Beruflich Dokumente

Kultur Dokumente

Vibration Analysis of Ball Bearings Seminar

Hochgeladen von

Arun Thomas0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten22 SeitenVibration

Originaltitel

Vibration Anlaysis

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenVibration

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten22 SeitenVibration Analysis of Ball Bearings Seminar

Hochgeladen von

Arun ThomasVibration

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 22

A SEMINAR ON

VIBRATION ANALYSIS OF

BALL BEARINGS

Guide, Presented by,

TONY VARGHESE Arun Thomas

Asst. Professor ROLL:NO:32

CONTENTS:

• Introduction

• Bearings

• Types Of Bearings

• Function of bearings

• Parts of bearing

• Vibration Anlysis

• Vibration Anlysis Method

• EMD Method

• Vibration Analysis of Rolling Element Bearings Defects

• VIBRATION ANALYSIS APPLICATION

• CONCLUSION

• Reference

INTRODUCTION:

• Rolling bearings are among the most important parts of

vehicles, work machines

• a defect in such a bearing would cause malfunction

• a lot of work has been done on vibration analysis of ball

bearings.

• Generally, the work may be categorized as

• time-domain approaches, frequency-domain approaches

and time–frequency analysis

BEARINGS:

• Machine element that constrains relative movement to the

desired motion

• Reduces friction betweeen moving parts

• Lubrication is used to reduce friction

• Reduces friction by virtue of its shape,by its material

TYPES OF BEARINGS:

• PLAIN BEARING: shaft rotating in a hole

• ROLLING ELEMENT BEARING:rolling element placed

between the turning and stationary races

• JEWEL BEARING:one of the bearing surface is made of

an ultra hard jewel material

• FLUID BEARING: a non contact bearing in which load is

supported by a magnetic field

• MAGNETIC BEARING:load is supported by a magnetic

field

• FLEXURE BEARING:motion is supported by a load

element which bends

FUNCTIONS OF BEARINGS

• Provides stability and frictionless motion to a rotating shaft

• Hold and guide to the shaft

• Smooth and free motion to save power

PARTS OF BEARINGS

• Inner Race: structure of

the bearing that the balls

rotate

• Balls:bearing spins

• Cage:act as a holder to

seperste the balls resting

within the inner and outer

races

• Outer Race:outer ring of

the bearing

VIBRATION ANALYSIS

• a technique used to

identify and predict

mechanical anomalies in

industrial machinery

• by measuring the vibration

and identifying the

frequencies involved

• vibration is recorded by

an accelerometer and the

data is processed by a

spectrum analyzer

VIBRATION ANALYSIS METHODS

• VERY HIGH FREQUENCY:

• ultra sound and stress testing

• shock pulse,spike energy

• HIGH ENERGY

• eveloping and amplitude demodulation

• acceleration spectrum

• MID LOW FREQUENCY

• velocity spectrum

• time waveform analysis

EMD METHOD

• EMD method is to decompose the original signal into

some different IMF components

• the number of extrema and the number of zero-crossings

must either be equal or differ at most by one.

• At any point, the mean value of the envelope defined by

local maxima and the envelope defined by the local

minima is zero

Vibration Analysis of Rolling Element

Bearings Defects

• Defects in the REB produce a series of impacts which

repeat periodically at a rate known as the bearing

frequencies

• Defects in the REB produce a series of impacts which

repeat periodically at a rate known as the bearing

frequencies

• defects occurring in the REB can be as classified asouter

raceway defect, inner raceway defect, ball defect.

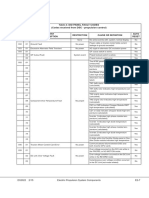

Dynamic response of a normal (no defect)

bearing system

• Fig {a} - Y-direction acceleration response of a normal

bearing system

• Fig {b}-frequency spectrum

Vibration response of normal bearing

• the response frequencies that may affect bearing life is in

the low-frequency range and are usually less than 500 Hz

• One of the peak frequencies is at about 102 Hz

• peak responses are also observed at the harmonics that

are multiples of this ball passing outer race frequency.

Dynamic response of the bearing with

defect

Vibration response of abnormal bearing

• The acceleration response of the defective bearing

system is much higher than that of the normal bearing

system

• frequency spectrum also reveals a peak at 102 Hz

• when the ball passes over the defect, the shape of the

acceleration response is different between the three

functions

Application in vibration analysis of ball

bearings

Normal bearing:

• the vibration signal is complex and

nonlinear due to the compliance

vibration and the effect of lubrication

• vibrations mainly come from the

varying compliance of the structure,

internal excitations and external

disturbance

• frequency of

• natural vibrations is high

• DEFECT BEARING

• When a defect in one surface of a bearing strikes

a mating surface under load (axial load), an

impulse is produced, which excites resonances

in the bearing system

• the impulse is produced periodically.

• the impacts produced by the defect can be

modeled as an infinite series of impulses of

equal amplitude,

VIBRATION ANALYSIS APPLICATION

Detect issues causing failure:

• poor lubrication

• fluting

• cocked bearing

• skidding and sliding

DETECT FAULTS THAT RESULT IN BEARING DAMAGE

• unbalance

• misalignment

• loosness

• resonance

CONCLUSION

The purpose of vibration analyis of bearing is to determine:

• occurence and cause of oscillations

• the possibility of eliminating their occurence to ensure life

expectancy

• to maximise the reliability of the machine in operation

• different varient of damage

• the amplitude sensitivity

REFERENCES

Peter Sulka,Alzbeta Sapietova,Ondrej Stalmach.Vibration analysis and comparison of

damaged and undamaged rolling ball bearing.

H.Saruhan,S.Sardemir,I UYGUR.Vibration analysis of rolling element bearings defect

Qiuhua Du,Shunian Yang.Apllication of the EMD method in the vibration analysis of ball

bearings

Jing Liu,Yimin Shao,Tiek C.Lim.Vibration analysis of ball bearings with a localized defect

applying piecewise response function

THANK YOU

Das könnte Ihnen auch gefallen

- Vibration Analysis of Ball Bearings: A Seminar OnDokument22 SeitenVibration Analysis of Ball Bearings: A Seminar OnArun ThomasNoch keine Bewertungen

- Orbit Plot Analysis: For Checking Condition of A MachineDokument24 SeitenOrbit Plot Analysis: For Checking Condition of A MachineRAKOTONDRAMPARANY Ndimby Njara StephaneNoch keine Bewertungen

- Vibration AnalysisDokument30 SeitenVibration Analysisvinay muleyNoch keine Bewertungen

- 4.0 Shaft, Axle & BearingDokument75 Seiten4.0 Shaft, Axle & BearingphyrdowsNoch keine Bewertungen

- Summer Training at Iocl: Presented By: Anand Kumar Presented To: Rakesh Jain Gopal AgrwalDokument25 SeitenSummer Training at Iocl: Presented By: Anand Kumar Presented To: Rakesh Jain Gopal AgrwalAnshuman KashyapNoch keine Bewertungen

- Machine Tool Vibration and DampersDokument42 SeitenMachine Tool Vibration and DampersGeofrey L PaulNoch keine Bewertungen

- Model 2020Dokument72 SeitenModel 2020AekDzLaiNoch keine Bewertungen

- UTP Adjunct Lecture 2016: Fundamentals of Casing Vibration AnalysisDokument21 SeitenUTP Adjunct Lecture 2016: Fundamentals of Casing Vibration AnalysisMazin Abdalla0% (1)

- Active Magnetic Bearings: Seminar OnDokument9 SeitenActive Magnetic Bearings: Seminar OnAswin PsyNoch keine Bewertungen

- Machine Tool Vibration: Causes, Effects and ControlDokument42 SeitenMachine Tool Vibration: Causes, Effects and ControlLuis NunesNoch keine Bewertungen

- Module 3ADokument35 SeitenModule 3AShahzaib SalmanNoch keine Bewertungen

- MEE342 - Shaft Design PrinciplesDokument27 SeitenMEE342 - Shaft Design PrinciplesBrettNoch keine Bewertungen

- Mechanical Vibration Ch-6Dokument34 SeitenMechanical Vibration Ch-6Befikad BekeleNoch keine Bewertungen

- Vibration Monitoring and AnalysisDokument56 SeitenVibration Monitoring and AnalysisMithlesh SharmaNoch keine Bewertungen

- Condition Monitoring For ElectricalDokument28 SeitenCondition Monitoring For ElectricalArindam SamantaNoch keine Bewertungen

- Machine Design PresentaionDokument24 SeitenMachine Design PresentaionAwais RaoNoch keine Bewertungen

- Introduction To VibrationsDokument36 SeitenIntroduction To VibrationsMajid SattarNoch keine Bewertungen

- Machinery VibrationDokument16 SeitenMachinery VibrationADOBONoch keine Bewertungen

- BearingsDokument48 SeitenBearingsgaurav tiwariNoch keine Bewertungen

- Vibration Monitoring SystemDokument32 SeitenVibration Monitoring Systembpk03Noch keine Bewertungen

- Noise and Vibration Control in Ic Engine: - :presented By:-Kokate Prasad Sayaji Guided By: Prof. FaragadeDokument18 SeitenNoise and Vibration Control in Ic Engine: - :presented By:-Kokate Prasad Sayaji Guided By: Prof. FaragadeKISHANKUMAR KSHIRSAGARNoch keine Bewertungen

- Diagonoses Gearbox in FieldDokument45 SeitenDiagonoses Gearbox in FieldImran Ahmad100% (1)

- CNC Machine Design FeaturesDokument63 SeitenCNC Machine Design FeaturesmahavircNoch keine Bewertungen

- Vibration LimitsDokument37 SeitenVibration LimitssanketNoch keine Bewertungen

- Machine Components: Rolling-Element BearingsDokument11 SeitenMachine Components: Rolling-Element Bearingsanhntran4850Noch keine Bewertungen

- Rotor Balancing: HG 4 (Chapter 8)Dokument30 SeitenRotor Balancing: HG 4 (Chapter 8)Robby DwitamaNoch keine Bewertungen

- Fixturlaser Introduction To Shaft AlignmentDokument23 SeitenFixturlaser Introduction To Shaft Alignmenthicham 85Noch keine Bewertungen

- Unit 4Dokument60 SeitenUnit 4sughashiniNoch keine Bewertungen

- Chatter - Origin and SuppressionDokument20 SeitenChatter - Origin and SuppressionmixarimNoch keine Bewertungen

- Wind Turbine Rotor Balance Static V Dynamic Rev4 ExtDokument14 SeitenWind Turbine Rotor Balance Static V Dynamic Rev4 ExtmlenzNoch keine Bewertungen

- Design Features of LHB Fiat BogieDokument38 SeitenDesign Features of LHB Fiat BogienagaNoch keine Bewertungen

- Element of CNC MachinesDokument60 SeitenElement of CNC MachinesGururaj Gadad100% (3)

- Djj5133 Engineering Design Case Study 2 Lecturer Name: Mohd Fuaad Bin Fesul Name:Muhammad Haziq Hidayat Bin Rahim MATRIX NO: 23DKM18F2029Dokument44 SeitenDjj5133 Engineering Design Case Study 2 Lecturer Name: Mohd Fuaad Bin Fesul Name:Muhammad Haziq Hidayat Bin Rahim MATRIX NO: 23DKM18F2029Kubheran SelvathuraiNoch keine Bewertungen

- Wheel Bearing Training TimkenDokument53 SeitenWheel Bearing Training TimkentamNoch keine Bewertungen

- Unit 1 - Gear Manufacturing ProcessDokument54 SeitenUnit 1 - Gear Manufacturing ProcessAkash DivateNoch keine Bewertungen

- Bearing Damage AnalysisDokument36 SeitenBearing Damage AnalysisWasif Aziz100% (2)

- Dr. Sidra Khanam Assistant Professor Department of Mechanical Engineering Aligarh Muslim UniversityDokument33 SeitenDr. Sidra Khanam Assistant Professor Department of Mechanical Engineering Aligarh Muslim UniversityAmir Mahmoud Mahdavi Abhari100% (1)

- Rotordynamics Module V56!16!9Dokument57 SeitenRotordynamics Module V56!16!9shubham patilNoch keine Bewertungen

- Presentation On CrankshaftDokument20 SeitenPresentation On CrankshaftSachin Kumar100% (7)

- Presentation On Design of Crankshaft Using Catia V5Dokument16 SeitenPresentation On Design of Crankshaft Using Catia V5Naveen KumarNoch keine Bewertungen

- Overrunning Alternator Pulleys Oap 1Dokument1 SeiteOverrunning Alternator Pulleys Oap 1venothNoch keine Bewertungen

- Precision Machine Design: Topic 3 Examples of ErrorsDokument24 SeitenPrecision Machine Design: Topic 3 Examples of ErrorsFelipe Soares MaiaNoch keine Bewertungen

- 2 VaDokument48 Seiten2 VamtttusharNoch keine Bewertungen

- Introduction To Vibration: R.Narasimha Swamy Senior ConsultantDokument43 SeitenIntroduction To Vibration: R.Narasimha Swamy Senior Consultanthemanth45Noch keine Bewertungen

- Design of Wheel Hub - 2nd ReviewDokument32 SeitenDesign of Wheel Hub - 2nd ReviewMadhusudhan ReddyNoch keine Bewertungen

- CM Case StudiesDokument27 SeitenCM Case StudiesOnkarbearing CompanyNoch keine Bewertungen

- Rolling Bearing Lecturer: Types, Applications and SelectionDokument25 SeitenRolling Bearing Lecturer: Types, Applications and SelectionAtul KumarNoch keine Bewertungen

- Internship Presentation: By:-Rahul Sharma ROLL NO: - 18394Dokument25 SeitenInternship Presentation: By:-Rahul Sharma ROLL NO: - 18394Rahul SharmaNoch keine Bewertungen

- Air BDokument20 SeitenAir BVaibhav Chaudhari BldNoch keine Bewertungen

- Lecture-Journal Bearings MD - 2Dokument55 SeitenLecture-Journal Bearings MD - 2Brain HackerNoch keine Bewertungen

- Wear Particle Analysis Correlation To Vibration DataDokument28 SeitenWear Particle Analysis Correlation To Vibration DatasaeedhayatiNoch keine Bewertungen

- WishboneDokument14 SeitenWishboneSapana Kudake SK0% (1)

- Shaft Coupling and AlignmentDokument17 SeitenShaft Coupling and AlignmentKiddos GardenerNoch keine Bewertungen

- Referncce Material 3Dokument53 SeitenReferncce Material 3LohithaNoch keine Bewertungen

- Unit 1 Machine ElementsDokument59 SeitenUnit 1 Machine Elementsaddiwate67% (3)

- Crankshaft StiffnessDokument21 SeitenCrankshaft StiffnessChor FenolNoch keine Bewertungen

- Machine Tool Guideway DesignDokument76 SeitenMachine Tool Guideway DesignSrinivas MurthyNoch keine Bewertungen

- Rotating Structure Modal AnalysisDokument9 SeitenRotating Structure Modal Analysisgautham_93Noch keine Bewertungen

- Rolling Element Bearing Failures GuideDokument89 SeitenRolling Element Bearing Failures GuidepowerplantcvNoch keine Bewertungen

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsVon EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsBewertung: 4 von 5 Sternen4/5 (1)

- 02 Student Placement Report Thursday 11 2019 O.H.T.-iiDokument978 Seiten02 Student Placement Report Thursday 11 2019 O.H.T.-iiAll SidesNoch keine Bewertungen

- Code Fault DSCDokument27 SeitenCode Fault DSCCristopher Oliver SalazarNoch keine Bewertungen

- CPM1A-AD041 Datasheet EnglishDokument2 SeitenCPM1A-AD041 Datasheet EnglishtupitxNoch keine Bewertungen

- 7070 CCG Ra 139 - Iss - 1Dokument2 Seiten7070 CCG Ra 139 - Iss - 1mehdi227Noch keine Bewertungen

- Arduino I2C tutorial for controlling devicesDokument18 SeitenArduino I2C tutorial for controlling devicesSigid AriewibowoNoch keine Bewertungen

- Alcohol SensorDokument8 SeitenAlcohol Sensorshahbazalam4a5Noch keine Bewertungen

- REF7541a SMDokument29 SeitenREF7541a SMslickwhb707Noch keine Bewertungen

- A E Wilcox - Car of The WeekDokument1 SeiteA E Wilcox - Car of The WeekDigital MediaNoch keine Bewertungen

- Technical Guideline TCG 006BDokument12 SeitenTechnical Guideline TCG 006BrakhbirNoch keine Bewertungen

- 37 Sensor Testing Module GuideDokument38 Seiten37 Sensor Testing Module Guide213eknoNoch keine Bewertungen

- Instrumentation & MeasurementDokument7 SeitenInstrumentation & MeasurementSadia AhmadNoch keine Bewertungen

- SAPCDokument2 SeitenSAPCShanArisNoch keine Bewertungen

- EA 1968-07 - TextDokument164 SeitenEA 1968-07 - TextUnderstand CamelsNoch keine Bewertungen

- FUJI FRENIC Mega Manual PDFDokument287 SeitenFUJI FRENIC Mega Manual PDFAli Fajar100% (1)

- Mod PamDokument7 SeitenMod PamGanesh Kumar CNoch keine Bewertungen

- Mongoose Pro User ManualDokument17 SeitenMongoose Pro User Manualsunil601100% (1)

- Signals and Systems (2nd Edition) - Oppenheim Matlab ProjectDokument2 SeitenSignals and Systems (2nd Edition) - Oppenheim Matlab ProjectdavStonerNoch keine Bewertungen

- Canon MP630 Error CodesDokument4 SeitenCanon MP630 Error CodesnickususNoch keine Bewertungen

- Comparative Analysis of Electrical Parameters For Three PhaseDokument12 SeitenComparative Analysis of Electrical Parameters For Three PhaseJishnu M PillaiNoch keine Bewertungen

- Comparing Communication MethodsDokument4 SeitenComparing Communication MethodsKenny VillafanaNoch keine Bewertungen

- MQ07 enDokument22 SeitenMQ07 enmabruk12Noch keine Bewertungen

- Linear TransformerDokument44 SeitenLinear TransformerRonmark AbinoNoch keine Bewertungen

- Centralized Traffic Control (CTC) Is A Form ofDokument7 SeitenCentralized Traffic Control (CTC) Is A Form ofAmitJollyNoch keine Bewertungen

- Build PeoertiesDokument3 SeitenBuild PeoertiesHegbbNoch keine Bewertungen

- 2007 12 ICC Incremental TrainingDokument129 Seiten2007 12 ICC Incremental Trainingvikas.vkp50% (4)

- NEC Microcontrller Development ToolsDokument60 SeitenNEC Microcontrller Development ToolsfinitebookNoch keine Bewertungen

- Understanding audio block diagrams through a schematic exampleDokument18 SeitenUnderstanding audio block diagrams through a schematic exampleS NNoch keine Bewertungen

- Lamb ChopDokument5 SeitenLamb ChopZenonNoch keine Bewertungen

- Vpt7 DocumentationDokument70 SeitenVpt7 Documentationurbster1Noch keine Bewertungen

- AWQ5522EGEDokument2 SeitenAWQ5522EGEpant.vk8514Noch keine Bewertungen