Beruflich Dokumente

Kultur Dokumente

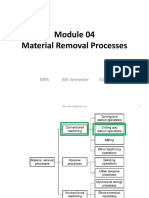

Types of Lathe

Hochgeladen von

Maliha_Bakhshi_93400 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten23 SeitenThe document describes different types of lathes and drilling machines. It discusses engine lathes, tracer lathes, automatic lathes, turret lathes, computer controlled lathes, drill presses including sensitive drill presses, upright drill presses, radial arm drill presses, and special purpose drill machines like gang drilling machines and multiple spindle drilling machines.

Originalbeschreibung:

Originaltitel

lecture#9

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document describes different types of lathes and drilling machines. It discusses engine lathes, tracer lathes, automatic lathes, turret lathes, computer controlled lathes, drill presses including sensitive drill presses, upright drill presses, radial arm drill presses, and special purpose drill machines like gang drilling machines and multiple spindle drilling machines.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten23 SeitenTypes of Lathe

Hochgeladen von

Maliha_Bakhshi_9340The document describes different types of lathes and drilling machines. It discusses engine lathes, tracer lathes, automatic lathes, turret lathes, computer controlled lathes, drill presses including sensitive drill presses, upright drill presses, radial arm drill presses, and special purpose drill machines like gang drilling machines and multiple spindle drilling machines.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 23

Types of Lathe

Engine Lathe

– The most common form of lathe, motor driven

and comes in large variety of sizes and shapes.

Engine Lathe

– Slight differences in the various engine lathes

make it easy to group them into three categories:

– Lightweight bench engine lathes

Engine Lathe

• Precision tool room lathes

Engine Lathe

• Gap lathes

Tracer Lathe

a lathe that has the ability to follow a template to copy a shape or contour.

Automatic Lathe

A lathe in which the work piece is automatically fed and removed without use of

an operator. Cutting operations are automatically controlled by a sequencer of

some form

Turret Lathe

lathe which have multiple tools mounted on turret either attached to the tailstock or the

cross-slide, which allows for quick changes in tooling and cutting operations.

– Computer Controlled Lathe

– A highly automated lathe, where both cutting, loading,

tool changing, and part unloading are automatically

controlled by computer coding.

Drilling Machine (Press)

Drilling Machine (Press)

• A drill press is a machine that turns and

advances a rotary tool into a workpiece. The

drill press is used primarily for drilling holes,

but when used with the proper tooling, it can

be used for a number of machining

operations. The most common machining

operations performed on a drill press are

drilling, reaming, tapping, counterboring,

countersinking, and spotfacing.

Basic Types of Drilling Machines

• There are many different types or

configurations of drilling machines, but most

drilling machines will fall into four broad

categories:

• Sensitive

• Upright

• radial

• special purpose

Sensitive drill press

Sensitive drill press

• a light-duty type of drilling machine

• High speed

• machine can only be hand fed.

• The sensitive drill press is manufactured in a

floor style or a bench style.

UPRIGHT DRILL PRESS

UPRIGHT DRILL PRESS

• Heavy duty type of drilling machine normally

incorporating a geared drive spindle head.

• This type of drilling machine is used on large hole-

producing operations that typically involve larger or

heavier parts.

• The upright drill press allows the operator to hand

feed or power feed the tool into the workpiece. The

power feed mechanism automatically advances the

tool into the workpiece.

• Some types of upright drill presses are also

manufactured with automatic table-raising

mechanisms.

RADIAL ARM DRILL PRESS

RADIAL ARM DRILL PRESS

• The radial arm drill press allows the operator to position

the spindle directly over the workpiece rather than move

the workpiece to the tool.

• The design of the radial drill press gives it a great deal of

versatility, especially on parts too large to position easily.

Radial drills offer power feed on the spindle, as well as an

automatic mechanism to raise or lower the radial arm.

• The wheel head, which is located on the radial arm, can

also be traversed along the arm, giving the machine

added ease of use as well as versatility.

• Radial arm drill presses can be equipped with a tilting

table. This gives the operator the ability to drill

intersecting or angular holes in one setup.

SPECIAL PURPOSE DRILL MACHINES

• There are a number of types of special

purpose drilling machines. The purposes of

these types of drilling machines vary. Special

purpose drilling machines include machines

capable of drilling 20 holes at once or drilling

holes as small as 0.01 of an inch.

Gang Drilling Machines

Gang Drilling Machines

• Gang drill press has several work heads

positioned over a single table.

• This type of drill press is used when successive

operations are to be done.

• For instance, the first head may be used to spot

drill. The second head may be used to tap drill.

The third head may be used, along with a

tapping head, to tap the hole. The fourth head

may be used to chamfer.

Multiple Spindle Drilling Machine

Multiple Spindle Drilling Machine

• The multiple spindle drilling machine is commonly

referred to as a multispindle drill press.

• This special purpose drill press has many spindles

connected to one main work head

• All of the spindles are fed into the workpiece at

the same time.

• This type of drilling machine is especially useful

when you have a large number of parts with many

holes located close together.

Das könnte Ihnen auch gefallen

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Von EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Noch keine Bewertungen

- Drilling Machines and Its TypesDokument26 SeitenDrilling Machines and Its TypesRana MohsinNoch keine Bewertungen

- Drilling Machine Operations & ClassificationsDokument23 SeitenDrilling Machine Operations & Classificationsmuneiah100% (1)

- Boring MachineDokument38 SeitenBoring Machinemitmandsaur67% (3)

- Chapter 3 - Drilling MachinesDokument111 SeitenChapter 3 - Drilling MachinesbmdbmdbmdNoch keine Bewertungen

- DrillingDokument71 SeitenDrillingravi upadhyayNoch keine Bewertungen

- Ny AssignmentDokument20 SeitenNy AssignmentNiraj H SinghaNoch keine Bewertungen

- No No No 552266Dokument129 SeitenNo No No 552266Drew LadlowNoch keine Bewertungen

- U-5 Boring and Jig Boring MachineDokument27 SeitenU-5 Boring and Jig Boring Machineapi-271354682Noch keine Bewertungen

- Module - 4 - Shaper, Planer, Slotter, Grinding MachinesDokument70 SeitenModule - 4 - Shaper, Planer, Slotter, Grinding MachinesIrfan ShaikhNoch keine Bewertungen

- Workshop Technology-Ii: Submitted by DheerajDokument46 SeitenWorkshop Technology-Ii: Submitted by DheerajShanu RawNoch keine Bewertungen

- Mechanical: SUB: Manufacturing Processes-1 Topic:Boring MachineDokument18 SeitenMechanical: SUB: Manufacturing Processes-1 Topic:Boring MachinePRADIPNoch keine Bewertungen

- Boring MachineDokument25 SeitenBoring MachineSreedhar PugalendhiNoch keine Bewertungen

- Working Principle of LatheDokument30 SeitenWorking Principle of LatheDURGGA PRASADDNoch keine Bewertungen

- Drilling MachinesDokument19 SeitenDrilling MachinesKim Argyle SalinasNoch keine Bewertungen

- Drilling and Milling Machine OperationDokument36 SeitenDrilling and Milling Machine OperationJessa D. HernandezNoch keine Bewertungen

- General Purpose Machine Tools - SpalDokument32 SeitenGeneral Purpose Machine Tools - SpalRavichandran GNoch keine Bewertungen

- General Purpose Machine Tools - SpalDokument33 SeitenGeneral Purpose Machine Tools - SpalmecoolguysNoch keine Bewertungen

- Special Purpose LathesDokument33 SeitenSpecial Purpose LathesChadaram JagadishNoch keine Bewertungen

- Lecture#09 (A) Shaper, Planer, Slotter and Boring MachineDokument12 SeitenLecture#09 (A) Shaper, Planer, Slotter and Boring MachineQazi Muhammed FayyazNoch keine Bewertungen

- 04-03 Drilling and Related OperationsDokument52 Seiten04-03 Drilling and Related OperationsRafiaNoch keine Bewertungen

- Drillingandboring 160625093737Dokument122 SeitenDrillingandboring 160625093737nnitinsharma87Noch keine Bewertungen

- Grinding MachineDokument38 SeitenGrinding MachineFaisal MaqsoodNoch keine Bewertungen

- Haper, Lotter Lanner: Created byDokument21 SeitenHaper, Lotter Lanner: Created byBharathiraja MoorthyNoch keine Bewertungen

- Machine Tools and Machining 2Dokument38 SeitenMachine Tools and Machining 2Faisal Maqsood100% (1)

- Reciprocating Type Machine ToolsDokument18 SeitenReciprocating Type Machine ToolsSpartan 117Noch keine Bewertungen

- Shaping and PlaningDokument30 SeitenShaping and Planingmantana11Noch keine Bewertungen

- Drilling MachineDokument28 SeitenDrilling Machineultimatestar1571Noch keine Bewertungen

- Drill PressDokument50 SeitenDrill PressLovely Jaze SalgadoNoch keine Bewertungen

- Lathe AttachmentsDokument21 SeitenLathe AttachmentsSandeep NayakNoch keine Bewertungen

- s6 Machining Operations-1Dokument94 Seitens6 Machining Operations-1Libin AbrahamNoch keine Bewertungen

- Drilling FEADokument44 SeitenDrilling FEAVinay BharadwajNoch keine Bewertungen

- Report 2 - MillingDokument34 SeitenReport 2 - Millingمحمد طه100% (1)

- Multi Spindl Drilling MachineDokument38 SeitenMulti Spindl Drilling MachineBoopathi KalaiNoch keine Bewertungen

- Lathe Machine: - IntroductionDokument29 SeitenLathe Machine: - IntroductionQazi Muhammed FayyazNoch keine Bewertungen

- Drillingmachine1 151022133645 Lva1 App6891Dokument17 SeitenDrillingmachine1 151022133645 Lva1 App6891Fatin Nadzira0% (1)

- Unit-3 (1) MPDokument98 SeitenUnit-3 (1) MPVishvas SinghhNoch keine Bewertungen

- Drilling Machine and TypesDokument15 SeitenDrilling Machine and TypesNaveen luckyNoch keine Bewertungen

- Drilling Machine and TypesDokument15 SeitenDrilling Machine and TypesFaisNoch keine Bewertungen

- (Print) Drilling Machine and TypesDokument15 Seiten(Print) Drilling Machine and TypesMunem ShahriarNoch keine Bewertungen

- DrillingDokument18 SeitenDrillingakhilteja1286Noch keine Bewertungen

- Unit 4 Drilling MachinesDokument91 SeitenUnit 4 Drilling MachinesMALINoch keine Bewertungen

- Boring Machines: Salunke M.DDokument36 SeitenBoring Machines: Salunke M.DjssrikantamurthyNoch keine Bewertungen

- Shaper Planner SlotterDokument49 SeitenShaper Planner SlottershahidNoch keine Bewertungen

- L3 Lathe SlideDokument36 SeitenL3 Lathe SlideSajen PokharelNoch keine Bewertungen

- Machining Time and Power EstimationDokument50 SeitenMachining Time and Power EstimationGnanakumar GanesanNoch keine Bewertungen

- Presentation of Lathe MachineDokument27 SeitenPresentation of Lathe Machinesamurai7_77Noch keine Bewertungen

- Shaper, Planer, Slotter and Boring MachineDokument10 SeitenShaper, Planer, Slotter and Boring Machinemuhammad umarNoch keine Bewertungen

- Lathe Machine and Its OperationsDokument16 SeitenLathe Machine and Its OperationsLokesh PatilNoch keine Bewertungen

- Unit IV - MaterialDokument28 SeitenUnit IV - MaterialSai RamNoch keine Bewertungen

- Milling Machine PDFDokument64 SeitenMilling Machine PDFJhon Ashley NahibuanNoch keine Bewertungen

- Mes Drill, Mill, Shaper, Grinding ClassDokument46 SeitenMes Drill, Mill, Shaper, Grinding ClassomkardashetwarNoch keine Bewertungen

- Unit - Ii Semi-Automatic and Automatic MachinesDokument19 SeitenUnit - Ii Semi-Automatic and Automatic Machinesعلي محمد100% (1)

- Machine Shop TheoryDokument28 SeitenMachine Shop Theoryjulito paquitNoch keine Bewertungen

- Planer Machine 1Dokument20 SeitenPlaner Machine 1Kim Argyle SalinasNoch keine Bewertungen

- Me 6402 Manufacturing Technology-Ii Unit IiDokument15 SeitenMe 6402 Manufacturing Technology-Ii Unit Iiananda narayananNoch keine Bewertungen

- 2 3 Basic Machine Tool Operations Drilling MachinesDokument34 Seiten2 3 Basic Machine Tool Operations Drilling MachinesJiggy Lawrence BathanNoch keine Bewertungen

- Common Tools and ProcessesDokument20 SeitenCommon Tools and Processesメルヴリッ クズルエタNoch keine Bewertungen

- SEC-ws - 6-2Dokument26 SeitenSEC-ws - 6-2nadeemsaifi3644Noch keine Bewertungen

- Milling Machine: Prepared By: J.M.PATELDokument20 SeitenMilling Machine: Prepared By: J.M.PATELjigneshpimpalNoch keine Bewertungen

- Flecha CardanDokument6 SeitenFlecha CardanCarlos roberto Aguiirre rosalesNoch keine Bewertungen

- Efficiency of Heat EnginesDokument38 SeitenEfficiency of Heat EnginesGaming JcNoch keine Bewertungen

- Full Line Catalog: P-SeriesDokument44 SeitenFull Line Catalog: P-Seriesyoopr2Noch keine Bewertungen

- Parts Catalogue 527114408 - ENDokument230 SeitenParts Catalogue 527114408 - ENNiko BabinetsNoch keine Bewertungen

- SidewallPropeller Catalog PDFDokument44 SeitenSidewallPropeller Catalog PDFVontrex EngrNoch keine Bewertungen

- Js205 Tracked Excavator I Specification: EngineDokument4 SeitenJs205 Tracked Excavator I Specification: EngineKasidin100% (1)

- Boiler Lit-Up PDFDokument2 SeitenBoiler Lit-Up PDFHoncho Abhi Sinha100% (1)

- Hughes 500 C IpcDokument479 SeitenHughes 500 C IpcRodolfo Rol100% (1)

- Study Ghap4Dokument40 SeitenStudy Ghap4sententialL peetNoch keine Bewertungen

- ENGEL Victory enDokument17 SeitenENGEL Victory enValentinIvascuNoch keine Bewertungen

- 3408C & 3412C Electrical System Marine Auxillary Generator SetDokument2 Seiten3408C & 3412C Electrical System Marine Auxillary Generator SetHamid Essarbouti100% (1)

- Volvo 1998 V70 S70 C70 Parts-CatalogueDokument1.176 SeitenVolvo 1998 V70 S70 C70 Parts-CatalogueEero Aho88% (16)

- MotorDokument48 SeitenMotorHernan CuevasNoch keine Bewertungen

- RCE World Rallycross Championship 2014 New PDFDokument40 SeitenRCE World Rallycross Championship 2014 New PDFAnita DiazNoch keine Bewertungen

- SST-140 Corporate BrochureDokument8 SeitenSST-140 Corporate Brochureandri.plneNoch keine Bewertungen

- 216-Article Text-404-1-10-20200827Dokument3 Seiten216-Article Text-404-1-10-20200827BADINEHALSANDEEPNoch keine Bewertungen

- Regulador AxialDokument12 SeitenRegulador Axialluis_d_mNoch keine Bewertungen

- Vibration of The Millenium Bridge LondonDokument16 SeitenVibration of The Millenium Bridge LondonSilver Olguín CamachoNoch keine Bewertungen

- Manual Compresor Water FurnaceDokument50 SeitenManual Compresor Water FurnaceFred GarciaNoch keine Bewertungen

- Toyota BT Traigo 9FBMK20T-35T Chapter 15 (Oil Control Valve) 25 - 03 - 2022 Service TrainingDokument28 SeitenToyota BT Traigo 9FBMK20T-35T Chapter 15 (Oil Control Valve) 25 - 03 - 2022 Service TrainingDennis SteinbuschNoch keine Bewertungen

- Cilindri PDFDokument40 SeitenCilindri PDFSlobodan SavicNoch keine Bewertungen

- Energy Saving Hydraulic DriveDokument20 SeitenEnergy Saving Hydraulic DriveJamin SmtpngNoch keine Bewertungen

- Bolt Capacities: Grade 4.6 Bolts in S355Dokument3 SeitenBolt Capacities: Grade 4.6 Bolts in S355Ah ChiaNoch keine Bewertungen

- ENG 046 CVVT OCV InspectionDokument5 SeitenENG 046 CVVT OCV Inspectionpacosworld100% (1)

- 2022-2 Spindle MultiphyicsDokument81 Seiten2022-2 Spindle Multiphyics潘季宏Noch keine Bewertungen

- Numericals For Pahse IIDokument7 SeitenNumericals For Pahse IIArun Singh0% (1)

- Ropar ItemInventoryItemWiseList 10-02-2024Dokument2 SeitenRopar ItemInventoryItemWiseList 10-02-2024lahotishreyanshNoch keine Bewertungen

- 2004 Evap System Repair Instructions - 4.2l - Bravada, Envoy & TrailblazerDokument29 Seiten2004 Evap System Repair Instructions - 4.2l - Bravada, Envoy & Trailblazerisshmang100% (2)

- Circle Seal Controls 500 Series Relief ValveDokument6 SeitenCircle Seal Controls 500 Series Relief ValveJai BhandariNoch keine Bewertungen

- Plastic Analysis of Unbraced Portal Frames of Steel Structures in PDFDokument99 SeitenPlastic Analysis of Unbraced Portal Frames of Steel Structures in PDFbiniamNoch keine Bewertungen