Beruflich Dokumente

Kultur Dokumente

Overhauling 10kw Induction Motor

Hochgeladen von

Ramprabu ChandrasekarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Overhauling 10kw Induction Motor

Hochgeladen von

Ramprabu ChandrasekarCopyright:

Verfügbare Formate

Describe step by step method of overhauling of 10 Kw , 50hz , 440Volts, 3

phase induction motor?

1. Check availability of spares for the motor.

2. Check the importance of motor, according to plan your work.

3. Prepare all the things one day before O/H.

4. Make permit to work and isolation duly signed by the authorities.

5.Discuss everything pertaining to motor from beginning of the

process to the end of process. Use the proper PPE’s and tools for this

operation.

6. Make everyone understand the pros and cons of the work.

7. Isolate the power supply from all means to motor. Put lock out and tag

out. Check for remote start and put tag panel.

8. Ensure main power supply isolated from Main Sw Board and local starter

panel..Remove fuses for extra precaution in starter panel.

9. Place all Lock out and Tag outs.

10. Check insulation of motor and resistive value between the winding on

the motor terminals.

11. Remove the wire connection of motor.

12. Mark the connection of the motor rotation.

13. Check the direction of the motor rotation.

14. Disconnect the all wire to the motor, Check if heater

provide, then carefully disconnect those wires also.

15. Mark its base with permanent marker for reference.

16. Mark the coupling connected to motor.

17. Take out the motor from its place and keep at safe

place or at the workshop.

18. Mark the motor frame w.r.t its cover front and rear

end.

19. Remove the cooling fan and the locking pin.

20. Open the both ends vover. Clean the fins of the

motor.

21. Remove the rotor carefully and place it safe place.

22. Check the condition of both rotor and stator.

23. Look for and wear and tear on the rotor, stator and

inside the motor from both ends.

24. Ensure there is no sign of damage.

25. If and sign of insulation damage, apply the varnish

and dry it sufficiently. Avoid extra varnishes as it causes

heating and reduce air gap.

26. Remove the bearing carefully from both ends of the

rotor with bearing puller.

27. Clean the Rotor and stator with dry air.

28. Check the new bearings and compare with old ones

for confirmation.

29. Heat the new bearing uptp 70-8-deg in oil bath or in

bearing oven.

30. Put the bearing on the shaft of rotor only after

cleaning the shaft.

31. Ensure the freeness of the bearings and check the proper sitting of

bearing on the shaft.

32. Now assemble the rotor into stator and match the marking of

covers on both side.

33. Use pellet and hammer on the covers of the motors to insert them

properly.

34. Tighten the belt evenly and slowly on both sides.

35. After putting both side covers, check the freeness of the shaft and

check for any abnormality. Check the action of bearings.

36. Insert the fan and locking pin.

37 Now fix the motor at its base as per marking and connect the

coupling.

38 Ensure free movement of coupling shaft.

39 Check the insulation and resistance of the motor before

connecting the wires and compare it with last reading taken.

40 Connect the wires at the terminal and box up the terminal cover.

37 Check the insulation and resistance of the motor before

connecting the wires and compare it with last reading taken.

38 Connect the wires at the terminal and box up the terminal cover.

41. Remove all tools from working places and clean the area.

42. Remove the lock out and tag out.

43 Give a just kick to motor and observe the motor the correct

rotation and other abnormalities.

44. Now start the motor and check the amperes and compare with last

reading taken. Touch the motor check the temperature of motor

body by hand and by hand temp gun.

45.If everything goes good, close the permit to work & energy

isolation, report to C/E regarding completion of work.

46. Make necessary log entries.

Das könnte Ihnen auch gefallen

- Bharat Heavy Electricals Limited: Thermal Power Plant Industrial TrainingDokument20 SeitenBharat Heavy Electricals Limited: Thermal Power Plant Industrial TrainingSaurabh SinghNoch keine Bewertungen

- Electrical Systems & Components: Power Factor, Loads, Alternators, Generators, Starters, Transformers, Motors, Batteries, Cables, Relays & MoreDokument4 SeitenElectrical Systems & Components: Power Factor, Loads, Alternators, Generators, Starters, Transformers, Motors, Batteries, Cables, Relays & MoreNirjhar Ganguly100% (1)

- Emergency generator testingDokument4 SeitenEmergency generator testingnarendra_katdareNoch keine Bewertungen

- Electrical Engineering Interview Questions GuideDokument13 SeitenElectrical Engineering Interview Questions GuiderufitejNoch keine Bewertungen

- Function 5 OralsDokument4 SeitenFunction 5 OralsAditya Arya0% (1)

- C Boilermaking PDFDokument9 SeitenC Boilermaking PDFParameswararao BillaNoch keine Bewertungen

- Direct - Indirect - Regenerative Method of TestingDokument29 SeitenDirect - Indirect - Regenerative Method of TestingASHIM KUMAR SAHUNoch keine Bewertungen

- List of Technical Short CourseDokument3 SeitenList of Technical Short Coursealibanker100% (1)

- Steam Turbine CompoundingDokument13 SeitenSteam Turbine CompoundingDivya Prakash Srivastava100% (3)

- 300+ TOP ELECTRICAL ENGINEERING Interview Questions & Answers PDFDokument88 Seiten300+ TOP ELECTRICAL ENGINEERING Interview Questions & Answers PDFdileep sriNoch keine Bewertungen

- Engine Weekly Work Done ReportDokument2 SeitenEngine Weekly Work Done ReportJojo Saligan0% (1)

- Elec Oral Ques MMD KolkataDokument7 SeitenElec Oral Ques MMD KolkataAkshay Ankit100% (2)

- Experiment 2: Level Transmitter CalibrationDokument13 SeitenExperiment 2: Level Transmitter CalibrationMuhammad FawwazNoch keine Bewertungen

- Electrical Theory Basic InformationDokument208 SeitenElectrical Theory Basic InformationArun Jey100% (1)

- Global Coriander Production and Trade OverviewDokument28 SeitenGlobal Coriander Production and Trade OverviewBba RockzeNoch keine Bewertungen

- SWITCHYARDDokument30 SeitenSWITCHYARDKaran TripathiNoch keine Bewertungen

- Technical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Dokument12 SeitenTechnical Data & Curves For BFP Motor (MDL#BPL-027) - R3 - Cat A Approved DTD 16.03.2011Bijaya Kumar MohantyNoch keine Bewertungen

- Training Repoart GEB Gandhinagar GujaratDokument42 SeitenTraining Repoart GEB Gandhinagar GujaratSUDHIR CHAUHAN100% (1)

- Thermal Power Plant Training Training Report-Aniket KaushalDokument44 SeitenThermal Power Plant Training Training Report-Aniket KaushalAniket Kaushal88% (16)

- VWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Dokument20 SeitenVWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Kaushik ChakrabortyNoch keine Bewertungen

- Interview Questions Electrical EnggDokument21 SeitenInterview Questions Electrical Enggwelcome2twinkle_2272100% (1)

- MEO Orals On Marine Electro Technology Function 5Dokument19 SeitenMEO Orals On Marine Electro Technology Function 5Rajeev ValunjkarNoch keine Bewertungen

- Generator Operation ManualDokument73 SeitenGenerator Operation ManualFerdinand DescalzoNoch keine Bewertungen

- Classification of Transmission LinesDokument15 SeitenClassification of Transmission LinesJim Erol BancoroNoch keine Bewertungen

- Electrical systems and componentsDokument6 SeitenElectrical systems and componentsArun Paul RayenNoch keine Bewertungen

- IE Rules For DP Structure - Electrical Notes & ArticlesDokument8 SeitenIE Rules For DP Structure - Electrical Notes & ArticlesHubert BonamisNoch keine Bewertungen

- Interview Questions For Eee StudentsDokument11 SeitenInterview Questions For Eee StudentsAli ZafarNoch keine Bewertungen

- Technical BookDokument33 SeitenTechnical BookPrakash JegannathanNoch keine Bewertungen

- Generating Transformer ManufacturingDokument19 SeitenGenerating Transformer ManufacturingROHIT YADAV100% (1)

- Curriculum Vitae of ETO Seeking Seagoing PositionDokument3 SeitenCurriculum Vitae of ETO Seeking Seagoing PositionHARI KUMAR MNoch keine Bewertungen

- Overhauling Report Final DraftDokument11 SeitenOverhauling Report Final DraftYITESH RAHANGDALE100% (2)

- AbstractDokument3 SeitenAbstractKartik Patel100% (1)

- QuestionsDokument15 SeitenQuestionsKAKUMANUNoch keine Bewertungen

- ETO QuestionsDokument2 SeitenETO QuestionsSuraj vs. World100% (1)

- MEO Class 4 Exam - Electrical Oral Question & Answers PDFDokument6 SeitenMEO Class 4 Exam - Electrical Oral Question & Answers PDFabhishek rathourNoch keine Bewertungen

- No Load Test On Single Phase Induction MotorDokument1 SeiteNo Load Test On Single Phase Induction Motorg3v5Noch keine Bewertungen

- Aarti Steel WHR PDDDokument34 SeitenAarti Steel WHR PDDKvvPrasadNoch keine Bewertungen

- ETO Entrance Exam Syllabus and SubjectsDokument3 SeitenETO Entrance Exam Syllabus and SubjectsabhilashNoch keine Bewertungen

- Afbc Vol-IiDokument81 SeitenAfbc Vol-IiVijay RajNoch keine Bewertungen

- DC GeneratorDokument6 SeitenDC GeneratorUditya K100% (1)

- Meo Class 4 - Electricals: Section - 1Dokument85 SeitenMeo Class 4 - Electricals: Section - 1Mrithesh KathirNoch keine Bewertungen

- Alternator Fault FindingDokument41 SeitenAlternator Fault FindingRoberto Emme100% (1)

- Single Phase Induction MotorDokument5 SeitenSingle Phase Induction MotorSridhar SridharNoch keine Bewertungen

- Three Phase AlternatorDokument8 SeitenThree Phase AlternatorJames BalaisNoch keine Bewertungen

- Steam Plant & BoilersDokument41 SeitenSteam Plant & BoilersAbdallah MansourNoch keine Bewertungen

- To Determine The Efficiency of A DC Machine by Direct Load TestDokument8 SeitenTo Determine The Efficiency of A DC Machine by Direct Load Testdns sNoch keine Bewertungen

- Motors: Why Starters Are Not Used For Land Based Installations?Dokument12 SeitenMotors: Why Starters Are Not Used For Land Based Installations?avm4343100% (1)

- Digha TourismDokument13 SeitenDigha TourismArka Narayan DashguptaNoch keine Bewertungen

- AC to DC Converter Project Report Using MATLAB SimulinkDokument75 SeitenAC to DC Converter Project Report Using MATLAB SimulinkVishal Bhadalda100% (1)

- 21 Floating Power Plant Sarah BellewDokument17 Seiten21 Floating Power Plant Sarah BellewinderjitNoch keine Bewertungen

- Unit: HT Motor Revision No: 0 Page 1 of 2: Title: Standard Operation ProceedureDokument2 SeitenUnit: HT Motor Revision No: 0 Page 1 of 2: Title: Standard Operation ProceedureSarah FrazierNoch keine Bewertungen

- Disadvantages of Supercritical BoilerDokument2 SeitenDisadvantages of Supercritical Boilerpriyajsingh100% (1)

- Bhel Haridwar - Training Report - 800 MW Bar CIM Block 4 (EEE)Dokument27 SeitenBhel Haridwar - Training Report - 800 MW Bar CIM Block 4 (EEE)Amit Kumar67% (6)

- Presentation On Air Circuit Breaker: Vidhyavardhini Institute of Technolofy PALDokument23 SeitenPresentation On Air Circuit Breaker: Vidhyavardhini Institute of Technolofy PALPrathamesh MhatugadeNoch keine Bewertungen

- Indicator DiagramsDokument9 SeitenIndicator DiagramsBhupender RamchandaniNoch keine Bewertungen

- NPT Operation and Maintenance Manual For Gas GeneratorDokument60 SeitenNPT Operation and Maintenance Manual For Gas GeneratorJORGE LUIS MENDOZA SANCHEZ100% (1)

- Maintenance - Motor, Switchgear, Capacitor, Battery & Acb or VCBDokument10 SeitenMaintenance - Motor, Switchgear, Capacitor, Battery & Acb or VCBMohammad TammamNoch keine Bewertungen

- Servo Motor VI Fortuna Serie 6Dokument77 SeitenServo Motor VI Fortuna Serie 6Gilberto Oliveira67% (3)

- NEMA Induction motor Machine Instructions GB 3 Motores NEMA de jaula de ardilla Instrucciones ES 11 ABB AutomationDokument20 SeitenNEMA Induction motor Machine Instructions GB 3 Motores NEMA de jaula de ardilla Instrucciones ES 11 ABB AutomationErik Huang100% (1)

- Electrical Inspection ProcedureDokument17 SeitenElectrical Inspection Proceduredidi sudiNoch keine Bewertungen

- Oral DocsDokument75 SeitenOral DocsRamprabu ChandrasekarNoch keine Bewertungen

- Oral PrepartionDokument29 SeitenOral PrepartionRamprabu ChandrasekarNoch keine Bewertungen

- Ritinkar Sen - Motor Q&ADokument381 SeitenRitinkar Sen - Motor Q&ARamprabu Chandrasekar100% (2)

- Surveyor's day report on MAN dual-fuel enginesDokument45 SeitenSurveyor's day report on MAN dual-fuel enginesRamprabu ChandrasekarNoch keine Bewertungen

- Oil Mist DetectorsDokument31 SeitenOil Mist DetectorsRamprabu Chandrasekar100% (1)

- Wifi PBLM Solver PDFDokument18 SeitenWifi PBLM Solver PDFZakariya ThoubaNoch keine Bewertungen

- Refrigeration and Air ConditioningDokument26 SeitenRefrigeration and Air ConditioningRamprabu ChandrasekarNoch keine Bewertungen

- Ritinkar Sen - Motor Q&ADokument381 SeitenRitinkar Sen - Motor Q&ARamprabu Chandrasekar100% (1)

- Surveyor's day report on MAN dual-fuel enginesDokument45 SeitenSurveyor's day report on MAN dual-fuel enginesRamprabu ChandrasekarNoch keine Bewertungen

- 5ff63bf7758eb270a4a2b62f2d8149de.xlsDokument10 Seiten5ff63bf7758eb270a4a2b62f2d8149de.xlsRamprabu ChandrasekarNoch keine Bewertungen

- Fresh Water GeneratorDokument7 SeitenFresh Water GeneratorRamprabu ChandrasekarNoch keine Bewertungen

- Networking: - Computer NetworkDokument32 SeitenNetworking: - Computer NetworkCaunan Joanna PaulineNoch keine Bewertungen

- Wifi PBLM Solver PDFDokument18 SeitenWifi PBLM Solver PDFZakariya ThoubaNoch keine Bewertungen

- Main EngineDokument3 SeitenMain EngineRamprabu ChandrasekarNoch keine Bewertungen

- SCADADokument21 SeitenSCADARamprabu ChandrasekarNoch keine Bewertungen

- All About Steering System.Dokument12 SeitenAll About Steering System.Ramprabu Chandrasekar100% (1)

- IInd ED CONTROL - Steering SystemDokument49 SeitenIInd ED CONTROL - Steering SystemRamprabu ChandrasekarNoch keine Bewertungen

- Introduction to PLC Hardware and ProgrammingDokument77 SeitenIntroduction to PLC Hardware and ProgrammingUsama Spiffy100% (1)

- Overhauling 10kw Induction MotorDokument6 SeitenOverhauling 10kw Induction MotorRamprabu ChandrasekarNoch keine Bewertungen

- Fire DoorsDokument4 SeitenFire DoorsRamprabu ChandrasekarNoch keine Bewertungen

- Cathodic ProtectionDokument2 SeitenCathodic ProtectionRamprabu ChandrasekarNoch keine Bewertungen

- Radar Block DiagramDokument190 SeitenRadar Block DiagramRamprabu ChandrasekarNoch keine Bewertungen

- Prevent, Control & Fight Fire On BoardDokument26 SeitenPrevent, Control & Fight Fire On BoardRamprabu Chandrasekar50% (2)

- Fire Detector Circuit and Instrument FaultsDokument5 SeitenFire Detector Circuit and Instrument FaultsRamprabu ChandrasekarNoch keine Bewertungen

- Engine GovernorDokument23 SeitenEngine GovernorRamprabu Chandrasekar100% (1)

- Purifiers GmeDokument59 SeitenPurifiers GmeRamprabu ChandrasekarNoch keine Bewertungen

- Image Description Europe (EN 2) United States Australian Suitable SuppressionDokument2 SeitenImage Description Europe (EN 2) United States Australian Suitable SuppressionRamprabu ChandrasekarNoch keine Bewertungen

- Dr. D. D. Ebenezer Propulsion Course CUSATDokument37 SeitenDr. D. D. Ebenezer Propulsion Course CUSATAviral chandanNoch keine Bewertungen

- 3.7 Engine SpecDokument6 Seiten3.7 Engine SpecSal GarzaNoch keine Bewertungen

- LPG and Propane Pumps LPG & PROPANE Piping and AccessoriesDokument7 SeitenLPG and Propane Pumps LPG & PROPANE Piping and AccessoriesOmar WardehNoch keine Bewertungen

- Eaton Fuller 15webDokument4 SeitenEaton Fuller 15webmancorabechNoch keine Bewertungen

- Dry Fuel Cell ManualDokument24 SeitenDry Fuel Cell ManualniculaenicuNoch keine Bewertungen

- Cab Wiring ConnectorsDokument6 SeitenCab Wiring ConnectorsLucho Volvo TronicNoch keine Bewertungen

- ERIKC Update CRDi Catalog-Diesel Injector Spare PartsDokument63 SeitenERIKC Update CRDi Catalog-Diesel Injector Spare PartsЕкатерина КалашниковаNoch keine Bewertungen

- 096Dokument1 Seite096NUr RIZKI KURNIAWANNoch keine Bewertungen

- Ijet 24380Dokument5 SeitenIjet 24380sender2000Noch keine Bewertungen

- Bảng mã lỗi Wise15Dokument56 SeitenBảng mã lỗi Wise15Bach Nguyen XuanNoch keine Bewertungen

- 627G Wheel Tractor-Scraper Electrical System: Machine Harness Connector and Component LocationsDokument4 Seiten627G Wheel Tractor-Scraper Electrical System: Machine Harness Connector and Component LocationsMauricio BellidoNoch keine Bewertungen

- Dual Mass FlywheelDokument2 SeitenDual Mass FlywheelAmit SinghNoch keine Bewertungen

- Dump Valve LB Rna RNB RNCDokument8 SeitenDump Valve LB Rna RNB RNCRyanNoch keine Bewertungen

- Moheb Botros Wadie: DucationDokument7 SeitenMoheb Botros Wadie: Ducationmoheb botrosNoch keine Bewertungen

- Engine Controls (Powertrain Management) - ALLDATA RepairDokument6 SeitenEngine Controls (Powertrain Management) - ALLDATA RepairAngel HermidaNoch keine Bewertungen

- FE800 Bedienungsanleitung Standard 3297-80D1 1 ENGLDokument44 SeitenFE800 Bedienungsanleitung Standard 3297-80D1 1 ENGLMantencion ProverdeNoch keine Bewertungen

- Connect AiM Devices to EFI Euro 1 ECUDokument6 SeitenConnect AiM Devices to EFI Euro 1 ECUFabian MenesesNoch keine Bewertungen

- Manual Roto Screw PumpDokument10 SeitenManual Roto Screw PumpKELVIN TECHNOLOGIESNoch keine Bewertungen

- DrillingDokument27 SeitenDrillinggsudhanta1604Noch keine Bewertungen

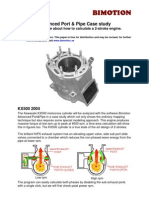

- Bimotion 2-Stroke Case StudyDokument11 SeitenBimotion 2-Stroke Case Studytfour200080% (5)

- 918M PDFDokument4 Seiten918M PDFYundi GaoNoch keine Bewertungen

- VEBM460104 WA380-3 With-Diagrams 09-06 PDFDokument970 SeitenVEBM460104 WA380-3 With-Diagrams 09-06 PDFouael86% (7)

- Cradle Bor EOperation ManualDokument10 SeitenCradle Bor EOperation ManualengmuhmudNoch keine Bewertungen

- EXCEL For Pump DesignDokument2 SeitenEXCEL For Pump Designkad-7Noch keine Bewertungen

- Differential Mechanism GuideDokument10 SeitenDifferential Mechanism GuideAdelina Oprea100% (1)

- Ingersoll Rand p425 Wip Rev SeccionDokument27 SeitenIngersoll Rand p425 Wip Rev SeccionMartin RamirezNoch keine Bewertungen

- Ab Dick FlyerDokument6 SeitenAb Dick FlyerHernan edgardo Cortez laraNoch keine Bewertungen

- Tm9 2320 208 20pDokument156 SeitenTm9 2320 208 20ptelematico69100% (1)

- Rebuilding GMs Gen 4 EngineDokument13 SeitenRebuilding GMs Gen 4 EngineDaniel JueNoch keine Bewertungen

- Cam Sheet Cutting ReportDokument57 SeitenCam Sheet Cutting ReportJAYAPRABHAKARAN N NNoch keine Bewertungen