Beruflich Dokumente

Kultur Dokumente

Ash Handling System

Hochgeladen von

netygen10 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

159 Ansichten24 SeitenThe document discusses ash handling systems for coal power plants. It defines ash as residue remaining after coal combustion. It notes that large power plants produce thousands of tons of ash per day that must be disposed of to prevent pollution. It then describes how bottom ash and fly ash are collected and handled through various collection, transport, and disposal systems, including wet and dry collection methods, transport via water, conveyors, or trucks, and disposal in ponds or landfills. It also discusses uses for fly ash in construction materials or other products.

Originalbeschreibung:

Ash Handling System

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document discusses ash handling systems for coal power plants. It defines ash as residue remaining after coal combustion. It notes that large power plants produce thousands of tons of ash per day that must be disposed of to prevent pollution. It then describes how bottom ash and fly ash are collected and handled through various collection, transport, and disposal systems, including wet and dry collection methods, transport via water, conveyors, or trucks, and disposal in ponds or landfills. It also discusses uses for fly ash in construction materials or other products.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

159 Ansichten24 SeitenAsh Handling System

Hochgeladen von

netygen1The document discusses ash handling systems for coal power plants. It defines ash as residue remaining after coal combustion. It notes that large power plants produce thousands of tons of ash per day that must be disposed of to prevent pollution. It then describes how bottom ash and fly ash are collected and handled through various collection, transport, and disposal systems, including wet and dry collection methods, transport via water, conveyors, or trucks, and disposal in ponds or landfills. It also discusses uses for fly ash in construction materials or other products.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 24

Ash Handling

System

23 January 2019 PMI Revision 00 1

WHAT IS ASH?

Ash is the residue remaining after the coal has been

incinerated to constant weight under standard conditions.

Ash is oxidised form of the mineral matters present in

coal.

Typical ash composition : SiO2, Al2O3, Fe2O3, CaO,

MgO etc.

Coal with more SiO2 & Al2O3, Ash MP > 1400ºC

Coal with more Fe2O3, CaO & MgO, Ash MP < 1100ºC

23 January 2019 PMI Revision 00 2

WHY ASH HANDLING?

Ash content of Indian coal used in power station is

about 30 to 40 %.

A typical 2000 MW station produce around 9000T to

12000T of ash per day.

This huge amount of ash needs to be disposed off

continuously.

Necessary care to be taken for preventing pollution

Ash Handling system takes care the above requirement

23 January 2019 PMI Revision 00 3

WHAT HAPPENS TO THE ASH

PRODUCED?

20 % Of the ash falls at the bottom of the furnace known

as Bottom Ash (BA).

80 % of the ash carried away with flue gas known as FA.

BA can form slag and clinker depending on the temp.

of the combustion zone and environment inside.

reducing environment (Less O2) reduces ash MP.

BA is disposed off through BA disposal system.

FA is collected through ESP and disposed through FA

disposal system.

23 January 2019 PMI Revision 00 4

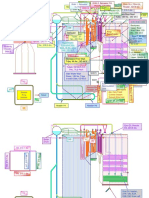

Overburden Surge Pile

Coal Seam Pulverize (-150)

Electrostatic Precipitator Boiler

Flue Gas Flue Gas

Fly Ash

Fly Ash Bottom Ash

Bottom

Fly Ash

Ash

Smoke

Stack

23 January 2019 PMI Revision 00 5

Ash volumes and properties

Furnace ESP

(1300 - 1500°C)

Economizer Electrostatic Stack

Precipitator

Air

preheater

Pulverize APH

d

Stage B: 17 %

Stage A: 80 %

Stage C: 3 %

Coal

Coal Bottom AshEco Ash APH Ash Fly ash

100 % 10-20 % 1% 1% 80-90 % Ash

Fineness

23 January 2019 PMI Revision 00 6

BA Handling System

BA can be collected at furnace bottom as Wet or Dry form.

Wet bottom ash system consists of i)Trough seal, ii)BA

gate, iii)Hopper, iv)Scrapper Conveyer, v)Clinker grinder,

vi)BA trench, vii)BA tank, viii)BA pump, ix)BA pond.

Dry BA consists of i)Trough seal, ii)BA gate, iii)Hopper,

iv)Scrapper Conveyer, v)Clinker grinder, vi)Silo.

Trough seal : A channel around the furnace bottom

filled with water where the furnace bottom end is

immersed in water. This is to prevent air ingression in the

boiler during operation.

23 January 2019 PMI Revision 00 7

Direct Disposal

23 January 2019 PMI Revision 00 8

BA Handling System

BA Gate: Each hopper has separate gate to isolate Scrapper

conveyor from running furnace for any repairing at scrapper.

Scrapper Conveyer : Consists of number of scrapper bars

fasten at both the ends with two chain which can run on

chain pulley and driven by scrapper conveyor motor. The

whole conveyor is submerged in water for wet BA system.

Bottom ash after falling on scrapper is scrapped away by the

running conveyor to one end of the conveyor to clinker

grinder.

Clinker grinder : Any big size ash clinker is crushed to

enable to be carried away by water jet through BA trench.

BA trench : Through water jet ash slurry is carried away to

BA tank

23 January 2019 PMI Revision 00 9

23 January 2019 PMI Revision 00 10

23 January 2019 PMI Revision 00 11

23 January 2019 PMI Revision 00 12

23 January 2019 PMI Revision 00 13

23 January 2019 PMI Revision 00 14

BA Handling System

BA pump : Ash slurry handling pump. It carries ash to the BA pond.

Depending on the distance of BA pond two or more BA pumps

connected in series.

BA pond : Finally ash is discharged to ash pond. It is a large area

surrounded by embankment. Ash mixed with water is allowed to settle

for considerable time. Water from top surface is allowed to go out from

the pond through a designed escape route. Quality of water discharge is

always monitor for turbidity and heavy metal. Piezo meter is used for

monitoring the slope stability of the embankment.

BA Supporting water pumps

LP BA pump : Supply water to trough seal, scrapper conveyor sump,

BA sump and LP jets.

HP BA pump : HP jets in BA trench and line cleaning.

23 January 2019 PMI Revision 00 15

Dry BA Handling System

Dry BA collection system after clinker grinder collect ash

to silo through a transport mechanism for further transport

through road system.

23 January 2019 PMI Revision 00 16

23 January 2019 PMI Revision 00 17

FA Handling System

FA is collected from Air heater hopper, Eco hopper and

ESP hopper.

Either through flushing apparatus or hydrobactur system.

In Flushing apparatus system ash is allowed to fall in

flushing apparatus under gravitation.

Water jet in flushing apparatus carries away the ash to FA

trench

High pressure jets further carries it to FA sump.

Series pumping carries the ash slurry to FA pond.

23 January 2019 PMI Revision 00 18

23 January 2019 PMI Revision 00 19

Dry FA Handling System

Hydrobackter is a vacuum device to collect ash from the

hopper.

Water jet ejectors used for creating vacuum.

Dry ash thus collected to silo through belt conveyor.

Dry ash is disposed through road transport to a dry ash

disposal system. Part of it sold for commercial purpose

23 January 2019 PMI Revision 00 20

23 January 2019 PMI Revision 00 21

ASH UTILISATION

Major usage of ash

•Fly ash bricks / blocks

•Cellular concrete products

•Light weight aggregates

•Concrete and mortar

•In manufacture of cement

•In manufacture of asbestos products

•Road construction

•Embankment/back fills/land development

•Controlled low strength material (CLSM)

•In agriculture

•Mine filling

•Manufacture of fertiliserPMI Revision 00

23 January 2019 22

Other usage

•Manufacture of distemper

•Floor and wall tiles

•Refractory bricks

•Manufacture of ceramics

•Use with Ferro cement

•Recovery of metals

•Use in grouting

•Manufacture of alum

•Extraction of Cenospheres

•Domestic cleaning powder

•In synthetic wood

23 January 2019 PMI Revision 00 23

THANK YOU

23 January 2019 PMI Revision 00 24

Das könnte Ihnen auch gefallen

- 3600-2018 v2Dokument10 Seiten3600-2018 v2Abid Ahmad0% (6)

- 13.ahp 11.07.20Dokument40 Seiten13.ahp 11.07.20Prakash PatelNoch keine Bewertungen

- Barring StallingDokument6 SeitenBarring Stallingnetygen1100% (3)

- MotPRO Commissioning ManualDokument45 SeitenMotPRO Commissioning Manualnetygen1100% (6)

- Mill RejectDokument26 SeitenMill Rejectnetygen1100% (2)

- NTPC Vindhyachal-Six Sigma ProjectDokument88 SeitenNTPC Vindhyachal-Six Sigma Projectnetygen1Noch keine Bewertungen

- Toaz - Info Aci 347 01 Guide To Formwork For Concrete PRDokument32 SeitenToaz - Info Aci 347 01 Guide To Formwork For Concrete PRAli KayaNoch keine Bewertungen

- ESPDokument24 SeitenESPparag pariharNoch keine Bewertungen

- Ash Handling SystemDokument24 SeitenAsh Handling SystemAyan MajiNoch keine Bewertungen

- Index: 1. Introduction To Ash and Ash Disposal System 2. Components of Ash Handling 3. Different Systems in Ash HandlingDokument11 SeitenIndex: 1. Introduction To Ash and Ash Disposal System 2. Components of Ash Handling 3. Different Systems in Ash HandlingcmcNoch keine Bewertungen

- Ash Handling PlantDokument24 SeitenAsh Handling Plantsekhar_ntpcNoch keine Bewertungen

- # AhpDokument21 Seiten# AhprahulNoch keine Bewertungen

- UntitledDokument8 SeitenUntitledPMG Bhuswal ProjectNoch keine Bewertungen

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersDokument41 SeitenBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanNoch keine Bewertungen

- Ash Handling SystemDokument16 SeitenAsh Handling SystemashokNoch keine Bewertungen

- Schematic Diagram of Sealing & Cooling Water For CepDokument12 SeitenSchematic Diagram of Sealing & Cooling Water For Cepjp mishraNoch keine Bewertungen

- Parameter 500 MWDokument3 SeitenParameter 500 MWBalraj Padmashali100% (1)

- VHB Presentation (Compatibility Mode) PDFDokument21 SeitenVHB Presentation (Compatibility Mode) PDFhirenkumar patelNoch keine Bewertungen

- Draught System Gyanendra Sharma NPTI DelhiDokument24 SeitenDraught System Gyanendra Sharma NPTI DelhiNPTINoch keine Bewertungen

- Supercritical Boiler Cleanup Cycle: Ranjan KumarDokument23 SeitenSupercritical Boiler Cleanup Cycle: Ranjan Kumarscentpcbarauni BARAUNINoch keine Bewertungen

- Thermal Power PlantDokument13 SeitenThermal Power PlantSanat KumarNoch keine Bewertungen

- Once Through: Steam GeneratorsDokument21 SeitenOnce Through: Steam GeneratorsrajrampallyNoch keine Bewertungen

- Write Up On Crusher HouseDokument3 SeitenWrite Up On Crusher HouseKumaraswamyNoch keine Bewertungen

- 13 MW Steam Turbine 50 HZ NewDokument6 Seiten13 MW Steam Turbine 50 HZ Newteewee_cuteNoch keine Bewertungen

- Conference - Air Quality Control Systems in Thermal Power Plants - f1Dokument4 SeitenConference - Air Quality Control Systems in Thermal Power Plants - f1Megha ShuklaNoch keine Bewertungen

- Boiler ConstructionDokument4 SeitenBoiler ConstructionrpshvjuNoch keine Bewertungen

- CFCB Bed Ash CoolerDokument11 SeitenCFCB Bed Ash CoolerUdhayakumar VenkataramanNoch keine Bewertungen

- 1c Low Mass Flux Once Through Boiler Design Application and PDFDokument52 Seiten1c Low Mass Flux Once Through Boiler Design Application and PDFfrlamontNoch keine Bewertungen

- Circulating Fluidized Bed Boiler Gyanendra Sharma NPTI DelhiDokument48 SeitenCirculating Fluidized Bed Boiler Gyanendra Sharma NPTI DelhiNPTINoch keine Bewertungen

- Otsc - Control Final-BoilerDokument85 SeitenOtsc - Control Final-BoilerKumar100% (1)

- Boiler Dantrubin Control Rembang Dan PacitanDokument39 SeitenBoiler Dantrubin Control Rembang Dan Pacitanbintang arcano lugasNoch keine Bewertungen

- Technical Specification For Fly Ash Handling System, R0Dokument7 SeitenTechnical Specification For Fly Ash Handling System, R0SumitskbNoch keine Bewertungen

- 500MW-Boiler - Salient FeatureDokument7 Seiten500MW-Boiler - Salient FeatureAhemadNoch keine Bewertungen

- SUPER CRITICAL BOILER (660 MW) at PROJECTDokument53 SeitenSUPER CRITICAL BOILER (660 MW) at PROJECTWahedali SayyedNoch keine Bewertungen

- Ir-Cfbc Boiler Drive Start/Stop LogicDokument6 SeitenIr-Cfbc Boiler Drive Start/Stop Logicsambhu100% (1)

- Reduction in Boiler Cooling TimeDokument16 SeitenReduction in Boiler Cooling Timejp mishraNoch keine Bewertungen

- History of Thermal Power PlantsDokument9 SeitenHistory of Thermal Power PlantsAnonymous gr5Pr9AVNoch keine Bewertungen

- Presentation of Kawasaki FGD and SCR SystemDokument20 SeitenPresentation of Kawasaki FGD and SCR Systemjitendrashukla10836Noch keine Bewertungen

- Proveness CriteriaDokument366 SeitenProveness CriteriaHimadri SNoch keine Bewertungen

- Turbines - New Module Hay PDFDokument191 SeitenTurbines - New Module Hay PDFThái Mai Đình100% (1)

- 2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriDokument51 Seiten2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriChanna BasavaNoch keine Bewertungen

- Flexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCDokument27 SeitenFlexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCLakshmi NarayanNoch keine Bewertungen

- 1.1 Background of Project 1.2 Assignment & Objectives 1.3 Instruction To Reader 1.4 Limitation 1.5 Organisational ProfileDokument87 Seiten1.1 Background of Project 1.2 Assignment & Objectives 1.3 Instruction To Reader 1.4 Limitation 1.5 Organisational Profilezerocool86100% (1)

- SESI-TSPL-OPN-SOP-BTG-012 (APH Fire)Dokument9 SeitenSESI-TSPL-OPN-SOP-BTG-012 (APH Fire)sourav mahapatraNoch keine Bewertungen

- Firing, NOx 0042005Dokument78 SeitenFiring, NOx 0042005JKKNoch keine Bewertungen

- WHRB Interlocks: S. No Boiler Equipment Logic For InterlocksDokument2 SeitenWHRB Interlocks: S. No Boiler Equipment Logic For InterlocksAmeer MeerNoch keine Bewertungen

- Esp Ash Hopper & Blow Tank SystemDokument13 SeitenEsp Ash Hopper & Blow Tank SystemZaid ChelseaNoch keine Bewertungen

- C& I For SupercriticalDokument93 SeitenC& I For SupercriticalPrudhvi RajNoch keine Bewertungen

- Understanding Air Preheater Performance: Storm Technologies, IncDokument4 SeitenUnderstanding Air Preheater Performance: Storm Technologies, IncMahesh MishraNoch keine Bewertungen

- Poor Oil Gun Performance in BoilersDokument3 SeitenPoor Oil Gun Performance in BoilersRAPRATSINNoch keine Bewertungen

- Ash Handling PlantDokument9 SeitenAsh Handling Plantvinod kumarNoch keine Bewertungen

- GEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingDokument24 SeitenGEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingAkasthiyanNoch keine Bewertungen

- Control Write Up R1 - Khaperkheda PDFDokument71 SeitenControl Write Up R1 - Khaperkheda PDFAsif ShaikhNoch keine Bewertungen

- Final YearDokument51 SeitenFinal YearAnand Kumar0% (1)

- Boiler TrainingDokument40 SeitenBoiler TrainingHarry Ansari100% (1)

- Chapter 13Dokument27 SeitenChapter 13bhaskarNoch keine Bewertungen

- Terminal Points (TBWES & Toshiba) JSPL, 8 X 660 MWDokument6 SeitenTerminal Points (TBWES & Toshiba) JSPL, 8 X 660 MWpunitg_2Noch keine Bewertungen

- Surging & Blow Out of Loop Seals in A CFBC BoilerDokument9 SeitenSurging & Blow Out of Loop Seals in A CFBC Boilermohamed faragNoch keine Bewertungen

- ASH Handling 4Dokument42 SeitenASH Handling 4Tamíris da Costa100% (2)

- DR NTTPSDokument41 SeitenDR NTTPSnagasuresh100% (1)

- Coal Fired Boiler - PrincipalsDokument145 SeitenCoal Fired Boiler - PrincipalsArfan AnwarNoch keine Bewertungen

- 3223some Issues of Optimizing The Schemes of Pneumatic Ash Removal Systems of Thermal Power PlantsDokument6 Seiten3223some Issues of Optimizing The Schemes of Pneumatic Ash Removal Systems of Thermal Power Plantsrmm99rmm99Noch keine Bewertungen

- Gen Seal Oil SystemgDokument5 SeitenGen Seal Oil SystemgAlok Ranjan TripathiNoch keine Bewertungen

- Super Critical Boiler Technology SKDDokument35 SeitenSuper Critical Boiler Technology SKDSwapnil TingusleNoch keine Bewertungen

- 57-62 1m809 - Eng72dpiDokument6 Seiten57-62 1m809 - Eng72dpiAbhinav TewariNoch keine Bewertungen

- NTPC PMI OFF AshHandlingSystemDokument24 SeitenNTPC PMI OFF AshHandlingSystemAshish UppuNoch keine Bewertungen

- St-1 Boiler Hydrotest Checklist During Short Shutdown Location: Turbine SideDokument3 SeitenSt-1 Boiler Hydrotest Checklist During Short Shutdown Location: Turbine Sidenetygen1Noch keine Bewertungen

- Seal Oil SystemDokument18 SeitenSeal Oil Systemnetygen1Noch keine Bewertungen

- Feeder Gear Box Feeder GearDokument9 SeitenFeeder Gear Box Feeder Gearnetygen1Noch keine Bewertungen

- Airtel Digital TV Monthly Packages - DTH Packs & Prices in Delhi, Kolkata, MumbaiDokument24 SeitenAirtel Digital TV Monthly Packages - DTH Packs & Prices in Delhi, Kolkata, Mumbainetygen1Noch keine Bewertungen

- Stg-1 TDBFP Isolation NormalisationDokument4 SeitenStg-1 TDBFP Isolation Normalisationnetygen1Noch keine Bewertungen

- A Purpose:-: Ntpc/Tstps Operation Department Operating Instruction For Management of Turbine DrainsDokument13 SeitenA Purpose:-: Ntpc/Tstps Operation Department Operating Instruction For Management of Turbine Drainsnetygen175% (4)

- Revised Boiler Start Up Procedure For 500 MW BHEL Make UnitsDokument22 SeitenRevised Boiler Start Up Procedure For 500 MW BHEL Make Unitsnetygen1Noch keine Bewertungen

- Air Leak in Test of Esp ProcedureDokument5 SeitenAir Leak in Test of Esp Procedurenetygen1Noch keine Bewertungen

- Date: 04/10/2007: Area - TG UNIT - 3/4/5/6Dokument3 SeitenDate: 04/10/2007: Area - TG UNIT - 3/4/5/6netygen1Noch keine Bewertungen

- Android For Beginners Revised Edition 2Dokument180 SeitenAndroid For Beginners Revised Edition 2Syed HasnatNoch keine Bewertungen

- Paper4 Mill RejectDokument39 SeitenPaper4 Mill Rejectnetygen1Noch keine Bewertungen

- Effect of Fast Cut Back (FCB) in A Typical Coal FiredDokument15 SeitenEffect of Fast Cut Back (FCB) in A Typical Coal Firednetygen1Noch keine Bewertungen

- CMC PresentationDokument28 SeitenCMC PresentationKeshav KawreNoch keine Bewertungen

- Turbine Governing Syatem in Power PlantDokument113 SeitenTurbine Governing Syatem in Power Plantnetygen1100% (1)

- CERC - 2014-19 Tariff RegulationsDokument80 SeitenCERC - 2014-19 Tariff Regulationsnetygen10% (1)

- PKR MillsDokument37 SeitenPKR Millsnetygen1Noch keine Bewertungen

- Fuel FiringDokument39 SeitenFuel Firingnetygen1Noch keine Bewertungen

- Ash Handling System For EET-r3Dokument49 SeitenAsh Handling System For EET-r3netygen1Noch keine Bewertungen

- Ozone Treatment For Cooling Towers and Potable WaterDokument19 SeitenOzone Treatment For Cooling Towers and Potable Waternetygen1Noch keine Bewertungen

- Casio Watch ManualDokument4 SeitenCasio Watch Manualnetygen1Noch keine Bewertungen

- Transformer Protection: by Y. K. PandharipandeDokument33 SeitenTransformer Protection: by Y. K. Pandharipandenetygen1100% (1)

- Numerical Protections.: Y. K. PandharipandeDokument8 SeitenNumerical Protections.: Y. K. Pandharipandenetygen1Noch keine Bewertungen

- Feeder - Protn - AkhilDokument57 SeitenFeeder - Protn - Akhilnetygen1100% (1)

- Instrument T F Transformers: Akhil Kumar Gupta Akhil Kumar Gupta Sr. Faculty MemberDokument102 SeitenInstrument T F Transformers: Akhil Kumar Gupta Akhil Kumar Gupta Sr. Faculty Membernetygen1100% (2)

- Estimating Quantity of Concrete Hollow Block (Wall)Dokument6 SeitenEstimating Quantity of Concrete Hollow Block (Wall)Joshua Eroisa SantosNoch keine Bewertungen

- Materials System SpecificationDokument10 SeitenMaterials System SpecificationMoustafa Bayoumi100% (1)

- Precast SectionsDokument16 SeitenPrecast SectionsRigid JointNoch keine Bewertungen

- As 2528-1982 Bolts Studbolts and Nuts For Flanges and Other High and Low Temperature ApplicationsDokument8 SeitenAs 2528-1982 Bolts Studbolts and Nuts For Flanges and Other High and Low Temperature ApplicationsSAI Global - APAC67% (3)

- Two Way Slab Design With VBADokument6 SeitenTwo Way Slab Design With VBAprabin gautamNoch keine Bewertungen

- List of Seminar Topic-MP-2Dokument2 SeitenList of Seminar Topic-MP-2yagnesh50% (2)

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDokument1 SeiteRas Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNoch keine Bewertungen

- Design Guide 22 Facade Attachments To Steel Framed BuildingsDokument222 SeitenDesign Guide 22 Facade Attachments To Steel Framed BuildingsDavid Alejandro Mendez Tovar50% (2)

- Fish Landing FinalDokument9 SeitenFish Landing FinalJEROME TUMPAGNoch keine Bewertungen

- SECTION 02820 Fences and Gates Rev 0Dokument41 SeitenSECTION 02820 Fences and Gates Rev 0Abdul HannanNoch keine Bewertungen

- Plumbing Objective Type QuestionsDokument6 SeitenPlumbing Objective Type QuestionsmanishNoch keine Bewertungen

- Mix Design PQC m40 Opc 53Dokument7 SeitenMix Design PQC m40 Opc 53Dipayan Misra100% (1)

- MethodsDokument3 SeitenMethodsshin orata100% (1)

- S.L Name of Item Unit Remarks Anower L.M Md. Ali Sazzad Vai Salahuddi N Selim Jahid SirajDokument2 SeitenS.L Name of Item Unit Remarks Anower L.M Md. Ali Sazzad Vai Salahuddi N Selim Jahid SirajhelalNoch keine Bewertungen

- Example: No 21: Brand Dimention (Doxwt) StandardDokument44 SeitenExample: No 21: Brand Dimention (Doxwt) Standarddianudin safarudinNoch keine Bewertungen

- WPQ D1.1 - Single ProcessDokument1 SeiteWPQ D1.1 - Single ProcessParminder SinghNoch keine Bewertungen

- Maximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDokument5 SeitenMaximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDevanshu KrNoch keine Bewertungen

- Annular Cutter Feeds and SpeedsDokument1 SeiteAnnular Cutter Feeds and SpeedsAnonymous JzEb8CXErNoch keine Bewertungen

- Pool Circulation PDF Document Aqua Middle East FZCDokument18 SeitenPool Circulation PDF Document Aqua Middle East FZCAdolfsmith69Noch keine Bewertungen

- Modular Bookcase Project DiagramDokument7 SeitenModular Bookcase Project DiagramDony RamdhaniNoch keine Bewertungen

- Particle Reinforced and Fiber Reinforced Composites OverviewDokument29 SeitenParticle Reinforced and Fiber Reinforced Composites OverviewJoy SueltoNoch keine Bewertungen

- Brendan Miles Building PathologyDokument17 SeitenBrendan Miles Building PathologyBrendan John-Jo MilesNoch keine Bewertungen

- C Si MN Thickness (MM) Yield Point (Mpa) Tensile Strength (Mpa) Elongation (%) Bend Test (In Radius) F S Applicable Thickness (MM) SpecDokument1 SeiteC Si MN Thickness (MM) Yield Point (Mpa) Tensile Strength (Mpa) Elongation (%) Bend Test (In Radius) F S Applicable Thickness (MM) SpecEri Dya FadliNoch keine Bewertungen

- Steel Forgings, General Requirements: Standard Specification ForDokument14 SeitenSteel Forgings, General Requirements: Standard Specification ForRupam BaruahNoch keine Bewertungen

- 90° Anchor BoltDokument2 Seiten90° Anchor BoltJovito EdillonNoch keine Bewertungen

- Gas Division: ArfluDokument56 SeitenGas Division: ArfluDammnNoch keine Bewertungen

- Method Statement of STP Tank Inside & Outer Side Wall Water ProofingDokument5 SeitenMethod Statement of STP Tank Inside & Outer Side Wall Water ProofingparthNoch keine Bewertungen