5 SeitenKübra Şendoğan CVKübra ŞendoğanNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Contemporary Architecture Is The Architecture of The 21st Century. No Single Style Is DominantDokument2 SeitenContemporary Architecture Is The Architecture of The 21st Century. No Single Style Is DominantShubham DuaNoch keine Bewertungen

- Review Test 1: Circle The Correct Answers. / 5Dokument4 SeitenReview Test 1: Circle The Correct Answers. / 5XeniaNoch keine Bewertungen

- Curriculum Vitae: Educational Background Certification Major Name of Institute PeriodDokument2 SeitenCurriculum Vitae: Educational Background Certification Major Name of Institute PeriodTHEVINESHNoch keine Bewertungen

- PresentationDokument6 SeitenPresentationVruchali ThakareNoch keine Bewertungen

- Competent Testing Requirements As Per Factory ActDokument3 SeitenCompetent Testing Requirements As Per Factory Actamit_lunia100% (1)

- Th-Sunday Magazine 6 - 2Dokument8 SeitenTh-Sunday Magazine 6 - 2NianotinoNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Mge - Ex11rt - Installation and User Manual PDFDokument38 SeitenMge - Ex11rt - Installation and User Manual PDFRafa TejedaNoch keine Bewertungen

- TVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsDokument9 SeitenTVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsNelPalalonNoch keine Bewertungen

- Nursing Care Plan For AIDS HIVDokument3 SeitenNursing Care Plan For AIDS HIVFARAH MAE MEDINA100% (2)

- Richard IIIDokument36 SeitenRichard IIIXuan Mai Nguyen ThiNoch keine Bewertungen

- Operaciones UnitariasDokument91 SeitenOperaciones UnitariasAlejandro ReyesNoch keine Bewertungen

- Job Stress InterventionsDokument5 SeitenJob Stress InterventionscocaralucamihaelaNoch keine Bewertungen

- Sullivan's Interpersonal TheoryDokument27 SeitenSullivan's Interpersonal TheoryJezalen GonestoNoch keine Bewertungen

- Activity 4 - Energy Flow and Food WebDokument4 SeitenActivity 4 - Energy Flow and Food WebMohamidin MamalapatNoch keine Bewertungen

- Electron LayoutDokument14 SeitenElectron LayoutSaswat MohantyNoch keine Bewertungen

- Title - Dating Virtual To Coffee Table Keywords - Dating, Application BlogDokument3 SeitenTitle - Dating Virtual To Coffee Table Keywords - Dating, Application BlogRajni DhimanNoch keine Bewertungen

- Summer Internship Project Report ANALYSIDokument60 SeitenSummer Internship Project Report ANALYSIKshitija KudacheNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Directorate of Indian Medicines & Homoeopathy, Orissa, Bhubaneswar Listof The Homoeopathic Dispensaries BhadrakDokument1 SeiteDirectorate of Indian Medicines & Homoeopathy, Orissa, Bhubaneswar Listof The Homoeopathic Dispensaries Bhadrakbiswajit mathematicsNoch keine Bewertungen

- STIHL TS410, TS420 Spare PartsDokument11 SeitenSTIHL TS410, TS420 Spare PartsMarinko PetrovićNoch keine Bewertungen

- Open Book Online: Syllabus & Pattern Class - XiDokument1 SeiteOpen Book Online: Syllabus & Pattern Class - XiaadityaNoch keine Bewertungen

- Annexure To SOW 3 STD Specification For Welding and NDT PipingDokument15 SeitenAnnexure To SOW 3 STD Specification For Welding and NDT PipingASHISH GORDENoch keine Bewertungen

- GNT 52 60HZ enDokument4 SeitenGNT 52 60HZ enEduardo VicoNoch keine Bewertungen

- On The Margins - A Study of The Experiences of Transgender College StudentsDokument14 SeitenOn The Margins - A Study of The Experiences of Transgender College StudentsRory J. BlankNoch keine Bewertungen

- Super Gene 1201-1300Dokument426 SeitenSuper Gene 1201-1300Henri AtanganaNoch keine Bewertungen

- Amazon VS WalmartDokument5 SeitenAmazon VS WalmartBrandy M. Twilley100% (1)

- Btech CertificatesDokument6 SeitenBtech CertificatesSuresh VadlamudiNoch keine Bewertungen

- Origins - and Dynamics of Culture, Society and Political IdentitiesDokument4 SeitenOrigins - and Dynamics of Culture, Society and Political IdentitiesJep Jep Panghulan100% (1)

- Coping Mechanism and Academic Performance Among FiDokument14 SeitenCoping Mechanism and Academic Performance Among FiMary Margaret MorillaNoch keine Bewertungen