Beruflich Dokumente

Kultur Dokumente

Soil Compaction: Principles of Geotechnical Engineering Eighth Edition

Hochgeladen von

Thony Cay0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

37 Ansichten39 Seitensdsdsdsds

Originaltitel

soil

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldensdsdsdsds

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

37 Ansichten39 SeitenSoil Compaction: Principles of Geotechnical Engineering Eighth Edition

Hochgeladen von

Thony Caysdsdsdsds

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 39

Principles of Geotechnical Engineering

Eighth Edition

Chapter 6

Soil Compaction

1 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Student Objectives and Outline

6.2 – Learn about compaction

6.3 – Learn about the standard Proctor test to obtain the

maximum dry unit weight

6.4 – Understand what factors affect the degree of

compaction achieved by a soil

6.5 – Learn about the modified Proctor test and why it

represents field conditions better than the standard test

2 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Student Objectives and Outline (cont.)

6.6 – Learn about some correlations involving compaction

6.7 – Understand the structure of compacted clay soil

6.8 – Know how compaction affects cohesive soil

properties

6.9 – Learn about compaction in the field

6.10 – Understand specifications for field compaction and

the ways that contractors try to meet them economically

3 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Student Objectives and Outline (cont.)

6.11 – Learn about the sand cone, rubber balloon, and

nuclear methods of determining unit weight of compaction

6.12 – Learn about compaction of organic materials

6.13 – Understand that some soils have better

compaction characteristics than others

6.14 – Learn about some special methods of compaction

4 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.2 Compaction-General Principles

Compaction is the densification of soil by removal of air

Compaction:

Increases the strength of soils

Decreases the amount of settlement of structures

Increases the stability of the slopes of embankments

Vibration and rollers may be used to compact soil

5 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Compaction-General Principles (cont.)

Compaction may be measured in terms of dry unit weight

Water acts as a softening agent during compaction

The dry unit weight at 𝑤 = 𝑤1 is:

𝛾𝑑 𝑤=𝑤1 = 𝛾𝑑 𝑤=0 + Δ𝛾𝑑

The dry unit weight increases initially as water is added

6 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Compaction-General Principles (cont.)

After a certain point

(𝑤 = 𝑤2 ), the dry unit

weight decreases as the

moisture content increases

The moisture content at

maximum dry weight is the

optimum moisture content

7 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.3 Standard Proctor Test

In the Proctor test, soil is

mixed with varying

amounts of water

The soil is then compacted

within a mold by 25 blows

with a standard sized

hammer

8 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Standard Proctor Test (cont.)

The dry unit weight may be

calculated as follows:

𝛾

𝛾𝑑 =

𝑤 %

1+

100

The dry unit weight may

then be plotted against the

moisture content

9 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Standard Proctor Test (cont.)

The theoretical maximum dry unit weight is given by:

𝛾𝑤

𝛾𝑧𝑎𝑣 =

1

𝑤+

𝐺𝑠

𝛾𝑧𝑎𝑣 is the zero-air-void unit weight (which should be the

maximum dry unit weight), and 𝐺𝑠 is the specific gravity

of soil solids

10 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.4 Factors Affecting Compaction

The soil type affects the

maximum dry unit weight

and optimum moisture

content

Some soils, like sand,

exhibit compaction curves

other than a single-peaked

bell shape

11 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Factors Affecting Compaction (cont.)

12 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Factors Affecting Compaction (cont.)

As the compaction effort

increases, the maximum

dry unit weight increases

Additionally, the optimum

moisture content is

decreased

Degree of compaction is

not directly proportional to

compaction effort

13 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.5 Modified Proctor Test

The modified Proctor test is designed to better represent

field conditions, and uses a heavier hammer with a larger

drop, but the same mold

This increases the compaction effort, which in turn

increases the measured maximum dry unit weight

14 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.6 Empirical Relationships

Gurtug and Sridharan proposed the following correlations

based on the plastic limit of cohesive soils:

𝑤𝑜𝑝𝑡 % = 1.95 − 0.38 log 𝐸 𝑃𝐿

𝛾𝑑 𝑚𝑎𝑥 𝑘𝑁Τ𝑚3 = 22.68𝑒 −0.0183𝑤𝑜𝑝𝑡 (%)

𝑃𝐿 is the plastic limit (in %), and 𝐸 is the compaction

energy (2700 𝑘𝑁/𝑚3 for the modified Proctor test)

Similar relationships exist in terms of the plasticity index

and the liquid limit

15 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.7 Structure of Compacted Clay Soil

At a given moisture

content, increased

compactive effort gives the

particles a more parallel

orientation

16 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.8 Effect of Compaction on

Cohesive Soil Properties

Compaction changes the

structure of cohesive soils

Hydraulic conductivity

measures how easily water

flows through the soil

It is higher on the dry side

of the optimum moisture

content, due to large pores

17 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Effect of Compaction on Cohesive Soil

Properties (cont.)

At low pressures, soil is

more compressible when

compacted on the wet side

of the optimum moisture

At higher pressures, the

same soil will be more

compressible if compacted

on the dry side instead

18 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Effect of Compaction on Cohesive Soil

Properties (cont.)

Some clays expand with

addition of moisture and

shrink when drying

This can cause stresses on

the foundations of

structures

19 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.9 Field Compaction

Most field compaction is done with rollers, including:

Smooth-wheel rollers

Pneumatic rubber-tired rollers

Sheepsfoot rollers

Vibratory rollers

Handheld vibrating plates may be used for compaction

over a small area

20 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Smooth-wheeled rollers

Smooth-wheeled rollers are

useful for proof rolling

subgrades and finishing

operation of fills with sandy

and clayey soils

Contact pressures can be

up to 310-380 𝑘𝑁/𝑚2

21 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Pneumatic rubber-tired rollers

Pneumatic rollers are also

useful for compacting

sandy and clayey soils

Contact pressures range

from 600-700 𝑘𝑁/𝑚2

22 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Sheepsfoot rollers

Sheepsfoot rollers have

small projections, which

make them more effective

at compacting clayey soils

Contact pressures range

from 1400-7000 𝑘𝑁/𝑚2

23 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Vibratory rollers

Vibratory rollers help

compact granular soils

Vibrators may be attached

to other types of rollers

Weights are rotated off-

center to produce vibration

24 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Field Compaction

Soil is spread in layers

Water is sprayed on each

layer, which is then

compacted by a roller

The amount of moisture

and the number of roller

passes affects the final dry

unit weight

25 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.10 Specifications for Field Compaction

The relative compaction, 𝑅, is defined as:

𝛾𝑑 𝑓𝑖𝑒𝑙𝑑

𝑅 % = × 100

𝛾𝑑 𝑚𝑎𝑥−𝑙𝑎𝑏

In terms of the relative density, 𝐷𝑟 :

𝑅0

𝑅=

1 − 𝐷𝑟 1 − 𝑅0

Where:

𝛾𝑑 𝑚𝑖𝑛

𝑅0 =

𝛾𝑑 𝑚𝑎𝑥

26 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Specifications for Field Compaction (cont.)

In order to achieve the

desired dry unit weight, the

moisture content must fall

between 𝑤1 and 𝑤2

There is a moisture

content, 𝑤3 , that will allow

the desired dry unit weight

with minimum effort

27 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.11 Determination of Field Unit Weight of

Compaction

The field unit weight of compaction may be measured by:

The sand cone method

The rubber balloon method

The nuclear method

28 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

The Sand Cone Method

A small hole is excavated

in the compacted area

The hole is filled with sand

using the jar to determine

the volume of the hole

The dry unit weight then

calculated

29 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

The Rubber Balloon Method

This procedure is similar to

the sand cone method

However, the volume is

measured using a rubber

balloon filled with water

from a calibrated vessel

30 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

The Nuclear Method

Nuclear density meters use

radioactive isotope sources

Dense soil absorbs more

gamma radiation than

loose soil

The meters operate either

in drilled holes or from the

soil surface

31 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.12 Compaction of Organic Soil and

Waste Materials

The presence of organic

materials in a soil reduces

its strength

The maximum dry unit

weight of compaction

decreases with increasing

organic content

32 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Compaction of Organic Soil and

Waste Materials (cont.)

The optimum moisture

content increases with an

increase in organic content

Soils with more than about

10% organic material are

undesirable for compaction

33 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.13 Evaluation of Soils as

Compaction Material

34 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

6.14 Special Compaction Techniques

Special compaction techniques are used for deep

compaction of in-place soils

These include:

Vibroflotation

Dynamic compaction

Blasting

35 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Vibroflotation

The Vibroflot unit contains

an eccentric weight and

vibrates horizontally

It has openings at the top

and bottom for water jets

The unit compacts a

cylinder of about 2m radius

each time it is lowered

36 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Dynamic Compaction

In dynamic compaction, a

heavy weight (80 to 360

kN) is dropped repeatedly

on the soil from a height of

7.5 to 30.5 m

37 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Blasting

Blasting involves detonating explosive charges at a depth

below the surface in saturated soil

Three to five detonations are usually necessary

Compaction over an area up to 18 m may be achieved

The charges are usually placed at a depth of two-thirds

the thickness of the soil layer to be compacted

38 © 2014 Cengage Learning Engineering. All Rights Reserved.

Principles of Geotechnical Engineering, Eighth Edition Das/Sobhan

Summary

The Proctor test is used to determine the maximum dry

unit weight of compaction and optimum moisture content

The energy of compaction of the test affects these values

Empirical relationships exist to estimate the maximum dry

unit weight and optimum moisture content of a soil

Smooth-wheel, sheepsfoot, and vibratory rollers are

generally used for field compaction, while vibroflotation,

dynamic compaction, and blasting are special techniques

39 © 2014 Cengage Learning Engineering. All Rights Reserved.

Das könnte Ihnen auch gefallen

- Gupta and Larson 1979Dokument3 SeitenGupta and Larson 1979tomppa21Noch keine Bewertungen

- Atom WorksheetsDokument4 SeitenAtom Worksheetsapi-271960049Noch keine Bewertungen

- Earthwork DesignDokument33 SeitenEarthwork DesignMangiNoch keine Bewertungen

- Geosythetic Reinforced Unpaved RoadDokument10 SeitenGeosythetic Reinforced Unpaved RoadPalak ShivhareNoch keine Bewertungen

- EHS Guidelines Offshore Oil and Gas June2015Dokument42 SeitenEHS Guidelines Offshore Oil and Gas June2015IFC Sustainability100% (3)

- Challenges Associated With Expansive Soils and Remedial MeasuresDokument13 SeitenChallenges Associated With Expansive Soils and Remedial MeasuresSaurav BhattacharjeeNoch keine Bewertungen

- Exp. 6Dokument11 SeitenExp. 6Thony CayNoch keine Bewertungen

- Road Engineering & Geotechnical Branch Compaction GuideDokument47 SeitenRoad Engineering & Geotechnical Branch Compaction GuidegabemzamanNoch keine Bewertungen

- CE 408 Transportation Engineering: Technological Institute of The PhilippinesDokument119 SeitenCE 408 Transportation Engineering: Technological Institute of The PhilippinesThony CayNoch keine Bewertungen

- IRC - 075-1979 Design of High Embankments PDFDokument149 SeitenIRC - 075-1979 Design of High Embankments PDFRoshanRSVNoch keine Bewertungen

- Advanced Concrete Technology-3Dokument358 SeitenAdvanced Concrete Technology-3c kumarNoch keine Bewertungen

- DNV-RP-F106 (2003) - Factory Applied External Pipeline Coatings For Corrosion ControlDokument32 SeitenDNV-RP-F106 (2003) - Factory Applied External Pipeline Coatings For Corrosion ControlJohnnyNoch keine Bewertungen

- Airfield Pavement RehabilitationDokument114 SeitenAirfield Pavement RehabilitationTim LinNoch keine Bewertungen

- Operation and maintenance of gravel roads - A literature studyDokument252 SeitenOperation and maintenance of gravel roads - A literature studyDanielSantosNoch keine Bewertungen

- Chapter 02Dokument199 SeitenChapter 02351brendan83% (6)

- Perfumed Laundry Detergent PowdersDokument7 SeitenPerfumed Laundry Detergent PowdersNur AmaninaNoch keine Bewertungen

- 1 What Is LevelingDokument19 Seiten1 What Is LevelingAbduraman Isa100% (1)

- CEB 705 - Week 11 - Lecture 1 - Road Construction MethodsDokument37 SeitenCEB 705 - Week 11 - Lecture 1 - Road Construction MethodsCharles Taloboe100% (1)

- Sludge Dewatering PDFDokument36 SeitenSludge Dewatering PDFPaul Maposa100% (2)

- Geometric Design ManualDokument240 SeitenGeometric Design ManualRiyaad MandisaNoch keine Bewertungen

- Green City FreiburgDokument24 SeitenGreen City FreiburgrodridoNoch keine Bewertungen

- Palm Based Non Hydrogenated Creamer PDFDokument4 SeitenPalm Based Non Hydrogenated Creamer PDFbellesuperNoch keine Bewertungen

- Claycrete English v3Dokument22 SeitenClaycrete English v3supernaenergy100% (1)

- Elements Compounds MixturesDokument55 SeitenElements Compounds MixturesFatima ?Noch keine Bewertungen

- Soil Cement: An Economical Construction MaterialDokument18 SeitenSoil Cement: An Economical Construction MaterialChiñmayà Prãdhàñ100% (1)

- Punggol: From Farmland To Smart Eco-TownDokument70 SeitenPunggol: From Farmland To Smart Eco-TownMr Lokovettor100% (1)

- Assessing Existing Pavement for Long-Term PerformanceDokument119 SeitenAssessing Existing Pavement for Long-Term PerformanceRobeam Solomon100% (1)

- Clinical Chemistry - Theory, Analysis, CorrelationDokument344 SeitenClinical Chemistry - Theory, Analysis, Correlationaristides.quinteroNoch keine Bewertungen

- Sand DrainsDokument7 SeitenSand DrainsdayanidhiNoch keine Bewertungen

- DesignManualforLowVolumeRoadsPartG PDFDokument115 SeitenDesignManualforLowVolumeRoadsPartG PDFElias KbNoch keine Bewertungen

- Performance-Based Measurement of Optimum Moisture For Soil CompactionDokument53 SeitenPerformance-Based Measurement of Optimum Moisture For Soil CompactionEncik ComotNoch keine Bewertungen

- Field Compaction Methods For Soils PDFDokument4 SeitenField Compaction Methods For Soils PDFJohn N. Constance100% (1)

- AP-R548-17 Fundamental Objectives of Road DesignDokument60 SeitenAP-R548-17 Fundamental Objectives of Road Designdandewjanger100% (1)

- Comparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionDokument5 SeitenComparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionIAEME PublicationNoch keine Bewertungen

- Compaction and Water Content Ratio of Compacted Soil Using Hilf Rapid MethodDokument7 SeitenCompaction and Water Content Ratio of Compacted Soil Using Hilf Rapid MethodErdrick PérezNoch keine Bewertungen

- Transition Curves in Road DesignDokument31 SeitenTransition Curves in Road DesignjamilthaljiNoch keine Bewertungen

- Transition CurveDokument4 SeitenTransition CurvePrashant ThapaliyaNoch keine Bewertungen

- Ap G34 13 PDFDokument26 SeitenAp G34 13 PDFJames Mellan100% (1)

- Section I: Routine Maintenance and Rehabilitation: Understanding Road Cross SectionDokument32 SeitenSection I: Routine Maintenance and Rehabilitation: Understanding Road Cross SectionJuliette Mburu100% (1)

- 7.0 Super Elevation DesignDokument15 Seiten7.0 Super Elevation DesignGerald MagingaNoch keine Bewertungen

- Soil CementDokument10 SeitenSoil CementPramudyo BayuNoch keine Bewertungen

- Gravel Road Maintenance: Problems Associated With Gravel RoadsDokument56 SeitenGravel Road Maintenance: Problems Associated With Gravel RoadsBlen tesfayeNoch keine Bewertungen

- Sustainable Urban Infrastructure: Stefan Denig Sustainable Cities Program Siemens AG March 2011Dokument22 SeitenSustainable Urban Infrastructure: Stefan Denig Sustainable Cities Program Siemens AG March 2011Muhammad Fairuz AbdullahNoch keine Bewertungen

- Highway Engineering Rural Roads and Pavements (1921)Dokument391 SeitenHighway Engineering Rural Roads and Pavements (1921)teslionNoch keine Bewertungen

- Widening Pavements Curves Due Off-Tracking VehiclesDokument10 SeitenWidening Pavements Curves Due Off-Tracking VehiclesMuhammad TahirNoch keine Bewertungen

- Road Superelevation Section & Plan ViewsDokument21 SeitenRoad Superelevation Section & Plan Viewsfareedazizi50% (2)

- Chapter 15 - Unpaved RoadsDokument22 SeitenChapter 15 - Unpaved RoadsDiyoke Henry100% (1)

- A Road Building Opportunity PURE - CRETE - Eng - 02252011Dokument48 SeitenA Road Building Opportunity PURE - CRETE - Eng - 02252011PAYLEUNoch keine Bewertungen

- GreenSpaces Full EnglishDokument34 SeitenGreenSpaces Full EnglishMtnNoch keine Bewertungen

- Enhancement of Soil Index Properties by Adding Stone Dust MixDokument7 SeitenEnhancement of Soil Index Properties by Adding Stone Dust MixInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- FHWA MSE and Reinforced Soil Design and Construction GuidelinesDokument419 SeitenFHWA MSE and Reinforced Soil Design and Construction GuidelinesmpvfolloscoNoch keine Bewertungen

- Construction Equipment RollersDokument16 SeitenConstruction Equipment RollersAditi BazajNoch keine Bewertungen

- Structural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday KumarDokument4 SeitenStructural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday Kumarivanhendriprasetyo 127Noch keine Bewertungen

- Analysis of Skew Bridge2Dokument26 SeitenAnalysis of Skew Bridge2Divya UpadhyayNoch keine Bewertungen

- Transpotation - Emulsions For Highway ConstructionDokument20 SeitenTranspotation - Emulsions For Highway ConstructionAtish KumarNoch keine Bewertungen

- Mechanical Properties Soil Stabilized With Nano Calcium Carbonate and Reinforced With Carpet Waste FibersDokument11 SeitenMechanical Properties Soil Stabilized With Nano Calcium Carbonate and Reinforced With Carpet Waste FibersCristianAMejiaNoch keine Bewertungen

- Stabilization of Soil in Road Construction Using Lime and Fly AshDokument9 SeitenStabilization of Soil in Road Construction Using Lime and Fly AshIJRASETPublicationsNoch keine Bewertungen

- Pavement AashtoDokument28 SeitenPavement AashtoJoe Ady ShaputraNoch keine Bewertungen

- Green BuildingDokument23 SeitenGreen BuildingSatyabrata MishraNoch keine Bewertungen

- Sodic Soils ByMarcusDokument40 SeitenSodic Soils ByMarcusWenhao WangNoch keine Bewertungen

- USQ Superelevation GuideDokument17 SeitenUSQ Superelevation GuideSalehuddin RamliNoch keine Bewertungen

- Road Note 8 (Sub Soil Drainage)Dokument25 SeitenRoad Note 8 (Sub Soil Drainage)Someshwar Rao ThakkallapallyNoch keine Bewertungen

- DN Pav 03026 02 PDFDokument42 SeitenDN Pav 03026 02 PDFEng Venance MasanjaNoch keine Bewertungen

- Use of Recycled Materials in Road ConstructionDokument8 SeitenUse of Recycled Materials in Road ConstructionLaoye Abdulrahman AdewaleNoch keine Bewertungen

- Estimation of Subgrade Resilient Modulus From Soil Index PropertiesDokument7 SeitenEstimation of Subgrade Resilient Modulus From Soil Index Propertiesmamoun_hammad7917Noch keine Bewertungen

- 2005 Road Design Standards Rural Roads FinalDokument117 Seiten2005 Road Design Standards Rural Roads FinalOGSAJIBNoch keine Bewertungen

- QTMR Pavement Rehabilitation Manual 2012-04Dokument381 SeitenQTMR Pavement Rehabilitation Manual 2012-04Jean PajueloNoch keine Bewertungen

- Report No. 4Dokument153 SeitenReport No. 4Thony CayNoch keine Bewertungen

- CE 408 Transportation Engineering: Technological Institute of The PhilippinesDokument13 SeitenCE 408 Transportation Engineering: Technological Institute of The PhilippinesThony CayNoch keine Bewertungen

- Steel Chapter 3 EditedDokument29 SeitenSteel Chapter 3 EditedThony CayNoch keine Bewertungen

- 4 StrengthOfFlexuralMembersDokument2 Seiten4 StrengthOfFlexuralMembersThony CayNoch keine Bewertungen

- Technological Institute of The Philippines: Quezon CityDokument9 SeitenTechnological Institute of The Philippines: Quezon CityThony CayNoch keine Bewertungen

- Factors Influencing The Strength of Flexural Members: Learning Module Number 4Dokument5 SeitenFactors Influencing The Strength of Flexural Members: Learning Module Number 4Thony CayNoch keine Bewertungen

- Factors Influencing The Strength of Flexural Members: Learning Module Number 4Dokument5 SeitenFactors Influencing The Strength of Flexural Members: Learning Module Number 4Thony CayNoch keine Bewertungen

- Ce511 S1 Cay Asg1.1Dokument14 SeitenCe511 S1 Cay Asg1.1Thony CayNoch keine Bewertungen

- Report No. 1Dokument104 SeitenReport No. 1Thony CayNoch keine Bewertungen

- Technological Institute of The Philippines: Quezon CityDokument9 SeitenTechnological Institute of The Philippines: Quezon CityThony CayNoch keine Bewertungen

- Ce511 S1 Cay Sim1.1Dokument8 SeitenCe511 S1 Cay Sim1.1Thony CayNoch keine Bewertungen

- Ce511 S1 Cay PS2.1Dokument2 SeitenCe511 S1 Cay PS2.1Thony CayNoch keine Bewertungen

- Report 2 Highway EngineeringDokument44 SeitenReport 2 Highway EngineeringThony CayNoch keine Bewertungen

- Report 3 Highway EngineeringDokument93 SeitenReport 3 Highway EngineeringThony CayNoch keine Bewertungen

- Business ModelDokument3 SeitenBusiness ModelThony CayNoch keine Bewertungen

- Ce511 S1 Cay Asg1.1Dokument14 SeitenCe511 S1 Cay Asg1.1Thony CayNoch keine Bewertungen

- SsssssDokument32 SeitenSsssssThony CayNoch keine Bewertungen

- Ce511 S1 Cay Asg1.1Dokument9 SeitenCe511 S1 Cay Asg1.1Thony CayNoch keine Bewertungen

- Technological Institute of The Philippines: Quezon CityDokument9 SeitenTechnological Institute of The Philippines: Quezon CityThony CayNoch keine Bewertungen

- Classification of Soil: Principles of Geotechnical Engineering Eighth EditionDokument15 SeitenClassification of Soil: Principles of Geotechnical Engineering Eighth EditionThony CayNoch keine Bewertungen

- Business ModelDokument3 SeitenBusiness ModelThony CayNoch keine Bewertungen

- Pre SpanishDokument27 SeitenPre SpanishThony CayNoch keine Bewertungen

- Classification of Soil: Principles of Geotechnical Engineering Eighth EditionDokument15 SeitenClassification of Soil: Principles of Geotechnical Engineering Eighth EditionThony CayNoch keine Bewertungen

- Classification of Soil: Principles of Geotechnical Engineering Eighth EditionDokument15 SeitenClassification of Soil: Principles of Geotechnical Engineering Eighth EditionThony CayNoch keine Bewertungen

- Weight-Volume Relationships: Principles of Geotechnical Engineering Eighth EditionDokument22 SeitenWeight-Volume Relationships: Principles of Geotechnical Engineering Eighth EditionThony CayNoch keine Bewertungen

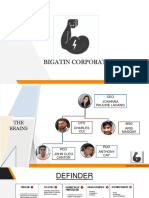

- BigatinDokument10 SeitenBigatinThony CayNoch keine Bewertungen

- BigatinDokument11 SeitenBigatinThony CayNoch keine Bewertungen

- 17-7 PH Stainless SteelDokument2 Seiten17-7 PH Stainless Steelzain malikNoch keine Bewertungen

- EDXRF Analysis of Polymer Films Thickness and CompositionDokument2 SeitenEDXRF Analysis of Polymer Films Thickness and CompositionnadiarhNoch keine Bewertungen

- 9 Nomenclature of Inorganic CompoundsDokument42 Seiten9 Nomenclature of Inorganic CompoundsGlen MangaliNoch keine Bewertungen

- Food Process Engineering Lab 3. BOILER OPERATIONDokument22 SeitenFood Process Engineering Lab 3. BOILER OPERATIONMuhyiddin Noor AfandiNoch keine Bewertungen

- PCRDokument42 SeitenPCRNopiyana PujiastutiNoch keine Bewertungen

- Kinkelder StandardDokument24 SeitenKinkelder StandardJason StephensNoch keine Bewertungen

- Edexcel Science Past Paper 2020Dokument17 SeitenEdexcel Science Past Paper 2020Rumika PereraNoch keine Bewertungen

- Lab Report Chemist 3Dokument3 SeitenLab Report Chemist 3Aiman Athirah Binti Hasbullah E21A0446Noch keine Bewertungen

- Company Profile 4 April - CompressedDokument10 SeitenCompany Profile 4 April - CompressedPhilip PhilipsNoch keine Bewertungen

- AKP123Dokument70 SeitenAKP123goswamiphotostatNoch keine Bewertungen

- 1 - Pharmacokinetics IDokument20 Seiten1 - Pharmacokinetics IabdallaNoch keine Bewertungen

- Corrosion Prevention and ControlDokument19 SeitenCorrosion Prevention and ControlJosa FatyNoch keine Bewertungen

- Kanthal Appliance Heating Alloys Handbook PDFDokument33 SeitenKanthal Appliance Heating Alloys Handbook PDFwillwNoch keine Bewertungen

- Special Fiber Optic PDFDokument18 SeitenSpecial Fiber Optic PDFtarluzNoch keine Bewertungen

- Cuellar Bermudez S P Aguilar Hernandez I PDFDokument20 SeitenCuellar Bermudez S P Aguilar Hernandez I PDFJader MendozaNoch keine Bewertungen

- T50 300 Xl092grexbDokument3 SeitenT50 300 Xl092grexbSykat ZamanNoch keine Bewertungen

- Train for Acid Gas Incinerator MaintenanceDokument19 SeitenTrain for Acid Gas Incinerator MaintenanceAenur RofiiqNoch keine Bewertungen

- Analisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabDokument2 SeitenAnalisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabJohnatan HernándezNoch keine Bewertungen

- Will Silver Bromide PrecipitateDokument14 SeitenWill Silver Bromide PrecipitateLeonidasNoch keine Bewertungen

- Interpretation Guide: Aerobic Count PlateDokument6 SeitenInterpretation Guide: Aerobic Count PlateJinalNoch keine Bewertungen

- Physics 207 Lecture 22: Ideal Fluid Flow, Bernoulli's PrincipleDokument13 SeitenPhysics 207 Lecture 22: Ideal Fluid Flow, Bernoulli's PrincipleAdithyaNoch keine Bewertungen