Beruflich Dokumente

Kultur Dokumente

Cofferdams: Civil Engineering Practice (CE-203)

Hochgeladen von

Ali100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

45 Ansichten31 SeitenOriginaltitel

5. Cofferdams.pptx

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

45 Ansichten31 SeitenCofferdams: Civil Engineering Practice (CE-203)

Hochgeladen von

AliCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 31

Cofferdams

Civil Engineering Practice (CE-203)

Department of Civil Engineering

University of Engineering & Technology, Taxila, Pakistan

Cofferdams

A cofferdam is a temporary structure designed to keep water

and/or soil out of the excavation in which a bridge pier or other

structure is built.

When construction must take place below the water level, a

cofferdam is built to give workers a dry work environment. Sheet

piling is driven around the work site, seal concrete is placed into

the bottom to prevent water from seeping in from underneath

the sheet piling, and the water is pumped out.

The word "cofferdam" comes from "coffer" meaning box, in other

words a dam in the shape of a box.

Use of Cofferdam

For dam construction, two cofferdams are usually built, one

upstream and one downstream of the proposed dam, after an

alternative diversion tunnel or channel has been provided for the

river flow to bypass the dam foundation area.

These cofferdams are typically a conventional embankment dam

of both earth and rock fill, but concrete or some sheet piling also

may be used.

Typically, upon completion of the dam and associated structures,

the downstream coffer is removed and the upstream coffer is

flooded as the diversion is closed and the reservoir begins to fill.

Use of Cofferdam

Dependent upon the geography of a dam site, in some

applications, a "U"-shaped cofferdam is used in the construction

of one half of a dam.

When complete, the cofferdam is removed and a similar one is

created on the opposite side of the river for the construction of

the dam's other half.

Types of Cofferdams

Considering the material used in their construction, cofferdams

may be divided into the following categories.

1. Earthen cofferdam

2. Rock-fill cofferdam

3. Single-walled cofferdam

4. Double-walled cofferdam

5. Crib cofferdam

6. Cellular cofferdam (Circular or diaphragm type)

Types of Cofferdams

1. Earthen Cofferdam

Types of Cofferdams

1. Earthen Cofferdam

It essentially consists of an earthen embankment built around

the area to be enclosed. It is constructed in places where the

depth of water is not much, say 13 to 18 in. and the velocity of the

current is very low.

As a precautionary measure, the earth bank is carried about one

meter above the water level. The top width of the bank should

not be less than 1 in. and the side slopes in a vary from 1 : 1 to 1 :

2. The earth embankment should be built from a mixture of clay

and sand or clay and gravel.

If the estimated quantity of clay is not easily obtainable, the

banks may be constructed with a central clay wall with slopes of

sand on either side.

Types of Cofferdams

1. Earthen Cofferdam

In order to prevent the embankment from scouring due to the

action of water, side slopes of the bank on water side should be

pitched with rubble boulders. If the current of water is such that

there is a danger of the earthen embankment getting washed

away, canvas bags half filled with material of embankment

(mixture of clay, sand or gravel) are stacked one over the other to

form the embankment.

After the work of construction of cofferdam is over, the water

from the enclosed area is pumped out so as to leave a dry surface

inside. Excavations can then be performed to the required depth

and the work of construction of foundations carried out.

Types of Cofferdams

2. Rock Fill Cofferdam

If the depth of water to be retained by the embankment of

cofferdam that is of order of 18 to 30 in., stone or rubble is used

for the embankment.

This construction is adopted only if the stone is easily available

in the nearby areas. The stones are assembled in the required

shape of the embankment and the voids are partially filled with

earth and stone-chips. The side slope on the water side is

protected by pitching.

Types of Cofferdams

3. Single-Walled Coffer Dam

Types of Cofferdams

3. Single-Walled Coffer Dam

This type of cofferdam is used in places where the area to be

enclosed is very small and the depth of water is more, say 4.5 to 6

m.

Timber piles known as guide piles are first driven deep into the

firm ground below the river bed. Depending upon the velocity of

the current of the water in the river, the centre to centre spacing

of the piles may vary between 1.8 to 4 m. Longitudinal runners

called wales are then bolted to the guide piles at suitable

distance apart.

Types of Cofferdams

3. Single-Walled Coffer Dam

Steel or wooden sheet piles are then driven into the river bed

along the wales and are secured to the wales by bolts.

The sheets on the two faces arc braced by trussed arrangement of

struts. This helps in increasing the stability of walls against the

water pressure.

Half-filled bags of sand stacked on the inside and the outside

faces of the sheets help in increasing the stability of cofferdam.

After the cofferdam is constructed, the water in the enclosed area

is pumped out and the construction work is taken up.

Types of Cofferdams

4. Double-Walled Cofferdam

Types of Cofferdams

4. Double-Walled Cofferdam

Its construction is same as that of a single-walled cofferdam except

that in place of one wall, a pair of walls with a gap in between is

used all along the boundary of the space to be enclosed. This type

of cofferdam can be used in depth of water up to 12 m.

As the depth of water increases, the wall should be made wider in

order to make it stable against overturning and sliding. The

distance between the two walls depends upon the depth of water.

The thickness of wall should be equal to the depth of water up to 3

m.

For greater depths of water, the thickness of wall should be 3 m.

plus ½ the depth of water in excess of 3 m. At their top, the two

faces of the walls are connected by steel rods spaced at close

intervals. To prevent the leakage from the ground below, the sheet

piles are driven to a good depth in the bed.

Types of Cofferdams

5. Crib Cofferdam

Types of Cofferdams

5. Crib Cofferdam

A crib is a framework of horizontal timbers installed in alternate

courses to form pockets which can be filled with earth or stones.

The length and breadth of each crib depend upon the depth of

water and the current of flow.

The framework of the cofferdam (made from, logs of wood) is

prepared on ground and then floated to the site where the

cofferdam is to be constructed.

The layers of sand and the other loose material overlying the

impervious hard bed is dredged out.

Types of Cofferdams

5. Crib Cofferdam

Crib is then sunk to the position, the bottom of each crib is given

a shape to fit in the variation in the surface of bed rock.

The space inside the crib is then filled with stone or any other

material, so as to make it stable against sliding and overturning.

Timber or steel sheet piles are then driven around the crib.

Types of Cofferdams

6. Cellular Cofferdam

This type of cofferdam is mostly used for de-watering large areas

in places where the depth of water may be of the order of 18 to 21

m.

Cellular cofferdams are mostly used during the construction of

marine structures like dams, locks, wharves etc.

Cellular cofferdam is made by driving straight web steel sheet

piles, arranged to from a series of inter-connected cells.

The cells are constructed in various shapes and styles to suit the

requirements of site.

Finally the cells are filled with clay, sand or gravel to make them

stable against the various forces to which they are likely to be

subjected to.

Types of Cofferdams

6. Cellular Cofferdam

The two common shapes of the cellular cofferdam are:

i. Circular type cellular cofferdam

ii. Diaphragm type cellular cofferdam

Types of Cofferdams

6. Cellular Cofferdam

i. Circular Type

Types of Cofferdams

6. Cellular Cofferdam (Circular Type)

The circular type of cellular cofferdam has the advantage that

each cell may be filled completely to the top before starting the

construction of the next cell without causing any distortion to

the shell of the cofferdam.

Thus, when one cell is completely filled up it can be used for

placing crane or other equipment required for the construction

of other cells.

In addition, each cell acts as a self-supporting independent unit

and in case one of the cells collapses due to scour or interlock

damage or some other reason, it does not produce any adverse

effect on the neighboring cells it is found that the interlock

stresses reach their maximum permissible value when the

diameter of cell is about 21 meter.

Types of Cofferdams

6. Cellular Cofferdam

ii. Diaphragm Type

Types of Cofferdams

6. Cellular Cofferdam (Diaphragm Type)

This consists of a series of diaphragm of steel sheet piles

connected as shown in the figure.

The straight diaphragm wails are connected to each other by

steel piles arranged in the form of arches on either sides.

The radius of the connecting arcs is generally made equal to the

distance between the straight diaphragm walls. With this

arrangement, the tension in the arcs and cross wails remain

equal.

After the cells are driven to the required depth, they are filled

with earth, sand, gravel or other filling material.

Advantages of Cofferdam

Performing work over water has always been more difficult and

costly than performing the same work on land.

When the work is performed below water, the difficulties and

cost difference can increase geometrically with the depth at

which the work is performed.

The key to performing marine construction work efficiently is to

minimize work over water, and perform as much of the work as

possible on land.

Advantages of Cofferdam

Below some of the advantages of cofferdams are listed:

a. Allow excavation and construction of structures in otherwise

poor environment.

b. Provides safe environment to work.

c. Steel sheet piles are easily installed and removed.

d. Materials can typically be reused on other projects.

e. Contractors typically have design responsibility.

Cofferdam Components

Main components of the cofferdams are the following:

1. Sheet Piles

2. Bracing Frame

3. Concrete Seal

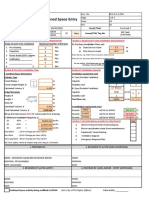

Cofferdam Components

Typical Cofferdam without seal or piles

Cofferdam Components

Typical Cofferdam with seal and piles

Cofferdam Components

1. Sheet Piling

Sheet piling is a manufactured construction product with a

mechanical connection “interlock” at both ends of the section.

These mechanical connections interlock with one another to

form a continuous wall of sheeting.

Sheet pile applications are typically designed to create a rigid

barrier for earth and water, while resisting the lateral pressures

of those bending forces.

The shape or geometry of a section lends to the structural

strength. In addition, the soil in which the section is driven has

numerous mechanical properties that can affect the

performance.

Cofferdam Components

2. Bracing Frame

The typical cofferdam, such as a bridge pier, consists of sheet

piles set around a bracing frame and driven into the soil

sufficiently far to develop vertical and lateral support and to cut

off the flow of soil and, in some cases the flow of water.

The structure inside may be founded directly on rock or firm soil

or may require pile foundations. In the latter case, these

generally extend well below the cofferdam.

Cofferdam Components

3. Concrete Seal

Inside excavation is usually done using clam shell buckets. In

order to dewater the cofferdam, the bottom must be stable and

able to resist hydrostatic uplift.

Placement of an underwater concrete seal course is the fastest

and most common method.

An underwater concrete seal course may then be placed prior to

dewatering in order to seal off the water, resist its pressure, and

also to act as a slab to brace against the inward movement of the

sheet piles in order to mobilize their resistance to uplift under

the hydrostatic pressure .

Das könnte Ihnen auch gefallen

- Assignment 9.3 - DamsDokument6 SeitenAssignment 9.3 - DamsJurel GonzalesNoch keine Bewertungen

- Mohamed Elfatih - TechnicalDokument11 SeitenMohamed Elfatih - Technical6qwhnq9z4h100% (1)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Von EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Noch keine Bewertungen

- Final ProposalDokument23 SeitenFinal Proposalpriyanshu pathakNoch keine Bewertungen

- Stone Pitching 22Dokument2 SeitenStone Pitching 22Deven Patle100% (1)

- Making ways for better days with soil stabilizationDokument36 SeitenMaking ways for better days with soil stabilizationJean MbuNoch keine Bewertungen

- Chapter 1 and 2Dokument27 SeitenChapter 1 and 2Carlo Magistrado PadillaNoch keine Bewertungen

- Civil Engineering Final Year Project Ideas ListDokument3 SeitenCivil Engineering Final Year Project Ideas ListDHARANI SHANMUGAM100% (1)

- 1 What Is LevelingDokument19 Seiten1 What Is LevelingAbduraman Isa100% (1)

- Retrofit CFRP Seminar FinalDokument24 SeitenRetrofit CFRP Seminar FinalSachin H MNoch keine Bewertungen

- Dam Seepage ExplainedDokument12 SeitenDam Seepage ExplainedCzar Alexis FernandezNoch keine Bewertungen

- Types of PavementDokument10 SeitenTypes of Pavementmohsen.911.mkNoch keine Bewertungen

- Prefaricated Structures Unit IIIDokument53 SeitenPrefaricated Structures Unit IIIvgshankar26100% (1)

- Chapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Dokument30 SeitenChapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Frederick AgliamNoch keine Bewertungen

- Field TripDokument16 SeitenField TripChidi HenryNoch keine Bewertungen

- 60 PDFDokument7 Seiten60 PDFYogiIndraPrayogaNoch keine Bewertungen

- Geotechnical Investigation Group 38Dokument30 SeitenGeotechnical Investigation Group 38nyangoma vivian100% (1)

- Project Journal 2Dokument4 SeitenProject Journal 2Victor SalamiNoch keine Bewertungen

- FerroDokument129 SeitenFerrosureshrakesh0% (1)

- Claycrete English v3Dokument22 SeitenClaycrete English v3supernaenergy100% (1)

- Green Concrete Composition 1Dokument3 SeitenGreen Concrete Composition 1Shubham SinghNoch keine Bewertungen

- Technical Design Manual: Rainscapes Permeable PavementDokument29 SeitenTechnical Design Manual: Rainscapes Permeable PavementGeorge ClooneyNoch keine Bewertungen

- Research ProposalDokument10 SeitenResearch ProposalshrikantharleNoch keine Bewertungen

- A Road Building Opportunity PURE - CRETE - Eng - 02252011Dokument48 SeitenA Road Building Opportunity PURE - CRETE - Eng - 02252011PAYLEUNoch keine Bewertungen

- Dam Construction: Aggregate Production - The Acceptability of Natural Aggregates Is Judged Upon The PhysicalDokument4 SeitenDam Construction: Aggregate Production - The Acceptability of Natural Aggregates Is Judged Upon The PhysicalAbdi KaamilNoch keine Bewertungen

- Geopolymeric Building Materials by Synergetic Utilisation of Industrial WastesDokument2 SeitenGeopolymeric Building Materials by Synergetic Utilisation of Industrial WastesNithin Devarajan67% (3)

- What Is Floor Screed - Its Types, Materials, Construction and UsesDokument5 SeitenWhat Is Floor Screed - Its Types, Materials, Construction and UsesJustin MusopoleNoch keine Bewertungen

- CC Road Construction: Materials, Machinery and StepsDokument18 SeitenCC Road Construction: Materials, Machinery and StepsJayesh GojiyaNoch keine Bewertungen

- Introduction Classification Advantages and Disadvantages Site Selection Selection of Type of DamDokument30 SeitenIntroduction Classification Advantages and Disadvantages Site Selection Selection of Type of DamKubaNoch keine Bewertungen

- Sewer AppurtenancesDokument19 SeitenSewer AppurtenancesReshmy M RajuNoch keine Bewertungen

- Types of PavementDokument4 SeitenTypes of Pavementibrahim0007100% (1)

- Test 1 - Concrete Mix Design DishanDokument20 SeitenTest 1 - Concrete Mix Design DishanYasndra AbeygunewardhaneNoch keine Bewertungen

- Types of Diversion Headworks WeirsDokument14 SeitenTypes of Diversion Headworks WeirsRAKESH KUMAR 061Noch keine Bewertungen

- Box Pushing Technology PresentationDokument13 SeitenBox Pushing Technology PresentationVirendra Kumar PareekNoch keine Bewertungen

- Flexible PavementsDokument13 SeitenFlexible PavementsAhmad NajiNoch keine Bewertungen

- Sand Replacement by Glass Powder in ConcreteDokument41 SeitenSand Replacement by Glass Powder in Concretewaquar khan100% (2)

- Unit - IV Consolidation of SoilDokument64 SeitenUnit - IV Consolidation of Soilgopierode4100% (1)

- Road Construction Inplant TrainingDokument31 SeitenRoad Construction Inplant TrainingAditya ChopraNoch keine Bewertungen

- Concrete Project ReportDokument16 SeitenConcrete Project ReportMayur Madhukar Mankar100% (1)

- Chapter 4 Pre-Stressed ConcreteDokument23 SeitenChapter 4 Pre-Stressed ConcreteDdeqz Elina Bueno INoch keine Bewertungen

- Module 5 - Part 1 (Ce 361 - Advanced Concrete Technology)Dokument13 SeitenModule 5 - Part 1 (Ce 361 - Advanced Concrete Technology)lakshmi dileepNoch keine Bewertungen

- PHASE 1 PPT CRCTDDokument14 SeitenPHASE 1 PPT CRCTDSudhira ShettyNoch keine Bewertungen

- 8 Assessment of Factors Affecting Labor Productivity On Road Construction ProjectsDokument12 Seiten8 Assessment of Factors Affecting Labor Productivity On Road Construction Projectsemer_quezonNoch keine Bewertungen

- Brick Laying1Dokument9 SeitenBrick Laying1সন্দীপ চন্দ্রNoch keine Bewertungen

- GGBS Effect on Concrete Properties Self-StudyDokument16 SeitenGGBS Effect on Concrete Properties Self-Studysuraj george kNoch keine Bewertungen

- Civil Highway Network System ReportDokument30 SeitenCivil Highway Network System Reportsayali patilNoch keine Bewertungen

- Soil Stabilization Methods ExplainedDokument8 SeitenSoil Stabilization Methods Explainedhimabindugvsd71Noch keine Bewertungen

- Final Project ReportDokument40 SeitenFinal Project Reportmariam100% (1)

- Earth Dam LectureDokument32 SeitenEarth Dam Lecturejahid shohagNoch keine Bewertungen

- Submitted By: Garvit Goyal B.Tech 4 Year Civil BranchDokument23 SeitenSubmitted By: Garvit Goyal B.Tech 4 Year Civil BranchAfghanistan AfghanNoch keine Bewertungen

- Selection of FoundationDokument16 SeitenSelection of FoundationroshanNoch keine Bewertungen

- Lecture 5 Highway Construction MaterialsDokument15 SeitenLecture 5 Highway Construction MaterialsCherylNoch keine Bewertungen

- Strength Properties of Coconut Shell ConcreteDokument9 SeitenStrength Properties of Coconut Shell Concreteabdul imranNoch keine Bewertungen

- Green Concrete: An Environmentally Friendly Building MaterialDokument19 SeitenGreen Concrete: An Environmentally Friendly Building MaterialSatyam SatyaNoch keine Bewertungen

- Floor Finishes: Chitkara School of Planning & Architecture, Chitkara UniversityDokument36 SeitenFloor Finishes: Chitkara School of Planning & Architecture, Chitkara UniversityArsh ChaudharyNoch keine Bewertungen

- Common Plumbing Fixtures and Installation RequirementsDokument23 SeitenCommon Plumbing Fixtures and Installation RequirementsashuNoch keine Bewertungen

- Construction of Road Foundation On Soft SoilDokument8 SeitenConstruction of Road Foundation On Soft SoilAnuragBajpai0% (1)

- Thermal Stresses and Temperature Control of Mass ConcreteVon EverandThermal Stresses and Temperature Control of Mass ConcreteNoch keine Bewertungen

- Ecohydrology: Vegetation Function, Water and Resource ManagementVon EverandEcohydrology: Vegetation Function, Water and Resource ManagementNoch keine Bewertungen

- Stability of SlopesDokument72 SeitenStability of SlopesAliNoch keine Bewertungen

- TunnelingDokument39 SeitenTunnelingAliNoch keine Bewertungen

- Management: Notes byDokument108 SeitenManagement: Notes byAliNoch keine Bewertungen

- Lateral Earth Pressure PDFDokument33 SeitenLateral Earth Pressure PDFAliNoch keine Bewertungen

- Earth MovingDokument63 SeitenEarth MovingAliNoch keine Bewertungen

- Construction - Defects - PPTX.PPTX Filename UTF-8''6. Construction DefectsDokument79 SeitenConstruction - Defects - PPTX.PPTX Filename UTF-8''6. Construction DefectsAliNoch keine Bewertungen

- Soil Mechanics - Ii: Lecture No.15Dokument73 SeitenSoil Mechanics - Ii: Lecture No.15Ali100% (1)

- Permeabilty: Soil Mechanics - IiDokument48 SeitenPermeabilty: Soil Mechanics - IiAliNoch keine Bewertungen

- Bearing Capacity of SoilDokument23 SeitenBearing Capacity of SoilAliNoch keine Bewertungen

- Construction - Defects - PPTX.PPTX Filename UTF-8''6. Construction DefectsDokument79 SeitenConstruction - Defects - PPTX.PPTX Filename UTF-8''6. Construction DefectsAliNoch keine Bewertungen

- Construction Machinery: Civil Engineering Practice (CE-203)Dokument81 SeitenConstruction Machinery: Civil Engineering Practice (CE-203)AliNoch keine Bewertungen

- Civil Engineering Practice (CE-203)Dokument63 SeitenCivil Engineering Practice (CE-203)AliNoch keine Bewertungen

- Civil Engineering Practice (CE-203)Dokument31 SeitenCivil Engineering Practice (CE-203)AliNoch keine Bewertungen

- TunnelingDokument39 SeitenTunnelingAliNoch keine Bewertungen

- Construction MachineryDokument81 SeitenConstruction MachineryAliNoch keine Bewertungen

- Cofferdams, Construction ProcedureDokument15 SeitenCofferdams, Construction ProcedurefleaxxNoch keine Bewertungen

- General Psychology Module 1.1Dokument6 SeitenGeneral Psychology Module 1.1Niño Gabriel MagnoNoch keine Bewertungen

- Porter's Five Forces: Submitted by Subham Chakraborty PGDMDokument5 SeitenPorter's Five Forces: Submitted by Subham Chakraborty PGDMSubham ChakrabortyNoch keine Bewertungen

- Middle Range TheoriesDokument134 SeitenMiddle Range TheoriesMary Joyce MejiaNoch keine Bewertungen

- Baumann Forklift Dx50!14!40 S N 5361 Spare Parts CatalogueDokument22 SeitenBaumann Forklift Dx50!14!40 S N 5361 Spare Parts Catalogueanneclark120297mgz100% (108)

- Ecco ADokument5 SeitenEcco Aouzun852Noch keine Bewertungen

- The Art of Grooming - 230301 - 222106Dokument61 SeitenThe Art of Grooming - 230301 - 222106ConstantinNoch keine Bewertungen

- IEC 60793-1-30-2001 Fibre Proof TestDokument12 SeitenIEC 60793-1-30-2001 Fibre Proof TestAlfian Firdaus DarmawanNoch keine Bewertungen

- AGITAN Defoamer Technologies PDFDokument15 SeitenAGITAN Defoamer Technologies PDFMarco Lopez100% (1)

- Experiment 4 The DC Compound Generator: Muhammad Al-Ariff Bin Selamat (112215), Muhammad Azfar Amin Bin Ahmad MokhtarDokument5 SeitenExperiment 4 The DC Compound Generator: Muhammad Al-Ariff Bin Selamat (112215), Muhammad Azfar Amin Bin Ahmad MokhtarOne Love Jah LoveNoch keine Bewertungen

- Chapter 6 (Latest) - Value Orientation and Academic AchievementDokument21 SeitenChapter 6 (Latest) - Value Orientation and Academic AchievementNur Khairunnisa Nezam IINoch keine Bewertungen

- BrainSpace - January 2024 CADokument46 SeitenBrainSpace - January 2024 CARafal ZawadkaNoch keine Bewertungen

- Worksheet Chapter 50 Introduction To Ecology The Scope of EcologyDokument2 SeitenWorksheet Chapter 50 Introduction To Ecology The Scope of EcologyFernando CastilloNoch keine Bewertungen

- Area Manager ChecklistDokument7 SeitenArea Manager ChecklistUtkarsh RaiNoch keine Bewertungen

- Ventilation Plan For Confined Space EntryDokument9 SeitenVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- Snel White Paper 2020Dokument18 SeitenSnel White Paper 2020Zgodan NezgodanNoch keine Bewertungen

- Product PlanningDokument23 SeitenProduct PlanningGrechen CabusaoNoch keine Bewertungen

- Chapter 10 TestDokument7 SeitenChapter 10 Testapi-348969276Noch keine Bewertungen

- This Study Resource Was: Practice Questions and Answers Inventory Management: EOQ ModelDokument7 SeitenThis Study Resource Was: Practice Questions and Answers Inventory Management: EOQ Modelwasif ahmedNoch keine Bewertungen

- 20752-Reservoir Management Training An Lntegrated ApproachDokument6 Seiten20752-Reservoir Management Training An Lntegrated ApproachdanonninoNoch keine Bewertungen

- New Membership Application GemsDokument5 SeitenNew Membership Application Gemslaguila18Noch keine Bewertungen

- AssignmentDokument15 SeitenAssignmentWahab MirzaNoch keine Bewertungen

- Legal Opinion WritingDokument53 SeitenLegal Opinion WritingBenedict AnicetNoch keine Bewertungen

- Chapter 2 - Cross-Cultural Management SkillsDokument26 SeitenChapter 2 - Cross-Cultural Management Skillsfatematuj johoraNoch keine Bewertungen

- Building Resilience Philippines Urban PoorDokument16 SeitenBuilding Resilience Philippines Urban PoorYasmin Pheebie BeltranNoch keine Bewertungen

- Large Generator Protection enDokument14 SeitenLarge Generator Protection enNguyen Xuan TungNoch keine Bewertungen

- HydrodynamicsDokument122 SeitenHydrodynamicsIustin Cristian100% (2)

- Phy433 Lab Report 1Dokument9 SeitenPhy433 Lab Report 1rabbani abdul rahimNoch keine Bewertungen

- Axion DatabaseDokument25 SeitenAxion Databasemacy williamsNoch keine Bewertungen

- Temp Gradient For Warping Stress in Rigid PavementDokument9 SeitenTemp Gradient For Warping Stress in Rigid PavementAmul KotharkarNoch keine Bewertungen

- 005-012 Fuel Injection Pumps, In-Line: InstallDokument14 Seiten005-012 Fuel Injection Pumps, In-Line: InstallMuhammad Ishfaq100% (3)