Beruflich Dokumente

Kultur Dokumente

Determination of The Size and Shape of The Open Pit Mine

Hochgeladen von

ohnthaik0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

78 Ansichten20 SeitenOriginaltitel

Determination of the Size and Shape of the Open Pit Mine.pptx

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

78 Ansichten20 SeitenDetermination of The Size and Shape of The Open Pit Mine

Hochgeladen von

ohnthaikCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 20

Chapter 4

Determination of the Size and

Shape of the Open Pit Mine

Dr.Ohn Thaik

Professor

Department of Mining Engineering

Introduction

• Ore Reserve

• the ultimate (final) pit limits

• Techniques used in designing an ultimate pit

(1) hand methods,

(2) computer methods, and

(3) computer assisted hand methods

• The size and shape of the pit depends upon

economic factors and design/production

constraints.

Data for designing an Ultimate Pit

• (1) vertical sections, (2) horizontal sections for

each level, (3) stripping curve, (4) bench

height,(5) bank slope angle between levels, (6)

level berm width, (7) roadway width, (8) pit

slope angles at ultimate pit limits (estimated

average including roads and ramps and

between roads and ramps), and (9) minimum

width of pit bottom.

Hand Method

Basic Concepts

Figure. Cross-section through an idealized orebody.

• the width of the slice has been selected as 1.4

units (u) and the thickness of the section (into

the page) as 1 unit. Beginning with strip 1 the

volumes of waste (Vw) and ore (Vo) are

calculated. The volumes are:

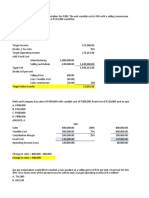

• Assuming that the net value from selling one unit volume of ore (that money

remaining after all expenses have been paid) is $1.90 and the cost for mining and

disposing of the waste is $1/unit volume, the net value for strip 1 is

Figure. Diagrammatic representation of the final pit outline on this section

• If the process is now repeated for strips 2, 3

and 4, the results are as given below:

• the net value changes from (+) to (−) as the pit

is expanded. For strip 3, the net value is just

about zero. This pit position is termed

‘breakeven’ since the costs involved in mining

the strip just equal the revenues. It is the

location of the final pit wall.

• The breakeven stripping ratio which is strictly

applied at the wall is

• Since the net value of 1 unit of ore is $1.90

and the cost for 1 unit of waste is $1, one can

mine 1.9 units of waste to recover 1 unit of

ore

Figure. Final pit outline showing ore-waste distribution

• The overall stripping ratio (OSR) for this

section is calculated as

This is compared to the instantaneous stripping ratio at the pit

boundary

ISR (pit limit) = 1.9

The OSR must always be less than the ISR (pit limit).

The net value for the section (assuming unit thickness) is

NV = Ore area × Net ore value −Waste area ×Waste removal cost

= B × $1.90 − A × $1 = 62 × $1.90 − 50 × $1 = $68

Figure.Stripping ratio – ore grade curve used for pit limit determinations

(Koskiniemi, 1979)

Figure. Pit limit determination with bottom in waste (Koskiniemi, 1979).

• Bottom in waste: pit limit guess #1 (Line G1)

• Bottom in waste: pit limit guess #2 (Line G2).

• Bottom in waste: pit limit guess #3 (Line G3)

• Bottom in waste: pit limit guess #4 (Line G4)

Das könnte Ihnen auch gefallen

- Pit Limits CH 6Dokument10 SeitenPit Limits CH 6Waqar AnwarNoch keine Bewertungen

- Stripping Ratio PDFDokument59 SeitenStripping Ratio PDFKeylla Chavez RosasNoch keine Bewertungen

- Determination of The Optimum Crown Pillar Thickness Between OpenDokument8 SeitenDetermination of The Optimum Crown Pillar Thickness Between OpenluisparedesNoch keine Bewertungen

- Mining Engineering Careers ExplainedDokument10 SeitenMining Engineering Careers ExplainedIngrid Ayala DelgadoNoch keine Bewertungen

- Rock Excavation EngineeringDokument1 SeiteRock Excavation EngineeringanupamkherNoch keine Bewertungen

- Rock Mechanics 988Dokument69 SeitenRock Mechanics 988Sheshu BabuNoch keine Bewertungen

- Lab 9 - Schmidt Hammer Rebound HardnessDokument7 SeitenLab 9 - Schmidt Hammer Rebound HardnessankeshNoch keine Bewertungen

- Estimation of Fines Generated by Blasting (Onederra, Esen, Jankovic-IMM-113-4)Dokument11 SeitenEstimation of Fines Generated by Blasting (Onederra, Esen, Jankovic-IMM-113-4)Kevin EduardoNoch keine Bewertungen

- Nirm Vib ReportDokument96 SeitenNirm Vib ReportcjmchandanaNoch keine Bewertungen

- ROCK MECHANICS All Lectures 77 PDFDokument1 SeiteROCK MECHANICS All Lectures 77 PDFmazharNoch keine Bewertungen

- Geotechnical Factors Influencing Selection of Mining MethodDokument4 SeitenGeotechnical Factors Influencing Selection of Mining MethodMichael AltamiranoNoch keine Bewertungen

- M. Farhad Howladar - Coal Mining Impacts On Water Environs Around The Barapukuria Coal Mining Area, DinajpurDokument12 SeitenM. Farhad Howladar - Coal Mining Impacts On Water Environs Around The Barapukuria Coal Mining Area, DinajpurAbu NaserNoch keine Bewertungen

- IAMGOLD Geotech Logging 20071101 PrintDokument42 SeitenIAMGOLD Geotech Logging 20071101 PrintJoseph Mofat100% (1)

- Sub-Level Caving: Where Is It Headed?Dokument8 SeitenSub-Level Caving: Where Is It Headed?anon_747293279Noch keine Bewertungen

- Equivalent OrificeDokument2 SeitenEquivalent OrificeSami Faizaan100% (2)

- Ultimate Pit Design Using Surpac: Mentored ByDokument40 SeitenUltimate Pit Design Using Surpac: Mentored ByjunaifaNoch keine Bewertungen

- The Swebrec Function - Blast Fragmentation...Dokument31 SeitenThe Swebrec Function - Blast Fragmentation...Sandy Prieto Ili100% (1)

- Methods For Design & Sability Ug ExcavationDokument67 SeitenMethods For Design & Sability Ug Excavationbishal pradhanNoch keine Bewertungen

- Optimization of Drilling and Blasting Operations in An Open Pit Mine-The SOMAIR ExperienceDokument4 SeitenOptimization of Drilling and Blasting Operations in An Open Pit Mine-The SOMAIR ExperienceWilkhen ChuraNoch keine Bewertungen

- Rock Mechanic LabDokument32 SeitenRock Mechanic LabOolasyar KhattakNoch keine Bewertungen

- Kuliah 7. DiscontinuitiesDokument55 SeitenKuliah 7. DiscontinuitiestrumanNoch keine Bewertungen

- CVEN9522 and CVEN9776 Rock Engineering.Dokument4 SeitenCVEN9522 and CVEN9776 Rock Engineering.Milton TeranNoch keine Bewertungen

- Methane Layering in MinesDokument5 SeitenMethane Layering in MinesAnurag TripathyNoch keine Bewertungen

- An Empirical Relation To Calculate The Proper Burden in Blast Design of Open Pit Mines Based On Modification of The Konya RelationDokument6 SeitenAn Empirical Relation To Calculate The Proper Burden in Blast Design of Open Pit Mines Based On Modification of The Konya RelationhnavastNoch keine Bewertungen

- Syllabus Mining and Mineral ProcessingDokument9 SeitenSyllabus Mining and Mineral ProcessingArief NuzulNoch keine Bewertungen

- Heavy Mineral Concentration in BangladeshDokument2 SeitenHeavy Mineral Concentration in BangladeshApu DeyNoch keine Bewertungen

- O-Pitblast - Decks ManiualDokument30 SeitenO-Pitblast - Decks ManiualAftherJemigDamanikNoch keine Bewertungen

- 27th HKT Workshop Abstracts PublishedDokument238 Seiten27th HKT Workshop Abstracts PublishedtasaddaqYounasNoch keine Bewertungen

- 23 Failure Criteria For Rocks PDFDokument20 Seiten23 Failure Criteria For Rocks PDFVu ThuygiangNoch keine Bewertungen

- Mine GasesDokument48 SeitenMine GasesRavi Krishnan100% (1)

- A Review of The Methods To Incorporate The Geological Characteristics of Rock Masses in Blastability Assessments For Selective Blast DesignDokument37 SeitenA Review of The Methods To Incorporate The Geological Characteristics of Rock Masses in Blastability Assessments For Selective Blast DesignME-MNG-15 RameshNoch keine Bewertungen

- Chapter 3 Mine Ventialtion ProblemDokument3 SeitenChapter 3 Mine Ventialtion ProblemfahimNoch keine Bewertungen

- UG Mine Design for Fishmeri Gold DepositDokument97 SeitenUG Mine Design for Fishmeri Gold DepositLiNoch keine Bewertungen

- BenchFill VillaescusaDokument10 SeitenBenchFill VillaescusaFredd_AlvaroNoch keine Bewertungen

- Recoverable Resources Estimation: Indicator Kriging or Uniform Conditioning?Dokument4 SeitenRecoverable Resources Estimation: Indicator Kriging or Uniform Conditioning?Elgi Zacky ZachryNoch keine Bewertungen

- Gate Mining 2007-2019 PapersDokument220 SeitenGate Mining 2007-2019 PapersAarya raj singh RanawatNoch keine Bewertungen

- Duke Hanna 2003 Geological Interpretation For Resource Modelling and EstimationDokument10 SeitenDuke Hanna 2003 Geological Interpretation For Resource Modelling and EstimationJorge Mauricio LevetNoch keine Bewertungen

- Lecture Outline on Ore Reserve ClassificationDokument41 SeitenLecture Outline on Ore Reserve ClassificationPerkas GaunderNoch keine Bewertungen

- Pillar Design FundamentalsDokument9 SeitenPillar Design FundamentalsMichael David Altamirano MackenzieNoch keine Bewertungen

- Rock ExcavationDokument15 SeitenRock ExcavationRushbh Patil100% (1)

- Preliminary EvaluationDokument5 SeitenPreliminary EvaluationAryan AnandNoch keine Bewertungen

- Block CavingDokument6 SeitenBlock CavingArsa Iskaq IchsanNoch keine Bewertungen

- Full Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineDokument10 SeitenFull Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineandresmaureiravNoch keine Bewertungen

- PNGE 343 Chapter 2 Volumetric CalculationsDokument20 SeitenPNGE 343 Chapter 2 Volumetric CalculationsHafizNoch keine Bewertungen

- ISRM Suggested Method for Determination of the Schmidt Hammer Rebound HardnessDokument10 SeitenISRM Suggested Method for Determination of the Schmidt Hammer Rebound HardnessmuazNoch keine Bewertungen

- Mine PlanningDokument10 SeitenMine PlanningFebri Ruswandi Anggara PutraNoch keine Bewertungen

- GSI Guidelines for Scientific Riverbed MiningDokument5 SeitenGSI Guidelines for Scientific Riverbed MiningLori PierceNoch keine Bewertungen

- Spontaneous Combustion - Narrabri MineDokument14 SeitenSpontaneous Combustion - Narrabri Mineduncanmac200777Noch keine Bewertungen

- Optimization of Blasting Parameters in Opencast Mines 06Dokument79 SeitenOptimization of Blasting Parameters in Opencast Mines 06Cesar Agustinus NugrahaNoch keine Bewertungen

- Questions 1Dokument15 SeitenQuestions 1Har AhmadNoch keine Bewertungen

- Pillar Design: DR - Ohn Thaik Department of Mining EngineeringDokument38 SeitenPillar Design: DR - Ohn Thaik Department of Mining EngineeringohnthaikNoch keine Bewertungen

- GATE Mining Engineering PDFDokument2 SeitenGATE Mining Engineering PDFSandeep SinghNoch keine Bewertungen

- Rock Blasting: Indices de VolavilidadDokument18 SeitenRock Blasting: Indices de VolavilidadPablo Robert López Nicolaz100% (1)

- Chapter 4Dokument20 SeitenChapter 4ohnthaikNoch keine Bewertungen

- Chapter 4Dokument20 SeitenChapter 4ohnthaikNoch keine Bewertungen

- Lecture 2Dokument18 SeitenLecture 2se ruNoch keine Bewertungen

- 5 EarthworksDokument45 Seiten5 EarthworkssonypspaoloNoch keine Bewertungen

- StrippingRatios and PitLimitsDokument12 SeitenStrippingRatios and PitLimitsmekuchta100% (1)

- Building Material Estimates and Rates Build Up: Second EditionVon EverandBuilding Material Estimates and Rates Build Up: Second EditionNoch keine Bewertungen

- Economic Block ModelsDokument8 SeitenEconomic Block ModelsohnthaikNoch keine Bewertungen

- Stripping RatiosDokument8 SeitenStripping RatiosohnthaikNoch keine Bewertungen

- Economic Considerations: DR - Ohn Thaik Professor Department of Mining EngineeringDokument35 SeitenEconomic Considerations: DR - Ohn Thaik Professor Department of Mining EngineeringohnthaikNoch keine Bewertungen

- Mineral Occurrences of Myanmar (Continuation)Dokument51 SeitenMineral Occurrences of Myanmar (Continuation)ohnthaikNoch keine Bewertungen

- Guidelines and Considerations For Open Pit Designers: March 2018Dokument16 SeitenGuidelines and Considerations For Open Pit Designers: March 2018Sime ToddNoch keine Bewertungen

- Blasting Management and MonitoringDokument22 SeitenBlasting Management and MonitoringohnthaikNoch keine Bewertungen

- Pillar Design: DR - Ohn Thaik Department of Mining EngineeringDokument38 SeitenPillar Design: DR - Ohn Thaik Department of Mining EngineeringohnthaikNoch keine Bewertungen

- Types of Placer DepositDokument2 SeitenTypes of Placer DepositohnthaikNoch keine Bewertungen

- CH.1 Guidelines For Seleting Mining MethodDokument49 SeitenCH.1 Guidelines For Seleting Mining MethodohnthaikNoch keine Bewertungen

- Comparison With Hand CalculationsDokument5 SeitenComparison With Hand CalculationsRean Airlangga100% (1)

- Rock Slope FailureDokument30 SeitenRock Slope Failuretsinghal_19Noch keine Bewertungen

- Australian Mineral EconomicsDokument257 SeitenAustralian Mineral EconomicsohnthaikNoch keine Bewertungen

- Laboratory Testing Manual (2000) PDFDokument330 SeitenLaboratory Testing Manual (2000) PDFandressaoliveira2301100% (8)

- Rock Mechanics Lab Manual PDFDokument299 SeitenRock Mechanics Lab Manual PDFohnthaikNoch keine Bewertungen

- Mineral Deposit Evaluation PDFDokument449 SeitenMineral Deposit Evaluation PDFohnthaik100% (2)

- Rock and Rock Mass StrengthDokument28 SeitenRock and Rock Mass StrengthUmer FarooqNoch keine Bewertungen

- Contemporary Issues and ChallengesDokument216 SeitenContemporary Issues and ChallengesahmedbaloNoch keine Bewertungen

- Soil Mechanics Laboratory: A Guide For Preparing Laboratory ReportsDokument10 SeitenSoil Mechanics Laboratory: A Guide For Preparing Laboratory ReportsohnthaikNoch keine Bewertungen

- Estimation Mineral Resources Mineral Reserves 11-23-2003Dokument241 SeitenEstimation Mineral Resources Mineral Reserves 11-23-2003ohnthaikNoch keine Bewertungen

- CH.4 Water SupplyDokument92 SeitenCH.4 Water SupplyohnthaikNoch keine Bewertungen

- Chapter 4Dokument20 SeitenChapter 4ohnthaikNoch keine Bewertungen

- Myanmar Mine RulesDokument359 SeitenMyanmar Mine RulesohnthaikNoch keine Bewertungen

- Chapter 4Dokument20 SeitenChapter 4ohnthaikNoch keine Bewertungen

- Surface Foreman Study GuideDokument273 SeitenSurface Foreman Study Guideohnthaik100% (1)

- Chapter 4Dokument20 SeitenChapter 4ohnthaikNoch keine Bewertungen

- Guidelines For Evaluating Water in Pit Slope StabilityDokument615 SeitenGuidelines For Evaluating Water in Pit Slope Stabilityohnthaik100% (3)

- IBM TS3500 Command Line Interface (CLI) ExamplesDokument6 SeitenIBM TS3500 Command Line Interface (CLI) ExamplesMustafa BenmaghaNoch keine Bewertungen

- Pass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppDokument1 SeitePass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppAnoop SharmaNoch keine Bewertungen

- Troubleshooting Edge Quality: Mild SteelDokument14 SeitenTroubleshooting Edge Quality: Mild SteelAnonymous U6yVe8YYCNoch keine Bewertungen

- For-tea Tea Parlour Marketing Strategy Targets 40+ DemographicDokument7 SeitenFor-tea Tea Parlour Marketing Strategy Targets 40+ Demographicprynk_cool2702Noch keine Bewertungen

- Specialized Government BanksDokument5 SeitenSpecialized Government BanksCarazelli AysonNoch keine Bewertungen

- Fleck 3150 Downflow: Service ManualDokument40 SeitenFleck 3150 Downflow: Service ManualLund2016Noch keine Bewertungen

- Library Management System (Final)Dokument88 SeitenLibrary Management System (Final)Ariunbat Togtohjargal90% (30)

- Guardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicDokument110 SeitenGuardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicTarun BharadwajNoch keine Bewertungen

- CVP Solution (Quiz)Dokument9 SeitenCVP Solution (Quiz)Angela Miles DizonNoch keine Bewertungen

- AssemblyinstructionsDokument12 SeitenAssemblyinstructionsPriscila AzevedoNoch keine Bewertungen

- Broschuere Unternehmen Screen PDFDokument16 SeitenBroschuere Unternehmen Screen PDFAnonymous rAFSAGDAEJNoch keine Bewertungen

- Successful Organizational Change FactorsDokument13 SeitenSuccessful Organizational Change FactorsKenneth WhitfieldNoch keine Bewertungen

- A Dream Takes FlightDokument3 SeitenA Dream Takes FlightHafiq AmsyarNoch keine Bewertungen

- BUSN7054 Take Home Final Exam S1 2020Dokument14 SeitenBUSN7054 Take Home Final Exam S1 2020Li XiangNoch keine Bewertungen

- UPGRADEDokument2 SeitenUPGRADEVedansh OswalNoch keine Bewertungen

- Superior University: 5Mwp Solar Power Plant ProjectDokument3 SeitenSuperior University: 5Mwp Solar Power Plant ProjectdaniyalNoch keine Bewertungen

- Duct Design ChartDokument7 SeitenDuct Design ChartMohsen HassanNoch keine Bewertungen

- Using The Marketing Mix Reading Comprenhension TaskDokument17 SeitenUsing The Marketing Mix Reading Comprenhension TaskMonica GalvisNoch keine Bewertungen

- Afar Partnerships Ms. Ellery D. de Leon: True or FalseDokument6 SeitenAfar Partnerships Ms. Ellery D. de Leon: True or FalsePat DrezaNoch keine Bewertungen

- 5030si PDFDokument2 Seiten5030si PDFSuperhypoNoch keine Bewertungen

- Stellar Competent CellsDokument1 SeiteStellar Competent CellsSergio LaynesNoch keine Bewertungen

- Proprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie AutovehiculDokument3 SeitenProprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie Autovehicultranspol2023Noch keine Bewertungen

- Cycles in Nature: Understanding Biogeochemical CyclesDokument17 SeitenCycles in Nature: Understanding Biogeochemical CyclesRatay EvelynNoch keine Bewertungen

- Corena s2 p150 - Msds - 01185865Dokument17 SeitenCorena s2 p150 - Msds - 01185865Javier LerinNoch keine Bewertungen

- (Jf613e) CVT Renault-Nissan PDFDokument4 Seiten(Jf613e) CVT Renault-Nissan PDFJhoanny RodríguezNoch keine Bewertungen

- Kunci Jawaban Creative English 3BDokument14 SeitenKunci Jawaban Creative English 3BLedjab Fatima67% (3)

- JWCh06 PDFDokument23 SeitenJWCh06 PDF007featherNoch keine Bewertungen

- Product Data: Airstream™ 42BHC, BVC System Fan CoilsDokument40 SeitenProduct Data: Airstream™ 42BHC, BVC System Fan CoilsMaxmore KarumamupiyoNoch keine Bewertungen

- Difference Between Knowledge and SkillDokument2 SeitenDifference Between Knowledge and SkilljmNoch keine Bewertungen

- Racial and Ethnic Challenges in the UAE vs UKDokument16 SeitenRacial and Ethnic Challenges in the UAE vs UKATUL KORINoch keine Bewertungen