Beruflich Dokumente

Kultur Dokumente

Power Plant

Hochgeladen von

GOD0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

90 Ansichten20 SeitenAn anti-lock braking system (ABS) prevents wheels from locking up during braking. Modern ABS uses speed sensors and electronically controlled valves to regulate brake pressure and allow steering control during hard braking. ABS provides shorter stopping distances, especially on slippery surfaces, and improved vehicle control. Major ABS manufacturers include Bosch, Delphi, Continental and Kelsey-Hayes. ABS benefits include safer braking in wet or slippery conditions while still allowing steering control, though initial costs and maintenance are limitations.

Originalbeschreibung:

file

Originaltitel

power plant

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAn anti-lock braking system (ABS) prevents wheels from locking up during braking. Modern ABS uses speed sensors and electronically controlled valves to regulate brake pressure and allow steering control during hard braking. ABS provides shorter stopping distances, especially on slippery surfaces, and improved vehicle control. Major ABS manufacturers include Bosch, Delphi, Continental and Kelsey-Hayes. ABS benefits include safer braking in wet or slippery conditions while still allowing steering control, though initial costs and maintenance are limitations.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

90 Ansichten20 SeitenPower Plant

Hochgeladen von

GODAn anti-lock braking system (ABS) prevents wheels from locking up during braking. Modern ABS uses speed sensors and electronically controlled valves to regulate brake pressure and allow steering control during hard braking. ABS provides shorter stopping distances, especially on slippery surfaces, and improved vehicle control. Major ABS manufacturers include Bosch, Delphi, Continental and Kelsey-Hayes. ABS benefits include safer braking in wet or slippery conditions while still allowing steering control, though initial costs and maintenance are limitations.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 20

ANTILOCK BRAKING SYSTEM

Introduction

An Anti-lock Braking System (ABS) is a

safety system that allows the wheels on a

motor vehicle to continue interacting tractively

with the road surface as directed by driver

steering inputs while braking, preventing the

wheels from locking up (that is, ceasing

rotation) and therefore avoiding skidding.

History

The ABS was first developed for aircraft used in

1929 by the French automobile and aircraft

pioneer.

An early system was Dunlop's Maxaret system,

which was introduced in the 1950s and is still in

use on some aircraft models.

In 1958, a Royal Enfield Super Meteor motorcycle

was used by the Road Research Laboratory to test

the Maxaret anti-lock brake. The experiments

demonstrated that anti-lock brakes can be of great

value to motorcycles, for which skidding is

involved in a high proportion of accidents.

Stopping distances were reduced in most of the

tests compared with locked wheel braking,

particularly on slippery surfaces, in which the

improvement could be as much as 30 percent.

Experts saw little future in the system, however it

was not put into production by the company.

A fully mechanical system saw limited automobile

use in the 1960s in the Ferguson P99 racing car,

the Jensen FF, and the experimental all wheel

drive Ford Zodiac, but saw no further use; the

system proved expensive and unreliable in

automobile use.

Modern systems

Bendix Corporation, introduced a computerized,

three-channel, four-sensor all-wheel ABS called

"Sure Brake" for its 1971 Imperial .It was available

for several years thereafter, functioned as

intended, and proved reliable.

In 1971, General Motors introduced the

"Trackmaster" rear-wheel only ABS as an option

on their Rear-wheel drive Cadillac models.

In the same year, Nissan offered an EAL (Electro

Anti-lock System) as an option on the Nissan

President, which became Japan's first electronic

ABS.

In 1975, Robert Bosch took over the European

company Teldix and all patents registered by the

joint-venture and used this acquisition to build

the base of the ABS introduced on the market

some years later.

In 1978, the German firms Bosch and Daimler-

Benz co-developed an ABS technology that begun

in the early 1970s, and introduced the first

completely electronic four-wheeled multi-channel

ABS in trucks and the Mercedes-Benz S-Class.

In 1988, BMW introduced the

first motorcycle with an

electronic-hydraulic ABS the

BMW K100.

Honda followed suit in 1992 with the launch of

its first motorcycle ABS on the ST1100 Pan

European.

In 2005, Harley-Davidson began offering ABS

as an option for police bikes.

In 2007, Suzuki launched its GSF1200SA

(Bandit) with an ABS.

In 2008, ABS became a factory-installed option

on all Harley-Davidson Touring motorcycles

and standard equipment on selected models.

Simple brake system

Brake cylinder

Brake pedal

Pedal cylinder

This system increases the force of our foot by factor of 36

Friction

Difference between normal and ABS

braking systems

Components of ABS

Main Components

Speed sensors :- The anti-

lock braking system

needs some way of

knowing when a wheel is

about to lock up. The

speed sensors, which are

located at each wheel, or

in some cases in the

differential, provide this

information.

Valves :- There is a valve in the

brake line of each brake controlled

by the ABS. On some systems, the

valve has three positions: In

position one, the valve is open;

pressure from the master cylinder

is passed right through to the brake.

In position two, the valve blocks the

line, isolating that brake from the

master cylinder. This prevents the

pressure from rising further should

the driver push the brake pedal

harder.

In position three, the valve releases

some of the pressure from the

brake.

Valves and Pump

Pump :- Since the valve is able to release pressure

from the brakes, there has to be some way to put

that pressure back. That is what the pump does;

when a valve reduces the pressure in a line, the

pump is there to get the pressure back up.

Controller :- The controller is an ECU type unit in

the car which receives information from each

individual wheel speed sensor, in turn if a wheel

loses traction the signal is sent to the controller,

the controller will then limit the brake force

(EBD) and activate the ABS modulator which

actuates the braking valves on and off.

Anti-Lock Brake Types

Four-channel, four-sensor ABS.

This is the best scheme. There is a speed sensor on all four wheels and a

separate valve for all four wheels. With this setup, the controller

monitors each wheel individually to make sure it is achieving maximum

braking force.

Three-channel, three-sensor ABS.

This scheme, commonly found on pickup trucks with four-wheel ABS, has a

speed sensor and a valve for each of the front wheels, with one valve and

one sensor for both rear wheels. The speed sensor for the rear wheels is

located in the rear axle. This system provides individual control of the front

wheels, so they can both achieve maximum braking force. The rear wheels,

however, are monitored together; they both have to start to lock up before

the ABS will activate on the rear. With this system, it is possible that one of

the rear wheels will lock during a stop, reducing brake effectiveness.

One-channel, one-sensor

ABS This system is commonly found on pickup trucks with rear-

wheel ABS. It has one valve, which controls both rear wheels,

and one speed sensor, located in the rear axle. This system

operates the same as the rear end of a three-channel system.

The rear wheels are monitored together and they both have to

start to lock up before the ABS kicks in. In this system it is also

possible that one of the rear wheels will lock, reducing brake

effectiveness. This system is easy to identify. Usually there will

be one brake line going through a T-fitting to both rear wheels.

How can a new person detects the car is

equipped with ABS ?

A new driver can see an indicator in the

dash board named “ABS” and understand

that car is equipped with ABS.

And while in driving when brakes are

applied the driver can feel an pulsating

action of the brake pedal under his foot this

indicates that car is equipped with ABS.

WHO MAKES ANTILOCK BRAKES ?

The major suppliers of antilock brakes are:

Bendix, Acquired from Allied Signal by Bosch, used in Chrysler and

Jeep products.

Bosch, Main supplier for most imports and assorted domestic

vehicles.

Delco, Now known as Delphi, is used exclusively on GM applications.

Continental Teves, found on various Ford, GM, Chrysler and import

applications.

Kelsey-Hayes, supplier of rear-wheel ABS and four-wheel ABS

systems on Ford, Chevy and Dodge trucks.

Nippondenso, used on Infiniti and Lexus

Sumitomo, found on certain Mazda and Honda applications, as well

as Ford Escort.

Toyota, rear wheel only ABS systems on Toyota pickups.

Antilock Braking System

Advantages

Improved braking system on slippery and wet

surfaces.

Reduced friction on wheels and road, thus increased

efficiency of tyres (up to 30%).

Shortened vehicle stopping distance, i.e., vehicle is

stopped at lesser distance than a non ABS vehicle.

More safety on skidder roads and avoids over turning

of the vehicle.

Steering control is effective, i.e., vehicle can be steered

freely while braking also. Thus, avoids accidents.

A driver with minimal experience can also drive the

vehicle with ABS effectively , than an experienced

driver on the non ABS vehicle.

Antilock Braking System

Limitations

Initial cost difference between ABS and non

ABS vehicle

Maintenance problems arise as the whole

system is controlled by ECU (Electronic

Control Unit).

On concrete roads, the stopping distance might

be needed more.

Antilock Braking System

Das könnte Ihnen auch gefallen

- Introduction to Basics of Car Ownership Auto Mechanics FundamentalsVon EverandIntroduction to Basics of Car Ownership Auto Mechanics FundamentalsNoch keine Bewertungen

- Antilock Braking SystemDokument25 SeitenAntilock Braking SystemHarpreet SinghNoch keine Bewertungen

- Maintenance Manual ABS AraucaDokument39 SeitenMaintenance Manual ABS AraucaJeyson GonzalezNoch keine Bewertungen

- Telefunken TF-LED22S5T2 Chassis CV9202L-TDokument39 SeitenTelefunken TF-LED22S5T2 Chassis CV9202L-TzokiNoch keine Bewertungen

- GPS Vehicle Tracker: User Manual V5.0Dokument14 SeitenGPS Vehicle Tracker: User Manual V5.0harihaniNoch keine Bewertungen

- GPSTracker v4 PDFDokument19 SeitenGPSTracker v4 PDFhyu2123Noch keine Bewertungen

- Doc3271 FinalDokument90 SeitenDoc3271 Finalsferrar0Noch keine Bewertungen

- T630/T630B User Guide: Screw S Sim Cover Nano Sim Sim SlotDokument17 SeitenT630/T630B User Guide: Screw S Sim Cover Nano Sim Sim SlotDaniel ParNoch keine Bewertungen

- Mini Car-Person 103b Gsm-Gprs-Gps Tracking Device - Mk3Dokument9 SeitenMini Car-Person 103b Gsm-Gprs-Gps Tracking Device - Mk3Bilal Nuraldin EltayebNoch keine Bewertungen

- Oem Gps Tracker User ManualDokument13 SeitenOem Gps Tracker User ManualRoberto Perez RiveraNoch keine Bewertungen

- A005A320020-Basic Equipment (L0L) (5C0) From March 2012Dokument1.930 SeitenA005A320020-Basic Equipment (L0L) (5C0) From March 2012aungthawNoch keine Bewertungen

- Teves 20 GI ABS Electrical TestDokument18 SeitenTeves 20 GI ABS Electrical TestNick PNoch keine Bewertungen

- Smart Mirror Manual-1Dokument55 SeitenSmart Mirror Manual-1robNoch keine Bewertungen

- Service Manual: Model NoDokument48 SeitenService Manual: Model NoPravin MevadaNoch keine Bewertungen

- Elektrolux Professional DishwasherDokument114 SeitenElektrolux Professional DishwasherKarolinaNoch keine Bewertungen

- SM 29Dokument2.770 SeitenSM 29Guilherme Soldateli VidottoNoch keine Bewertungen

- Icar3 User's Manual-OkDokument7 SeitenIcar3 User's Manual-OkahhlNoch keine Bewertungen

- Obdlink SX QuickstartDokument2 SeitenObdlink SX QuickstartRenato AbalosNoch keine Bewertungen

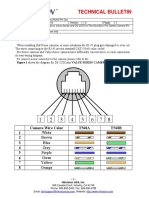

- Technical Bulletin: Camera Wire Color T568A T568B 1 2 3 4 5 6 7 8Dokument2 SeitenTechnical Bulletin: Camera Wire Color T568A T568B 1 2 3 4 5 6 7 8Mohran HakimNoch keine Bewertungen

- Hama 00012307 Code 8 in 1 Remote PDFDokument32 SeitenHama 00012307 Code 8 in 1 Remote PDFcrdiNoch keine Bewertungen

- Electrolux 24inch Built-In 2001 Mechanical Models fdb125 345 421 435 634 635 641 (ET) (LAVA-LOUÇAS)Dokument86 SeitenElectrolux 24inch Built-In 2001 Mechanical Models fdb125 345 421 435 634 635 641 (ET) (LAVA-LOUÇAS)Marincus AdrianNoch keine Bewertungen

- Rhinitis AlergiDokument160 SeitenRhinitis Alergiagus subagiartaNoch keine Bewertungen

- CANYON Smartwatches SW - Catalog-CompressedDokument29 SeitenCANYON Smartwatches SW - Catalog-Compressedwdc cdwNoch keine Bewertungen

- SptdatasheetDokument3 SeitenSptdatasheetRoy BianchiNoch keine Bewertungen

- Guia de Servicio Del Abs PDFDokument42 SeitenGuia de Servicio Del Abs PDFHarlinton descalziNoch keine Bewertungen

- Service Manual: Dishwasher ADP 4420 WHDokument16 SeitenService Manual: Dishwasher ADP 4420 WHsenatNoch keine Bewertungen

- Sony Bravia Service Manual Kdl-32ex525pdf (Dragged)Dokument1 SeiteSony Bravia Service Manual Kdl-32ex525pdf (Dragged)http://lamparinna.blogspot.comNoch keine Bewertungen

- Datasheet 251Dokument191 SeitenDatasheet 251Marcelo OemNoch keine Bewertungen

- Debugging The ATE Mark II ABS SystemDokument5 SeitenDebugging The ATE Mark II ABS SystemkousatoufikNoch keine Bewertungen

- DW-8888-02 Haier Dishwasher ESD20 Series Service Manual PDFDokument14 SeitenDW-8888-02 Haier Dishwasher ESD20 Series Service Manual PDFZeigtNoch keine Bewertungen

- Smart Watch CatalogueDokument13 SeitenSmart Watch CatalogueseenuNoch keine Bewertungen

- ADAS Description enDokument10 SeitenADAS Description enIonut-alexandru IordacheNoch keine Bewertungen

- 4G GPS Tracker Price ListDokument3 Seiten4G GPS Tracker Price Listrongli leeNoch keine Bewertungen

- DC DC Design GuideDokument23 SeitenDC DC Design Guidehammouche_soufianeNoch keine Bewertungen

- ATE Application Enhancement Tool Overview 1Dokument8 SeitenATE Application Enhancement Tool Overview 1georgetodorov23Noch keine Bewertungen

- Vestel Dish Washer ManualDokument30 SeitenVestel Dish Washer ManualsabrathaNoch keine Bewertungen

- Lavadora VestelDokument17 SeitenLavadora VestelpatriotismoNoch keine Bewertungen

- AbsDokument19 SeitenAbssharankumarNoch keine Bewertungen

- SM 55.c PDFDokument339 SeitenSM 55.c PDFjorge Angel Lope100% (1)

- A005R820021-Wiring Diagrams and Component LocationsDokument747 SeitenA005R820021-Wiring Diagrams and Component LocationswaggcasNoch keine Bewertungen

- Coban-Gps Tracker Price List For 50pcs 20161117Dokument6 SeitenCoban-Gps Tracker Price List For 50pcs 20161117DANIELNoch keine Bewertungen

- Service Manual: Gn2SkDokument176 SeitenService Manual: Gn2SkAdilson ToledoNoch keine Bewertungen

- 2002 2004 GEM Parts CatalogDokument176 Seiten2002 2004 GEM Parts Catalog4gempartsNoch keine Bewertungen

- Remote Access Via Internet To Your Hikvision DVRDokument5 SeitenRemote Access Via Internet To Your Hikvision DVRdejan_blazekaNoch keine Bewertungen

- TK103 User ManualDokument16 SeitenTK103 User ManualMiguel Ignacio ArayaNoch keine Bewertungen

- Hikvision DS-7104 7108 7116hwi-SlDokument2 SeitenHikvision DS-7104 7108 7116hwi-Slmaggeorge1Noch keine Bewertungen

- Ohp K-Line Usb Interface For BMW Coding and Diagnostics.: Installation GuideDokument8 SeitenOhp K-Line Usb Interface For BMW Coding and Diagnostics.: Installation GuideFadi EdlbiNoch keine Bewertungen

- Manual Gps Track gt001Dokument8 SeitenManual Gps Track gt001gcarlosghNoch keine Bewertungen

- How To Replace An ABS Control UnitDokument53 SeitenHow To Replace An ABS Control UnitاحمدميدوNoch keine Bewertungen

- Service Manual BORA 7-12KDokument71 SeitenService Manual BORA 7-12KmoshulNoch keine Bewertungen

- Honeywell Pro-Watch XProtect Access Integration User's ManualDokument23 SeitenHoneywell Pro-Watch XProtect Access Integration User's ManualChanmin TunNoch keine Bewertungen

- Electrical System - General NotesDokument73 SeitenElectrical System - General Notes19crystiNoch keine Bewertungen

- Kdl40d3100 LCD TVDokument73 SeitenKdl40d3100 LCD TVRM200Noch keine Bewertungen

- UntitledDokument52 SeitenUntitledVedranL84Noch keine Bewertungen

- Codes Options Audi Décryptage AutomatiqueDokument472 SeitenCodes Options Audi Décryptage AutomatiqueAntoine BrachetNoch keine Bewertungen

- Antilock Braking SystemDokument21 SeitenAntilock Braking SystemAditya Agrawal100% (1)

- ABS Brakes AutomaotiveDokument7 SeitenABS Brakes AutomaotiveRahul ShankhwarNoch keine Bewertungen

- The ABS SystemDokument11 SeitenThe ABS SystemHirtea RazvanNoch keine Bewertungen

- AbsDokument26 SeitenAbsVinit GuptaNoch keine Bewertungen

- JJ 615 Mechanical Maintenance and Component (Case Study Abs)Dokument17 SeitenJJ 615 Mechanical Maintenance and Component (Case Study Abs)Muhammad AiminNoch keine Bewertungen

- 6-Automotive UnderchassisDokument3 Seiten6-Automotive UnderchassisGOD100% (1)

- Internal Combustion Engine Induction TuningDokument39 SeitenInternal Combustion Engine Induction TuningTomás Sebastián Sanhueza Vásquez100% (2)

- Electrical System MaintenanceDokument3 SeitenElectrical System MaintenanceGODNoch keine Bewertungen

- Automobile Maintenance Management and TechniquesDokument2 SeitenAutomobile Maintenance Management and TechniquesGODNoch keine Bewertungen

- 6-Automotive UnderchassisDokument3 Seiten6-Automotive UnderchassisGODNoch keine Bewertungen

- T72Dokument6 SeitenT72GODNoch keine Bewertungen

- Alternative Fuels LNG, LPG, HydrogenDokument69 SeitenAlternative Fuels LNG, LPG, HydrogenGODNoch keine Bewertungen

- WKT MFGDokument4 SeitenWKT MFGGODNoch keine Bewertungen

- 5-Automotive Power TrainDokument3 Seiten5-Automotive Power TrainGODNoch keine Bewertungen

- Types of TeamsDokument9 SeitenTypes of TeamsGODNoch keine Bewertungen

- Inline Injection Pump RemovalDokument3 SeitenInline Injection Pump RemovalGOD100% (2)

- Precision MeasurementDokument33 SeitenPrecision MeasurementGOD100% (1)

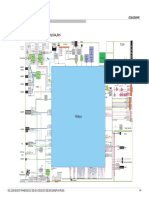

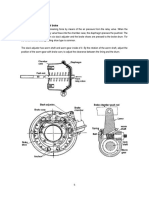

- Defense University, College of Engineering Project Proposal OnDokument15 SeitenDefense University, College of Engineering Project Proposal OnGODNoch keine Bewertungen

- Ex PaintDokument1 SeiteEx PaintGODNoch keine Bewertungen

- Stimulating Creative ThinkingDokument12 SeitenStimulating Creative ThinkingGODNoch keine Bewertungen

- AT 43 CH 24 Fuel Injection System DiagnosisDokument30 SeitenAT 43 CH 24 Fuel Injection System DiagnosisGODNoch keine Bewertungen

- At 43 CH 4 Diesel Engine OperationDokument46 SeitenAt 43 CH 4 Diesel Engine OperationGODNoch keine Bewertungen

- Engine Cooling SystemDokument16 SeitenEngine Cooling SystemGODNoch keine Bewertungen

- Driving in Complicated AreaDokument14 SeitenDriving in Complicated AreaGODNoch keine Bewertungen

- Hydraulic Control and Lubricating System of Power Train1Dokument21 SeitenHydraulic Control and Lubricating System of Power Train1GODNoch keine Bewertungen

- Record KeepingDokument12 SeitenRecord KeepingGODNoch keine Bewertungen

- Aouto Shop Hand Tools and Precesion Measuring Tools: Chapter-TwoDokument48 SeitenAouto Shop Hand Tools and Precesion Measuring Tools: Chapter-TwoGODNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Electronic Diesel Control: Eng. Fu'ad DaoudDokument23 SeitenElectronic Diesel Control: Eng. Fu'ad DaoudNimesh SilvaNoch keine Bewertungen

- H 38Dokument3 SeitenH 38Matei AlexandruNoch keine Bewertungen

- Konsep El Diagnosis PDFDokument30 SeitenKonsep El Diagnosis PDFJulius RonaldoNoch keine Bewertungen

- Internal Combustion Engine Induction TuningDokument39 SeitenInternal Combustion Engine Induction TuningTomás Sebastián Sanhueza Vásquez100% (2)

- Konsep El Diagnosis PDFDokument30 SeitenKonsep El Diagnosis PDFJulius RonaldoNoch keine Bewertungen

- Air Brake (5Dokument1 SeiteAir Brake (5GODNoch keine Bewertungen

- Hilti AnchorDokument5 SeitenHilti AnchorGopi KrishnanNoch keine Bewertungen

- VKC Group of Companies Industry ProfileDokument5 SeitenVKC Group of Companies Industry ProfilePavithraPramodNoch keine Bewertungen

- Audit Process - Performing Substantive TestDokument49 SeitenAudit Process - Performing Substantive TestBooks and Stuffs100% (1)

- Transportation and Academic Performance of Students in The Academic TrackDokument3 SeitenTransportation and Academic Performance of Students in The Academic TrackMary-Jay TolentinoNoch keine Bewertungen

- Nepal CountryReport PDFDokument64 SeitenNepal CountryReport PDFnickdash09Noch keine Bewertungen

- Engineering Materials-Istanbul .Technical UniversityDokument40 SeitenEngineering Materials-Istanbul .Technical UniversitybuggrraaNoch keine Bewertungen

- Bid Evaluation Report Sample TemplateDokument2 SeitenBid Evaluation Report Sample Templatemarie100% (8)

- Step Recovery DiodesDokument3 SeitenStep Recovery DiodesfahkingmoronNoch keine Bewertungen

- 671 - BP Well Control Tool Kit 2002Dokument19 Seiten671 - BP Well Control Tool Kit 2002Ibama MirillaNoch keine Bewertungen

- History of Phosphoric Acid Technology (Evolution and Future Perspectives)Dokument7 SeitenHistory of Phosphoric Acid Technology (Evolution and Future Perspectives)Fajar Zona67% (3)

- Advanced Excel Training ManualDokument6 SeitenAdvanced Excel Training ManualAnkush RedhuNoch keine Bewertungen

- Intel Server RoadmapDokument19 SeitenIntel Server Roadmapjinish.K.GNoch keine Bewertungen

- Glaciogenic: Hydrocarbon SystemsDokument2 SeitenGlaciogenic: Hydrocarbon SystemsAHMEDNoch keine Bewertungen

- Surface News - 20130704 - Low Res PDFDokument9 SeitenSurface News - 20130704 - Low Res PDFYoko GoldingNoch keine Bewertungen

- Formula Retail and Large Controls Planning Department ReportDokument235 SeitenFormula Retail and Large Controls Planning Department ReportMissionLocalNoch keine Bewertungen

- IMS DB Interview Questions: Beginner LevelDokument19 SeitenIMS DB Interview Questions: Beginner LevelsudhakarcheedaraNoch keine Bewertungen

- Mobile Fire Extinguishers. Characteristics, Performance and Test MethodsDokument28 SeitenMobile Fire Extinguishers. Characteristics, Performance and Test MethodsSawita LertsupochavanichNoch keine Bewertungen

- Defination of ValuesDokument11 SeitenDefination of ValuesDipannita GhoshNoch keine Bewertungen

- Rajkumar Kitchen Model Oil Expeller - INRDokument1 SeiteRajkumar Kitchen Model Oil Expeller - INRNishant0% (1)

- Course Syllabus: Ecommerce & Internet MarketingDokument23 SeitenCourse Syllabus: Ecommerce & Internet MarketingMady RamosNoch keine Bewertungen

- Techgig Open Round CompetitionDokument6 SeitenTechgig Open Round CompetitionAnil Kumar GodishalaNoch keine Bewertungen

- Wilo49608 Wilo Ge LeafletDokument46 SeitenWilo49608 Wilo Ge LeafletJair Jimenez HerreraNoch keine Bewertungen

- Biotechnology WebquestDokument2 SeitenBiotechnology Webquestapi-353567032Noch keine Bewertungen

- Capitol Medical Center, Inc. v. NLRCDokument14 SeitenCapitol Medical Center, Inc. v. NLRCFidel Rico NiniNoch keine Bewertungen

- General Description Product Summery: Bvdss Rdson IDDokument4 SeitenGeneral Description Product Summery: Bvdss Rdson IDJose Angel TorrealbaNoch keine Bewertungen

- Suggested Answers Spring 2015 Examinations 1 of 8: Strategic Management Accounting - Semester-6Dokument8 SeitenSuggested Answers Spring 2015 Examinations 1 of 8: Strategic Management Accounting - Semester-6Abdul BasitNoch keine Bewertungen

- Scout Activities On The Indian Railways - Original Order: MC No. SubjectDokument4 SeitenScout Activities On The Indian Railways - Original Order: MC No. SubjectVikasvijay SinghNoch keine Bewertungen

- Book Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDokument10 SeitenBook Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDataVersed100% (1)

- Pfmar SampleDokument15 SeitenPfmar SampleJustin Briggs86% (7)

- Wilcox - Umn - 0130E - 12886 - Competency RevisedDokument160 SeitenWilcox - Umn - 0130E - 12886 - Competency RevisedShasteen Bautista SantosNoch keine Bewertungen