Beruflich Dokumente

Kultur Dokumente

Zaragoza Factory - Our Product - en

Hochgeladen von

Engr Fahimuddin QureshiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Zaragoza Factory - Our Product - en

Hochgeladen von

Engr Fahimuddin QureshiCopyright:

Verfügbare Formate

Dry type transformers Zaragoza

Our product

© ABB Group 2009

| Slide 1

Index -

What is a dry transformer? Vacuum cast range

ABB general applications Standard technical features

Zaragoza’s competitive edges Short facts about the vacuum cast coil technology

Types and standards Environmental, climatic & fire classes

Cast coil transformers for special Vibration proof

applications

Environmental classes E2 & one step forward: E2+

Vacuum cast coil strong points

Features switching off endurance test

A revolutionary concept

Standard accessories

Main advantages

Temperature control devices and sensors

The most economical

Special accessories

The product basic range

Furthermore, any option is available

See our advantages

© ABB Group 2009

| Slide 2

Our product

What is a dry transformer?

ABB manufactures a transformer which does not

use any kind of liquid for cooling, it has windings

encapsulated under Vacuum, in epoxy resin

reinforced with glass net.

It is the most technologically advanced design

for extreme conditions.

ABB has flexibility to produce transformers for

optimum space utilization, and special

requirements.

These transformers meet strict parameters with

respect to electrical system demands, are

virtually maintenance free and are manufactured

in accordance with industry and international

standards including, IEC 60076-11, ISO 9001

and ISO 14001.

© ABB Group 2009

| Slide 3

Our product

ABB general applications

Marine Application Hydro automation & electrical systems

HVDC light / Windpark Utility Network

Compact Substations (CSS) Connection Plant Automation & Electrical Systems communication Management

MV Switchgear

Transformers Railway Power

(GIS / AIS) Gas-insulated GIS Substations

Switchgear (GIS) Supply

Rural Electrification (162/3 Hz)

Industrial Electrification Automation of Gas Urban Electrification

AIS Substations

and Water Plants &

Networks

© ABB Group 2009

| Slide 4

Our product

Zaragoza’s competitive edges

Most advanced production The deepest experience in the

technologies to guarantee the design to guarantee the best

best product quality. technical solutions in all

applications.

The most demanding quality

control system to guarantee the Present all over the world to

total reliability of the product. guarantee the best after sales

service.

Probably the largest production

center for dry type transformers in ISO 9001, ISO 14001 and UNE-

Europe. EN ISO/IEC 17025 certifications.

© ABB Group 2009

| Slide 5

Our product

Types and designs

Types:

Standard three phase transformer.

Double High Voltage transformer.

Multi winding transformer.

Low Voltage transformer.

Autotransformer.

Drive systems transformers.

Excitation systems transformers.

Standard designs:

High Voltage winding material: foil disks.

Low Voltage winding material: aluminum/copper

foils.

Insulation class: F, H.

© ABB Group 2009

| Slide 6

Our product

Where we have experience

Distribution applications.

Traction systems.

Rectifier system.

Marine applications

(Propulsion & Distribution).

Wind power applications.

Cement industry.

Steel plants.

Oil & gas.

Chemical & pharmaceutical.

Metal & mining.

Pulp & paper.

Power plants & utilities.

Airports.

High rise buildings.

© ABB Group 2009

| Slide 7

Our product

Vacuum cast coil strong points

Vacuum cast Stronger resistance against short-circuit stress.

coil

transformers Superior behaviour on load changes (thermal).

are according

to Linear distribution of BIL.

International

Highest possible security against cracks on coils.

standards.

No silicone during coil manufacturing.

Better performance under dynamic loads (mechanic).

Better performance under severe ambiental conditions (exceeding E2).

More suitability for extreme environmental conditions.

© ABB Group 2009

| Slide 8

Our product

A revolutionary concept

V alued points (ABB product)

A ll accesories available

C ertifications proving our quality

U nder vacuum benefits (Very low partial discharges)

U ndercut (New materials)

M aintenance free

C apable of withstanding all conditions (C2,E2+)

A ttractive appearance

S afety

T ailored solutions

C ontinuos improvements (> 52 kV level insulation)

O vervoltage transient design (> 20,000 on/off)

I mpulse lightening for high tensions (250 kV BIL)

L onger life (Class H)

© ABB Group 2009

| Slide 9

Our product

Main advantages: safe and environmental friendly

Reduced environmental contamination.

Zero risk of leakage of flammable

or contaminating substances.

Environmental safe in production.

Well suited to damp and contaminated areas.

No fire hazard.

Transformers are non flammable

and self-extinguishing.

High resistance to short circuits.

High capacity to support overloads.

High performance in dealing with seismic

phenomenon.

Capable of withstanding the most severe of

rolling and vibrating conditions.

© ABB Group 2009

| Slide 10

Our product

Main advantages: Zaragoza´s product competitive

edges

The lowest partial discharge value thanks to the most advanced casting

technology.

The typical partial discharges is below 5pC (maximum allowed 10pC).

Epoxy resin cast under vacuum avoids entry of moisture and protects against

aggressive environments.

Unique coil finishing provides smooth surface eliminating dust accumulation.

Self-extinguishing in the event of fire or arcing and no gases released with

potential danger.

Step lap core configuration granting lower values of no load losses, no load

current and noise level.

© ABB Group 2009

| Slide 11

Our product

Dry transformers versus oil transformers

The best alternative due to: Suitable to operate in humid or heavily polluted

environments (E2).

Fire hazard Suitable for operation, transport and storage at

Safety for people and property ambient temperatures down to minus 25 ºC (C2).

Restricted flammability, self fire extinction (F1).

Respect for natural life

Emission of toxic substances and opacity of fumes

is minimized (F1).

Partial discharges bellow 5 pC in average.

Withstand the same impulse test even for exposed

situation.

Have more ability to withstand thermal and dynamic

short circuit effects.

Mechanically stronger, safer against vibrations,

earthquakes, etc..

No liquid, neither leaks and no risk of polluting spills.

© ABB Group 2009

| Slide 12

Our product

Dry transformers versus oil transformers

Suitable to operate in humid or heavily polluted environments (E2).

Suitable for operation, transport and storage at ambient temperatures down

to minus 25 ºC (C2).

Restricted flammability, self fire extinction (F1).

Emission of toxic substances and opacity of fumes is minimized (F1).

Partial discharges bellow 5pC in average.

Withstand the same impulse test even for exposed situation.

Have more ability to withstand thermal and dynamic short circuit effects.

Mechanically stronger, safer against vibrations, earthquakes, etc..

No liquid, neither leaks and no risk of polluting spills.

© ABB Group 2009

| Slide 13

Our product

The most economical

Less space needed.

Less civil work needed.

No special safety features required.

(fire detection)

Maintenance free.

Longer transformer life due to low thermal

and dialectic ageing.

Can be installed closer to the point of

consumption

reducing load cable losses.

Optimal design subject to constant

improvements in design as new materials

become available.

Produced in high throughput, specialised and

efficient ABB factories.

© ABB Group 2009

| Slide 14

Our product

The product basic range

From 250 kVA up to 40 MVA.

High voltage: up to 72.5 kV.

Low voltage: up to 36 kV.

Classes: E2, C2, F1.

Partial discharges: <10 pC.

Ambient design: From -25 ºC up to 60 ºC.

Insulation: 155ºC (F), 180 ºC (class H).

Cooling: AN, ANAF (up to +40%), AFWF.

Enclosure protection degree: From IP00 up

to IP54.

© ABB Group 2009

| Slide 15

Our product

Vacuum cast range

Small cast coil Dry SPT hi-T Plus

© ABB Group 2009

| Slide 16

Our product

Standard technical features – Small cast coil

Standards IEC EN 60076-11, CENELEC HD 464, DIN 42563

Rated power up to 3,15 MVA

Rated voltage up to 36kV

Cooling AN

Protection degree IP00

High voltage winding Encapsulated, Aluminium foil

Low voltage winding Prepreg layer between turns, Aluminium full width

Temperature rise 100K

Insulation system temperature 155 ºC (Class F)

Partial discharges < 10 pC

© ABB Group 2009

| Slide 17

Our product

Standard technical features – Dry SPT

Standards IEC EN 60076-11, CENELEC HD 464, DIN 42563

Rated power up to 40 MVA

Rated voltage up to 72.5 kV

Cooling AN

Protection degree IP00

High voltage winding Encapsulated, Aluminium

Low voltage winding Encapsulated, Aluminium

Temperature rise 100K

Insulation system temperature 155 ºC (Class F)

Partial discharges < 10 pC

© ABB Group 2009

| Slide 18

Our product

hi-T Plus Standard technical features

Standards IEC EN 60076-11, CENELEC HD 464, DIN 42563

Rated power up to 3.15 MVA

Rated voltage up to 24kV

Cooling AN

Protection degree IP00

High voltage winding Aluminium

Low voltage winding Prepreg layer between turns, Aluminium full width Aluminium

Temperature rise 100K

Insulation system temperature 180 ºC (Class H)

Partial discharges < 10 pC

© ABB Group 2009

| Slide 19

Our product

Short facts about the vacuum cast coil technology

100% turns 0% turns

90%

Low Voltage winding

© ABB Group 2009

| Slide 20

Our product

Environmental, climatic and fire classes

Environment

E0 Normal indoor installation, no condensation, no considerable pollution.

E1 Limited pollution, occasional condensation eg off circuit periods.

E2 Heavy pollution, frequent condensation.

Climate

C1 Lower ambient temperatures:

Operation -5 °C

Storage and transport -25 °C

C2 Lower ambient temperatures:

Operation -25 ºC/-25 ºC

Storage and transport

© ABB Group 2009

| Slide 21

Our product

Environmental, climatic & fire classes

Fire

F0 No special requirements except typical characteristics for dry type transformers.

F1 Increase demands.

All material practically free of halogens

Limited formation of fumes

Limited contribution with calorific energy to the source of fire

Self extinguishing transformer fire

© ABB Group 2009

| Slide 22

Our product

Environmental, climatic & fire classes

Transformer

Zaragoza’s vacuum cast coil dry type transformers

inside the

humidity were certified for several tests by KEMA high

chamber with voltage laboratory.

saline

fog, before

environmental

test Tests such as:

performance.

Dielectric routine rests.

Thermal shock tests for class C2

transformers.

Lightning impulse tests.

Environmental tests with additional

specifications for class E2 (E2++) transformers.

All these tests were according to IEC 60076-11

Standard plus additional requests.

© ABB Group 2009

| Slide 23

Our product

Vibration proof

The vibration to which the transformer is

exposed to during its lifetime, was

summarized in an acceleration spectrum

with the simulation of its life cycle loads.

Multi-axis vibration tests, and shock tests

were performed as per IEC 68-2-6/59,

German edition EN 60068 parts 2-6 and 2-

59 as well as particular customer’s

requirements.

Extreme accelerations due to handling or

harsh vibration were also considered in

these tests.

© ABB Group 2009

| Slide 24

Our product

Environmental classes E2 & one step forward: E2+

E2 test is necessary when the transformer is going to be placed where frequent condensation or/and

heavy pollution.

Condensation test:

6 or more hours in the test chamber (condensation & humidity above 93%).

After 6 hours, the transformer is tested with induced voltage during 15 minutes at 1.1 times

the rated power.

Humidity penetration test:

144 hours inside the climatic chamber with air temperature at 50 3 ºC & relative humidity

at (90 5)%.

After 3 hours in ambient conditions the transformer shall be subjected to routine insulation

test at 80% of standard values.

During any voltage application will not be approved neither breakdown nor flashover or any serious

tracking.

© ABB Group 2009

| Slide 25

Our product

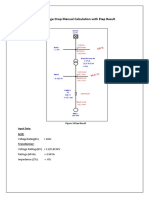

Environmental classes E2 & one step forward: E2+

Scope of supply:

3140 kVA,

Primary: 33000 V

Secundary: 1000-

400 V

Dyn5

Sn: 87074

E2+ (Plus): In condensation test, water conductivity is kept at 1,5 S/m, and dielectric tests

are carried out as for neutral isolated system.

Step one: After 6 hours in condensation chamber, with water conductivity 1,5 S/m passed dielectric

tests at 1.1 rated voltage, between line terminals and ground.

Step two: After 144 hours in climatic chamber passed routine dielectric tests at 80% of standard test

values.

Qualified to perform in the most severe environmental conditions

© ABB Group 2009

| Slide 26

Our product

Features switching off endurance test

After 20.000 switching off operations at full nap load voltage, the

transformer does not show any increase of partial discharges, neither

along the winding to the ground, partial discharges remained constant

along the test what means that the transformer has not suffered any

significant loss of life.

Our transformers are in good conditions very similar to a new one,

and can be put in operation in a network which has the same

conditions and capacity between the switchgear and transformer in a

test circuit.

© ABB Group 2009

| Slide 27

Our product

Standard accessories

9 1Terminal stip

1 2 Temperature

sensors

8

3 Earthing

Terminals

2

4 Pulling eyes

5 Wheels

6 Fans (option)

7 Tappings / Off

load tap changer

8 Lifting lugs

7 9 Rating Plate

3 4 5

© ABB Group 2009

| Slide 28

Our product

Temperature control device and sensors

TMD-T4 and

TMD-T4S T- 154 NT- 935 T- 119

Pt100 PTC 130-150 ºC

© ABB Group 2009

| Slide 29

Our product

Special accessories

Enclosures

Hydrocoolers

Anti vibrations devices On load

tap changer

(OLTC)

Earthing switch Surge arrester for HV and LV Plug in bushings Earthing bullet

© ABB Group 2009

| Slide 30

Our product

Special accessories

Fans for forced

Space heaters air cooling Current transformers

Electrostatic screen

© ABB Group 2009

| Slide 31

Our product

Furthermore, any option is available

Conductor material: aluminium / copper.

Low Voltage terminals located at the bottom of transformer.

Impregnated high voltage winding.

Encapsulated Low Voltage.

Delta connection encapsulated.

Plug-in connector.

Dual primary / secondary.

6/12/24 pulse rectifying transformer.

Bus bar flanges can be accommodated.

© ABB Group 2009

| Slide 32

Our product

Main advantages

Possibility to install any Step-lap configurate Aluminium foil disk in

kind of accesories High Voltage winding

Lowest partial discharge (>5 pC) High impulse withstand

due to epoxy resin casted under through foil-disk

vacuum winding

(horizontal process)

Unique coil finishing:

Smooth surface that

Dust / pollution resistance eliminates dust

thanks to the sealed technology acumulation

High capacity to

withstand overloads

Self- extinguish

due to high thermal

innertia

Axial short-circuit

forces retained & hight Bidirectional wheels

short circuit withstand Radial short

circuit forces retained

© ABB Group 2009

| Slide 33

© ABB Group 2009

| Slide 34

Das könnte Ihnen auch gefallen

- ABB KR Dry Type Transformer CatalogDokument16 SeitenABB KR Dry Type Transformer CatalogGia Minh ĐỗNoch keine Bewertungen

- Catalogo Contatores MTDokument56 SeitenCatalogo Contatores MTwillvinNoch keine Bewertungen

- Unisafe-Brochure Sept 2005Dokument8 SeitenUnisafe-Brochure Sept 2005Papun ScribdNoch keine Bewertungen

- Unigearzs2 - en - AbbDokument70 SeitenUnigearzs2 - en - AbbMoughad DiafNoch keine Bewertungen

- Siemens Ruggedcom RX1500 Product BrochureDokument16 SeitenSiemens Ruggedcom RX1500 Product BrochureBalaNoch keine Bewertungen

- LUCY30503 Aegis Brochure March WebReadyDokument28 SeitenLUCY30503 Aegis Brochure March WebReadyKhalid AwanNoch keine Bewertungen

- C-Line - Changeover Switches - CatalogueDokument56 SeitenC-Line - Changeover Switches - CataloguepookeNoch keine Bewertungen

- Transmission Products: Offering System Integration For Grid SolutionsDokument24 SeitenTransmission Products: Offering System Integration For Grid SolutionsPawan Patel Dada BhaiNoch keine Bewertungen

- Exm 2 - 200 Kva PDFDokument12 SeitenExm 2 - 200 Kva PDFRakesh YadavNoch keine Bewertungen

- Capacitors and Filters: Improving Power Quality For Efficiency and ReliabilityDokument24 SeitenCapacitors and Filters: Improving Power Quality For Efficiency and ReliabilityRaj ElectricalsNoch keine Bewertungen

- AWG Cable (Belden)Dokument31 SeitenAWG Cable (Belden)febripepNoch keine Bewertungen

- 1VDD006114 Catalogue SR-SP 36kV-EN 12-2019Dokument100 Seiten1VDD006114 Catalogue SR-SP 36kV-EN 12-2019ArturNoch keine Bewertungen

- Dynamitron - October 2016 - WebDokument12 SeitenDynamitron - October 2016 - WebChilmy Coklat SusuNoch keine Bewertungen

- Application Notes DMI, Metals 3BSM 013462-1Dokument2 SeitenApplication Notes DMI, Metals 3BSM 013462-1Kidzoy ShopNoch keine Bewertungen

- Seg C&i Bess 2307Dokument2 SeitenSeg C&i Bess 2307Alexander MorrisonNoch keine Bewertungen

- SEN Plus Brochure English Ed06!13!680808Dokument20 SeitenSEN Plus Brochure English Ed06!13!680808Hamad GulNoch keine Bewertungen

- In Novac I Ones 2014Dokument40 SeitenIn Novac I Ones 2014maciasrobNoch keine Bewertungen

- Azbil, MagneW3000 FLEX Electromagnetic Flowmeter ConverterDokument16 SeitenAzbil, MagneW3000 FLEX Electromagnetic Flowmeter ConverterRangga Taufiqurahman100% (1)

- EN SIMPLITZ Highbay G2 Datasheet v0p1 20171116Dokument2 SeitenEN SIMPLITZ Highbay G2 Datasheet v0p1 20171116bayuNoch keine Bewertungen

- Vacuum Cast Coil Catalogue EngDokument18 SeitenVacuum Cast Coil Catalogue EngDante FilhoNoch keine Bewertungen

- onsemiindustrial-drive-solutionsDokument49 Seitenonsemiindustrial-drive-solutionskondurumahi50Noch keine Bewertungen

- Eaton RMU RVAC Product Presentation - 06102017Dokument55 SeitenEaton RMU RVAC Product Presentation - 06102017levanphu90-1Noch keine Bewertungen

- MICRO SWITCH™ Basic Switches Line Guide - 004649-8-ENDokument7 SeitenMICRO SWITCH™ Basic Switches Line Guide - 004649-8-ENaqilNoch keine Bewertungen

- Automation BD BrochureDokument8 SeitenAutomation BD BrochureGaliousNoch keine Bewertungen

- ABBNG Profile 2009Dokument13 SeitenABBNG Profile 2009bjinx26Noch keine Bewertungen

- Schneider GHADokument128 SeitenSchneider GHAMuhathir AmmarNoch keine Bewertungen

- Micro Switch™ Basic Switches Line Guide: FeaturesDokument7 SeitenMicro Switch™ Basic Switches Line Guide: FeaturesPablo AllosiaNoch keine Bewertungen

- Abb Pricelist 2016 16.03.2016 PDFDokument216 SeitenAbb Pricelist 2016 16.03.2016 PDFhiralalnhpcNoch keine Bewertungen

- ABB Cast Resin Dry Type Transformer CATDokument16 SeitenABB Cast Resin Dry Type Transformer CATTruong Minh Rang50% (2)

- HV Circuit Breakers Brochure enDokument17 SeitenHV Circuit Breakers Brochure enClaude BowenNoch keine Bewertungen

- High-Voltage Circuit Breakers: From 72.5 KV Up To 1100 KVDokument17 SeitenHigh-Voltage Circuit Breakers: From 72.5 KV Up To 1100 KVBenbrahim AbdelkaderNoch keine Bewertungen

- Circuit-Breaker Switchgear OverviewDokument16 SeitenCircuit-Breaker Switchgear OverviewKenn NguyenNoch keine Bewertungen

- CarepolebrochureDokument4 SeitenCarepolebrochurenivya machadoNoch keine Bewertungen

- F&B Dry-Type Transformer PresentationDokument44 SeitenF&B Dry-Type Transformer PresentationAnh Tú NguyễnNoch keine Bewertungen

- L&T Co Profile RangeDokument24 SeitenL&T Co Profile RangeTariq NaukhezNoch keine Bewertungen

- SE India in Solar - 24th June 15Dokument24 SeitenSE India in Solar - 24th June 15Peeaar Green Energy SolutionsNoch keine Bewertungen

- ABB TransformersDokument18 SeitenABB TransformersEng HamiedNoch keine Bewertungen

- Product Overview Brochure. ABB Medium Voltage Products Our One-Stop Approach For Every Medium Voltage ApplicationDokument12 SeitenProduct Overview Brochure. ABB Medium Voltage Products Our One-Stop Approach For Every Medium Voltage ApplicationhafezasadNoch keine Bewertungen

- ABB Transformers Dimensions and Other Technical InformationsDokument22 SeitenABB Transformers Dimensions and Other Technical InformationsAbdul Muqeem Mohammed100% (1)

- Uksp MidenightDokument2 SeitenUksp MidenightAbdessamed BenlahbibNoch keine Bewertungen

- Durability and Reliability Meet Advanced Residential MeteringDokument2 SeitenDurability and Reliability Meet Advanced Residential MeteringWalter EguizabalNoch keine Bewertungen

- Fiber Optics Current Sensor (FOCS-FS) PresentationDokument18 SeitenFiber Optics Current Sensor (FOCS-FS) PresentationTrần MinhNoch keine Bewertungen

- 21 Conductor Marking Light BHT CompresseDokument2 Seiten21 Conductor Marking Light BHT CompresseNendi Suhendar M YunusNoch keine Bewertungen

- GE Energy Industrial Solutions. SEN Plus. SEN Plus LV EquipmentDokument48 SeitenGE Energy Industrial Solutions. SEN Plus. SEN Plus LV EquipmentLamia BekehchiNoch keine Bewertungen

- Hyundai HiE S395 415 Modulo Fotovoltaico SchedaDokument2 SeitenHyundai HiE S395 415 Modulo Fotovoltaico SchedaFederico De FranceschiNoch keine Bewertungen

- Cat UniGearZS2 PDFDokument52 SeitenCat UniGearZS2 PDFdwas1314Noch keine Bewertungen

- Azbil, MagneW3000 FLEX Electromagnetic Flowmeter Converter 7th EdDokument16 SeitenAzbil, MagneW3000 FLEX Electromagnetic Flowmeter Converter 7th EdRangga TaufiqurahmanNoch keine Bewertungen

- Ambit Switchgear PVT LTD.: Premium Electrical Panels ManufacturerDokument27 SeitenAmbit Switchgear PVT LTD.: Premium Electrical Panels ManufacturerHytech Pvt. Ltd.Noch keine Bewertungen

- ABB 1HSM 9543 01-10enDokument16 SeitenABB 1HSM 9543 01-10enmrivero1983Noch keine Bewertungen

- High Voltage Accessories Technical Instructions and Product RangeDokument16 SeitenHigh Voltage Accessories Technical Instructions and Product Rangeromany allamNoch keine Bewertungen

- Fupact: Catalog 2020Dokument170 SeitenFupact: Catalog 2020Ionescu Silvian IonutNoch keine Bewertungen

- D1 5 VSD TransformersDokument51 SeitenD1 5 VSD TransformersalgotrNoch keine Bewertungen

- LDK Leaflet Complete Web PDFDokument30 SeitenLDK Leaflet Complete Web PDFMauricioHormazaNoch keine Bewertungen

- Catálogo Schneider - PIAs 2017Dokument84 SeitenCatálogo Schneider - PIAs 2017Nicolás Santiago UgarteNoch keine Bewertungen

- NoseDokument13 SeitenNosegael103207Noch keine Bewertungen

- Lvcatm9oem en (Web) SchneiderDokument84 SeitenLvcatm9oem en (Web) SchneiderRafael AraujoNoch keine Bewertungen

- Power Electronics Design Handbook: Low-Power Components and ApplicationsVon EverandPower Electronics Design Handbook: Low-Power Components and ApplicationsBewertung: 4 von 5 Sternen4/5 (2)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Push - Pull Converter - 4 - Wavforms - Voltage - StressDokument18 SeitenPush - Pull Converter - 4 - Wavforms - Voltage - StressEngr Fahimuddin QureshiNoch keine Bewertungen

- Push - Pull Converter - 5 - B - H - Cruve - Transformer - Design - UpdatedDokument24 SeitenPush - Pull Converter - 5 - B - H - Cruve - Transformer - Design - UpdatedEngr Fahimuddin QureshiNoch keine Bewertungen

- Time Synchronization of Relays at NTDC Grid Stations-1Dokument1 SeiteTime Synchronization of Relays at NTDC Grid Stations-1Engr Fahimuddin QureshiNoch keine Bewertungen

- Flux Imbalances in Push Pull ConverterDokument5 SeitenFlux Imbalances in Push Pull ConverterEngr Fahimuddin QureshiNoch keine Bewertungen

- Effect of Z Tolerance and - Z Variation On Short CircuitDokument3 SeitenEffect of Z Tolerance and - Z Variation On Short CircuitEngr Fahimuddin QureshiNoch keine Bewertungen

- Conference 101719Dokument3 SeitenConference 101719Engr Fahimuddin QureshiNoch keine Bewertungen

- EE5943 Homework on HV Equipment TestingDokument4 SeitenEE5943 Homework on HV Equipment TestingEngr Fahimuddin QureshiNoch keine Bewertungen

- Interpretation of Gases Generated in Mineral OilDokument32 SeitenInterpretation of Gases Generated in Mineral OilEngr Fahimuddin QureshiNoch keine Bewertungen

- OSHA Safety ManualDokument278 SeitenOSHA Safety ManualEngr Fahimuddin QureshiNoch keine Bewertungen

- Distance Protection (Zone 2 Consideration)Dokument1 SeiteDistance Protection (Zone 2 Consideration)Engr Fahimuddin QureshiNoch keine Bewertungen

- CT Sizing - CT Over Dimensioning FactorDokument19 SeitenCT Sizing - CT Over Dimensioning FactorEngr Fahimuddin QureshiNoch keine Bewertungen

- HVDC Links in System OperationsDokument81 SeitenHVDC Links in System OperationsUtopia BogdanNoch keine Bewertungen

- Diagnostics of Winding Deformation in A Single-PhaDokument4 SeitenDiagnostics of Winding Deformation in A Single-PhaEngr Fahimuddin QureshiNoch keine Bewertungen

- Performance Analysis of Distance Relay On Shunt - Series Facts-CompDokument106 SeitenPerformance Analysis of Distance Relay On Shunt - Series Facts-CompEngr Fahimuddin QureshiNoch keine Bewertungen

- Investigation of A Transferred Voltage Surge Trbusic 19IPST033Dokument5 SeitenInvestigation of A Transferred Voltage Surge Trbusic 19IPST033Engr Fahimuddin QureshiNoch keine Bewertungen

- 2018 04 16 Tertiary Winding in Transformers PRCDokument17 Seiten2018 04 16 Tertiary Winding in Transformers PRCSaurav Kafle100% (1)

- Article Base Presentation Final 1Dokument26 SeitenArticle Base Presentation Final 1Engr Fahimuddin QureshiNoch keine Bewertungen

- Mho Relay 2 PDFDokument8 SeitenMho Relay 2 PDFArion BaboolalNoch keine Bewertungen

- Cable Voltage Drop CalculationDokument3 SeitenCable Voltage Drop CalculationEngr Fahimuddin QureshiNoch keine Bewertungen

- Article Download 1Dokument6 SeitenArticle Download 1Engr Fahimuddin QureshiNoch keine Bewertungen

- AuthorproofspringerDokument19 SeitenAuthorproofspringerEngr Fahimuddin QureshiNoch keine Bewertungen

- Case StudyDokument8 SeitenCase StudyEngr Fahimuddin QureshiNoch keine Bewertungen

- WAPDA Case Study Report on Sexual Harassment AllegationsDokument9 SeitenWAPDA Case Study Report on Sexual Harassment AllegationsEngr Fahimuddin QureshiNoch keine Bewertungen

- Short Circuit Study 11Dokument5 SeitenShort Circuit Study 11Engr Fahimuddin QureshiNoch keine Bewertungen

- Short Circuit Study 11Dokument5 SeitenShort Circuit Study 11Engr Fahimuddin QureshiNoch keine Bewertungen

- Underperforming Team TurnaroundDokument41 SeitenUnderperforming Team TurnaroundEngr Fahimuddin QureshiNoch keine Bewertungen

- Resident Manager Theft CaseDokument26 SeitenResident Manager Theft CaseEngr Fahimuddin QureshiNoch keine Bewertungen

- Cable Schedule For Low Impedance Bus Bar Protection PanelDokument4 SeitenCable Schedule For Low Impedance Bus Bar Protection PanelEngr Fahimuddin QureshiNoch keine Bewertungen

- Ex 12 HLOOKUPDokument2 SeitenEx 12 HLOOKUPEngr Fahimuddin QureshiNoch keine Bewertungen

- Who Is Telling The Truth FinalDokument41 SeitenWho Is Telling The Truth FinalEngr Fahimuddin Qureshi100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument9 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768luis alberto rodriguezNoch keine Bewertungen

- Induction Motor FundamentalsDokument26 SeitenInduction Motor FundamentalsarifulNoch keine Bewertungen

- Industrial Electrician Red Seal Exam Practice QuestionDokument7 SeitenIndustrial Electrician Red Seal Exam Practice Questionbrowningw25% (4)

- Edc 3Dokument17 SeitenEdc 3diode123Noch keine Bewertungen

- Calibration Procedure FOR Multimeters: Technical ManualDokument280 SeitenCalibration Procedure FOR Multimeters: Technical ManualXptoleo LeoNoch keine Bewertungen

- 3300 XL 8mm Proximity Transducer System Datasheet - 141194Dokument39 Seiten3300 XL 8mm Proximity Transducer System Datasheet - 141194eroolifyNoch keine Bewertungen

- Pulsed Eddy Current TestingDokument6 SeitenPulsed Eddy Current TestingYoungmin ParkNoch keine Bewertungen

- Strongly Correlated Quantum FluidsDokument138 SeitenStrongly Correlated Quantum FluidsArnab Barman RayNoch keine Bewertungen

- Code No.: 18EEC01 - Basic Electrical Engineering Exam QuestionsDokument2 SeitenCode No.: 18EEC01 - Basic Electrical Engineering Exam Questionsc_h_v_k_rNoch keine Bewertungen

- Time Domain Response of Second Order Linear CircuitsDokument15 SeitenTime Domain Response of Second Order Linear CircuitsMOHSINALI MOMINNoch keine Bewertungen

- Chapter 1 IntroductionDokument6 SeitenChapter 1 IntroductionJames Ryan GarmaNoch keine Bewertungen

- The Halogens: by Tom AND ChrisDokument13 SeitenThe Halogens: by Tom AND ChrisAFNAN AHMEDNoch keine Bewertungen

- Catálogo IFD 258 PDFDokument35 SeitenCatálogo IFD 258 PDFotavioalcaldeNoch keine Bewertungen

- Homopolar MotorDokument7 SeitenHomopolar MotorVĩ AoNoch keine Bewertungen

- 3Ph SIE IE1 Erhöhte Leistung 2009Dokument7 Seiten3Ph SIE IE1 Erhöhte Leistung 2009t_meierNoch keine Bewertungen

- Problem Set 4 - EE19Dokument2 SeitenProblem Set 4 - EE19Mark Anthony GarciaNoch keine Bewertungen

- Gt-4 PCB: Multiple Correct QuestionsDokument25 SeitenGt-4 PCB: Multiple Correct QuestionsrushiNoch keine Bewertungen

- Sem GuideDokument8 SeitenSem Guideapi-242278641Noch keine Bewertungen

- ELB118YCF 1x18W PLC PDFDokument1 SeiteELB118YCF 1x18W PLC PDFGur PyariNoch keine Bewertungen

- Sn11-12 Contactor MitsubishiDokument39 SeitenSn11-12 Contactor MitsubishiPa TricioNoch keine Bewertungen

- SP-430/SP-431: Application Examples Application ExamplesDokument2 SeitenSP-430/SP-431: Application Examples Application ExamplesnelusabieNoch keine Bewertungen

- Factors Affecting Capacitance PDFDokument1 SeiteFactors Affecting Capacitance PDFSomaya AliNoch keine Bewertungen

- Week-1 Module-5 Interaction Mechanism of EM Radiation With Ground and Spectral Response CurvesDokument15 SeitenWeek-1 Module-5 Interaction Mechanism of EM Radiation With Ground and Spectral Response CurvesTrambak BhattacharyaNoch keine Bewertungen

- Chapter 06Dokument53 SeitenChapter 06Sigmund PohanNoch keine Bewertungen

- ELLIPS ESE Lightning ArresterDokument6 SeitenELLIPS ESE Lightning ArresterRuchir Chaturvedi100% (1)

- PLC Micrologix 1000 1761-L32bwaDokument28 SeitenPLC Micrologix 1000 1761-L32bwaAdolfo MaresNoch keine Bewertungen

- BS En-50081-1 PDFDokument15 SeitenBS En-50081-1 PDFMohammed HilalNoch keine Bewertungen

- Reliable demagnetization of transformer cores with CPC 100Dokument4 SeitenReliable demagnetization of transformer cores with CPC 100Nemitha LakshanNoch keine Bewertungen

- W-1-Day-5-A - Grounding of TransformersDokument8 SeitenW-1-Day-5-A - Grounding of TransformersKASHIFNoch keine Bewertungen