Beruflich Dokumente

Kultur Dokumente

Ch12 - Flow

Hochgeladen von

Ramis Ali0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

40 Ansichten101 SeitenOriginaltitel

Ch12 - Flow.pptx

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

40 Ansichten101 SeitenCh12 - Flow

Hochgeladen von

Ramis AliCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 101

Flow Control

Dr. Ammar Hasan

What is flow

• Flow is the motion characteristic

of constrained fluids (liquids or

gases).

• In case of powdered solids, it is

the mass transported by time.

Dr. Ammar Hasan

What is flow

• Automated systems that control flow first

determine flow rates or volume by various

measurement techniques, and then use

the data to regulate the movement.

• These systems employ a source, a path, a

control function, an actuator, and a

measuring instrument to operate.

Dr. Ammar Hasan

Dr. Ammar Hasan

Dr. Ammar Hasan

Reasons for flow control

• To provide good control in the process industries,

accurate measurement of flow is essential. Three

reasons to monitor the flow of materials are:

• To ensure that the correct proportions of raw materials

are combined during manufacturing process.

• To ensure that ingredients are supplied at the proper

rate during mixing and blending of materials.

• To prevent a high flow rate that might cause pressure or

temperatures to become dangerous, overspills to occur

or machines to over speed.

Dr. Ammar Hasan

Units of flow measurement

• Volumetric flow rate

• Mass flow rate

Dr. Ammar Hasan

Volumetric Flow rate

• Volumetric flow rate instruments are used

to determine the volume of material that

flows during a specific period of time.

• The volume can he read as cubic feet,

gallons, or liters. The time can be read per

unit of time such as seconds, minutes, or

hours.

Dr. Ammar Hasan

Volumetric Flow rate

• In many situations, volumetric flow rate is not

measured directly. Instead, an inferred measurement is

taken.

• Inferred means that some other variable is measured,

and then translated into the reading that is required.

• For example, volumetric" flow rate of a liquid can be

determined by measuring the velocity at which it flows

through a pipe.

• By using the velocity measurement and the area of the

pipe, the volumetric flow rate can be calculated.

Dr. Ammar Hasan

Mass Flow rate

• Mass flow rate instruments are used to

determine the weight of materials that

flow during a specified time period.

• The weight can be read in pounds,

tons, grams, or kilograms.

• The time can be read per unit of time,

such as seconds, minutes, or hours.

Dr. Ammar Hasan

Solid flow measurement

• The solid materials that are measured

for mass flow rate are typically in the

form of small particles, such as

powder, pellets, or crushed material.

• A conveyor belt is usually used to

move these materials from one

location to another.

Dr. Ammar Hasan

Solid flow measurement

Dr. Ammar Hasan

Solid flow measurement

• The powder is released by the hopper and transferred to

another location, such as a mixing vat, a storage tank, or

the hold of a ship.

• A measurement is taken by a load cell device that

determines the weight of a fixed length of the belt.

• Using inferred data, such as the weight measurement

and speed of the belt, allows a calculation of the mass

flow rate.

• Mass flow rate = Weight * Belt speed .

length of weighing platform

Dr. Ammar Hasan

Fluid flow measurement

• Liquids, gases, and vapors are classified as

fluids.

• The accurate measurement and control of

fluid flow is essential in industrial processing

plants that use water, steam, gases,

petroleum, acids, base solutions, and other

types of fluid materials.

Dr. Ammar Hasan

Principles of Pipe Flow

• There are several influences that determine

how fluids flow through a system.

• These influences often have a significant

impact on how well a particular flow meter

will perform in a given application.

• The following terms list and describe each

influence. They must be understood when

studying the principles of liquid flow control:

Dr. Ammar Hasan

Principles of Pipe Flow

• Velocity: The velocity of a fluid is the speed at

which it moves through the pipe. The faster

the fluid is flowing, the more inertia it has.

Some flowmeters work well with very high or

very low velocity fluids, while others do not. In

the United States, the unit of measurement is

feet per second.

Dr. Ammar Hasan

Principles of Pipe Flow

• Density: The density of a fluid is its weight per

unit of volume. Both temperature and pressure

affect the density of fluids and can alter the

accuracy of measurements, especially for gases

and vapors. High temperatures or lower pressure

cause the fluid to expand so that the molecules

move farther apart, which causes the weight of a

given volume to be less than it would be at la

lower temperature or higher pressure.

Dr. Ammar Hasan

Principles of Pipe Flow

• Viscosity: The viscosity of a fluid represents the ease

with which it flows. A numerical unit of measure used

to represent viscosity is called the poise or centipoise.

A higher number indicates increased viscosity and

more reluctance to flow. The temperauues to which

the fluids are exposed affect viscosity. With liquid, a

lower temperature will cause the viscosity to

increase, creating more reluctance, which slows the

flow rate. With gases, a lower temperature decreases

viscosity, and creates less reluctance to flow.

Dr. Ammar Hasan

Principles of Pipe Flow

• Pipe size: The size of the pipe carrying a fluid

affects the flow. The larger the diameter, the

more easily the fluid will pass through.

Dr. Ammar Hasan

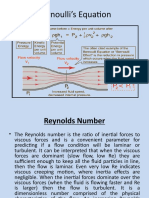

Reynolds number

• The number represents the ratio of the liquid’s

inertial forces to its drag (viscous) forces. The

velocity, pipe diameter, and fluid density are

inertial forces, and viscosity is the drag force.

The R number is used to identify the type of

flow currents that are likely to occur.

Dr. Ammar Hasan

Reynolds number

• At very low velocities, Reynolds number is low and

laminar flow takes place. With this type of flow, liquid

moves in layers.

• However, the fluids do not flow in uniform velocities

across a given cross section of the pipe.

• The layers in contact with the pipe wall move at

velocities close to zero because of friction.

• As drag forces decrease farther away from the pipe,

the layers progressively travel at faster speeds as they

near the center.

Dr. Ammar Hasan

Reynolds number

Dr. Ammar Hasan

Classification of flow meters

• Differential Pressure

– Differential Pressure Meter

– Rotameter

• Positive Displacement

– Rotary-Vane Flowmeter

– Lobed Impeller Flowmeter

• Velocity

– Turbine Flowmeter

Dr. Ammar Hasan

Differential pressure meter

• The differential pressure flowmeter is the

most common type of instrument used to

measure the flow of fluids through a pipe.

• These instruments account for well over 50

percent of all flow measuring devices used in

the process industry.

Dr. Ammar Hasan

Differential pressure meter

• A restriction on the flow, called-an orifice, is

installed in the pipe between two flanges.

• An orifice is a metal plate with a hole of a

specified size bored through it. The purpose of

the orifice is to reduce the area that the fluid

can flow through.

Dr. Ammar Hasan

Differential pressure meter

Dr. Ammar Hasan

Differential pressure meter

Dr. Ammar Hasan

Differential pressure meter

Dr. Ammar Hasan

Differential pressure meter

• According to the laws of conservation of energy,

the mass (fluid) entering a pipe must equal the

mass leaving the pipe during the same time

period.

• Therefore, the velocity of the fluid that leaves the

orifice is faster than the fluid that approaches it.

• According to Bernoulli’s principle, as the velocity

of a fluid increases, pressure decreases.

Dr. Ammar Hasan

Differential pressure meter

• The result is that there is more pressure on

the incoming side of the orifice than on the

outgoing side.

• As the fluid flow rate increases, the differential

pressure also increases.

• Velocity can be calculated from an inferred

differential pressure measurement and used

to determine volumetric flow rate

Dr. Ammar Hasan

Differential pressure meter

• There are several types of orifices/ primary

elements

Dr. Ammar Hasan

Differential pressure meter

• The disadvantage of the first design in is that

the plate has sharp corners on which solid

materials can catch. Therefore, it is not used

to measure slurries, dirty fluids, or corrosive

liquids.

Dr. Ammar Hasan

Differential pressure meter

• The flow nozzle type has a constriction with an

elliptical contour shape. Since there are no

sharp edges at the inlet side, there is less

friction to the flow. Therefore, because of its

slope, it is used to measure steam and high

capacity applications that deal with dirty or

corrosive liquids.

Dr. Ammar Hasan

Differential pressure meter

• The Venturi tube style consists of a converging

inlet section in which the cross section

decreases in size. Venturi tube has no sudden

change in contour, solid particles tend to slide

through its throat. The disadvantage ofthis

style is that the resulting measurements are

not as accurate.

Dr. Ammar Hasan

Differential pressure meter

• Video

Dr. Ammar Hasan

Differential pressure meter

• The advantages of using differential pressure meters are that

they are popular, well understood, inexpensive; they have no

moving parts; and they are well suited for most gases and

liquids.

• 0ne limitation is that there is a nonlinear relationship

between differential pressure and flow. Therefore, to linearize

the signal, a transmitter or controller is used to extract the

square root of the differential pressure measurement.

• Another limitation is that these meters present an

obstruction to flow, which results in some unrecoverable

pressure loss.

Dr. Ammar Hasan

Rotameter

• The rotameter is a variation of the differential

pressure flowmeter.

• The rotameter consists of a tapered metering ,

tube that is vertically mounted and a float that

is free to move up and down within the tube.

Dr. Ammar Hasan

Rota meter

Dr. Ammar Hasan

Rotameter

• The fluid to be measured enters the bottom of

the tube and exits at the top.

• Its operation is based on the variable

Equilibrium area principle, where the flow

raises the float to allow passage of the fluid

Dr. Ammar Hasan

Rotameter

• The movement of the float is directly

proportional to the flow rate.

• A marker on the float is used to identify a

number on a measurement scale that

indicates the flow rate.

Dr. Ammar Hasan

Positive Displacement Flowmeters

• Positive displacement (PD) devices are rotary

instruments that mechanically make direct

measurements to determine flow. They

operate by separating the fluid into segments

of known values, and passing them down-

stream through the pipe.

– Rotary-Vane Flowmeter

– Lobed Impeller Flowmeter

Dr. Ammar Hasan

Rotary Vane Flowmeter

• The most common type of positive

displacement meter sis the rotary-vane

flowmeter. This meter operates by fluid

entering each chamber section through the

inlet port. As fluid fills the chamber, it forces

the rotor to turn clockwise.

Dr. Ammar Hasan

Rotary Vane Flowmeter

• The chamber is separated by spring-loaded vanes

located in channels of the rotor body.

• As the rotor turns, the vanes slide in and out so that

they make constant contact with the cylinder wall.

• The fluid is discharged when each chamber section

reaches the outlet port.

• Since the volume of each revolution is known, the

volumetric flow rate can be determined by

multiplying the displacement times the RPM.

Dr. Ammar Hasan

Rotary Vane Flowmeter

• The chamber is separated by spring-loaded vanes

located in channels of the rotor body.

• As the rotor turns, the vanes slide in and out so that

they make constant contact with the cylinder wall.

• The fluid is discharged when each chamber section

reaches the outlet port.

• Since the volume of each revolution is known, the

volumetric flow rate can be determined by

multiplying the displacement times the RPM.

Dr. Ammar Hasan

Lobed Impeller Flowmeter

• The lobed impeller flow meter is a

positive displacement meter

constructed with two carefully

machined lobes Inlet Outlet that

have very close clearances with each

other and with the meter housing.

Dr. Ammar Hasan

Lobed Impeller Flowmeter

• Video

Dr. Ammar Hasan

Limitations of PD Meters

• The measurements taken from positive

displacement meters are accurate. However,

because they are self-powered they extract

some energy from the system.

• Also, since they consist of mechanical parts,

they are prone to wear.

Dr. Ammar Hasan

Velocity Meters

• Velocity flowmeters measure the velocity of

fluid flow directly.

• A volumetric flow measurement is determined

by the formula

volumetric flow rate = velocity * area of pipe

Dr. Ammar Hasan

Turbine Flowmeter

• The most common type of velocity meter is

the turbine flowmeter.

• Fluid flow causes a rotation of the turbine that

is proportional to the flow rate.

Dr. Ammar Hasan

Turbine Flowmeter

• The output of the turbine flowmeter is a pickup coil.

• Stationary flux lines extend from a permanent magnet

placed inside the coil to the area in which thee turbine

blades turn.

• Each time one of the ferrous blades passes through the

magnetic field, the flux lines become distorted due to a

change in reluctance.

• As the lines are being altered, they cut across the pickup coil

which generates a pulse voltage by induction.

• The frequency of the pulses is proportional to the rotational

speed of the turbine.

Dr. Ammar Hasan

Turbine Flowmeter

• Video

Dr. Ammar Hasan

Electronic Sensors

• Coriolis meter

• Rotor flow detector,

• electromagnetic flow detector

• thermal flowmeter

• vortex flowmeter

• ultrasonic flowmeter

• Time-of-flight meter.

Dr. Ammar Hasan

Coriolis Meter

• One type of device that measures mass of

liquids is the Coriolis meter. It features a U-

shaped tube for fluids to flow through.

Dr. Ammar Hasan

Coriolis Meter

• Fluctuating currents are sent through coils

mounted near the tube. The magnetic forces

they generate cause the tube to vibrate,

similar to a timing fork.

• As fluids flow through the tube, kinetic energy

is produced by its speed and mass. The energy

from the liquid tends to resist the vibrating

motion of the tube, causing it to twist

sideways.

Dr. Ammar Hasan

Coriolis Meter

• The degree of deflection is directly and linearly

proportional to the mass of liquid passing

through the U-tube.

• Magnetic position sensors are mounted on both

ends of the tube to measure the amount of

twist.

• The outputs from each sensor are conditioned

into standard signals before they are sent to

display units or to control equipment.

Dr. Ammar Hasan

Coriolis Meter

Dr. Ammar Hasan

Coriolis Meter

• The degree of deflection is directly and linearly

proportional to the mass of liquid passing

through the U-tube.

• Magnetic position sensors are mounted on both

ends of the tube to measure the amount of

twist.

• The outputs from each sensor are conditioned

into standard signals before they are sent to

display units or to control equipment.

Dr. Ammar Hasan

Coriolis Meter

• Coriolis meters are capable of measuring the

mass of all types of fluids.

• However, their accuracy can be diminished if

exposed to mechanical noise vibration.

Dr. Ammar Hasan

Rotor flow detectors

• They utilize a simple paddle wheel design to

provide flow indication.

Dr. Ammar Hasan

Rotor flow detectors

• A permanent , magnet is embedded in each of the

rotor blade.

• Fluid flow causes a rotor rotation that is

proportional to the flow rate.

• Each pass by a magnetized blade excites a Hall-effect

device in the sensor body, producing a voltage pulse.

• The number of electrical pulses counted for a period

of time is directly proportional to flow volume.

Dr. Ammar Hasan

Rotor flow detectors

Dr. Ammar Hasan

Rotor flow detectors

• This sensor can measure the flow rate of a wide variety of

liquids including acids, solvents, and most corrosive fluids.

• They have a flow response of 0.3fps to l0fps in pipe sizes

with diameters from 0.5 in. to 36in.

• Rotor flow meters must be placed on the edge of the flow.

• If the entire rotor is placed in the flow, the paddle wheel

may not turn at all.

• Turbine flow meters can be totally immersed within the

flow.

Dr. Ammar Hasan

Electromagnetic flow detector

• The electromagnetic flow detector is a

transducer that converts the volumetric flow

rate of a conductive substance into voltage.

• Major components are a flow tube, two

electromagnetic coils mounted across from

each other outside the flow tube, and two

electrodes inside the pipe wall.

Dr. Ammar Hasan

Electromagnetic flow detector

• The electromagnetic flow detector is a

transducer that converts the volumetric flow

rate of a conductive substance into voltage.

• Major components are a flow tube, two

electromagnetic coils mounted across from

each other outside the flow tube, and two

electrodes inside the pipe wall.

Dr. Ammar Hasan

Electromagnetic flow detector

Dr. Ammar Hasan

Electromagnetic flow detector

Dr. Ammar Hasan

Electromagnetic flow detector

• The electromagnetic flow detector’s principle of

operation is based on Faraday’s Law of electromagnetic

induction, which states that a voltage will be induced

into a conductor when it moves through a magnetic

field.

• The liquid serves as the moving conductor.

• The magnetic field is created by the energized coils,

which produce flux lines perpendicular to the fluid flow.

• The induced voltage is measured by the two electrodes.

Dr. Ammar Hasan

Electromagnetic flow detector

• This voltage is the summation of the voltage

developed by each molecule in the flowing

substance.

• As the fluid speed increases, the number of

molecules a voltage is induced into also

increases.

• Therefore, the amount of voltage produced is

proportional to the flow rate.

Dr. Ammar Hasan

Electromagnetic flow detector

• Electromagnetic flow detectors are generally

used to measure difficult and corrosive liquids

and slurries, such as acids, sewage,

detergents, and liquid foods.

Dr. Ammar Hasan

Thermal flowmeters

• Flow detectors that use a paddle wheel or an orifice

are susceptible to clogging.

• Also, their ability to detect flow at low velocities is

limited due to the inertia of the wheel or the inability

of the orifice sensors to detect small differential

pressures.

• Thermal flowmeters, that use a thermistor, have only

a sensor tip that is inserted into the flow stream.

• They do not become clogged and can detect very low

flow rates.

Dr. Ammar Hasan

Thermal flowmeters

Dr. Ammar Hasan

Thermal flowmeters

• It works on the principle of thermal conductivity.

Thermistor sensing head is mounted inside a pipe.

• As fluid passes, it carries away heat from the

thermistor.

• The higher the rate, the cooler the thermistor

becomes, increasing its resistance.

• The result is that the bridge becomes more unbalanced

and the output voltage goes higher.

• A meter with a flow rate scale is connected across the

output terminals and indicates the increase.

Dr. Ammar Hasan

Thermal flowmeters

• If the temperature of the fluid happens to change, so will the

thermistor resistance.

• To prevent the flowmeter from giving a false reading, a second

thermistor sensing head is used.

• Since both thermistors are in the pipe, the fluid temperature

affects their resistances equally.

• Their placement in the bridge causes the resulting voltage changes

to cancel each other.

• Therefore, the only voltage at the output is the one caused by the

flow rate.

• Thermistor 2 is shielded, so its resistance is not affected by the

flow.

Dr. Ammar Hasan

Thermal flowmeters (variation)

Dr. Ammar Hasan

Vortex flowmeters

• A blunt unstreamlined object such as a bar or

strut is placed in the flow path of the fluid.

• As the liquid is forced around the obstacle,

viscosity-related effects cause a series of

vortices to develop downstream.

Dr. Ammar Hasan

Vortex flowmeters

Dr. Ammar Hasan

Vortex flowmeters

• The swirls are shed from one side of the

obstacle and then the other in a predictable

pattern.

• Within a wide range of Reynolds numbers, the

number of vortices that appear downstream in

a given period is directly proportional to the

volumetric flow rate.

• A pressure detector placed downstream from

the blunt object detects the vortices.

Dr. Ammar Hasan

Vortex flowmeters

Dr. Ammar Hasan

Vortex flowmeters

• The sensing element converts the pressure fluctuations

into electrical pulse signals.

• Within the sensor, the electronics convert the frequency

into velocity, and velocity into a volumetric flow rate.

• The vortex meter requires little or no maintenance

because it is rugged, simple, and has no moving parts.

• However, since it introduces an obstruction in the pipe,

it is limited to measuring only clean liquids to avoid

clogging the pipe.

Dr. Ammar Hasan

Ultrasonic Doppler flowmeters

• It operates on a principle of sound

propagation in a liquid called the Doppler

effect.

• As current pulses are sent by an oscillator

through a piezoelectric transducer, it vibrates

and produces sound waves that are

transmitted upstream into the flowing liquid.

Dr. Ammar Hasan

Ultrasonic Doppler flowmeters

Dr. Ammar Hasan

Ultrasonic Doppler flowmeters

Dr. Ammar Hasan

Ultrasonic Doppler flowmeters

• Each ultrasonic wave is reflected from particles

or gas bubbles in the fluid back to a receiving

element.

• The receiver is a piezoelectric device that

detects pressure fluctuations created by the

pulsating sound Waves.

• This transducer converts the sound into

electronic pulses that are processed by the

measuring instrument circuitry.

Dr. Ammar Hasan

Ultrasonic Doppler flowmeters

• Because the fluid is moving toward the receiver, the

frequency of the reflected pulse received is higher than

that of the transmitted pulse.

• The difference in frequency is proportional to the fluid

velocity.

• As the velocity increases, the received frequency increases

to create larger differences relative to the fixed frequency

of the transmitter.

• Therefore, by measuring the frequency difference between

the electrical pulses of the oscillator and the pulses at the

receiver, flow rate can be recorded by the meter.

Dr. Ammar Hasan

Ultrasonic Doppler flowmeters

• Ultrasonic Doppler flowmeters are not suited

for clean fluids because they require particles

from which the sonic pulses are reflected.

• For this reason, and because the sensor is

placed outside the pipe, they are ideal for

dirty liquids and slurries.

Dr. Ammar Hasan

Ultrasonic Time-of-flight flowmeters

• The ultrasonic flowmeter using the Doppler

approach requires reflective objects in the

fluid. Therefore, it is ineffective when

measuring clean fluids.

• When very clean fluids are used, the time-of-

flight ultrasonic method is generally

recommended.

Dr. Ammar Hasan

Ultrasonic Time-of-flight flowmeters

• The time-of-flight approach operates on the

principle that the speed of an ultrasonic sound

wave will increase when transmitted in the

direction of flow, and decrease when transmitted

against the direction of flow movement.

• An analogy is that an airplane can fly faster when

traveling in the direction of the prevailing wind

current than it can when flying against the wind.

Dr. Ammar Hasan

Ultrasonic Time-of-flight flowmeters

• The time-of-flight flowmeter contains two

transducers, one on each side of the pipeline.

• An ultrasonic signal is sent from the upstream

transducer on a diagonal path toward the

downstream transducer.

Dr. Ammar Hasan

Ultrasonic Time-of-flight flowmeters

Dr. Ammar Hasan

Ultrasonic Time-of-flight flowmeters

Dr. Ammar Hasan

Ultrasonic Time-of-flight flowmeters

• As it travels through the flows tream, the natural

velocity of the ultrasonic signal is increased by

the speed at which the fluid flows.

• The time at which the signal travels from the

upstream detector to the downstream detector

is recorded.

• As soon as the downstream transducer receives

the signal, it records the time and sends a signal

back to the upstream transducer.

Dr. Ammar Hasan

Ultrasonic Time-of-flight flowmeters

• By moving against the direction of flow, this signal

travels at its natural speed minus the velocity of the

fluid.

• When the upstream transducer receives the signal,

the time is recorded.

• The difference in time it takes for the signals to move

in both directions is a direct measure of fluid velocity.

• This information is electronically converted to

volumetric flow rate.

Dr. Ammar Hasan

Ultrasonic Time-of-flight flowmeters

• One requirement for this type of meter is that the

liquid being measured must be relatively clean.

• Any particles in the fluid may absorb or scatter the

signal and make the reading inaccurate.

• The advantages of ultrasonic flowmeters are that they

are noninvasive and that the absence of obstructions

does not create a pressure loss.

• Their limitations are that they are relatively expensive

and are not as accurate as some other types of

flowmeters.

Dr. Ammar Hasan

Flowmeter Placement

• As fluid encounters obstacles, such as valves

or other geometric obstructions in the piping,

the flow profile may become distorted and

swirl.

Dr. Ammar Hasan

Flowmeter Placement

Dr. Ammar Hasan

Flowmeter Placement

• One of the effects of swirl is that fluid flows-in

a direction that is not parallel to the pipe, but

in a direction across the diameter to the pipe.

• Fluids flowing in such random paths can take

more time to move past the point of

measurement and cause the reading to

become inaccurate.

Dr. Ammar Hasan

Flowmeter Placement

• To minimize these conditions, the measuring

device should be placed to 20 pipeline

diameters downstream from an obstruction.

• One method used to eliminate destructive

swirls is to use a flow current produced

straightener.

Dr. Ammar Hasan

Flowmeter Placement

Dr. Ammar Hasan

Flowmeter Placement

Dr. Ammar Hasan

Flowmeter Placement

Dr. Ammar Hasan

Flowmeter Selection

• When selecting the most appropriate flow measuring device for a

particular application the following issues should be considered:

• Is the fluid gas or a liquid?

• Is the fluid corrosive?

• Is the fluid electrically conductive or not?

• Does the fluid contain a slurry or large solids?

• What is the fluid viscosity?

• Will the fluid density or viscosity change?

• Is there a need for a noninvasive approach?

• What is the need for accuracy and repeatability?

• What is the cost?

Dr. Ammar Hasan

Das könnte Ihnen auch gefallen

- Lec 11+12+13Dokument97 SeitenLec 11+12+13Ahsan HameedNoch keine Bewertungen

- Flow Measurement PDFDokument77 SeitenFlow Measurement PDFGaming UserNoch keine Bewertungen

- Flow Measuring InstrumentDokument26 SeitenFlow Measuring Instrumenthamza jelaniNoch keine Bewertungen

- Process Instrumentation Module 4Dokument68 SeitenProcess Instrumentation Module 4ibuddhaNoch keine Bewertungen

- Flow MeasurementDokument24 SeitenFlow MeasurementAmarDameneNoch keine Bewertungen

- Fluid Flow& Differential Pressure Flowmeters: Reading Chapter 6Dokument25 SeitenFluid Flow& Differential Pressure Flowmeters: Reading Chapter 6Duncan WoodNoch keine Bewertungen

- FlowDokument62 SeitenFlowbapita roy100% (1)

- FLOWDokument31 SeitenFLOWHassan HaiderNoch keine Bewertungen

- Basic Flowmeter (Industrial Instrumentation)Dokument41 SeitenBasic Flowmeter (Industrial Instrumentation)Muhammad HaryzaNoch keine Bewertungen

- Flowrate MeasurementDokument45 SeitenFlowrate MeasurementJohn Mark EbreoNoch keine Bewertungen

- Flow Sensors: Garfield Smith Selvin GrayDokument17 SeitenFlow Sensors: Garfield Smith Selvin GrayGarfield SmithNoch keine Bewertungen

- Chapter 1-4 Process Measurement and Devices Flow MeasurementDokument123 SeitenChapter 1-4 Process Measurement and Devices Flow Measurementamin shukriNoch keine Bewertungen

- Flow MeasurementDokument30 SeitenFlow Measurementsowbarnikaganesh17Noch keine Bewertungen

- Flow Measurement BasicDokument87 SeitenFlow Measurement BasicSri100% (2)

- Transportation and Metering of FluidsDokument50 SeitenTransportation and Metering of FluidsDedipya100% (2)

- Flow Measurement (Basics) : Ashvani Shukla C&I RelianceDokument47 SeitenFlow Measurement (Basics) : Ashvani Shukla C&I RelianceDavinci LeonardoNoch keine Bewertungen

- Flow Measurement (Basics) : Ashvani Shukla C&I RelianceDokument17 SeitenFlow Measurement (Basics) : Ashvani Shukla C&I RelianceSanthoshkumar SNoch keine Bewertungen

- Flow Presentation 16-5-2017Dokument41 SeitenFlow Presentation 16-5-2017Tauseef AhmadNoch keine Bewertungen

- Flow MeasurementDokument47 SeitenFlow MeasurementAshvani ShuklaNoch keine Bewertungen

- Ultrasonic MeasurementDokument11 SeitenUltrasonic MeasurementPradeep Kumar PrakashNoch keine Bewertungen

- Unit 4.1 FMDokument39 SeitenUnit 4.1 FMRishi Gethu MassNoch keine Bewertungen

- Flow MeasurementDokument16 SeitenFlow MeasurementNigel MagayaNoch keine Bewertungen

- Flow MeasurementDokument41 SeitenFlow MeasurementJay G. Lopez BSEE 1-ANoch keine Bewertungen

- Fluid Mechanics - Type of FlowmeterDokument9 SeitenFluid Mechanics - Type of FlowmeterMuhammad ZulhilmiNoch keine Bewertungen

- Chapter 5Dokument96 SeitenChapter 5MahainiIm RuzailyNoch keine Bewertungen

- Pacific School of Engineering, SuratDokument15 SeitenPacific School of Engineering, SuratbrijeshNoch keine Bewertungen

- Flow Sensors: Prepared By: Jesamy Van Carlo D. ValenzuelaDokument24 SeitenFlow Sensors: Prepared By: Jesamy Van Carlo D. ValenzuelaAaron Fredriel De GuzmanNoch keine Bewertungen

- 5-21 Electronic FlowmetersDokument19 Seiten5-21 Electronic FlowmetersDuncan WoodNoch keine Bewertungen

- Fluid Flow in Food ProcessingDokument40 SeitenFluid Flow in Food ProcessingSolomon Gebremariam100% (1)

- Flow Measurements: Prepared By: Mirroyal Ismayilov (R6KX99) Pu Ruijie (D13L6M) Kashif Ali (DL0YNX) Tobi Eso (DBZIC5)Dokument39 SeitenFlow Measurements: Prepared By: Mirroyal Ismayilov (R6KX99) Pu Ruijie (D13L6M) Kashif Ali (DL0YNX) Tobi Eso (DBZIC5)Mahmoud Abo ElnasrNoch keine Bewertungen

- Flow MeasurementDokument84 SeitenFlow MeasurementAmmar Fitri100% (1)

- Instrumentation Basics - 02 - Flow MeasurementDokument62 SeitenInstrumentation Basics - 02 - Flow MeasurementGhassan AL HaririNoch keine Bewertungen

- Flow MeasurementDokument44 SeitenFlow MeasurementJared Johnson100% (5)

- AB502 ST U4 RotameterDokument9 SeitenAB502 ST U4 RotameterHARSH MALVIYANoch keine Bewertungen

- Process Instrumentation (Flow) .Dokument40 SeitenProcess Instrumentation (Flow) .PratoyoNoch keine Bewertungen

- Fluid Mechanics 1685061120Dokument112 SeitenFluid Mechanics 1685061120fernandoNoch keine Bewertungen

- Flow Meter of Anaestheisa MachineDokument25 SeitenFlow Meter of Anaestheisa MachineYukta GaurNoch keine Bewertungen

- Types of Gas Mass Flow MetersDokument12 SeitenTypes of Gas Mass Flow MetersFirmansyah Budhi SaputhraNoch keine Bewertungen

- Humidity: Humidity Is The Amount ofDokument96 SeitenHumidity: Humidity Is The Amount ofArjhay GironellaNoch keine Bewertungen

- Flow ElementsDokument23 SeitenFlow ElementsG Vengat VinayagamNoch keine Bewertungen

- Questions 34 63Dokument30 SeitenQuestions 34 63dileepNoch keine Bewertungen

- METERS by ShellyDokument7 SeitenMETERS by ShellyTambok PandaNoch keine Bewertungen

- Fluids: Laminar or TurbulentDokument8 SeitenFluids: Laminar or TurbulentSelwah Hj AkipNoch keine Bewertungen

- Flow SensorsDokument60 SeitenFlow Sensorsbhaihello015Noch keine Bewertungen

- Me Lab 1 Draft Group ReportDokument12 SeitenMe Lab 1 Draft Group ReportAngelo PontivedraNoch keine Bewertungen

- CH 2001 Fluid Mechanics Video Lectures: Module 33: Flow MeasurementDokument34 SeitenCH 2001 Fluid Mechanics Video Lectures: Module 33: Flow MeasurementSai KumarNoch keine Bewertungen

- Ch13 - Level ControlDokument88 SeitenCh13 - Level ControlRamis AliNoch keine Bewertungen

- Material Handling & Auxiliaries - Day 3Dokument58 SeitenMaterial Handling & Auxiliaries - Day 3smendozaNoch keine Bewertungen

- Fluid Flow MeasurementDokument5 SeitenFluid Flow MeasurementKarla MaalihanNoch keine Bewertungen

- FluidKinematics Lesson5 FlowMeasurement HandoutDokument22 SeitenFluidKinematics Lesson5 FlowMeasurement HandoutYou Know WhoNoch keine Bewertungen

- Area Meter: - Athena Rene'e Battaglia - Jonalyn BritonDokument9 SeitenArea Meter: - Athena Rene'e Battaglia - Jonalyn BritonRaphael CuencaNoch keine Bewertungen

- Week 2 Day 2 FlowDokument70 SeitenWeek 2 Day 2 FlowOnii chan RhejNoch keine Bewertungen

- Water Measurement SchockDokument42 SeitenWater Measurement SchockPascal HernandezNoch keine Bewertungen

- Doppler Shift Flow MetersDokument15 SeitenDoppler Shift Flow MetersHonesto Raff IvanNoch keine Bewertungen

- Flow SensorsDokument57 SeitenFlow Sensorsbhaihello015Noch keine Bewertungen

- DischargeDokument20 SeitenDischargeanish.bhandariNoch keine Bewertungen

- 4 - Flow Measurment DevicesDokument50 Seiten4 - Flow Measurment DevicesAli MoustafaNoch keine Bewertungen

- Flow MeasurementDokument10 SeitenFlow Measurementnirvan93Noch keine Bewertungen

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeVon EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeBewertung: 4 von 5 Sternen4/5 (2)

- Ch17 - Industrial Detection SensorsDokument145 SeitenCh17 - Industrial Detection SensorsRamis AliNoch keine Bewertungen

- Ch10 - PressureDokument67 SeitenCh10 - PressureRamis AliNoch keine Bewertungen

- Ch13 - Level ControlDokument88 SeitenCh13 - Level ControlRamis AliNoch keine Bewertungen

- EE428 Industrial Process Control Chapter 9: AC Drives: Dr. Ammar HasanDokument43 SeitenEE428 Industrial Process Control Chapter 9: AC Drives: Dr. Ammar HasanRamis AliNoch keine Bewertungen

- EE428 Industrial Process Control Chapter 7: Servo Motors: Dr. Ammar HasanDokument101 SeitenEE428 Industrial Process Control Chapter 7: Servo Motors: Dr. Ammar HasanRamis AliNoch keine Bewertungen

- EE428 Industrial Process Control Part 4: Variable Speed DrivesDokument55 SeitenEE428 Industrial Process Control Part 4: Variable Speed DrivesRamis AliNoch keine Bewertungen

- GT8 - Oil Regeneration PPT - Conditioning - Case StudyDokument17 SeitenGT8 - Oil Regeneration PPT - Conditioning - Case StudyBentoJahezNoch keine Bewertungen

- Converter Transformers Manufactured For The Slovenian RailwaysDokument4 SeitenConverter Transformers Manufactured For The Slovenian RailwaysManuel PenrozNoch keine Bewertungen

- PHY101 Quiz 2 Solved by VU AnswerDokument17 SeitenPHY101 Quiz 2 Solved by VU Answersapen79344Noch keine Bewertungen

- Vibration Specifications Standards Electrical Motors With Alarm LimitsDokument3 SeitenVibration Specifications Standards Electrical Motors With Alarm LimitsHemanth KumarNoch keine Bewertungen

- Lagrangian MechanicsDokument15 SeitenLagrangian Mechanicsrr1819100% (1)

- Physics 2: Heat TransferDokument22 SeitenPhysics 2: Heat TransferAndreana Amor GulayNoch keine Bewertungen

- PV3500 Series 4-12KW MPPTDokument4 SeitenPV3500 Series 4-12KW MPPTAra AkramNoch keine Bewertungen

- Condensadora Pro Air 380VDokument2 SeitenCondensadora Pro Air 380VDavid IslaNoch keine Bewertungen

- HPM10000 72V Test ResultsDokument2 SeitenHPM10000 72V Test ResultsakseerNoch keine Bewertungen

- Mathematics For Science and Technology PrintableDokument130 SeitenMathematics For Science and Technology PrintableLuis ForniNoch keine Bewertungen

- Chapterwise Notes QNA Icse 9 Physics ICSE PDFDokument25 SeitenChapterwise Notes QNA Icse 9 Physics ICSE PDFisequaltoklasses.navneetNoch keine Bewertungen

- Prof TVKB Propeller TheoryDokument26 SeitenProf TVKB Propeller TheorytvkbhanuprakashNoch keine Bewertungen

- NEET Physics Syllabus PDFDokument11 SeitenNEET Physics Syllabus PDFYuvikaNoch keine Bewertungen

- Common Mode Inductors For Emi Filters Require Careful Attenuation To Core Material Selection (1995) (Magnetics)Dokument8 SeitenCommon Mode Inductors For Emi Filters Require Careful Attenuation To Core Material Selection (1995) (Magnetics)mapo mfaNoch keine Bewertungen

- TGS2201 FigaroDokument2 SeitenTGS2201 FigaroBernardita Salazar FonsecaNoch keine Bewertungen

- EIE101R01: Basic Electronics Engineering: Textbook and MaterialsDokument7 SeitenEIE101R01: Basic Electronics Engineering: Textbook and MaterialsAdal ArasuNoch keine Bewertungen

- Bulk MatterDokument38 SeitenBulk MatterBhanu Pratap SinghNoch keine Bewertungen

- MTD SeriesDokument2 SeitenMTD SeriesVuong GiaNoch keine Bewertungen

- Product Sheet: Part NumberDokument2 SeitenProduct Sheet: Part NumberLazar RaresNoch keine Bewertungen

- WheelHorse Battery Charger Service Manual For WheelHorse Model E-141 Electric Tractors 810274Dokument16 SeitenWheelHorse Battery Charger Service Manual For WheelHorse Model E-141 Electric Tractors 810274Kevins Small Engine and Tractor ServiceNoch keine Bewertungen

- Technical Specification - Nelson GardensDokument23 SeitenTechnical Specification - Nelson GardensMahdi KaboodanianNoch keine Bewertungen

- Specification - 11KV 300 SQ - MM XLPE CableDokument2 SeitenSpecification - 11KV 300 SQ - MM XLPE CableAsaf Khader AliNoch keine Bewertungen

- Etr4 11 ADokument4 SeitenEtr4 11 AMathiasNoch keine Bewertungen

- 000 - TRB1020 Turbomachinery HandbookDokument104 Seiten000 - TRB1020 Turbomachinery HandbookStefanos Diamantis0% (1)

- Electrostatics PDFDokument51 SeitenElectrostatics PDFSaksham GuptaNoch keine Bewertungen

- Fundamental Characteristics of Circuit BreakerDokument4 SeitenFundamental Characteristics of Circuit Breakerdejanoski_aNoch keine Bewertungen

- APS-U2001 Manual de ServicioDokument24 SeitenAPS-U2001 Manual de ServicioWilmer MaestreNoch keine Bewertungen

- Summer 2014Dokument2 SeitenSummer 2014Dax ShuklaNoch keine Bewertungen

- Electrical SafetyDokument16 SeitenElectrical SafetyPrakash KumarNoch keine Bewertungen

- Storage Tank Alumnuim Roof - LatestDokument22 SeitenStorage Tank Alumnuim Roof - LatesthgagNoch keine Bewertungen