Beruflich Dokumente

Kultur Dokumente

Kaizen Group Race 2

Hochgeladen von

Sharaf Ageed0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten27 SeitenKGR

Originaltitel

Kaizen group race 2

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenKGR

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten27 SeitenKaizen Group Race 2

Hochgeladen von

Sharaf AgeedKGR

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 27

Kaizen group race 2

1. Which of the following forms of muda is

LEAST likely to result in poor product quality?

a. Overproduction

b. Inventory

c. waiting

d. transport

1.C

2- The production of product in large lots has all

of the following disadvantages EXCEPT for:

a. Maximization of machine efficiencies

b. longer customer delivery lead time

c. additional product transportation expenses

d. potential product damage or deterioration costs

2.A

3- What is the best definition of takt time?

a. it is the speed at which parts must be

manufactured in order satisfy demand

b. it is the heartbeat of any lean system

c. It is a calculated time element that equals

customer demand

d. it is the application of kaizen to continuous flow

manufacturing

3.C

4- All of the following tools used for finding

potential causes of problems except:

a. Cause and effect diagram.

b. Ishakawa diagram.

c. Pareto diagram.

d. Fishbone diagram.

4.C

5- To Validate relationship between two

variables it is better to use:

a. Fishbone diagram

b. Pareto diagram

c. Scatter diagram

d. Control chart

5.C

6- Process mapping include all of the following

except?

a. SIPOC

b. VSM

c. CHECKSHEET

d. FLOWCHART

6.C

7- All of the above not used as a control chart

for attribute-type data except:

a. X – chart

b. np - chart

c. s – chart

d. R – chart

7.B

8. Pareto analysis is a method for:

a. prioritising data

b. to determine what percentage can be attributed

to any cause.

c. to ensure that the” vital few” are tackled first

and the “trivial many” are left for future

examination.

d. All of the above

8.D

9- Which of the following Japanese techniques is

most dearly identified with small incremental

change?

a. Kaizen

b. Kanban

c. poka – yoke

d. 5s strategy

9.A

10- An attempt to minimize the impact of

human error in a process is call:

a. jidohka

b. Kaizen

c. poka-yoke

d. muda

10.C

11- Lean thinking enables companies to:

I. Find the best way to specify value for the customer

II. Identify the value stream for each product

III. Permit the customer to pull value as needed from the

producer

IV. Reduce waste

a. I and IV only

b. II and III only

c. I, III, III and IV

d. I, II, and IV

11.C

12- Scatter diagrams used for all of the fallowing

except:

a. Validating relationship between two variables.

b. Displaying the direction of the relationship

c. Displaying the percentages and priority

relationship.

d. Displaying the strength of the relationship

12.C

13- When investigating TPM, which of the following would

NOT be considered one of the six negative contributors (Six

Losses) to equipment effectiveness?

A. Set-up and adjustment

B. reduced speed

C. reduced yield

D. work cell arrangement

13- D

Das könnte Ihnen auch gefallen

- Setting KPIs and Quality ObjectivesDokument48 SeitenSetting KPIs and Quality ObjectivesSharaf AgeedNoch keine Bewertungen

- 2 NCRs - QualityDokument3 Seiten2 NCRs - QualitySharaf AgeedNoch keine Bewertungen

- Setting KPIs and Quality ObjectivesDokument48 SeitenSetting KPIs and Quality ObjectivesSharaf AgeedNoch keine Bewertungen

- NCRs - QualityDokument8 SeitenNCRs - QualitySharaf AgeedNoch keine Bewertungen

- Internal AuditorDokument85 SeitenInternal AuditorSharaf AgeedNoch keine Bewertungen

- Doroob Endowment Co., Ltd. (Guarantee) : Octo, 2018Dokument9 SeitenDoroob Endowment Co., Ltd. (Guarantee) : Octo, 2018Sharaf AgeedNoch keine Bewertungen

- Hydroponics ManualDokument22 SeitenHydroponics ManualAbdullah Talib100% (1)

- Eai Assessment FlowchartDokument1 SeiteEai Assessment FlowchartSharaf AgeedNoch keine Bewertungen

- Ebios Exam Preparation GuideDokument9 SeitenEbios Exam Preparation GuideSharaf AgeedNoch keine Bewertungen

- 00 Aqap-2009 - Ed-3Dokument68 Seiten00 Aqap-2009 - Ed-3Sharaf AgeedNoch keine Bewertungen

- 0 Review of The Strategies For Technology Transfer in Manufacturing Sector in Developing Countries2Dokument4 Seiten0 Review of The Strategies For Technology Transfer in Manufacturing Sector in Developing Countries2Sharaf AgeedNoch keine Bewertungen

- GTC2015 - Papers List - v4 (150601)Dokument2 SeitenGTC2015 - Papers List - v4 (150601)Sharaf AgeedNoch keine Bewertungen

- Iso 45000Dokument25 SeitenIso 45000Sharaf Ageed75% (8)

- TRIZ 40 PrinciplesDokument42 SeitenTRIZ 40 Principlesjkulasa100% (3)

- Fayns Car Services: "Committed To Satisfy You"Dokument13 SeitenFayns Car Services: "Committed To Satisfy You"Sharaf AgeedNoch keine Bewertungen

- 3S HSE MS Compiance With ISO 14001 2004Dokument2 Seiten3S HSE MS Compiance With ISO 14001 2004Sharaf AgeedNoch keine Bewertungen

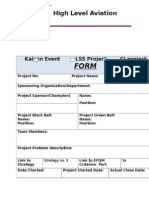

- High Level Aviation Academy: Kaizen Event LSS Project CI Project Determine Phase (Project Description)Dokument5 SeitenHigh Level Aviation Academy: Kaizen Event LSS Project CI Project Determine Phase (Project Description)Sharaf AgeedNoch keine Bewertungen

- GMP PharmaceuticalDokument2 SeitenGMP PharmaceuticalSharaf AgeedNoch keine Bewertungen

- High Level Aviation Academy: Kaizen Event LSS Project CI ProjectDokument2 SeitenHigh Level Aviation Academy: Kaizen Event LSS Project CI ProjectSharaf AgeedNoch keine Bewertungen

- Preview Gap Analysis ReportDokument5 SeitenPreview Gap Analysis ReportSharaf AgeedNoch keine Bewertungen

- KMS PractisionarDokument3 SeitenKMS PractisionarSharaf AgeedNoch keine Bewertungen

- QHSE Policy2Dokument1 SeiteQHSE Policy2Sharaf AgeedNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Chap015.ppt Independent-Demand InventoryDokument44 SeitenChap015.ppt Independent-Demand InventorySaad Khadur Eilyes100% (1)

- Chapter 13 HW SolutionsDokument41 SeitenChapter 13 HW Solutionsemaileric0% (1)

- Variable Costing - Cost Accounting QuizDokument2 SeitenVariable Costing - Cost Accounting QuizRizza Mae RodriguezNoch keine Bewertungen

- 02g MCQ Production BudgetsDokument7 Seiten02g MCQ Production BudgetsK Lam LamNoch keine Bewertungen

- Acctg U2 p2 July 2008Dokument7 SeitenAcctg U2 p2 July 2008Darion SankarNoch keine Bewertungen

- LILIANDokument36 SeitenLILIANOjay OnofreNoch keine Bewertungen

- CHL Unit 2 Task 9 ResponseDokument3 SeitenCHL Unit 2 Task 9 Responsekenneth chaunoda100% (2)

- Process Costing AssignmentDokument2 SeitenProcess Costing AssignmentHenry MaNoch keine Bewertungen

- Finman Chap3Dokument66 SeitenFinman Chap3Jollybelleann MarcosNoch keine Bewertungen

- Material Cost PDFDokument45 SeitenMaterial Cost PDFtnchsg0% (2)

- Activity Based Costing (ABC) and Just in Time Costing (JIT)Dokument18 SeitenActivity Based Costing (ABC) and Just in Time Costing (JIT)Clarissa TeodoroNoch keine Bewertungen

- SCM TransportDokument55 SeitenSCM TransportKushal KapoorNoch keine Bewertungen

- Inter - Org & Shipping NetworksDokument7 SeitenInter - Org & Shipping NetworksMohandossNoch keine Bewertungen

- CHO RUN LI s239374 - 184752 - Assignsubmission - File - Risks Optimization in SC PDFDokument6 SeitenCHO RUN LI s239374 - 184752 - Assignsubmission - File - Risks Optimization in SC PDFAndhika Supriat PutraNoch keine Bewertungen

- Game Plan Manufacturing GameDokument10 SeitenGame Plan Manufacturing GamePrathish100% (1)

- Principles of Mathematical Economics Applied To A Physical-Stores Retail BusinessDokument24 SeitenPrinciples of Mathematical Economics Applied To A Physical-Stores Retail BusinessSoumojit KumarNoch keine Bewertungen

- The Importance of Process CostingDokument3 SeitenThe Importance of Process CostingPraWin KharateNoch keine Bewertungen

- Accounting For Inventories: Key Terms and Concepts To KnowDokument23 SeitenAccounting For Inventories: Key Terms and Concepts To KnowMuhammad Fahad NaeemNoch keine Bewertungen

- QB-OSCM (204) - UnitwiseDokument3 SeitenQB-OSCM (204) - UnitwiseAmruta GholveNoch keine Bewertungen

- Sohria International Limited - StorekeeperDokument2 SeitenSohria International Limited - StorekeeperSAIDNoch keine Bewertungen

- TB1000 04 InventoryDiscussion QsDokument2 SeitenTB1000 04 InventoryDiscussion Qssamnjhmn sdNoch keine Bewertungen

- These NietoYDokument107 SeitenThese NietoYAmrik SinghNoch keine Bewertungen

- Inventory Management in Supply ChainDokument43 SeitenInventory Management in Supply ChainRashi VajaniNoch keine Bewertungen

- Multiple Choice Questions: D. Economic Order Quantity (EOQ)Dokument2 SeitenMultiple Choice Questions: D. Economic Order Quantity (EOQ)Vivek Singh SohalNoch keine Bewertungen

- Module 05-06-07 ProblemsDokument14 SeitenModule 05-06-07 ProblemsmaxzNoch keine Bewertungen

- Profit Planning: Budget - A Quantitative Plan For Acquiring and Using Resources Over A Specified Time PeriodDokument24 SeitenProfit Planning: Budget - A Quantitative Plan For Acquiring and Using Resources Over A Specified Time PeriodDahlia Abiera OritNoch keine Bewertungen

- 08032A BulletinDokument8 Seiten08032A BulletinnorisichNoch keine Bewertungen

- W2.2 SlidesDokument10 SeitenW2.2 SlidesLevan TsipianiNoch keine Bewertungen

- DBA7007Dokument8 SeitenDBA7007Rishil ShahNoch keine Bewertungen

- AP N MPS - FinalDokument40 SeitenAP N MPS - FinalKunwar RaviNoch keine Bewertungen