Beruflich Dokumente

Kultur Dokumente

KIL 2002 Oleochemicals - 2018

Hochgeladen von

Ed0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

30 Ansichten41 SeitenThis document discusses oleochemicals, which are chemicals derived from plant and animal fats. It provides background on the history and production of oleochemicals from palm oil and palm kernel oil. The main raw materials used are palm oil from the palm fruit mesocarp and palm kernel oil from the palm fruit nut. These oils undergo chemical and enzymatic reactions to produce basic oleochemical substances like fatty acids, fatty acid methyl esters, and fatty alcohols. These basic substances can then be further processed into a wide range of oleochemical derivatives with various industrial applications. However, the availability of raw materials for producing oleochemicals in Europe is threatened by policies incentivizing the burning of animal fats for renewable energy production

Originalbeschreibung:

Originaltitel

KIL 2002 Oleochemicals_2018.pptx

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document discusses oleochemicals, which are chemicals derived from plant and animal fats. It provides background on the history and production of oleochemicals from palm oil and palm kernel oil. The main raw materials used are palm oil from the palm fruit mesocarp and palm kernel oil from the palm fruit nut. These oils undergo chemical and enzymatic reactions to produce basic oleochemical substances like fatty acids, fatty acid methyl esters, and fatty alcohols. These basic substances can then be further processed into a wide range of oleochemical derivatives with various industrial applications. However, the availability of raw materials for producing oleochemicals in Europe is threatened by policies incentivizing the burning of animal fats for renewable energy production

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

30 Ansichten41 SeitenKIL 2002 Oleochemicals - 2018

Hochgeladen von

EdThis document discusses oleochemicals, which are chemicals derived from plant and animal fats. It provides background on the history and production of oleochemicals from palm oil and palm kernel oil. The main raw materials used are palm oil from the palm fruit mesocarp and palm kernel oil from the palm fruit nut. These oils undergo chemical and enzymatic reactions to produce basic oleochemical substances like fatty acids, fatty acid methyl esters, and fatty alcohols. These basic substances can then be further processed into a wide range of oleochemical derivatives with various industrial applications. However, the availability of raw materials for producing oleochemicals in Europe is threatened by policies incentivizing the burning of animal fats for renewable energy production

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 41

Oleo chemicals

CO4: Learning Outcome

Identify and list the main raw materials and

steps in the production of petrochemicals and

oleochemicals

What are oleochemicals?

Oleochemicals are chemicals derived from

plant and animal fats.

Types of feedstocks

Global vegetable oil production

History

We used to depend on petrochemicals

In late 1970s, crude oil price hiked.

Switched to oleochemicals because the production

process were cheaper

Oil palms gained attention because plant-based

lauric oils processed from palm kernel were

cheaper.

Since then, palm kernel oil (from palm fruit) were

used in the production of laundry detergent and

personal care items like toothpaste, soap bars,

shower cream and shampoo.

More History

What are oleochemicals?

Oleochemicals are chemicals derived from

plant and animal fats.

Common basic oleochemical substances are

fatty acids, fatty acid methyl esters (FAME),

fatty alcohols, fatty amines and glycerols.

Derived by various chemical and enzymatic

reactions of PO and PKO

How are PO and PKO produced?

Oil palm fruit

The oil palm fruit produces two types of oil,

palm oil from the mesocarp and palm kernel oil

from the nut, the endosperm.

They are chemically different and have

between them practically the entire range of

long, medium and short chain fatty acids.

Intro on palm plantation

edupalm.org.my

PO and PKO Supply Chain

Oleo chemicals

Oleochemicals – redefined?

Oleochemicals refer to chemicals obtained from

palm oil and palm kernel oil; Divided into two groups

of products, basic oleochemicals and

oleochemical derivatives.

Basic oleochemicals are fatty acids, methyl esters,

fatty alcohols, fatty amines and glycerol. They are

essentially the building blocks of the oleochemicals

industry. From these basic oleochemicals, a very

wide range of oleochemical derivatives can be

produced.

Since palm oil and palm kermel oil contain between

them almost the entire range of fatty

acids, practically all the oleochemicals can be

produced from them.

Oleochemicals Application

Oleochemicals Application

Oleochemicals Application

Summary

This is a flow chart leading from palm oil to basic oleochemicals & their

derivatives .

Examples

of Industrial

Oleochemicals

Applications

Margarine

Margarine is one of the most publicly known oleochemical

products. Indeed, vegetable oils used for its preparation are

naturally found in liquid form. One can think of soybean or

canola oil commonly found in grocery stores. Then, why is it that

margarine has a more solid consistency? This is due to the

chemical transformation of the oils used in its preparation. In

order to give a solid texture to oil, it goes through a

hydrogenation process which consists in transforming the

chemical bonds of the oil to give its liquid properties to the point

where we are left with a solid consistency. It is very important to

know about these chemical and control processes as an improper

process can lead to the formation of trans fatty acid, well-known

to cause long-term health problems.

Neutral pH soaps

Soap is the pioneer oleochemical product. Originally, alkaline ashes

were mixed with animal fat in order to make soaps which we still

find mainly in our everyday products. Obviously, the chemical

transformation processes are much more sophisticated and are

better controlled than before. However, soaps are products with

alkaline properties. The surfactant effect (i.e. which fosters the

contact between water and organic residues) of soap is in fact

based on the presence of a chemical function which is also

responsible for the product's alkalinity. Modern oil chemists have

been able to develop oleochemical derivatives from the same oils,

but with very different chemical functions. These products are now

found on the market as neutral pH surfactants and their properties

are used in a wide variety of household products. The advantage of

a neutral pH is that the product is less irritating to the skin

(alkalinity) and is unlikely to react with other components or

additives that could enter into the composition of the product

(chemical incompatibility).

Biodiesel

Vegetable oils were used as fuel in the very first trials to test Rudolph

Diesel's engine which now bears his name. Over time, several changes

were made to his invention and the diesel engine has been modified to

use a more effective petroleum-based product, fuel oil. Today,

environmental knowledge and concerns, such as global warming, are

encouraging us to reconsider the use of alternative fuels products issued

from biomass. Vegetable oil is no longer an acceptable fuel for use in

modern diesel engines as it is too viscous and too heavy. However, oil

chemists have developed a way to modify the properties of vegetable oil

to make a comparable fuel oil. By using «transesterification» of vegetable

oils with methanol or ethanol, we obtain methyl esters which are lighter

and less viscous. These synthetic derivatives of vegetable oil exhibit

acceptable properties for use in diesel engines. The mixture of quality

methyl esters, which can be substituted to fuel oil, is called «biodiesel».

Applications

While oleochemical applications in the food, pharmaceutical and

cosmetics sectors are more well-known by the public in general,

industrial applications represent more than 50% of the world's

production volume. The different sectors of industrial

oleochemistry are:

Mechanical fluids: lubricants, greases, hydraulic fluids, and coolants

Coating and adhesives: paints, varnishes, glues, paving

Materials: plastics, rubber, linoleum

Tensioactive agents: detergents, surfactants, soaps

Impregnation agents: waxes, inks, softening agents, wood

treatments

Fuels: biodiesel, oils, candle wax

Chemical intermediates: solvents, chemicals, additives

Cosmeceutical and pharmaceutical

Nutraceutical

Final applications

Global Issues

Issue 1: Raw materials availability

The European oleochemical industry is under threat. An

unintended threat of the current EU Renewable energy

policy has lead to an unprecedented increase in glycerine

production and to a significant threat to the availability of

animal fats as raw material for the European oleochemical

industry

Due to their classification as biomass, animal fats and

vegetable oils are increasingly burned or used in Biofuel

production to access “ credits” under the Emission Trading

Schemes or incentives intended to promote biofuels or

renewable energy

Biodiesel Biodiesel/Glycerine /Glycerine: the production of

methyl esters from vegetable oils & fats for use as biodiesel has

increased doubled the production of glycerine – by-product in the

production of oleochemicals – 300 000 T of subsidised glycerine

has appeared on the market and we expect this to reach 500 000 T

before 2010.

Glycerine prices dropped from 1.500 Euro/mt to below 500

Euro/mt

This has decreased the income of the European Oleochemical

industry by 300 Mio/year

Industry could only react by rationalising, closures, 1000 people

lost their jobs.

Historically, the European Oleochemical industry has always

been a net importer of animal fats mainly from North

America and Canada. Imports of animal fats into Europe

stopped when the BSE crisis materialised and the exporting

countries did not wish to remove the Specific risk materials

from the raw materials. Europe is too small a market for the

major exporting countries such as USA.

Animal fats cover more than 50 % of the raw material

requirements in the European Oleochemical Industry AND

ENABLES the European industry to compete with Asia

producers sourcing their raw materials from tropical oils

Subsidised burning of animal fats will disrupt completely the

supply/demand balance and the European Oleochemical

Industry, using the animal fats in an unsubsidised way, will

find itself without its main raw material at competitive

pricing. Furthermore, if all available European animal fats

would be used in the production of energy, it would only be

sufficient to supply one medium sized power plant generating

1.000 megawatt per year.

Impact:

Only by importing palm oil from South East Asia, would the

European Oleochemical industry have enough raw materials

to maintain its production level and maintain its supply

position to the European Industry as a whole.

This position is unfavourable because South East Asian

producers , with a rapidly increasing oleochemical industry,

have access to raw materials at the cheaper price (export

duty 15% for European importers) ; This measure subsidises

the exports of their oleochemical derivatives and causes a

distortion of competition for the European Oleochemical

Industry.

As a consequence, European Oleochemical Industry will be

forced either to close down their operations in Europe or

move its production facilities to the SEA region. A first

impact will be the loss of 10.000 jobs in Europe and the

departure to the SEA of more industries from Europe

causing further job losses and putting in danger the supply of

critical products in highly specialised branches of the

European Industry.

What EU wants?

The European oleochemical industry wishes to secure the

availability of animal fats as competitive feedstock for the

European Oleochemical Industry. To achieve this, animal fats

should be taken out of the EU definition of biomass and/or

no tax incentives should be given for the use of animal fats in

the generation of green electricity, heat or production of

Biodiesel.

What SEA wants?

In addition, we request that animal fats remain in the waste

regime as currently required by the animal by-products

legislation and the waste framework directive. Consequently

, burning of animal fats should only take place in facilities that

comply with waste incineration directive.

Thank you

Das könnte Ihnen auch gefallen

- Soap Manufacturing TechnologyVon EverandSoap Manufacturing TechnologyLuis SpitzBewertung: 4 von 5 Sternen4/5 (6)

- Design 2 MLDDokument9 SeitenDesign 2 MLDANIL KUMAR H CNoch keine Bewertungen

- Production of 120000 MTA Oleochemical Fatty Acids From Sunflower OilsDokument93 SeitenProduction of 120000 MTA Oleochemical Fatty Acids From Sunflower OilsRay LimNoch keine Bewertungen

- Refinery of Palm OilDokument36 SeitenRefinery of Palm Oildoshi_ritesh100% (6)

- Green Vegetable Oil Processing: Revsied First EditionVon EverandGreen Vegetable Oil Processing: Revsied First EditionWalter E. FarrBewertung: 3 von 5 Sternen3/5 (1)

- Semiconductor Science and Light Emitting DiodesDokument218 SeitenSemiconductor Science and Light Emitting DiodesBalaji Raja RajanNoch keine Bewertungen

- Sl. No. Name of The Sponsor Location Contact NoDokument12 SeitenSl. No. Name of The Sponsor Location Contact NoSampath R0% (1)

- Oleochemical - WikipediaDokument3 SeitenOleochemical - WikipediaNur Atiqah Ahmad100% (1)

- Oleochemistry - WikipediaDokument5 SeitenOleochemistry - WikipediaSerafeim SakkasNoch keine Bewertungen

- Palm Oil RelatedDokument5 SeitenPalm Oil RelatedSUDARSHAN dAWNoch keine Bewertungen

- OlennDokument46 SeitenOlennAbe KobNoch keine Bewertungen

- BF02678762Dokument2 SeitenBF02678762Dhruvesh SanghviNoch keine Bewertungen

- Chemical StructureDokument3 SeitenChemical StructureblezyjoymNoch keine Bewertungen

- OLEOCHEMISTRY - Chapter 1 - IntroductionDokument13 SeitenOLEOCHEMISTRY - Chapter 1 - IntroductionSaifuddin Aziz100% (1)

- 2018 - Winners and Losers From The Proposed Ban On Palm OilDokument3 Seiten2018 - Winners and Losers From The Proposed Ban On Palm Oilliliacul2000Noch keine Bewertungen

- Mineral OilDokument6 SeitenMineral OilDanielNoch keine Bewertungen

- Biodiesel: Ways of Obtaining and ImportanceDokument40 SeitenBiodiesel: Ways of Obtaining and ImportanceCarolina RamirezNoch keine Bewertungen

- Proposal 2011 (PALM OIL)Dokument13 SeitenProposal 2011 (PALM OIL)Mohd HazwanNoch keine Bewertungen

- Introduction To Chemical Refining - Oil Palm Knowledge BaseDokument3 SeitenIntroduction To Chemical Refining - Oil Palm Knowledge Basenoel.manroeNoch keine Bewertungen

- The Changing World of OleochemicalsDokument9 SeitenThe Changing World of OleochemicalsMarta Szymańska100% (1)

- Microbial LipidsDokument10 SeitenMicrobial LipidsSharif M Mizanur RahmanNoch keine Bewertungen

- CPI ReportDokument33 SeitenCPI ReportJoaquin ParasNoch keine Bewertungen

- Palm Oil: Biochemical, Physiological, Nutritional, Hematological, and Toxicological Aspects: A ReviewDokument24 SeitenPalm Oil: Biochemical, Physiological, Nutritional, Hematological, and Toxicological Aspects: A ReviewCarlos RomanNoch keine Bewertungen

- Lab 6. Oils and Fats AnalysisDokument4 SeitenLab 6. Oils and Fats AnalysisSomeBodyNoch keine Bewertungen

- 26.oils, Fat and WaxesDokument18 Seiten26.oils, Fat and WaxesRuel CedeñoNoch keine Bewertungen

- Refinery of Palm OilDokument14 SeitenRefinery of Palm OilEvantono Balin Christianto100% (1)

- The Adulteration of Essential Oils - and The Consequences ToDokument22 SeitenThe Adulteration of Essential Oils - and The Consequences ToBiol. Miguel Angel Gutiérrez DomínguezNoch keine Bewertungen

- Name: Mustafa Khader Abdel Abbas. Stage: (Morning) .: Biodisel Processing and ProductionDokument10 SeitenName: Mustafa Khader Abdel Abbas. Stage: (Morning) .: Biodisel Processing and Productionمصطفى الجبوريNoch keine Bewertungen

- Palm Oil (Q&A) 2013Dokument5 SeitenPalm Oil (Q&A) 2013labendetNoch keine Bewertungen

- Biodiesel - LurgiDokument8 SeitenBiodiesel - LurgiElżbieta SkrzyńskaNoch keine Bewertungen

- Enzymatic Synthesisof Biodieselvia Alcoholysisof Palm OilDokument10 SeitenEnzymatic Synthesisof Biodieselvia Alcoholysisof Palm Oilroberto.siregar4002Noch keine Bewertungen

- APPLICATIONS OF asdadasFATTY ACID METHYL ESTER NEWWWW - 2Dokument5 SeitenAPPLICATIONS OF asdadasFATTY ACID METHYL ESTER NEWWWW - 2Teo Yu XunNoch keine Bewertungen

- Fatty Alcohol Production ProcessDokument9 SeitenFatty Alcohol Production ProcessZevaniNoch keine Bewertungen

- FL - Course 6Dokument22 SeitenFL - Course 6Fianu AndreeaNoch keine Bewertungen

- Oleo Chemistry: Badrla SandeepDokument93 SeitenOleo Chemistry: Badrla Sandeepsab_franc5286Noch keine Bewertungen

- Hydraulic Oil DescriptionDokument4 SeitenHydraulic Oil DescriptionSeindahNyaNoch keine Bewertungen

- Palm Oil Fractionation: Article April 2007 With 5,542 ReadsDokument38 SeitenPalm Oil Fractionation: Article April 2007 With 5,542 ReadsFadzal Al-MuhandisNoch keine Bewertungen

- Mineral OilDokument6 SeitenMineral OilNgeke KekeNoch keine Bewertungen

- Cpi Ii Unit IiDokument55 SeitenCpi Ii Unit IiMurali Dharan100% (2)

- Product - PetroleumDokument19 SeitenProduct - PetroleumPrashant BarveNoch keine Bewertungen

- Development of Castor Oil Based Polymers - A ReviewDokument42 SeitenDevelopment of Castor Oil Based Polymers - A ReviewDevarshi ModiNoch keine Bewertungen

- The Uses of Oil Palm TreeDokument2 SeitenThe Uses of Oil Palm TreeNORAZIZUL ALINoch keine Bewertungen

- Waste Cooking Oil PDFDokument6 SeitenWaste Cooking Oil PDFRichard ObinnaNoch keine Bewertungen

- Sunflower OilDokument10 SeitenSunflower OiltnsamNoch keine Bewertungen

- Salimon Et Al-2010-European Journal of Lipid Science and Technology PDFDokument12 SeitenSalimon Et Al-2010-European Journal of Lipid Science and Technology PDFZeePeR Alex RachieruNoch keine Bewertungen

- Introducing The Latest Palm Biodiesel Technology To The WorldDokument8 SeitenIntroducing The Latest Palm Biodiesel Technology To The WorldRyou HikaruNoch keine Bewertungen

- 1 - EcodsDokument76 Seiten1 - EcodsMohammed Ajmal AnsariNoch keine Bewertungen

- Biolubricant From Vegetable Oils Using Heterogeneous CatalystDokument8 SeitenBiolubricant From Vegetable Oils Using Heterogeneous CatalystsrinivasanNoch keine Bewertungen

- Application of Catalyst Technology To Produce Oleochemical Base Materials of Palm Oil DerivativesDokument2 SeitenApplication of Catalyst Technology To Produce Oleochemical Base Materials of Palm Oil DerivativesHêny CarlênicNoch keine Bewertungen

- Cpi II Unit II NotesDokument13 SeitenCpi II Unit II NotesMurali DharanNoch keine Bewertungen

- ADRIANO-SALES - FIRJAM - Oleochemicals-from-Palm-Kernel-Oil Fatty Acid N Fatty Alkohol PDFDokument29 SeitenADRIANO-SALES - FIRJAM - Oleochemicals-from-Palm-Kernel-Oil Fatty Acid N Fatty Alkohol PDFjayan perkasaNoch keine Bewertungen

- Fats and OilsDokument44 SeitenFats and OilsTheodorus SiboroNoch keine Bewertungen

- 29 Kapilan Natesh 1-3 (278-282)Dokument5 Seiten29 Kapilan Natesh 1-3 (278-282)Fitriani Indah LestariNoch keine Bewertungen

- National Textile University: Name: Reg No.: Section: Subject: Assignment: Submitted DateDokument14 SeitenNational Textile University: Name: Reg No.: Section: Subject: Assignment: Submitted DateTariq ullahNoch keine Bewertungen

- Difference Between Wax and OilDokument26 SeitenDifference Between Wax and OilJessa Mae Malinao100% (2)

- Technology For Rerefining Used Lube Oils Applied in Europe: A ReviewDokument14 SeitenTechnology For Rerefining Used Lube Oils Applied in Europe: A ReviewPaula Citelli100% (1)

- Body and Hand Creams and LotionsDokument14 SeitenBody and Hand Creams and LotionsFEBINoch keine Bewertungen

- Palm Oil PolyurethaneDokument24 SeitenPalm Oil PolyurethaneIwan TejasukmanaNoch keine Bewertungen

- Che 243Dokument47 SeitenChe 243Carlyn HarfordNoch keine Bewertungen

- 8 2 Introduction To Biodiesel ProductionDokument7 Seiten8 2 Introduction To Biodiesel ProductionshawonscribdNoch keine Bewertungen

- Olive Oil: Chemistry and TechnologyVon EverandOlive Oil: Chemistry and TechnologyDimitrios BoskouBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Biodiesel Production101: Homebrew Edition: A Do It Yourself Guide to Produce Biodiesel on Your BackyardVon EverandBiodiesel Production101: Homebrew Edition: A Do It Yourself Guide to Produce Biodiesel on Your BackyardNoch keine Bewertungen

- Gourmet and Health-Promoting Specialty OilsVon EverandGourmet and Health-Promoting Specialty OilsBewertung: 3 von 5 Sternen3/5 (1)

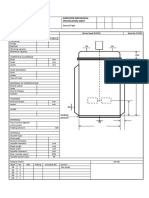

- Simplified Mechanical Specification Sheet SampleDokument2 SeitenSimplified Mechanical Specification Sheet SampleEdNoch keine Bewertungen

- Class Activity 2 PDFDokument1 SeiteClass Activity 2 PDFEdNoch keine Bewertungen

- MiniProject - Template - Business Proposal - KIX3002Dokument20 SeitenMiniProject - Template - Business Proposal - KIX3002EdNoch keine Bewertungen

- Chapter 2 - Physical TreatmentDokument44 SeitenChapter 2 - Physical TreatmentEdNoch keine Bewertungen

- Tutorial - Fuzzy Logic PDFDokument1 SeiteTutorial - Fuzzy Logic PDFEdNoch keine Bewertungen

- KIL3012 - WEEK 1 - 10.9.19 (Student Copy)Dokument61 SeitenKIL3012 - WEEK 1 - 10.9.19 (Student Copy)Ed100% (1)

- KIL3012 - WEEK 3 - 24.9.19 (Student Copy)Dokument84 SeitenKIL3012 - WEEK 3 - 24.9.19 (Student Copy)EdNoch keine Bewertungen

- GIS1012 Lifecycle Nutrition: Diet Planning and Food PyramidDokument23 SeitenGIS1012 Lifecycle Nutrition: Diet Planning and Food PyramidEdNoch keine Bewertungen

- Development of A Green LAB Process: Alkylation of Benzene With 1-Dodecene Over MordeniteDokument6 SeitenDevelopment of A Green LAB Process: Alkylation of Benzene With 1-Dodecene Over MordeniteEdNoch keine Bewertungen

- GIS1012 Lifecycle Nutrition: Water Soluble Vitamin 3Dokument36 SeitenGIS1012 Lifecycle Nutrition: Water Soluble Vitamin 3EdNoch keine Bewertungen

- GIS1012 Lifecycle Nutrition: Diet Planning and Food PyramidDokument23 SeitenGIS1012 Lifecycle Nutrition: Diet Planning and Food PyramidEdNoch keine Bewertungen

- EtheneDokument11 SeitenEtheneEdNoch keine Bewertungen

- LN13 GIS1012 LifecycleNutrition 2019Dokument23 SeitenLN13 GIS1012 LifecycleNutrition 2019Ed100% (1)

- Production of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesDokument13 SeitenProduction of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesATWIJUKIRE DICKENSNoch keine Bewertungen

- Computational Modelling in Drug DiscoveryDokument44 SeitenComputational Modelling in Drug DiscoverySalna Susan AbrahamNoch keine Bewertungen

- Reichold, Corrosion Guide 12.15.2010Dokument45 SeitenReichold, Corrosion Guide 12.15.2010Pradeep Srivastava100% (1)

- Unit 6 - Introduction To Volumetric Analysis - Subjects 0 PDFDokument92 SeitenUnit 6 - Introduction To Volumetric Analysis - Subjects 0 PDFSiti AmirahNoch keine Bewertungen

- Stainless Steel Braided Teflon Flexible Hoses Hht&Hhts SeriesDokument4 SeitenStainless Steel Braided Teflon Flexible Hoses Hht&Hhts SeriesMKOZERDEMNoch keine Bewertungen

- Basics of Thermal Power PlantDokument35 SeitenBasics of Thermal Power PlantMansoor Chowdhury100% (1)

- PH Calculation With CO2 AdditionDokument12 SeitenPH Calculation With CO2 AdditionPraveen KhatriNoch keine Bewertungen

- Disk CentifugeDokument24 SeitenDisk CentifugeNaik Larka100% (1)

- D 3002 DesignDokument20 SeitenD 3002 DesignmargaretramosNoch keine Bewertungen

- HW 3Dokument2 SeitenHW 3Christina HillNoch keine Bewertungen

- Bomba Goulsd Ic-125Dokument3 SeitenBomba Goulsd Ic-125ELMERNoch keine Bewertungen

- GUI Waste Incineration & Best Available Techniques (BAT) - Bref2004Dokument530 SeitenGUI Waste Incineration & Best Available Techniques (BAT) - Bref2004susCities100% (7)

- Introduction To Chemistry 4th Edition Bauer Birk Marks Test BankDokument52 SeitenIntroduction To Chemistry 4th Edition Bauer Birk Marks Test Bankcasey100% (21)

- Modelling of Aluminium Scrap Melting in A Rotary FurnaceDokument10 SeitenModelling of Aluminium Scrap Melting in A Rotary FurnaceestefanoveiraNoch keine Bewertungen

- 11th CRP - PT-3 - JEE (ADV) - PAPER-2 - 09-04-2023 - AnswerDokument1 Seite11th CRP - PT-3 - JEE (ADV) - PAPER-2 - 09-04-2023 - AnswerGully GamingNoch keine Bewertungen

- Loxiol® A 2 PDFDokument24 SeitenLoxiol® A 2 PDFXuân Giang NguyễnNoch keine Bewertungen

- Shell Gadus s1 Og 200 PDFDokument1 SeiteShell Gadus s1 Og 200 PDFMiskaDarainiNoch keine Bewertungen

- L9 Fastening System PDFDokument6 SeitenL9 Fastening System PDFMarcel BaqueNoch keine Bewertungen

- Microscopic Examination of Urine CompressedDokument75 SeitenMicroscopic Examination of Urine CompressedJheshari VinaNoch keine Bewertungen

- Finalreport PDFDokument47 SeitenFinalreport PDFNelCamHerNoch keine Bewertungen

- Pharmaceutical Industry BR 9108227 en Us 2102 1Dokument12 SeitenPharmaceutical Industry BR 9108227 en Us 2102 1PhongNoch keine Bewertungen

- Polymer Repair PDFDokument3 SeitenPolymer Repair PDFamirouche15Noch keine Bewertungen

- IOGP S-616 - 2022 - Supp. Specification To API SPEC 5L & ISO 3183 Line PipeDokument187 SeitenIOGP S-616 - 2022 - Supp. Specification To API SPEC 5L & ISO 3183 Line PipeFerryNoch keine Bewertungen

- Atoms and The Periodic TableDokument13 SeitenAtoms and The Periodic TableAnonymous Bv0YpFNoch keine Bewertungen

- التجربة الثانية الانكسارDokument3 Seitenالتجربة الثانية الانكسارAymen AbdulrahmanNoch keine Bewertungen

- Author's Accepted Manuscript: Physica B: Physics of Condensed MatterDokument29 SeitenAuthor's Accepted Manuscript: Physica B: Physics of Condensed MatteryassinebouazziNoch keine Bewertungen

- Numerical List SABSDokument1.143 SeitenNumerical List SABSJason GlassNoch keine Bewertungen