Beruflich Dokumente

Kultur Dokumente

AMS - VaporWorks - Rework 2011

Hochgeladen von

sshaffer_9Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AMS - VaporWorks - Rework 2011

Hochgeladen von

sshaffer_9Copyright:

Verfügbare Formate

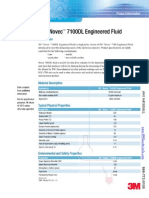

What Does Vapor Phase Mean to Single Component Rework?

The V-Works 24 Vapor Phase Rework Station

from Vapor Works, applies the precise

temperature control features of Vapor Phase,

to single component rework and repair.

Evolutionary Approach to

Rework

Impossible to overheat the

IC or Board.

Perfect for BGA Rework

Quick release nozzle

technology

Closed loop vapor system

Vapor Phase Rework Station

Model

V-Works 24

R&D Technical Services / Vapor Works

12261 Nicollet Ave. S. Suite A Burnsville, MN 55337

www.rdtechnicalservices.com;

AMS Materials, LLCsales@rdtechnicalservices.com

866-772-5108

Ph: 952-707-1931

Vapor Phase Rework Systems Overview

AMS Materials, LLC 866-772-5108

VAPOR PHASE

TECHNOLOGY

Comparison of Heat Transfer Methods

Pertains to both Reflow and Rework

AMS Materials, LLC 866-772-5108

Vapor Phase Rework Subassemblies

• Vapor Generation / Cooling

• Vapor Delivery

• Vapor Control Valve Assembly

• Nozzle Assembly

• Vapor and Working Fluid Recovery

• Preheat

• Controls

• Advantages

AMS Materials, LLC 866-772-5108

Vapor Generation / Cooling

AMS Materials, LLC 866-772-5108

Vapor Delivery

AMS Materials, LLC 866-772-5108

Vapor Control Valve Assembly

AMS Materials, LLC 866-772-5108

Nozzle Assembly

AMS Materials, LLC 866-772-5108

Working Fluid Recovery

AMS Materials, LLC 866-772-5108

Preheat Assembly

Global Bottom Side Preheat

Convected Zones

3 Individually Controlled Zones

Controllable Temp for Ideal Thermal Profile

Integrated Overtemp Alarms

AMS Materials, LLC 866-772-5108

Controls

AMS Materials, LLC 866-772-5108

250 Programmable Recipes

Standard Control Head

9 Character Alpha Numeric Recipe Names

3 Level Password Protection

6” Graphic Touch Screen Operator Interface

Full Safety Controls

Maintenance Control Screen

Vapor Pulse Capabilities

Red/Green Lighting for Easy Viewing

Individual Preheat Zone Control

AMS Materials, LLC 866-772-5108

Advantages

52 mm, 1.00 mm pitch HyperBGA

Uniform Heat Transfer Via Condensation Top and Bottom Side Component Profile

RD 70

250

245

240

235

230

225

Unaffected by Shadowing or Deflection 220

215

210

205

200

195

190

185

180

175

170

165

160

155

Absolute Limits to Maximum Reflow Temperature 150

145

140

135

130

125

C1(°C)

C*

120 C2(°C)

115

110

105

100

95

90

Closed Loop Vapor System

85

80

75

70

65

60

55

50

45

40

35

30

25

20

O2 Free at Reflow

15

10

5

0

10

19

28

37

46

55

64

73

82

91

100

109

118

127

136

145

154

163

172

181

190

199

208

217

226

235

244

253

262

271

280

289

298

307

316

325

334

343

352

361

370

379

388

397

406

415

424

2 second intervals

Impossible to Overheat IC

Perfect for Large BGA Rework and Challenging First Attach

AMS Materials, LLC 866-772-5108

R&D Technical Services / Vapor Works

12261 Nicollet Ave S. Suite A Burnsville, MN 55337

PH: 952-707-1931; Email: sales@rdtechnicalservices.com ; Web: www.rdtechnicalservices.com

AMS Materials, LLC 866-772-5108

Das könnte Ihnen auch gefallen

- Sbpln53a ENDokument2 SeitenSbpln53a ENhufuentsNoch keine Bewertungen

- Dry Out Procedure of IOCL Haldia Vacuum Heater APHDokument3 SeitenDry Out Procedure of IOCL Haldia Vacuum Heater APHraghbirNoch keine Bewertungen

- PID ScrollbarDokument9 SeitenPID ScrollbarJulieta Maria RodriguezNoch keine Bewertungen

- NLX-KK.1 Compressors: - Danfoss Compressors Latest Technical UpdateDokument2 SeitenNLX-KK.1 Compressors: - Danfoss Compressors Latest Technical Updatemuhammad irfanNoch keine Bewertungen

- 2CP EN 60HzDokument10 Seiten2CP EN 60HzMoutaz IsmailNoch keine Bewertungen

- Screw Compressor ASY (R-134) Series PDFDokument52 SeitenScrew Compressor ASY (R-134) Series PDFNajam2450% (2)

- Centrifugal Twin-Impeller Pumps: Installation and Use Performance RangeDokument12 SeitenCentrifugal Twin-Impeller Pumps: Installation and Use Performance Rangeمعين عزامNoch keine Bewertungen

- R-2000iA EW FootprintDokument2 SeitenR-2000iA EW Footprintto0984903132Noch keine Bewertungen

- PPK - Pinch - Hana IkbarDokument17 SeitenPPK - Pinch - Hana IkbarHuwaida IkbarNoch keine Bewertungen

- Motorised Valve - JohnsonDokument1 SeiteMotorised Valve - JohnsonSudeep SNoch keine Bewertungen

- HMCL API614 LOS FlyerDokument2 SeitenHMCL API614 LOS FlyerArjav DesaiNoch keine Bewertungen

- كتالوج الشيلراتDokument54 Seitenكتالوج الشيلراتFathy RakhaNoch keine Bewertungen

- L1 - ZALUX - BST 1.5 55-840 ET BPC 3x1,5Dokument2 SeitenL1 - ZALUX - BST 1.5 55-840 ET BPC 3x1,5luxcontrolsystems.geralNoch keine Bewertungen

- AgriblocDokument2 SeitenAgriblocamitNoch keine Bewertungen

- WiloDokument40 SeitenWilovn_hung3137Noch keine Bewertungen

- DB - 710 - 717 - 723 - GB - GEMU 723Dokument16 SeitenDB - 710 - 717 - 723 - GB - GEMU 723KrisNoch keine Bewertungen

- Gfps System Specification PVC C Metric en PDFDokument24 SeitenGfps System Specification PVC C Metric en PDFMohammed sabatinNoch keine Bewertungen

- Zamil Chiller - ASY Series PDFDokument51 SeitenZamil Chiller - ASY Series PDFRenato Abalos90% (10)

- Lit2688 Pd15-75b Parts ListDokument16 SeitenLit2688 Pd15-75b Parts ListAlfred HitchcockNoch keine Bewertungen

- Hydraulic CoolersDokument12 SeitenHydraulic Coolersarpit.vNoch keine Bewertungen

- Brochure cpCODokument12 SeitenBrochure cpCOJose ProbosteNoch keine Bewertungen

- FGN LED Type 'N' (Zones 2 & 22) - 42W - 5000K: FGN-Line Hazardous AreaDokument1 SeiteFGN LED Type 'N' (Zones 2 & 22) - 42W - 5000K: FGN-Line Hazardous AreajosehenriquezsotoNoch keine Bewertungen

- Furnas DP ContactorsDokument2 SeitenFurnas DP ContactorsRex SanchezNoch keine Bewertungen

- Water Cooled Screw Compressor ASW Series (R134a)Dokument45 SeitenWater Cooled Screw Compressor ASW Series (R134a)AAR143Noch keine Bewertungen

- WL175 WL250BR and WM175 Outdoor Luminaires Data Sheet en Tcm181-12693Dokument2 SeitenWL175 WL250BR and WM175 Outdoor Luminaires Data Sheet en Tcm181-12693Cristian AndresNoch keine Bewertungen

- 23 V2403mdi 27Dokument2 Seiten23 V2403mdi 27DaniloBarreraNoch keine Bewertungen

- 4-3. Factory Mode AdjustmentsDokument11 Seiten4-3. Factory Mode Adjustmentsjamal suwanNoch keine Bewertungen

- Spring Return and Double Acting Pneumatic Quarter-Turn Actuators For Output Torques To 27,624 LB - inDokument8 SeitenSpring Return and Double Acting Pneumatic Quarter-Turn Actuators For Output Torques To 27,624 LB - inThanh Vuong NguyenNoch keine Bewertungen

- Hob SelectionDokument4 SeitenHob SelectionVikas ChauhanNoch keine Bewertungen

- Technical Guidelines: Physical Properties of Refrigerants R-410ADokument2 SeitenTechnical Guidelines: Physical Properties of Refrigerants R-410AYaxmine Edward StylesNoch keine Bewertungen

- Air Pressure Reducing Valve: ACOS-10Dokument2 SeitenAir Pressure Reducing Valve: ACOS-10guslohNoch keine Bewertungen

- R 2000ic PDFDokument6 SeitenR 2000ic PDFPRASADNoch keine Bewertungen

- AUIRF2804 AUIRF2804S AUIRF2804L: Automotive GradeDokument16 SeitenAUIRF2804 AUIRF2804S AUIRF2804L: Automotive Gradegotcha75Noch keine Bewertungen

- Ev100 gb-1Dokument6 SeitenEv100 gb-1Geoffrey PearmainNoch keine Bewertungen

- OPI Centrifugal 2045LX Spec Sheet 2022Dokument1 SeiteOPI Centrifugal 2045LX Spec Sheet 2022Aldo Antonio Cortegana AbadNoch keine Bewertungen

- ATS104SPDokument2 SeitenATS104SP0960803095390% (1)

- Evaporadores ELADokument44 SeitenEvaporadores ELAanahijanethNoch keine Bewertungen

- SystemSpecification PVC-U Metric 2015 en PDFDokument24 SeitenSystemSpecification PVC-U Metric 2015 en PDFpablo mendoza ibarraNoch keine Bewertungen

- Keymc 0007 UsDokument8 SeitenKeymc 0007 UsDaniel BahamondeNoch keine Bewertungen

- Dk294j-Parts ManualDokument4 SeitenDk294j-Parts ManualJorge Alonso Fernandez50% (2)

- 2022-Cam Switches 18102021Dokument84 Seiten2022-Cam Switches 18102021Adrian Aslan ChannelNoch keine Bewertungen

- Elevator Control Valves: EN ISO 9001Dokument4 SeitenElevator Control Valves: EN ISO 9001Bantu BantuNoch keine Bewertungen

- Ev100 GBDokument6 SeitenEv100 GBCarlos PalmaNoch keine Bewertungen

- L1.i.10 - Dunabio - 280423 - Dbhe 1.5 61-840Dokument2 SeitenL1.i.10 - Dunabio - 280423 - Dbhe 1.5 61-840tomas.calhelha.ferreiraNoch keine Bewertungen

- October 1 2008: 2-16-46, Minami-Kamata, Ohta-Ku, Tokyo 144-8551, JAPAN TEL.+81-3-3732-2111 FAX.+81-3-3736-0261Dokument3 SeitenOctober 1 2008: 2-16-46, Minami-Kamata, Ohta-Ku, Tokyo 144-8551, JAPAN TEL.+81-3-3732-2111 FAX.+81-3-3736-0261Nishant PandyaNoch keine Bewertungen

- 138 O Legato Interlock Block 1600 X 800 X 800Dokument1 Seite138 O Legato Interlock Block 1600 X 800 X 800BogdanBNoch keine Bewertungen

- Elevator Control Valves: EN ISO 9001Dokument6 SeitenElevator Control Valves: EN ISO 9001Jibjab7Noch keine Bewertungen

- Wilo-SiFire-en-Fire Systems PDFDokument62 SeitenWilo-SiFire-en-Fire Systems PDFVictor GheorgheNoch keine Bewertungen

- اینورتر اسانسورDokument40 Seitenاینورتر اسانسور208020Noch keine Bewertungen

- High-Efficiency Model RC2 Series Screw CompressorDokument8 SeitenHigh-Efficiency Model RC2 Series Screw Compressorgyeong gyu moonNoch keine Bewertungen

- Thorn Impact 2 LED Batten IP65 96627497 - Combi - DatasheetDokument2 SeitenThorn Impact 2 LED Batten IP65 96627497 - Combi - DatasheetShiHong KuangNoch keine Bewertungen

- BIM Technical Standards - MEP Color Mapping - GSADokument4 SeitenBIM Technical Standards - MEP Color Mapping - GSASebastian RaduNoch keine Bewertungen

- Trane WarmtepompDokument8 SeitenTrane Warmtepomprunehaerynck2003Noch keine Bewertungen

- Compresores BitzerDokument24 SeitenCompresores BitzerRosa SilvaNoch keine Bewertungen

- 09 Chiller PDBDokument174 Seiten09 Chiller PDBFadi Najjar100% (1)

- Copeland Screw CompressorsDokument4 SeitenCopeland Screw Compressorsugas666999Noch keine Bewertungen

- AC EDGE Compressor CatalogueDokument23 SeitenAC EDGE Compressor CatalogueeddiebolanNoch keine Bewertungen

- Bevel Gear DatasheetDokument7 SeitenBevel Gear Datasheetmohammad khoraminiaNoch keine Bewertungen

- SKYDECK Hanger System: For Concrete Slab In-Fills and DropsDokument4 SeitenSKYDECK Hanger System: For Concrete Slab In-Fills and Dropstmg016Noch keine Bewertungen

- AMS - SQL - CFC Naming ConventionDokument10 SeitenAMS - SQL - CFC Naming Conventionsshaffer_9Noch keine Bewertungen

- AMS - 3M - Cool Under FireDokument8 SeitenAMS - 3M - Cool Under Firesshaffer_9Noch keine Bewertungen

- AMS - SQL - Refrigerant Ref TableDokument6 SeitenAMS - SQL - Refrigerant Ref Tablesshaffer_9Noch keine Bewertungen

- AMS - 3M - Fluorinert FC-3283Dokument4 SeitenAMS - 3M - Fluorinert FC-3283sshaffer_9Noch keine Bewertungen

- AMS - Bransonic General BrochureDokument8 SeitenAMS - Bransonic General Brochuresshaffer_9Noch keine Bewertungen

- Ams - 3M - PF-5060-DLDokument6 SeitenAms - 3M - PF-5060-DLsshaffer_9Noch keine Bewertungen

- Ams - 3M - PF-5060Dokument4 SeitenAms - 3M - PF-5060sshaffer_9Noch keine Bewertungen

- AMS - 3M - Fluorinert FC-3284Dokument4 SeitenAMS - 3M - Fluorinert FC-3284sshaffer_9Noch keine Bewertungen

- AMS - 3M - Fluorinert FC-70Dokument4 SeitenAMS - 3M - Fluorinert FC-70sshaffer_9Noch keine Bewertungen

- Ams - 3M - PF-5070Dokument4 SeitenAms - 3M - PF-5070sshaffer_9Noch keine Bewertungen

- Ams - 3M - TDS Hfe-72daDokument4 SeitenAms - 3M - TDS Hfe-72dasshaffer_9Noch keine Bewertungen

- AMS - Chemicals LRS FormulaDokument1 SeiteAMS - Chemicals LRS Formulasshaffer_9Noch keine Bewertungen

- AMS - 3M - Novec 7000Dokument6 SeitenAMS - 3M - Novec 7000sshaffer_9Noch keine Bewertungen

- AMS - 3M - Novec 7100DLDokument4 SeitenAMS - 3M - Novec 7100DLsshaffer_9Noch keine Bewertungen

- AMS - Branson - B252R TDSDokument2 SeitenAMS - Branson - B252R TDSsshaffer_9Noch keine Bewertungen

- AMS - 3M - Boiling Enhancement CoatingDokument2 SeitenAMS - 3M - Boiling Enhancement Coatingsshaffer_9Noch keine Bewertungen

- Data Sheet HFE-7300Dokument4 SeitenData Sheet HFE-7300sshaffer_9Noch keine Bewertungen

- AMS - Branson - B252R TDSDokument2 SeitenAMS - Branson - B252R TDSsshaffer_9Noch keine Bewertungen

- AMS - Branson - CH Tanks TDSDokument2 SeitenAMS - Branson - CH Tanks TDSsshaffer_9Noch keine Bewertungen

- AMS - Branson - S-8500 Generator TDSDokument2 SeitenAMS - Branson - S-8500 Generator TDSsshaffer_9Noch keine Bewertungen

- AMS - Branson - OMNI 2000 1620 1620RI TDSDokument2 SeitenAMS - Branson - OMNI 2000 1620 1620RI TDSsshaffer_9Noch keine Bewertungen

- AMS - Branson - OMNI 2000 1012 TDSDokument2 SeitenAMS - Branson - OMNI 2000 1012 TDSsshaffer_9Noch keine Bewertungen

- Aluminex 5: Material Safety Data SheetDokument10 SeitenAluminex 5: Material Safety Data SheetocalensNoch keine Bewertungen

- Industrial Automation Lab: Project ProposalDokument3 SeitenIndustrial Automation Lab: Project ProposalAmaan MajidNoch keine Bewertungen

- IRC CodesDokument23 SeitenIRC CodesabhijithavalNoch keine Bewertungen

- ToolsDokument1 SeiteToolsJolangNoch keine Bewertungen

- TRIAS - Master ProposalDokument12 SeitenTRIAS - Master ProposalHafidGaneshaSecretrdreamholicNoch keine Bewertungen

- A044 2019 20 Readiness Review Template For EAC 3-12-2018 FinalDokument25 SeitenA044 2019 20 Readiness Review Template For EAC 3-12-2018 FinalMohamed AbdelSalamNoch keine Bewertungen

- Test 1 AbsenteesDokument6 SeitenTest 1 AbsenteesHamza AhmedNoch keine Bewertungen

- SWOT Analysis of OLXDokument2 SeitenSWOT Analysis of OLXnupurpatra.techanalogyNoch keine Bewertungen

- Lecture 6 OptimizationDokument41 SeitenLecture 6 Optimizationaku_la100% (2)

- May (2012) Nonequivalent Comparison Group DesignsDokument21 SeitenMay (2012) Nonequivalent Comparison Group Designsmathworld_0204Noch keine Bewertungen

- 3.2 Server Maintenance Administration PlanDokument30 Seiten3.2 Server Maintenance Administration PlanAG Network ResourcesNoch keine Bewertungen

- Ionic EquilibriumDokument22 SeitenIonic EquilibriumbeherasubhammikunNoch keine Bewertungen

- Clock Divider and Pulse CounterDokument4 SeitenClock Divider and Pulse CounterRohit PanwarNoch keine Bewertungen

- Architechture of 8086 or Functional Block Diagram of 8086 PDFDokument3 SeitenArchitechture of 8086 or Functional Block Diagram of 8086 PDFAdaikkal U Kumar100% (2)

- Mod6 4Dokument10 SeitenMod6 4mn3mNoch keine Bewertungen

- Medica EasyLyte BrochureDokument6 SeitenMedica EasyLyte BrochureAnderson José Carrillo NárvaezNoch keine Bewertungen

- Lembar Observasi Kimia PKL 2023Dokument41 SeitenLembar Observasi Kimia PKL 2023Nur Sri WahyuniNoch keine Bewertungen

- Iot Based Home Automation Using NodemcuDokument52 SeitenIot Based Home Automation Using NodemcuSyed ArefinNoch keine Bewertungen

- Doors & People ManualDokument32 SeitenDoors & People ManualOscar Ayala100% (1)

- Truth Beyond Paradox (Final Download)Dokument217 SeitenTruth Beyond Paradox (Final Download)andreas waneyNoch keine Bewertungen

- Self-Assessment Observation and Assessment of Child DevelopmentDokument3 SeitenSelf-Assessment Observation and Assessment of Child Developmentapi-508676940Noch keine Bewertungen

- Training Wall Height On Convergent Stepped SpillwaysDokument10 SeitenTraining Wall Height On Convergent Stepped Spillwayschutton681Noch keine Bewertungen

- Activity 1-Introduce Biological ToolsDokument3 SeitenActivity 1-Introduce Biological ToolsHaroldNoch keine Bewertungen

- Capstone Project MarketingDokument9 SeitenCapstone Project MarketingKawalpreet SinghNoch keine Bewertungen

- ISC HydroCom ComparisonDokument22 SeitenISC HydroCom Comparisonrahilshah100Noch keine Bewertungen

- 2022 FM1 Five-Star PhysicianDokument39 Seiten2022 FM1 Five-Star PhysicianVaghani Dhruv SumantbhaiNoch keine Bewertungen

- Diagnosis Dan Tatalaksana Pasien Dengan Insufisiensi Akomodasi - Sri Hudaya WidihasthaDokument13 SeitenDiagnosis Dan Tatalaksana Pasien Dengan Insufisiensi Akomodasi - Sri Hudaya WidihasthamalaNoch keine Bewertungen

- Icbc Songs Line-Up 2Dokument118 SeitenIcbc Songs Line-Up 2paolojaspiras89% (9)

- Leaked New Zealand Health Data Had The Government Told The Truth About Vaccine Harms Lives Would HaveDokument8 SeitenLeaked New Zealand Health Data Had The Government Told The Truth About Vaccine Harms Lives Would HavemikeNoch keine Bewertungen

- Nts Tevta Test 22-03-15 Paper BDokument2 SeitenNts Tevta Test 22-03-15 Paper BBeTechieNoch keine Bewertungen