Beruflich Dokumente

Kultur Dokumente

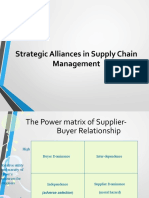

The Power Matrix of Supplier-Buyer Relationship

Hochgeladen von

selas_3819830 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

150 Ansichten32 SeitenThird-party logistics (3PL) is the evolution in logistics from suppliers focused on warehousing and transportation (thirdproviders) to suppliers offering a more integrated solution. Fourth-party logistics (4PL) refers to the suppliers offering more integrated solution. Retailer-supplier partnerships (RSP) and Distributor integration (DI) are examples of strategic alliances.

Originalbeschreibung:

Originaltitel

Strategic Alliance

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThird-party logistics (3PL) is the evolution in logistics from suppliers focused on warehousing and transportation (thirdproviders) to suppliers offering a more integrated solution. Fourth-party logistics (4PL) refers to the suppliers offering more integrated solution. Retailer-supplier partnerships (RSP) and Distributor integration (DI) are examples of strategic alliances.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

150 Ansichten32 SeitenThe Power Matrix of Supplier-Buyer Relationship

Hochgeladen von

selas_381983Third-party logistics (3PL) is the evolution in logistics from suppliers focused on warehousing and transportation (thirdproviders) to suppliers offering a more integrated solution. Fourth-party logistics (4PL) refers to the suppliers offering more integrated solution. Retailer-supplier partnerships (RSP) and Distributor integration (DI) are examples of strategic alliances.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 32

The Power matrix of Supplier-

Buyer Relationship

High

Buyer Dominance Inter-dependence

Relative utility

and scarcity of

buyer’s

resources for

suppliers

Independence Supplier Dominance

(adverse selection) (moral hazard)

Low

Low High

Relative utility and scarcity of supplier resources for buyers

Source: Andrew Cox, 2000

Critical success factors to

SA

• Trust

• Cooperation

• communication

Ways to Operate a

Company

• Internal activities

• Acquisition

• Arm’s length transaction

• Outsourcing

• Strategic alliance

Stages of Strategic Alliance

• Initial Euphoria

• Honeymoon period

• Dawning realization

• Aftershock

• Damage control

Conceptual model of alliance

development

• Alliance conceptualization

• Alliance pursuance

• Alliance confirmation

• Alliance implementation/continuity

Types of alliance

• Opportunistic alliance

• Complementary strategic alliance

Why Strategic Alliance?

• Adding value to products/services

• Improving market access

• Strengthening operations

• Adding technological strength

• Enhancing strategic growth

• Building financial strength

Types of Alliance

• Third-party logistics (3PL)

• Fourth-party logistics (4PL)

• Retailer-supplier partnerships (RSP)

• Distributor integration (DI)

Third Party Logistics

• What is 3PL?

– Outside firms perform materials management

and logistics functions

– Long term commitments and multiple functions

• What are the advantages of 3PL?

– Focus on core strengths

– Provides technological flexibility

– Provides flexibility in

• geography

• workforce size

• additional services

• resource flexibility

3PL

• Use of an outside company to perform

all or part of the form’s materials

management and product distribution

function

• Relationship vs. transactional based

• Single-function vs. multi-function

• Long-term vs. short-term commitments

3PL

• Disadvantages

– Loss of control

– 3PL employees may interact with customers

• 3PL’s address this with uniforms, logos, etc

– Sharing of confidential info

• Examples

– Simmons and Ryder Integrated Logistics

• On site rep, all logistics managed by Ryder, JIT

manufacturing

– SonicAir

• Rapid delivery of spare parts

• 67 warehouses

• Sophisticated software for inventory and rapid delivery

4PL

It refers to the evolution in logistics from

suppliers focused on warehousing and

transportation (third-party logistics

providers) to suppliers offering a more

integrated solution. Among other services,

fourth-party logistics providers include

supply chain management and solutions,

change management capabilities, and value

added services in their offering.

Strategic Alliance:

Types of SA

• Quick Response:

– Vendors receive POS data from retailers, and use

this information to synchronize production and

inventory activities at the supplier.

– The retailer still prepares individual orders, but the

POS data is used by the supplier to improve

forecasting and scheduling.

– Example: Milliken and Company: The lead time

from order receipt at Milliken’s textile plants to

final clothing receipt at several of the department

stores involved was reduced from eighteen weeks

down to three weeks.

Strategic Alliance:

Types of SA

• Continuous Replenishment: Vendors receive

POS data and use it prepare shipments at

previously agreed upon intervals to maintain

agreed to levels of inventory.

– Wal-Mart, Kmart

• Advanced Continuous Replenishment:

Suppliers may gradually decrease inventory

levels at the retailer’s store or distribution

center as long as service levels are met.

Inventory levels are thus continuously

improved in a structured way.

– Kmart

Requirements for Effective

Strategic Alliance

• Advanced information systems

• Top management commitment

– Information must be shared

– Power and responsibility within an organization

might change (for example, contact with customers

switches from sales and marketing to logistics)

• Mutual trust

– Information sharing

– Management of the entire supply chain

– Initial loss of revenues

Important SA Issues

• Inventory ownership:

– Retailer owns inventory

– Supplier owns the goods until they are

sold (consignment)

• Why would a firm do this?

• Performance measures: Fill rate,

inventory level, inventory turns

Important SA Issues

• Confidentiality

• Communication and cooperation

– When First Brands started partnering with

Kmart, Kmart often claimed that its

supplier was not living up to its agreement

to keep two weeks of inventory at all

times. It turned out that this was due to

the fact that the two companies employed

different forecasting methods.

Steps in SA Implementation

• Contractual negotiations

– Ownership

– Credit terms

– Ordering decisions

– Performance measures

• Develop or integrate information systems

• Develop effective forecasting techniques

• Develop a tactical decision support tool to

assist in coordinating inventory

management and transportation policies

Main Characteristics of SA

Criteria Decision Inventory New Skills

Types Maker Ownership Employed by vendors

Quick Retailer Retailer Forecasting Skills

Response

Continuous Contractually Agreed Either Forecasting &

Replenishment to Levels Party Inventory Control

Advanced Contractually agreed Either Forecasting &

Continuous to & Continuously Party Inventory Control

Replenishment Improved Levels

VMI Vendor Either Retail

Party Management

Advantages of SA

• Fully utilize system knowledge

– Consider the partnership between White-

Hall Robbins (W-R), who makes over-

the-counter drugs such as Advil, and

Kmart. W-R initially disagreed with Kmart

about forecasts, and in this case, it

turned out that W-R forecasts were more

accurate because they have a much

more extensive knowledge of their

products than Kmart does.

Advantages of SA

• Decrease required inventory

levels

• Improve service levels

• Decrease work duplication

• Improve forecasts

Disadvantages of SA

• Expensive advanced technology is

required.

• Supplier/retailer trust must be

developed.

• Supplier responsibility increases.

• Expenses at the supplier often

increase.

–Why? How can this be addressed?

Examples of SA Successes

and Failures

• Western Publishing-Golden Books:

– Western Publishing is using VMI for its Golden Books

line of children’s books at several retailers.

– POS data automatically triggers re-orders when

inventory falls below a reorder point.

– This inventory is delivered either to a distribution

center, or in many cases, directly to the store.

– Ownership of the books shifts to the retailer once

deliveries have been made.

– In the case of Toys R Us, the company has even

managed the entire book section for the retailer,

including inventory from suppliers other than Western

Publishing.

– Extra sales, increased costs to Western

Examples of SA Successes

and Failures

• VF Corporation’s Market Response System:

– The VF Corporation, which has many well known

brand names (including Wrangler, Lee, Girbaud,

and many others), began its VMI program in 1989.

– Currently, about 40 percent of its production is

handled using some type of automatic

replenishment scheme.

– This is particularly notable because the program

encompasses 350 different retailers, 40,000 store

locations, and more than 15 million replenishment

levels.

– VF’s program is considered one of the most

successful in the apparel industry.

Examples of SA Successes

and Failures

• Spartan Stores

– Spartan Stores, a grocery chain, shut down its

VMI effort about one year after its inception.

– One problem was that buyers were not

spending any less time on reorders than they

did before

– This was because they didn’t trust the

suppliers enough to be able to stop carefully

monitoring the inventories and deliveries of

the VMI items, and intervening at the slightest

hint of trouble.

Examples of SA Successes

and Failures

• Spartan Stores (continued)

– Suppliers didn’t do much to allay these

fears. The problems were not with the

suppliers’ forecasts; instead, they were

due to the suppliers’ inability to deal with

promotions, which are a key part of the

grocery business.

– Since they were unable to appropriately

account for promotions, delivery levels

were often unacceptably low during these

periods of peak demand.

Distributor Integration

• Parts are shared across the distributor network

• Specialized service requests are steered to

appropriate dealers or distributors.

• What is required?

– Trust

– Pledges

– Guarantees from the manufacturer

– Advanced information systems

• Disadvantages

– Incentives for dealers – are they giving away competitive

advantages?

– Skills and responsibilities are taken from some

dealers/distributors.

• Examples - Caterpillar, Okuma

Information for Coordination

of Systems

• Information is required to move from local

to global optimization

• Questions:

– Who will optimize?

– How will savings be split?

• Information is needed :

– Production status and costs

– Transportation availability and costs

– Inventory information

– Capacity information

– Demand information

Role of Information in

Supply Chain Success

Information Global Coordinated Supply Chain

Scope Decisions Success

Information Technology in a

Supply Chain: Legacy

Systems

Strategic

Planning

Operational

Supplier Manufacturer Distributor Retailer Customer

Information Technology in a

Supply Chain: ERP Systems

Strategic

Planning

Potential ERP Potential

Operational ERP ERP

Supplier Manufacturer Distributor Retailer Customer

Information Technology in a

Supply Chain: Analytical

Applications

Strategic

SCM

Planning APS Transport & Inventory Dem Plan

Planning

Supplier

Apps

Transport execution & CRM/SFA

MES

WMS

Operational

Supplier Manufacturer Distributor Retailer Customer

Das könnte Ihnen auch gefallen

- Strategic AlliancesDokument23 SeitenStrategic AlliancesViraj DhuriNoch keine Bewertungen

- Case - Lee DungareesDokument4 SeitenCase - Lee DungareesVikas MongaNoch keine Bewertungen

- InventoryDokument34 SeitenInventorymbapritiNoch keine Bewertungen

- Case Study VolkswagonDokument2 SeitenCase Study VolkswagonManish DiehardNoch keine Bewertungen

- PDF Ba 5025 Logistics Management Notes - Compress PDFDokument96 SeitenPDF Ba 5025 Logistics Management Notes - Compress PDFUdayanidhi RNoch keine Bewertungen

- Chapter 6 - International Logistics, Risks InsuranceDokument41 SeitenChapter 6 - International Logistics, Risks InsuranceJason StevenNoch keine Bewertungen

- Corporate Culture at WestJet - AnswerDokument3 SeitenCorporate Culture at WestJet - AnswerTheBestMan250% (2)

- Supply Chain Management - Inventory ControlDokument67 SeitenSupply Chain Management - Inventory ControlSujay ChavanNoch keine Bewertungen

- Distribution Supply Chain Management - Sourcing & ProcurementDokument39 SeitenDistribution Supply Chain Management - Sourcing & ProcurementshoaibnadirNoch keine Bewertungen

- Chapter 2: Operations Strategy and CompetitivenessDokument3 SeitenChapter 2: Operations Strategy and CompetitivenessMarie GonzalesNoch keine Bewertungen

- Principles of Supply Chain Management: A Balanced Approach: Prepared by Daniel A. Glaser-Segura, PHDDokument20 SeitenPrinciples of Supply Chain Management: A Balanced Approach: Prepared by Daniel A. Glaser-Segura, PHDmanikamathurNoch keine Bewertungen

- Chapter-7 Corporate Level Strategu - Growth or ExpansionDokument27 SeitenChapter-7 Corporate Level Strategu - Growth or ExpansionShradha SaxenaNoch keine Bewertungen

- International Trade TheoryDokument24 SeitenInternational Trade TheorybitunmouNoch keine Bewertungen

- Chapter 8 Consumer Attitude Formation and ChangeDokument3 SeitenChapter 8 Consumer Attitude Formation and ChangeSaief DipNoch keine Bewertungen

- The Competition Is Not Between Individual Firms, But Between Supply ChainsDokument40 SeitenThe Competition Is Not Between Individual Firms, But Between Supply ChainsexceptionalhighdeeNoch keine Bewertungen

- SCM K-6 (CH 6) Strategic AlliancesDokument44 SeitenSCM K-6 (CH 6) Strategic AlliancesAndriGunawan100% (2)

- Notes Logistics Supply Chain Management IgnouDokument353 SeitenNotes Logistics Supply Chain Management IgnouAashika Shome100% (1)

- Cross Cultural Management - NotesDokument9 SeitenCross Cultural Management - NotesSanjay TimilsinaNoch keine Bewertungen

- Channel of Distribution and LogisticsDokument9 SeitenChannel of Distribution and LogisticsSalman KhalidNoch keine Bewertungen

- Business Environment Question PaperDokument2 SeitenBusiness Environment Question PaperSajo Sam50% (6)

- OM - M16 - Supply Chain ManagementDokument40 SeitenOM - M16 - Supply Chain ManagementGreesu GreesuNoch keine Bewertungen

- Lecture Notes Topic 7 Management and LeadershipDokument9 SeitenLecture Notes Topic 7 Management and LeadershipS MNoch keine Bewertungen

- The New Aaa Supply Chain: Hau L. LeeDokument4 SeitenThe New Aaa Supply Chain: Hau L. LeeNataly Alonso Chavero100% (1)

- Summary Logistics Chapter 1 5 7-8-10 en 14.docx FDokument21 SeitenSummary Logistics Chapter 1 5 7-8-10 en 14.docx FasdfasfasdfasdfasdfsdafNoch keine Bewertungen

- SNOP Framework: Supply Chain Management (MGB LSC 114)Dokument8 SeitenSNOP Framework: Supply Chain Management (MGB LSC 114)Madhav Chowdary TumpatiNoch keine Bewertungen

- 09 Supply Chain Coordination1Dokument27 Seiten09 Supply Chain Coordination1soireeNoch keine Bewertungen

- Supply Chain ManagementDokument11 SeitenSupply Chain ManagementrahilkatariaNoch keine Bewertungen

- Retailing Managemen T: Text and CasesDokument16 SeitenRetailing Managemen T: Text and Casesbiotech_savvyNoch keine Bewertungen

- Chapter 16 - Strategic Challenges and Change For Supply ChainsDokument26 SeitenChapter 16 - Strategic Challenges and Change For Supply ChainsArmanNoch keine Bewertungen

- An Introduction To SwapsDokument4 SeitenAn Introduction To Swaps777antonio777Noch keine Bewertungen

- Self Check ExerciseDokument12 SeitenSelf Check ExerciseBhargav D.S.Noch keine Bewertungen

- UNIT-3: Procurement, Purchasing & Manufacturing StrategiesDokument20 SeitenUNIT-3: Procurement, Purchasing & Manufacturing StrategiesFadekemi AdelabuNoch keine Bewertungen

- Economic Assignment Tyre Industry: ScopeDokument8 SeitenEconomic Assignment Tyre Industry: ScopeNivedita RoyNoch keine Bewertungen

- Discussion Ch13Dokument3 SeitenDiscussion Ch13edy100% (1)

- Suuply Chain Dewan Farooque Motors Limited ReportDokument18 SeitenSuuply Chain Dewan Farooque Motors Limited ReportKashif Abbas100% (1)

- Chap 012Dokument24 SeitenChap 012hikariyukaiNoch keine Bewertungen

- IndustIndustry Analysis - 5 ForcesDokument36 SeitenIndustIndustry Analysis - 5 ForcesSIVAKUMAR_GNoch keine Bewertungen

- Study On Financial Ratio Analysis of Vellore Cooperative Sugar MillsDokument7 SeitenStudy On Financial Ratio Analysis of Vellore Cooperative Sugar MillsTim CechiniNoch keine Bewertungen

- Domestic & Global Supply ChainDokument15 SeitenDomestic & Global Supply ChainAnjana SebastianNoch keine Bewertungen

- Timon's ModelDokument10 SeitenTimon's ModelSunil KumarNoch keine Bewertungen

- Bozhan Tif ch02Dokument11 SeitenBozhan Tif ch02Jimmi Singh100% (1)

- Significance and Limitations of Financial StatementsDokument14 SeitenSignificance and Limitations of Financial StatementsabbyplexxNoch keine Bewertungen

- What Is Supply Chain ManagementDokument6 SeitenWhat Is Supply Chain ManagementHusain ShiyajiNoch keine Bewertungen

- Global SourcingDokument26 SeitenGlobal SourcingOwais BhattNoch keine Bewertungen

- Supply Chain ManagementDokument26 SeitenSupply Chain Managementzahid_497Noch keine Bewertungen

- Session 2-Demand AnalysisDokument18 SeitenSession 2-Demand AnalysisAmit KadamNoch keine Bewertungen

- Marketing Management: Rin Detergent Case StudyDokument4 SeitenMarketing Management: Rin Detergent Case StudyNageeta BaiNoch keine Bewertungen

- Service Marketing Question BankDokument9 SeitenService Marketing Question BankKarthika NathanNoch keine Bewertungen

- PPM NotesDokument14 SeitenPPM NotesNilabjo Kanti PaulNoch keine Bewertungen

- Assignment Supply Chain Management BY Virupaksha Reddy.T ROLL NUMBER: 510916226 OM0003 SET-1Dokument12 SeitenAssignment Supply Chain Management BY Virupaksha Reddy.T ROLL NUMBER: 510916226 OM0003 SET-1virupaksha12Noch keine Bewertungen

- International Strategic Management A Complete Guide - 2020 EditionVon EverandInternational Strategic Management A Complete Guide - 2020 EditionNoch keine Bewertungen

- Value Chain Management Capability A Complete Guide - 2020 EditionVon EverandValue Chain Management Capability A Complete Guide - 2020 EditionNoch keine Bewertungen

- Business Improvement Districts: An Introduction to 3 P CitizenshipVon EverandBusiness Improvement Districts: An Introduction to 3 P CitizenshipNoch keine Bewertungen

- Inventory Record Accuracy: Unleashing the Power of Cycle CountingVon EverandInventory Record Accuracy: Unleashing the Power of Cycle CountingBewertung: 3 von 5 Sternen3/5 (2)

- Strategic Alliance in SCMDokument31 SeitenStrategic Alliance in SCMRajeev RanjanNoch keine Bewertungen

- Quick ResponseDokument26 SeitenQuick ResponseROHITNoch keine Bewertungen

- S3 U4 MiniTestDokument3 SeitenS3 U4 MiniTestĐinh Thị Thu HàNoch keine Bewertungen

- Pot-Roasted Beef BrisketDokument4 SeitenPot-Roasted Beef Brisketmarcelo nubileNoch keine Bewertungen

- KM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)Dokument4 SeitenKM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)krzysiek1975Noch keine Bewertungen

- Full Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full ChapterDokument13 SeitenFull Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full Chapterpoetrycloudyzjm12q100% (19)

- Behavior Intervention MenuDokument56 SeitenBehavior Intervention Menuapi-479527084100% (4)

- The Ethics of Peacebuilding PDFDokument201 SeitenThe Ethics of Peacebuilding PDFTomas Kvedaras100% (2)

- Sistemas de Mando CST Cat (Ing)Dokument12 SeitenSistemas de Mando CST Cat (Ing)Carlos Alfredo LauraNoch keine Bewertungen

- Product Handbook Arendal 1961 Series SubwoofersDokument44 SeitenProduct Handbook Arendal 1961 Series SubwoofersDomagoj KovacevicNoch keine Bewertungen

- Earth Science NAME - DATEDokument3 SeitenEarth Science NAME - DATEArlene CalataNoch keine Bewertungen

- Action Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorDokument1 SeiteAction Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorEdelmar BenosaNoch keine Bewertungen

- Kursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014Dokument12 SeitenKursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014ihsanyusoffNoch keine Bewertungen

- Unit 1 Building A Professional Relationship Across CulturesDokument16 SeitenUnit 1 Building A Professional Relationship Across CulturesAlex0% (1)

- Microsome S9 Prep ProtocolDokument22 SeitenMicrosome S9 Prep ProtocolSAN912Noch keine Bewertungen

- P6 - TT2 - Revision Test 2021-2022 Page 1 of 11Dokument11 SeitenP6 - TT2 - Revision Test 2021-2022 Page 1 of 11Nilkanth DesaiNoch keine Bewertungen

- Level I 2018 2019 Program Changes PDFDokument2 SeitenLevel I 2018 2019 Program Changes PDFMuhammad BurairNoch keine Bewertungen

- Setting and Plot: Old YellerDokument8 SeitenSetting and Plot: Old YellerWalid AhmedNoch keine Bewertungen

- Sub-Wings of YuvanjaliDokument2 SeitenSub-Wings of Yuvanjalin_tapovan987100% (1)

- Chudamani Women Expecting ChangeDokument55 SeitenChudamani Women Expecting ChangeMr AnantNoch keine Bewertungen

- Lab 1Dokument51 SeitenLab 1aliNoch keine Bewertungen

- Solid Waste Management in The World's Cities, UN-HABITAT: January 2010Dokument17 SeitenSolid Waste Management in The World's Cities, UN-HABITAT: January 2010Rajasri SNoch keine Bewertungen

- Materials Management - 1 - Dr. VP - 2017-18Dokument33 SeitenMaterials Management - 1 - Dr. VP - 2017-18Vrushabh ShelkarNoch keine Bewertungen

- DC Generator - Construction, Working Principle, Types, and Applications PDFDokument1 SeiteDC Generator - Construction, Working Principle, Types, and Applications PDFGokul GokulNoch keine Bewertungen

- Te-Chemical Sem5 CPNM-CBCGS Dec19Dokument2 SeitenTe-Chemical Sem5 CPNM-CBCGS Dec19Mayank ShelarNoch keine Bewertungen

- Volcanoes Sub-topic:Volcanic EruptionDokument16 SeitenVolcanoes Sub-topic:Volcanic EruptionVhenz MapiliNoch keine Bewertungen

- Hackerearth Online Judge: Prepared By: Mohamed AymanDokument21 SeitenHackerearth Online Judge: Prepared By: Mohamed AymanPawan NaniNoch keine Bewertungen

- The Fastest Easiest Way To Secure Your NetworkDokument9 SeitenThe Fastest Easiest Way To Secure Your NetworkMark ShenkNoch keine Bewertungen

- Amerex Ansul Badger Ul Catalogo Por PartesDokument37 SeitenAmerex Ansul Badger Ul Catalogo Por PartesPuma De La Torre ExtintoresNoch keine Bewertungen

- XXXX96 01 01 2023to28 08 2023Dokument18 SeitenXXXX96 01 01 2023to28 08 2023dabu choudharyNoch keine Bewertungen

- Teaching PowerPoint Slides - Chapter 5Dokument19 SeitenTeaching PowerPoint Slides - Chapter 5Azril ShazwanNoch keine Bewertungen

- Dragons ScaleDokument13 SeitenDragons ScaleGuilherme De FariasNoch keine Bewertungen