Beruflich Dokumente

Kultur Dokumente

Unit - V Shafts & Shaft Couplings

Hochgeladen von

chinnapa reddy reddy0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten13 SeitenOriginaltitel

V_Unit_shafts

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten13 SeitenUnit - V Shafts & Shaft Couplings

Hochgeladen von

chinnapa reddy reddyCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 13

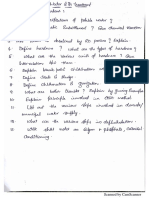

UNIT – V

Shafts & Shaft Couplings:

Shafts: Design of solid and hollow shafts for

strength and rigidity – Design of shafts for

combined bending and axial loads – Shaft sizes

– BIS code.

Shaft Couplings: Rigid couplings – Muff,

Split muff and Flange coupling,

Flexible coupling– Bushed-Pin Coupling.

• A shaft is a rotating machine element which is used to transmit power from

one place to another.

• The power is delivered to the shaft by some tangential force and the resultant

torque.

• In order to transfer the power from one shaft to another, the various

members such as pulleys, gears etc., are mounted on it.

• These members along with the forces exerted upon them causes the shaft to

bending.

• In other words, A shaft is used for the transmission of torque and bending

moment.

• The various members are mounted on the shaft by means of keys.

Material Used for Shafts

• The material used for ordinary shafts is carbon steel of

grades

• 40 C 8,

• 45 C 8,

• 50 C 4 and 50 C 12.

• When a shaft of high strength is required, then an alloy

steel such as

nickel,

nickel-chromium or

chrome-vanadium steel is used.

Properties of Shaft Materials

The material used for shafts should have the

following properties :

• 1. It should have high strength.

• 2. It should have good machinability.

• 3. It should have low notch sensitivity factor.

• 4. It should have good heat treatment

properties.

• 5. It should have high wear resistant properties.

Types of Shafts

• 1. Transmission shafts. These shafts transmit power between

the source and the machines absorbing power.

• The counter shafts, line shafts, over head shafts and all factory

shafts are transmission shafts. Since these shafts carry

machine parts such as pulleys, gears etc., therefore they are

subjected to bending in addition to twisting.

• 2. Machine shafts. These shafts form an integral part of the

machine itself. The crank shaft is an example of machine

shaft.

Stresses in Shafts

• The following stresses are induced in the shafts :

• 1. Shear stresses due to the transmission of torque (i.e. due

to torsional load).

• 2. Bending stresses (tensile or compressive) due to the forces

acting upon machine elements

like gears, pulleys etc. as well as due to the weight of the shaft

itself.

• 3. Stresses due to combined torsional and bending loads.

Design of Shafts

• The shafts may be designed on the basis of

1. Strength, and 2. Rigidity and stiffness.

• In designing shafts on the basis of strength, the following cases may be

considered :

• (a) Shafts subjected to twisting moment or torque only,

• (b) Shafts subjected to bending moment only,

• (c) Shafts subjected to combined twisting and bending moments, and

• (d) Shafts subjected to axial loads in addition to combined torsional and

bending loads.

Shafts Subjected to Twisting Moment Only

Das könnte Ihnen auch gefallen

- Part-Iv: Drive ShaftDokument32 SeitenPart-Iv: Drive Shaftgebremariam birkieNoch keine Bewertungen

- MEE342 - Principles of Mechanical Design: Dr. Haolin ZhuDokument27 SeitenMEE342 - Principles of Mechanical Design: Dr. Haolin ZhuBrettNoch keine Bewertungen

- Chronic Kidney DiseaseDokument15 SeitenChronic Kidney Diseaseapi-270623039Noch keine Bewertungen

- The Essentials of Material Science and Technology for EngineersVon EverandThe Essentials of Material Science and Technology for EngineersBewertung: 5 von 5 Sternen5/5 (1)

- Project Scheduling and TrackingDokument47 SeitenProject Scheduling and TrackingArun VinodhNoch keine Bewertungen

- IMS Objectives Targets 2Dokument2 SeitenIMS Objectives Targets 2FaridUddin Ahmed100% (3)

- 02 BPCrankshaftDokument129 Seiten02 BPCrankshaftrajishrrrNoch keine Bewertungen

- MRBR ATR 72 Rev18Dokument424 SeitenMRBR ATR 72 Rev18Juan Forero OrtizNoch keine Bewertungen

- Rotordynamics Module V56!16!9Dokument57 SeitenRotordynamics Module V56!16!9shubham patil100% (1)

- Also Called Anti Friction Bearing (Misnomer) Consists 4 Parts 2. Outer Race 3. Rolling Elements (Balls, Roller, Needle) 4. CageDokument37 SeitenAlso Called Anti Friction Bearing (Misnomer) Consists 4 Parts 2. Outer Race 3. Rolling Elements (Balls, Roller, Needle) 4. Cagerahil100% (1)

- Lecture 8 Shaft DesignDokument65 SeitenLecture 8 Shaft DesignYasir A. Al-Shataif100% (1)

- Machine Design PresentaionDokument24 SeitenMachine Design PresentaionAwais RaoNoch keine Bewertungen

- Excon2019 ShowPreview02122019 PDFDokument492 SeitenExcon2019 ShowPreview02122019 PDFSanjay KherNoch keine Bewertungen

- TCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFDokument41 SeitenTCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFFabian OrtuzarNoch keine Bewertungen

- Jesus Prayer-JoinerDokument13 SeitenJesus Prayer-Joinersleepknot_maggotNoch keine Bewertungen

- Lecture - 3 - SHAFT DESIGNDokument48 SeitenLecture - 3 - SHAFT DESIGNHammad RazaNoch keine Bewertungen

- ME374 Module 2Dokument57 SeitenME374 Module 2Christian Breth BurgosNoch keine Bewertungen

- Element of CNC MachinesDokument63 SeitenElement of CNC MachinesmahavircNoch keine Bewertungen

- German Atv-Dvwk Rules and StandardsDokument25 SeitenGerman Atv-Dvwk Rules and StandardsMehmet Emre Bastopcu100% (1)

- Unit 1 Machine ElementsDokument59 SeitenUnit 1 Machine Elementsaddiwate67% (3)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsVon EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsBewertung: 4 von 5 Sternen4/5 (1)

- Theories of International InvestmentDokument2 SeitenTheories of International InvestmentSamish DhakalNoch keine Bewertungen

- Sustainable Development - FinalDokument39 SeitenSustainable Development - Finalchinnapa reddy reddyNoch keine Bewertungen

- Design of ShaftsDokument10 SeitenDesign of ShaftsAshish KeshkamatNoch keine Bewertungen

- FMC Derive Price Action GuideDokument50 SeitenFMC Derive Price Action GuideTafara MichaelNoch keine Bewertungen

- DME Unit 2 Design of Machine Elements - Shaft IntroDokument10 SeitenDME Unit 2 Design of Machine Elements - Shaft IntrorenoldelsenNoch keine Bewertungen

- ACFrOgCBbUzWbifi3HUd2hlv2jClqW1h-MLkfgt7 ek4q4UNn-Lf6zxYt7xUcFMyudSogv6iFTQj76J0WFOChJEeD9Ls5XnmhkehuXoNULGMspr3hsaJCXlYtUi4dYD oMG3j3t1tYtdWZD7Jc2oDokument33 SeitenACFrOgCBbUzWbifi3HUd2hlv2jClqW1h-MLkfgt7 ek4q4UNn-Lf6zxYt7xUcFMyudSogv6iFTQj76J0WFOChJEeD9Ls5XnmhkehuXoNULGMspr3hsaJCXlYtUi4dYD oMG3j3t1tYtdWZD7Jc2oShriparno deyNoch keine Bewertungen

- ShaftdesignlecDokument10 SeitenShaftdesignlecTalha AbbasiNoch keine Bewertungen

- ShaftsDokument33 SeitenShafts20BME011 HARSHIT GUPTANoch keine Bewertungen

- Scriet (Agriculture Depatment), Ccsu Meerut: Machine Design (Unit 1, Shaft Lecture 1)Dokument2 SeitenScriet (Agriculture Depatment), Ccsu Meerut: Machine Design (Unit 1, Shaft Lecture 1)Vivek MishraNoch keine Bewertungen

- UNIT - 1.1 Shafts, Keys, Coupling and BearingDokument75 SeitenUNIT - 1.1 Shafts, Keys, Coupling and BearingJeetender Mishra100% (1)

- Chapter 1 ShaftDokument21 SeitenChapter 1 ShaftRayuth KEATNoch keine Bewertungen

- Machine Elements, Power Transmission Devices-pages-BY MBOKEHDokument93 SeitenMachine Elements, Power Transmission Devices-pages-BY MBOKEHAvopaul ZeNoch keine Bewertungen

- Design of Shaft PDFDokument73 SeitenDesign of Shaft PDFDhruv PancholiNoch keine Bewertungen

- 4.1 Machine Tool SpindleDokument24 Seiten4.1 Machine Tool SpindleaniketNoch keine Bewertungen

- ShaftDokument3 SeitenShaftrajibaecNoch keine Bewertungen

- Shaft 141118092812 Conversion Gate02Dokument14 SeitenShaft 141118092812 Conversion Gate02Aso SerwanNoch keine Bewertungen

- Module 3ADokument35 SeitenModule 3AShahzaib SalmanNoch keine Bewertungen

- Welcome IN Sem Ii: by Prof. N. S. SurnerDokument95 SeitenWelcome IN Sem Ii: by Prof. N. S. SurnerBalamuruganNoch keine Bewertungen

- MACHINE DESIGN Part2Dokument16 SeitenMACHINE DESIGN Part2MADHESWARAN SNoch keine Bewertungen

- Shafts and Shaft ComponentsDokument16 SeitenShafts and Shaft ComponentsAya AyaNoch keine Bewertungen

- 2A EM1 ShaftDokument34 Seiten2A EM1 Shaftsayyid alkahfiNoch keine Bewertungen

- 4.0 Shaft, Axle & BearingDokument75 Seiten4.0 Shaft, Axle & BearingphyrdowsNoch keine Bewertungen

- Shaft DesignDokument73 SeitenShaft Designmeenakumari05Noch keine Bewertungen

- Roller BearingsDokument21 SeitenRoller Bearings21B65A0347 THARIGOPULA SAI KUMARNoch keine Bewertungen

- A1 BEDPLATEDokument56 SeitenA1 BEDPLATELakshan KarunarathneNoch keine Bewertungen

- Shaft DesignDokument37 SeitenShaft DesignFarah HumaNoch keine Bewertungen

- Rolling Contact Bearings PDFDokument15 SeitenRolling Contact Bearings PDFnaufal labibNoch keine Bewertungen

- Unit - Iii Gear Manufacturing Process: Sprx1008 - Production Technology - IiDokument19 SeitenUnit - Iii Gear Manufacturing Process: Sprx1008 - Production Technology - Iiramesh gondilNoch keine Bewertungen

- Chapter # 10 Mechanical Springs: Haider AliDokument34 SeitenChapter # 10 Mechanical Springs: Haider AliMuhammad Zia Ur RehmanNoch keine Bewertungen

- LM2.1 FinalDokument47 SeitenLM2.1 FinalMADHESWARAN SNoch keine Bewertungen

- Ball Bearing Design Classes 2021Dokument75 SeitenBall Bearing Design Classes 2021Apurba barmanNoch keine Bewertungen

- Design of Machine Element IIDokument41 SeitenDesign of Machine Element IIYohanis AgumaseNoch keine Bewertungen

- Machine Design Me-305: TH THDokument118 SeitenMachine Design Me-305: TH THTAHAAHMED KHANNoch keine Bewertungen

- Referncce Material 3Dokument53 SeitenReferncce Material 3LohithaNoch keine Bewertungen

- Selection of Antifriction BearingsDokument22 SeitenSelection of Antifriction BearingsSunil MandoreNoch keine Bewertungen

- BearingsDokument35 SeitenBearingsmahendra babu mekalaNoch keine Bewertungen

- Gearbox DesignDokument94 SeitenGearbox DesignHema KumarNoch keine Bewertungen

- Chap 3MHDokument43 SeitenChap 3MHAnonymous HzaFK17Kb100% (1)

- Subscribe To Deepl Pro To Edit This Document.: Visit For More InformationDokument15 SeitenSubscribe To Deepl Pro To Edit This Document.: Visit For More InformationAlpa Butarbutar20Noch keine Bewertungen

- Edm MicroprojectDokument18 SeitenEdm MicroprojectAkshay KhangreNoch keine Bewertungen

- Shaft 2013Dokument23 SeitenShaft 2013Rinardi SoetjiptoNoch keine Bewertungen

- Shaft Design and Its ApplicationDokument19 SeitenShaft Design and Its ApplicationAli MahmoudNoch keine Bewertungen

- Rolling Bearing: by Dr. Atul KumarDokument25 SeitenRolling Bearing: by Dr. Atul KumarAtul KumarNoch keine Bewertungen

- Chapter 3 - Machine Tool DrivesDokument112 SeitenChapter 3 - Machine Tool Drivesaman muleNoch keine Bewertungen

- Shaft Design1Dokument23 SeitenShaft Design120pwmct0739Noch keine Bewertungen

- Springs: Shammy Kumar Assistant Professor Department of Mechanical Engg. SRM University, CHENNAIDokument25 SeitenSprings: Shammy Kumar Assistant Professor Department of Mechanical Engg. SRM University, CHENNAIAshish SinghNoch keine Bewertungen

- BearingDokument6 SeitenBearingDnyaneshwar DhumalNoch keine Bewertungen

- Emd Micro Project FinalDokument15 SeitenEmd Micro Project Finalom pawarNoch keine Bewertungen

- Introduction To ShaftsDokument10 SeitenIntroduction To Shaftsसुमित शर्माNoch keine Bewertungen

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Von EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Noch keine Bewertungen

- Wa0026Dokument92 SeitenWa0026chinnapa reddy reddyNoch keine Bewertungen

- Wa0000Dokument1 SeiteWa0000chinnapa reddy reddyNoch keine Bewertungen

- Wa0013Dokument10 SeitenWa0013chinnapa reddy reddyNoch keine Bewertungen

- ChinnaDokument1 SeiteChinnachinnapa reddy reddyNoch keine Bewertungen

- DME-I Assignment From All Units - 2019-20Dokument3 SeitenDME-I Assignment From All Units - 2019-20chinnapa reddy reddyNoch keine Bewertungen

- Design of Machine Elements-I: Keys, Cotters and Knuckle JointsDokument17 SeitenDesign of Machine Elements-I: Keys, Cotters and Knuckle Jointschinnapa reddy reddyNoch keine Bewertungen

- ChinnaDokument1 SeiteChinnachinnapa reddy reddyNoch keine Bewertungen

- Knuckle JointDokument18 SeitenKnuckle Jointchinnapa reddy reddyNoch keine Bewertungen

- II B.Tech II Sem. FMHM: Topic: Pelton Wheel TurbineDokument22 SeitenII B.Tech II Sem. FMHM: Topic: Pelton Wheel Turbinechinnapa reddy reddyNoch keine Bewertungen

- Termodinamik Proplemleri ÇözümleriDokument33 SeitenTermodinamik Proplemleri ÇözümleriTarah HurstNoch keine Bewertungen

- (/Nirfindia/Home) Welcome To Data Capturing System: Engineering Full ReportDokument23 Seiten(/Nirfindia/Home) Welcome To Data Capturing System: Engineering Full Reportchinnapa reddy reddyNoch keine Bewertungen

- School of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1Dokument2 SeitenSchool of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1STEM Education Vung TauNoch keine Bewertungen

- Talking Art As The Spirit Moves UsDokument7 SeitenTalking Art As The Spirit Moves UsUCLA_SPARCNoch keine Bewertungen

- Acute Coronary SyndromeDokument30 SeitenAcute Coronary SyndromeEndar EszterNoch keine Bewertungen

- Opc PPT FinalDokument22 SeitenOpc PPT FinalnischalaNoch keine Bewertungen

- LEIA Home Lifts Guide FNLDokument5 SeitenLEIA Home Lifts Guide FNLTejinder SinghNoch keine Bewertungen

- Law of EvidenceDokument14 SeitenLaw of EvidenceIsha ChavanNoch keine Bewertungen

- Borang Ambulans CallDokument2 SeitenBorang Ambulans Callleo89azman100% (1)

- .Urp 203 Note 2022 - 1642405559000Dokument6 Seiten.Urp 203 Note 2022 - 1642405559000Farouk SalehNoch keine Bewertungen

- WL-80 FTCDokument5 SeitenWL-80 FTCMr.Thawatchai hansuwanNoch keine Bewertungen

- Ob NotesDokument8 SeitenOb NotesRahul RajputNoch keine Bewertungen

- Technical Specification For 33KV VCB BoardDokument7 SeitenTechnical Specification For 33KV VCB BoardDipankar ChatterjeeNoch keine Bewertungen

- AnticyclonesDokument5 SeitenAnticyclonescicileanaNoch keine Bewertungen

- NDY 9332v3Dokument8 SeitenNDY 9332v3sulphurdioxideNoch keine Bewertungen

- Obesity - The Health Time Bomb: ©LTPHN 2008Dokument36 SeitenObesity - The Health Time Bomb: ©LTPHN 2008EVA PUTRANTO100% (2)

- CX Programmer Operation ManualDokument536 SeitenCX Programmer Operation ManualVefik KaraegeNoch keine Bewertungen

- Comparitive Study ICICI & HDFCDokument22 SeitenComparitive Study ICICI & HDFCshah faisal100% (1)

- What Is TranslationDokument3 SeitenWhat Is TranslationSanskriti MehtaNoch keine Bewertungen

- Equivalent Fractions Activity PlanDokument6 SeitenEquivalent Fractions Activity Planapi-439333272Noch keine Bewertungen

- Digital MetersDokument47 SeitenDigital MetersherovhungNoch keine Bewertungen

- The Homework Song FunnyDokument5 SeitenThe Homework Song Funnyers57e8s100% (1)