Beruflich Dokumente

Kultur Dokumente

Automated Construction by Contour Crafting Technology Srinivas B V 1Rn16Cv051

Hochgeladen von

Srinivas B VOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Automated Construction by Contour Crafting Technology Srinivas B V 1Rn16Cv051

Hochgeladen von

Srinivas B VCopyright:

Verfügbare Formate

AUTOMATED CONSTRUCTION BY CONTOUR

CRAFTING TECHNOLOGY

SRINIVAS B V 1RN16CV051

UNDER THE GUIDANCE:

ARJUN P

ASSISTANT PROFESSOR

DEPT. OF CIVIL ENGINEERING

RNS INSTITUTE OF TECHNOLOGY

(Affiliated to Visvesvaraya Technological University ,Belagavi ,Karnataka)

Dr .Vishnuvardhan Road, RR Nagar , Bengaluru – 560 098

CONTENTS

•Introduction

•Contour Crafting

•Literature Survey

•House Building Process

•Characteristics

•Applications

•Advantages and Disadvantages

•Huashag Tengda: Mansion

•Conclusion

•References

Department of civil engineering, RNSIT, Bengaluru 1

INTRODUCTION

• Contour crafting is a building printing technology being

researched by Behrokh Khoshnevis of the University of

Southern California's Information Sciences

• NASA funded a small study at the University of Southern California

to further develop the Contour Crafting 3D printing technique.

• After 3 years of research came out with the new process of building

construction which replaced “cast-in-place” to layer by layer

approach.

• The aim of this technology is to improve the speed, safety, quality

and cost of construction.

Department of civil engineering, RNSIT, Bengaluru 2 3

CONTOUR CRAFTING

CC is an additive fabrication technology by using

computer control.

CC is a layered fabrication method which combines ancient

surface forming concepts with modern robotics technology.

Department of civil engineering, RNSIT, Bengaluru 3

CONTOUR CRAFTING Cont…

• A single house or colony of houses each with

possibly different design may be automatically

constructed in a single run by the help of computer

control.

• Conduits for electrical, plumbing and air

conditioning are embedded in cc construction.

• It provides better surface quality & high speed

fabrication.

Department of civil engineering, RNSIT, Bengaluru 4

LITERATURE SURVEY

AUTHORS TITLE DESCRIPTION

Hrishekesh V. Patil Contour Crafting (A This paper aims at methodology for

et al Management Tool process planning and optimization in

for Swift order to efficiently construct complicated

Construction) large-scale structures by Contour Crafting

systems using different hardware

configurations.

Ali Mokhtari et al Automatic Paper aims to describe the operational

Construction by steps of creating a whole building by the

Contour Crafting machine reviewing relevant literature.

Technology

William J. Leonard Case Study on 3D This paper will analyze implementation

Printing strategies used on three different

Implementation construction projects using 3D printing and

Strategies will evaluate what made them successful

and what

challenges were faced.

Department of civil engineering, RNSIT, Bengaluru 5

HOUSE BUILDING PROCESS

Department of civil engineering, RNSIT, Bengaluru 6

HOUSE BUILDING PROCESS Cont…

Department of civil engineering, RNSIT, Bengaluru 7

HOUSE BUILDING PROCESS Cont…

Department of civil engineering, RNSIT, Bengaluru 8

HOUSE BUILDING PROCESS Cont…

Department of civil engineering, RNSIT, Bengaluru 9

CHARACTERISTICS

1. DESIGN FLEXIBILITY

• The process allows

architects to design

structures with functional

and exotic architectural

geometries.

2. UTILITY CONDUITS

• These may be built into

the walls of a building

structure precisely based

on the CAD data.

Department of civil engineering, RNSIT, Bengaluru 10

CHARACTERISTICS Cont…

3. AUTOMATIC TILING OF FLOORS AND WALLS

4. AUTOMATED PAINTING

• After layer wise construction of walls a spray painting

robotics manipulator, attached to cc main structure

paint each wall according to desired specification.

Department of civil engineering, RNSIT, Bengaluru 11

CHARACTERISTICS Cont…

5. AUTOMATED REINFORCEMENT

Department of civil engineering, RNSIT, Bengaluru 12

CHARACTERISTICS Cont…

6. AUTOMATED PLUMBING

• For plumbing, after fabrication of several wall

layers, a segment of copper pipe is attached

through the constructed conduit onto the lower

segment already installed.

Department of civil engineering, RNSIT, Bengaluru 13

CHARACTERISTICS Cont…

7.AUTOMATED ELECTRICAL & COMMUNICATION

UTILITIES

• Conductive elements for power and communication lines

are imbedded in polymeric blocks and are assembled

robotically to form the desired electrical and

communication networks.

Department of civil engineering, RNSIT, Bengaluru 14

APPLICATIONS

1. APPLICATIONS IN EMERGENCY HOUSING

• Can deliver houses to disaster victims very rapidly.

• 200 sq. foot house in less than 24 hours.

• Uses in-situ construction materials, saving the time

and cost.

• Automated process, labor needs are minimized.

Department of civil engineering, RNSIT, Bengaluru 15

APPLICATIONS Cont…

2. LOW INCOME HOUSING

• It can reduce cost of financing by reducing the

duration of project. can decrease about four times

of the construction cost because of its simplicity,

materials’ saving and short time productivity (10

houses in one day, for example).

• Can reduce the cost of materials, because it is

waste less process.

• Can reduce the labor cost.

• Can save the life of labors, because it is very safe

method of construction.

Department of civil engineering, RNSIT, Bengaluru 16

APPLICATIONS Cont…

3. SPACE TECHNOLGY

• Laboratories or manufacturing facilities is the key

element for long-term human survival on the

Moon or Mars.

• Contour Crafting technology has the potential to

build safe reliable, and affordable lunar and

Martian structures.

• Systems are being developed that exploit in situ

resources and can utilize lunar regolith as

construction material.

Department of civil engineering, RNSIT, Bengaluru 17

ADVANTAGES

• Economical

• Environmental friendly

• Great architectural flexibility

• High speed of construction

• No wastage of materials

DISADVANTAGES

• The foundation has to be built using Traditional

Methods.

• High Switching Costs for Construction Companies.

Department of civil engineering, RNSIT, Bengaluru 18

HUASHAG TENGDA : MANSION

• In Beijing ,the Chinese construction company HuaShang Tengda constructed a

400-square-meter mansion using 3D concrete printers to complete this project

in just 45 days.

• This project is especially impressive because the mansion is earthquake proof

and can withstand quakes up to magnitudes of 8 on the Richter scale.

• The walls of the mansion are 250 mm thick and were printed using

approximately 20 tons of C30 concrete.

Department of civil engineering, RNSIT, Bengaluru 19

CONCLUSION

• Due to its speed and its ability to use in-situ

materials, Contour Crafting has the potential

for immediate application in low income

housing and emergency shelter construction.

• Construction machines built for Contour

Crafting may be fully electric and hence

emission free.

• There are numerous research tasks that need to

be undertaken to bring the CC construction

technology to commercial use.

Department of civil engineering, RNSIT, Bengaluru 20

REFERENCES

REFERENCE

1. Hrishekesh V. Patil (2019) “Contour Crafting (A Management

Tool for Swift Construction)”

2. Ali Mokhtari (2018) “Automatic Construction by Contour

Crafting Technology”

3. William J. Leonard (2017) “Case Study on 3D Printing

Implementation Strategies”

Department of civil engineering, RNSIT, Bengaluru 21

Das könnte Ihnen auch gefallen

- Automation and Robotics in Construction XIVon EverandAutomation and Robotics in Construction XIAlan ChamberlainNoch keine Bewertungen

- Contour CraftingDokument43 SeitenContour CraftingTEMY PETERNoch keine Bewertungen

- Architectural Style of CHARANJIT SHAHDokument7 SeitenArchitectural Style of CHARANJIT SHAHApoorv KalraNoch keine Bewertungen

- Civil Engineering Seminar Topics - Mivan TechnologyDokument17 SeitenCivil Engineering Seminar Topics - Mivan TechnologyNikhil ThoteNoch keine Bewertungen

- Final Internship PresentationDokument16 SeitenFinal Internship PresentationephNoch keine Bewertungen

- SELF HEALING OF CONCRETE Pranayyy2Dokument21 SeitenSELF HEALING OF CONCRETE Pranayyy2Kalyan Reddy AnuguNoch keine Bewertungen

- For Cement in Concrete: Bagasse Ash As Partially ReplacementDokument20 SeitenFor Cement in Concrete: Bagasse Ash As Partially ReplacementSheraz JamaliNoch keine Bewertungen

- 12.project Report IDokument52 Seiten12.project Report IsrinivasanNoch keine Bewertungen

- Seminar Report (1) .docxNEWDokument16 SeitenSeminar Report (1) .docxNEWMd AwesshadabNoch keine Bewertungen

- Seminar Report On Highway Management SystemDokument22 SeitenSeminar Report On Highway Management SystemAditya ansuman RoutNoch keine Bewertungen

- Slip FormationDokument28 SeitenSlip Formationpawan_aggarwal_22100% (2)

- Academic Site Visit Report On Design of Steel Structures at Kimaya SteelDokument16 SeitenAcademic Site Visit Report On Design of Steel Structures at Kimaya SteelKiranMDeoreNoch keine Bewertungen

- Seminar 33 1gd17cv012Dokument22 SeitenSeminar 33 1gd17cv012Nithesh KumarNoch keine Bewertungen

- Civil Engineering Training College ReportDokument23 SeitenCivil Engineering Training College ReportabhishekNoch keine Bewertungen

- ATMOSPHERIC WATER GENERATOR Project Report Unais PPDokument27 SeitenATMOSPHERIC WATER GENERATOR Project Report Unais PPThe REBELNoch keine Bewertungen

- A Project Report On Earthquake Resistant Building Using E Tabs and Manual Designing. PaperDokument3 SeitenA Project Report On Earthquake Resistant Building Using E Tabs and Manual Designing. PaperAbdul RazzakNoch keine Bewertungen

- A Project On Nagarjuna DamDokument3 SeitenA Project On Nagarjuna Damapi-19889358Noch keine Bewertungen

- Mivan TechnologyDokument14 SeitenMivan TechnologyBro PatilNoch keine Bewertungen

- 2007-Mechanical and Civil Engineering-PatilDokument3 Seiten2007-Mechanical and Civil Engineering-PatilSaul Lopez MejiaNoch keine Bewertungen

- Green Concrete: WWW - SeminarDokument12 SeitenGreen Concrete: WWW - SeminarSuraj Deb BarmaNoch keine Bewertungen

- Precast Cement Concrete Block Construction - Seminar Report, PPT, PDF For Civil EngineeringDokument12 SeitenPrecast Cement Concrete Block Construction - Seminar Report, PPT, PDF For Civil EngineeringSoc Rua NguyenNoch keine Bewertungen

- Nano Concrete PPT 01JST17CV414 001Dokument22 SeitenNano Concrete PPT 01JST17CV414 001sanjayNoch keine Bewertungen

- 2016-17 Autumn 8952 20792616Dokument13 Seiten2016-17 Autumn 8952 20792616Deb PradhanNoch keine Bewertungen

- Seminar Report CivilDokument46 SeitenSeminar Report CivilHemam Prasanta100% (2)

- Seminar Report (PRN 10009)Dokument33 SeitenSeminar Report (PRN 10009)SALONI BHOSALENoch keine Bewertungen

- Internship Trainning ReportDokument38 SeitenInternship Trainning ReportRahul Kumar DabotraNoch keine Bewertungen

- Project Report ON "Sanitation Tunnel"Dokument51 SeitenProject Report ON "Sanitation Tunnel"sayalitekeNoch keine Bewertungen

- A Project Report On Earthquake Resistant Building Using E Tabs and Manual Designing. PaperDokument9 SeitenA Project Report On Earthquake Resistant Building Using E Tabs and Manual Designing. PaperAbdul RazzakNoch keine Bewertungen

- Underwater WindmillDokument16 SeitenUnderwater Windmilldarshan aNoch keine Bewertungen

- Clay-Fly Ash Bricks: Seminar Report OnDokument29 SeitenClay-Fly Ash Bricks: Seminar Report OnadnanNoch keine Bewertungen

- Smart Police StationDokument32 SeitenSmart Police Stationshah karanNoch keine Bewertungen

- Primary SchoolDokument57 SeitenPrimary SchoolMUUTHUKRISHNAN100% (1)

- Study of Prefabrication in IndiaDokument6 SeitenStudy of Prefabrication in IndiaSayed WafiNoch keine Bewertungen

- Study and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadDokument5 SeitenStudy and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadMananNoch keine Bewertungen

- 454545454545Dokument25 Seiten454545454545Thirupathi YadavNoch keine Bewertungen

- Self Healing ConcreteDokument22 SeitenSelf Healing ConcreteVinod KumarNoch keine Bewertungen

- New Updated Project ReportDokument26 SeitenNew Updated Project ReportsharanyaNoch keine Bewertungen

- Ready Mix Concrete: Technical Seminar Report OnDokument7 SeitenReady Mix Concrete: Technical Seminar Report OnadityaNoch keine Bewertungen

- Civil Earthquake Resistent Building Construction ReportDokument25 SeitenCivil Earthquake Resistent Building Construction ReportAjay WaswaniNoch keine Bewertungen

- A Project Report On Design of EarthquakeDokument53 SeitenA Project Report On Design of EarthquakeSidd PriyamNoch keine Bewertungen

- U Boot ReportDokument17 SeitenU Boot ReportVishal RnadeNoch keine Bewertungen

- A.S Civil Engineering Project Centre: Projects Delivered To All Over Cities in Tamilnadu & India Project TitlesDokument9 SeitenA.S Civil Engineering Project Centre: Projects Delivered To All Over Cities in Tamilnadu & India Project TitlesCivil Engineering projectNoch keine Bewertungen

- Group A - Case Study - Building ServicesDokument17 SeitenGroup A - Case Study - Building ServicesEmmanuel AndenyangNoch keine Bewertungen

- U Boot TechnologyDokument22 SeitenU Boot TechnologyNaveen PipperaNoch keine Bewertungen

- Company Profile: - Name of The CompanyDokument41 SeitenCompany Profile: - Name of The CompanyPreetham N ANoch keine Bewertungen

- Transparent Concrete Report 11Dokument13 SeitenTransparent Concrete Report 11Rachitha PrachithaNoch keine Bewertungen

- Research Project ReportDokument55 SeitenResearch Project ReportShashank VermaNoch keine Bewertungen

- General Seminar Report PDFDokument21 SeitenGeneral Seminar Report PDFabuzarNoch keine Bewertungen

- Dissertation Body - Final For Printing PDFDokument54 SeitenDissertation Body - Final For Printing PDFLivya RobyNoch keine Bewertungen

- Mivan 5 PDFDokument9 SeitenMivan 5 PDFUtkarsh SuranaNoch keine Bewertungen

- Seminar Report-ModelDokument21 SeitenSeminar Report-ModelAMALRADH S 18B452Noch keine Bewertungen

- Civil Engineering Project On Mini Civil StationDokument93 SeitenCivil Engineering Project On Mini Civil StationMahaManthraNoch keine Bewertungen

- Sludge Bricks NewDokument14 SeitenSludge Bricks Newvadluri NishiNoch keine Bewertungen

- Prefabricated Multistory Structure Exposure To Engineering Seismicity by Using SAPDokument9 SeitenPrefabricated Multistory Structure Exposure To Engineering Seismicity by Using SAPInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- U Boot BetonDokument23 SeitenU Boot BetonMegha KallihalNoch keine Bewertungen

- Visvesvaraya Technological University: Jnana Sangama, Belagavi - 590 001Dokument5 SeitenVisvesvaraya Technological University: Jnana Sangama, Belagavi - 590 001ShainNoch keine Bewertungen

- Water Gems SyllabusDokument2 SeitenWater Gems SyllabusDeepak BharatiNoch keine Bewertungen

- Comparative Analysis On Cost and Duration of MIVAN Formwork Building and Conventional Formwork Building PDFDokument3 SeitenComparative Analysis On Cost and Duration of MIVAN Formwork Building and Conventional Formwork Building PDFSanjay Dhariwal JainNoch keine Bewertungen

- Earthquake Resistant Building Seminar ReportDokument4 SeitenEarthquake Resistant Building Seminar ReportRaju KINGNoch keine Bewertungen

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Von EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Noch keine Bewertungen

- Smart MaterialsDokument24 SeitenSmart MaterialsSrinivas B VNoch keine Bewertungen

- Vacuum DewaterDokument16 SeitenVacuum DewaterSrinivas B VNoch keine Bewertungen

- Case Study On 3D Printing Implementation StrategiesDokument7 SeitenCase Study On 3D Printing Implementation StrategiesSrinivas B VNoch keine Bewertungen

- Srinivas ReportDokument20 SeitenSrinivas ReportSrinivas B VNoch keine Bewertungen

- Visvesvaraya Technological University: Srinivas B V 1RN16CV051Dokument20 SeitenVisvesvaraya Technological University: Srinivas B V 1RN16CV051Srinivas B VNoch keine Bewertungen

- Visvesvaraya Technological University: Srinivas B V 1RN16CV051Dokument20 SeitenVisvesvaraya Technological University: Srinivas B V 1RN16CV051Srinivas B VNoch keine Bewertungen

- Foam ConcreteDokument25 SeitenFoam ConcreteSrinivas B VNoch keine Bewertungen

- Doglegged Stair Case: Floor LevelDokument1 SeiteDoglegged Stair Case: Floor LevelSrinivas B VNoch keine Bewertungen

- Lintel and Sunshade: 2T 12 Anchor BarsDokument1 SeiteLintel and Sunshade: 2T 12 Anchor BarsSrinivas B VNoch keine Bewertungen

- Doglegged Stair Case: Floor LevelDokument1 SeiteDoglegged Stair Case: Floor LevelSrinivas B VNoch keine Bewertungen

- Lintel and Sunshade: 2T 12 Anchor BarsDokument1 SeiteLintel and Sunshade: 2T 12 Anchor BarsSrinivas B VNoch keine Bewertungen

- D6-Model pdf6 PDFDokument1 SeiteD6-Model pdf6 PDFSrinivas B VNoch keine Bewertungen

- Irjet V3i12208 PDFDokument4 SeitenIrjet V3i12208 PDFSrinivas B VNoch keine Bewertungen

- D6-Model pdf6 PDFDokument1 SeiteD6-Model pdf6 PDFSrinivas B VNoch keine Bewertungen

- Seismic Performance of Multi-Storey RCC Building With Floating ColumnsDokument12 SeitenSeismic Performance of Multi-Storey RCC Building With Floating ColumnsSrinivas B VNoch keine Bewertungen

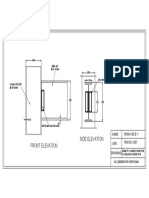

- Front Elevation Side Elevation: 300 ISMB 400 at 61.6 KG/M 250Dokument1 SeiteFront Elevation Side Elevation: 300 ISMB 400 at 61.6 KG/M 250Srinivas B VNoch keine Bewertungen

- Voice Communication Between Humans and MachinesDokument559 SeitenVoice Communication Between Humans and MachinesNamaku AjiNoch keine Bewertungen

- HaTelit Presentation 2Dokument18 SeitenHaTelit Presentation 2Bagas YandiNoch keine Bewertungen

- 2013 SKF Training Handbook: Reliability Maintenance InstituteDokument134 Seiten2013 SKF Training Handbook: Reliability Maintenance InstituteBalázs HernádiNoch keine Bewertungen

- BPV Certification Form Checklist AccreditationDokument13 SeitenBPV Certification Form Checklist AccreditationAnonymous XBq5J84Noch keine Bewertungen

- Mechatronics Lecture NotesDokument272 SeitenMechatronics Lecture Notesdanrcg100% (1)

- Mastip Technology IntroductionDokument12 SeitenMastip Technology IntroductionQuang PhamNoch keine Bewertungen

- CSY3013 SE3 Brief Assignment 1-23-24Dokument9 SeitenCSY3013 SE3 Brief Assignment 1-23-24anishgajurel7Noch keine Bewertungen

- Irc LoadingDokument5 SeitenIrc LoadingSeethapathi Asst. Professor-Sr.ScaleNoch keine Bewertungen

- A Mini Project 12Dokument33 SeitenA Mini Project 12Sai Raghu Nath Goud100% (1)

- A516 MaterialDokument3 SeitenA516 MaterialductaiutcNoch keine Bewertungen

- D 2938 - 95 R02 PDFDokument3 SeitenD 2938 - 95 R02 PDFJosephNoch keine Bewertungen

- Agile TestingDokument2 SeitenAgile TestingYogesh KumbharNoch keine Bewertungen

- LPICDokument2 SeitenLPICLaith MousaNoch keine Bewertungen

- 06 EC2WS Frank Geotechnics PDFDokument55 Seiten06 EC2WS Frank Geotechnics PDFLuigiForgerone100% (1)

- Ritek Design GuideDokument191 SeitenRitek Design GuideAnonymous YW5mvpNoch keine Bewertungen

- BTP Assignment Set - 2018 PDFDokument17 SeitenBTP Assignment Set - 2018 PDF9510851294Noch keine Bewertungen

- Mechanical Engineering Study Plan (139 Credit Hours) : First Semester Second SemesterDokument1 SeiteMechanical Engineering Study Plan (139 Credit Hours) : First Semester Second Semesterاحمد حسنNoch keine Bewertungen

- Software Project Management, Walker Royce Pearson Education, 2005-2-1-21-27-9Dokument2 SeitenSoftware Project Management, Walker Royce Pearson Education, 2005-2-1-21-27-9hugoqbNoch keine Bewertungen

- DSI Geotechnic en PDFDokument44 SeitenDSI Geotechnic en PDFAhmed Mostafa AL-AboudyNoch keine Bewertungen

- Signals and Systems Course PlanDokument6 SeitenSignals and Systems Course Planaarthi.lj5371Noch keine Bewertungen

- The Ultimate Electrical Engineering Book List With Emphasis On ElectromagneticsDokument15 SeitenThe Ultimate Electrical Engineering Book List With Emphasis On ElectromagneticsAsdf FdsaNoch keine Bewertungen

- Testing A Metalenclosed Bus PDFDokument10 SeitenTesting A Metalenclosed Bus PDFTunoNegro1Noch keine Bewertungen

- CV AshutoshDokument2 SeitenCV AshutoshAshutoshNoch keine Bewertungen

- Warehouse Design & LayoutDokument39 SeitenWarehouse Design & Layoutarya ramadhanuNoch keine Bewertungen

- Civil Offer LetterDokument4 SeitenCivil Offer LetterArjit Singh80% (5)

- Final Even Sem Exam-May-2017Dokument17 SeitenFinal Even Sem Exam-May-2017Vara PrasadNoch keine Bewertungen

- 13 - Structural Design Retaining Walls-3Dokument23 Seiten13 - Structural Design Retaining Walls-3faridhassaniNoch keine Bewertungen

- Norsok MDS TableDokument2 SeitenNorsok MDS TableerstendrainNoch keine Bewertungen

- DDRCS Project IS Codes-1Dokument3 SeitenDDRCS Project IS Codes-1Devendra SharmaNoch keine Bewertungen

- Arc Flash Risk Assessment MethodologyDokument5 SeitenArc Flash Risk Assessment MethodologypecampbeNoch keine Bewertungen