Beruflich Dokumente

Kultur Dokumente

CMAP Bulk Carrier

Hochgeladen von

Vijay Damley100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

63 Ansichten2 SeitenUnderstanding Bulk carrier as a ship

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenUnderstanding Bulk carrier as a ship

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

63 Ansichten2 SeitenCMAP Bulk Carrier

Hochgeladen von

Vijay DamleyUnderstanding Bulk carrier as a ship

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

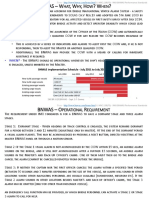

Structure

Side rolling hatch covers on large

Dimensions

ships Length: 130 350 m

Fore and rolling hatch covers on Breadth: 30 60 m

Special Precautions smaller ships Draft: 10 20 m

Danger of cargo shifting Top side ballast tanks may be used Capacity/Deadweight: 20000-400000t

Danger of liquefaction for grain loading Typical speed: 12 14 kts

Danger of very high GM resulting May have duct keel

in structural damages due o violent Alternated holds are strengthened

rolling for heavy cargo loading

Danger of cargo exceeding Ships have fuller forms suitable for Cargoes

Transportable moisture limits slower speeds Ores

Stresses created due to long Sugar

length Sulpher

Salt

Grain

Coal

Minerals in bulk

Options of Steel, CKD, Stone blocks

and logs on small bulk carriers

Bulk Carrier

Cargo securing Features

Lashings with wires and chains

Ship is divided by athwart ship watertight

for log cargoes

corrugated bulkheads to form cargo holds

Trimming required for bulk

Trading Holds have hopper sides on bottom and

cargoes especially for low angle

Normally all over the world top

of repose

as tramping. Older ports Hatch covers are operated hydraulically

Bagged cargo may be loaded on

are suitable for smaller Normally fuel oil tanks are centreline

top for slack grain hold

ships. Bigger ships use double bottom tanks

specially designed Special equipment is provided for hold

terminals cleaning

Mechanical ventilators

Documents Upto deadweight of 100000 t ship may

For normal ship have own cargo gear like cranes or special

Documents of compliance Ballast management gear

Grain loading booklet Double bottom tanks, Top Normally discharges with grabs with

International Maritime side tanks, afterpeak tank conveyor belts

Solid Bulk Cargoes and forepeak tank

(IMSBC) Code, In heavy ballast condition, 1

or 2 holds are used for ballast

Midship Section of a Bulk carrier

Das könnte Ihnen auch gefallen

- The Icfai University, Dehradun Convocation 2018 JULY 14, 2018 (SATURDAY)Dokument4 SeitenThe Icfai University, Dehradun Convocation 2018 JULY 14, 2018 (SATURDAY)Deepak SachdevNoch keine Bewertungen

- 16 RepairDokument11 Seiten16 RepairarmanimamsNoch keine Bewertungen

- Electronic Chart Display and Information System (Ecdis)Dokument15 SeitenElectronic Chart Display and Information System (Ecdis)Amit Pandey100% (1)

- Rasagna ResumeDokument4 SeitenRasagna ResumeRasagna RavavarapuNoch keine Bewertungen

- Liverpool Oral NotesDokument58 SeitenLiverpool Oral NoteshosseinNoch keine Bewertungen

- Vertical Long. Section at Center Line: Ship ConstructionDokument7 SeitenVertical Long. Section at Center Line: Ship ConstructionarmanimamsNoch keine Bewertungen

- Fleetwood Chief Mate Admission FormDokument11 SeitenFleetwood Chief Mate Admission FormChandanKumarNoch keine Bewertungen

- Official Log BookDokument14 SeitenOfficial Log Bookpronab rahaNoch keine Bewertungen

- UK Masters OralsDokument8 SeitenUK Masters OralsJagjit SinghNoch keine Bewertungen

- 1098 Application of AIS AtoN On Buoys PDFDokument27 Seiten1098 Application of AIS AtoN On Buoys PDFJorge Marcillo100% (1)

- Bulk CargoDokument66 SeitenBulk CargoNeil Silveira100% (1)

- 3 Portable Securing EquipmentDokument22 Seiten3 Portable Securing Equipmentjimmy_shroff100% (1)

- BLearning Booklet 2017Dokument16 SeitenBLearning Booklet 2017Soul MarinerNoch keine Bewertungen

- P020213 Stability BookDokument115 SeitenP020213 Stability BookPETERNoch keine Bewertungen

- Us Cogsa: History of Limitation of Liability For Cargo DamageDokument15 SeitenUs Cogsa: History of Limitation of Liability For Cargo DamageAnkit MauryaNoch keine Bewertungen

- 100 Ror Situations PDFDokument20 Seiten100 Ror Situations PDFRoselle LimbagaNoch keine Bewertungen

- 2.ship ConstDokument74 Seiten2.ship ConstArjun AchuNoch keine Bewertungen

- TeapDokument207 SeitenTeapDharani KNoch keine Bewertungen

- AG - Ship Stability CSM SeacosDokument12 SeitenAG - Ship Stability CSM Seacosreuben ephraimNoch keine Bewertungen

- Xtra 1st Class PDFDokument12 SeitenXtra 1st Class PDFnishantNoch keine Bewertungen

- Eng KnowledgeDokument44 SeitenEng KnowledgeDinchak RRAHNoch keine Bewertungen

- Nautical EngineeringDokument37 SeitenNautical EngineeringForanypurpose ForanypurposeNoch keine Bewertungen

- Module 24 Damage StabilityDokument9 SeitenModule 24 Damage StabilitySippu SifathullahNoch keine Bewertungen

- Unit 3 Ship StructuresDokument21 SeitenUnit 3 Ship StructuresRodrigo LimaNoch keine Bewertungen

- Nautical ScienceDokument39 SeitenNautical ScienceDheerajKaushalNoch keine Bewertungen

- Unit-I 1. Explain About Lines Plan of A Ship? AnsDokument14 SeitenUnit-I 1. Explain About Lines Plan of A Ship? AnsDeepak Pooranachandran100% (1)

- Safe Navigation in The Kanmon Kaikyo PDFDokument19 SeitenSafe Navigation in The Kanmon Kaikyo PDFQuân Nguyễn100% (1)

- 180k Bulk Carrier ReportDokument173 Seiten180k Bulk Carrier ReportAdrian Gilby100% (1)

- Various Moorings: Open MoorDokument6 SeitenVarious Moorings: Open MoorAamir SirohiNoch keine Bewertungen

- RD Sharma 1 Main&AdvDokument160 SeitenRD Sharma 1 Main&AdvRaviTuduNoch keine Bewertungen

- Basics On Marine NavigationDokument5 SeitenBasics On Marine NavigationYowjess100% (1)

- Capt. IVR Function-1Dokument6 SeitenCapt. IVR Function-1Jagjit Singh100% (1)

- CM SQA Stability Past PapersDokument36 SeitenCM SQA Stability Past Papersdrupway.demoNoch keine Bewertungen

- 1 Cargo WorkDokument16 Seiten1 Cargo Workcaptpkkhare100% (1)

- Cargowork 4 Bulk CargoesDokument55 SeitenCargowork 4 Bulk CargoesMahami M Prosper100% (1)

- Chief Mate Unlimited Orals Report 2023 01 Wadood PassDokument2 SeitenChief Mate Unlimited Orals Report 2023 01 Wadood PassGalvino GomesNoch keine Bewertungen

- Grain RegulationsDokument70 SeitenGrain RegulationsEisn 2020100% (1)

- P-II - Naval Arch 90 OlvedDokument181 SeitenP-II - Naval Arch 90 OlvedChristopher JebarajNoch keine Bewertungen

- Parametric RollingDokument7 SeitenParametric RollingneerajNoch keine Bewertungen

- Oral TipsDokument147 SeitenOral TipsRaj MalikNoch keine Bewertungen

- 1.III CargoWork Notes Rev (Dartwaykyat)Dokument38 Seiten1.III CargoWork Notes Rev (Dartwaykyat)Tun Lin NaingNoch keine Bewertungen

- Carriage SteelDokument38 SeitenCarriage SteelbernardinodinoNoch keine Bewertungen

- Iamu Aga 2016s Proceeding Full-FinalDokument461 SeitenIamu Aga 2016s Proceeding Full-FinalKathrin KatsNoch keine Bewertungen

- CH 08 Transferring Circular Position LinesDokument5 SeitenCH 08 Transferring Circular Position LinesAmit PandeyNoch keine Bewertungen

- Bridge Watchkeeping MMD QuestionsDokument1 SeiteBridge Watchkeeping MMD Questionspramod_kbNoch keine Bewertungen

- 2nd Matet QN Pprs Till Jan 20 PG 57Dokument194 Seiten2nd Matet QN Pprs Till Jan 20 PG 57Devanshu SharmaNoch keine Bewertungen

- Introduction To TSSDokument11 SeitenIntroduction To TSSnoczviviNoch keine Bewertungen

- DF0LD34 - Ship Stability An IntroductionDokument12 SeitenDF0LD34 - Ship Stability An IntroductionEdvin EdwNoch keine Bewertungen

- Harmonized System of Ship Survey and Certification Enters Into ForceDokument8 SeitenHarmonized System of Ship Survey and Certification Enters Into ForceErrol RodriguesNoch keine Bewertungen

- Seamanship & COSWP Notes ConsolidatedDokument92 SeitenSeamanship & COSWP Notes ConsolidatedNeeraj S0% (2)

- Orals by Karthik Revision Function 3 Chef MateDokument75 SeitenOrals by Karthik Revision Function 3 Chef MateAnkit MauryaNoch keine Bewertungen

- BNWASDokument3 SeitenBNWASKaruna Lakhani100% (1)

- Stability Notes (Vishnu Kant Bhardwaj) PDFDokument45 SeitenStability Notes (Vishnu Kant Bhardwaj) PDFKirtishbose ChowdhuryNoch keine Bewertungen

- Positive Displacement PumpsDokument6 SeitenPositive Displacement PumpsSrinivas DsNoch keine Bewertungen

- Deck Department Leadership Through Bridge Team ManagementDokument4 SeitenDeck Department Leadership Through Bridge Team ManagementAboody AL-ghamdyNoch keine Bewertungen

- WW - Mark V - Fact Sheet - March 2011 - FINAL 21 03 11Dokument3 SeitenWW - Mark V - Fact Sheet - March 2011 - FINAL 21 03 11Boogi Andika TamamiNoch keine Bewertungen

- Poles Beneath The Compass PositionDokument36 SeitenPoles Beneath The Compass PositionRajeewa Wickramahewage100% (1)

- BilgingDokument10 SeitenBilgingImanNoch keine Bewertungen

- Minimum Critical Distance For Avoiding Action by Stand On VesselDokument10 SeitenMinimum Critical Distance For Avoiding Action by Stand On Vesselboca1966Noch keine Bewertungen

- A Vessel For Every Need - Mitsui O.S.K. Lines, 2015Dokument12 SeitenA Vessel For Every Need - Mitsui O.S.K. Lines, 2015ali_alsabbaghNoch keine Bewertungen

- RopesDokument14 SeitenRopesVijay DamleyNoch keine Bewertungen

- IMU Ship DimensionsDokument19 SeitenIMU Ship DimensionsVijay DamleyNoch keine Bewertungen

- IMU GSK IntroductionDokument53 SeitenIMU GSK IntroductionVijay DamleyNoch keine Bewertungen

- Shell and Deck PlatingDokument22 SeitenShell and Deck PlatingVijay DamleyNoch keine Bewertungen

- Ship Building MaterialsDokument11 SeitenShip Building MaterialsVijay Damley0% (1)

- Rubric For Audio Speech DeliveryDokument2 SeitenRubric For Audio Speech DeliveryMarie Sol PanganNoch keine Bewertungen

- 5 Ways To Make A USB BootableDokument6 Seiten5 Ways To Make A USB Bootableconnect.rohit85Noch keine Bewertungen

- Projected Costs of Generating Electricity (EGC) 2005Dokument233 SeitenProjected Costs of Generating Electricity (EGC) 2005susantojdNoch keine Bewertungen

- CV TitchievDokument3 SeitenCV TitchievIna FarcosNoch keine Bewertungen

- Technical Textile and SustainabilityDokument5 SeitenTechnical Textile and SustainabilityNaimul HasanNoch keine Bewertungen

- 1013CCJ - T3 2019 - Assessment 2 - CompleteDokument5 Seiten1013CCJ - T3 2019 - Assessment 2 - CompleteGeorgie FriedrichsNoch keine Bewertungen

- Concise Beam DemoDokument33 SeitenConcise Beam DemoluciafmNoch keine Bewertungen

- Assessment PN1096617Dokument14 SeitenAssessment PN1096617Amr TarekNoch keine Bewertungen

- Principal Examiner Feedback Summer 2016: Pearson Edexcel GCSE in Statistics (2ST01) Higher Paper 1HDokument14 SeitenPrincipal Examiner Feedback Summer 2016: Pearson Edexcel GCSE in Statistics (2ST01) Higher Paper 1HHeavenly SinNoch keine Bewertungen

- Video Course NotesDokument18 SeitenVideo Course NotesSiyeon YeungNoch keine Bewertungen

- The Algorithm Development and Implementation For 3D Printers Based On Adaptive PID ControllerDokument8 SeitenThe Algorithm Development and Implementation For 3D Printers Based On Adaptive PID ControllerShahrzad GhasemiNoch keine Bewertungen

- Pin Joint en PDFDokument1 SeitePin Joint en PDFCicNoch keine Bewertungen

- Plantas Con Madre Plants That Teach and PDFDokument15 SeitenPlantas Con Madre Plants That Teach and PDFJetNoch keine Bewertungen

- Car Section 2 Series (H) Part-IiDokument6 SeitenCar Section 2 Series (H) Part-Iipandurang nalawadeNoch keine Bewertungen

- Lecture No. 11Dokument15 SeitenLecture No. 11Sayeda JabbinNoch keine Bewertungen

- 009 Attached-1 NAVFAC P-445 Construction Quality Management PDFDokument194 Seiten009 Attached-1 NAVFAC P-445 Construction Quality Management PDFSor sopanharithNoch keine Bewertungen

- Study On The Form Factor and Full-Scale Ship Resistance Prediction MethodDokument2 SeitenStudy On The Form Factor and Full-Scale Ship Resistance Prediction MethodRaka AdityaNoch keine Bewertungen

- SUNGLAO - TM PortfolioDokument60 SeitenSUNGLAO - TM PortfolioGIZELLE SUNGLAONoch keine Bewertungen

- Indian Pharmaceutical IndustryDokument25 SeitenIndian Pharmaceutical IndustryVijaya enterprisesNoch keine Bewertungen

- Introduction To Soft Floor CoveringsDokument13 SeitenIntroduction To Soft Floor CoveringsJothi Vel Murugan83% (6)

- Michael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Dokument222 SeitenMichael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Sølve StoknesNoch keine Bewertungen

- Bhagwan Mahavir College of Architecture: Topic: Lacing, Batteneing, BracingDokument14 SeitenBhagwan Mahavir College of Architecture: Topic: Lacing, Batteneing, BracingJai MenDparaNoch keine Bewertungen

- Modicon PLC CPUS Technical Details.Dokument218 SeitenModicon PLC CPUS Technical Details.TrbvmNoch keine Bewertungen

- Nptel Online-Iit KanpurDokument1 SeiteNptel Online-Iit KanpurRihlesh ParlNoch keine Bewertungen

- American J of Comm Psychol - 2023 - Palmer - Looted Artifacts and Museums Perpetuation of Imperialism and RacismDokument9 SeitenAmerican J of Comm Psychol - 2023 - Palmer - Looted Artifacts and Museums Perpetuation of Imperialism and RacismeyeohneeduhNoch keine Bewertungen

- IOM - Rampa Hidráulica - Blue GiantDokument32 SeitenIOM - Rampa Hidráulica - Blue GiantPATRICIA HERNANDEZNoch keine Bewertungen

- Nicole Rapp Resume 3Dokument2 SeitenNicole Rapp Resume 3api-341337144Noch keine Bewertungen

- Blackstone The Dash Model #1610 Owner's ManualDokument53 SeitenBlackstone The Dash Model #1610 Owner's ManualSydney Adam SteeleNoch keine Bewertungen

- 10 - SHM, Springs, DampingDokument4 Seiten10 - SHM, Springs, DampingBradley NartowtNoch keine Bewertungen

- Solution Documentation For Custom DevelopmentDokument52 SeitenSolution Documentation For Custom DevelopmentbayatalirezaNoch keine Bewertungen