Beruflich Dokumente

Kultur Dokumente

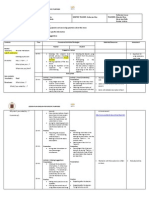

Draft Copy Factory Continuous Improvement Plan 2011

Hochgeladen von

DamianOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Draft Copy Factory Continuous Improvement Plan 2011

Hochgeladen von

DamianCopyright:

Verfügbare Formate

Initative Activity

W k1

W k2

B o ttl i n g l i n e l a b o IuMr P R O V E O V E R A L L P R O D U C T I O N L I N E O E E F R O M 4 W E E K L Y E X I T L E V E L F O R 2 0 1 0

SI Intiative Activities

P ro je c t # 0 Owner Owner

Brief Senior Team and highlight targets and activities on the

Brief the factory CI Plan

teams of the Set the vision for the factory regarding the improvement and

Improvement generate understanding and focus.

Brief Shift Managers, Supervisors and Lines teams

objectives for 2011

F 5 = 3 9 .0 8 % ) T O 4 W E E K L Y E X IT L E V E L F O R 2 0 1 1 O F 5 0 %

highlighting their involvement in the process, the targets and

activities.

Current 16wk average OEE is 38.84%, the "Best of the best"

Implement the 4 stage OEE improvement methodology

OEE achieved during this period has been 56.42%. To

across each shift and line. Teams to be briefed in the

Line A achieve this requires a 14% reduction in the average weekly

methodology and utilise exsisting "S.I.C" sheets to support

downtime from 1211 mins to 1045mins with an average BPM

the process.

of 81

Current 16wk average OEE is 43.36%, the "Best of the best"

OEE achieved during this period has been 50.07%. To Simplify the existing OEE dashboard data and provide an

Line B achieve this requires a 2% reduction in the average weekly easy method for identifying line OEE performance and focus

downtime from 1038 mins to 1024mins with an average BPM improvement activities.

of 50.

Current 16wk average OEE is 28.40%, the "Best of the best"

Implement "SMED/Quick Change over" methodology to

OEE achieved during this period has been 48.25%. To

P ro je c t # 1

implement a standardised/best practice approach in

Line C achieve this requires a 27% reduction in the average weekly

reducing current changeovers. (Utilise the "Very Basic

downtime from 589 mins to 428mins with an average BPM of

Process For Reducing Changeovers")

67

Current 16wk average OEE is 41.63%, the "Best of the best"

Drive equipment reliability improvements through the

OEE achieved during this period has been 50.27%. To

utilisation of line data. Brief the production line "Senior

Line D achieve this requires a 58% reduction in the average weekly

Operatives" to ensure all downtime is recorded under the

downtime from 975mins to 406mins with an average BPM of

appropriate category on the line "SIC" sheets.

82

Current 16wk average OEE is 36.54%, the "Best of the best"

OEE achieved during this period has been 48.01%. To Formalise a regular product/line run rate review between

Line 1 achieve this requires a 23% reduction in the average weekly operations & planning as part of a line performance

downtime from 2111mins to 1615mins with an average BPM improvement initiative.

of 50

Current 16wk average OEE is 44.59%, the "Best of the best"

OEE achieved during this period has been 58.43%. To Evaluate current Planned Preventative Maintenance activities

Line 2 achieve this requires a 25% reduction in the overall average and establish their effectiveness in reducing equipment

weekly downtime from 1845mins to 1377mins with an related downtime.

average BPM of 45

p r o d u c ti v i ty i m p r o v e m e n t

To achieve an average overall OEE of 50% Devise a generic daily shift handover report to collate and

Overall through a targeted reduction in the overall communicate all issues affecting factory 2 & 5 performance

downtime by 25%, and costs.

P ro je c t # 2

Factory 2

Undertake a labour mapping exercise within each factory to

Review the current labour deployement within the factoy and

establisd the current baseline. Utilising this data identify,

identify opportunities to improve productivity whilst

challenge and implement effective productivity improvement

maintaining bothe product quality and production efficiency.

opportunities.

Factory 5

Using the current data collection system, formalise a

During the first 13 weeks of 2011 the average yield variance

"Checking Methodology" for Orange, Lime & Lemon yields

experienced has been 42.89% compared to the budget

Orange Yield to identify and report losses at each stage of the process

C i tr u s & P u r e e Y i e l d i m p r o v e m e n t

target of 45.1%. This equates to an average weekly loss of

and validate the existing losses being used as part of the

approx £4.85k or an annualised loss of £252k

acceptable yield Loss.

During the first 13 weeks of 2011 the average yield variance Review the current loss process flow and identify any

experienced has been 32.2% compared to the budget target additional/missed routes not currently being recorded.

Lime Yield

of 39.5%. This equates to an average weekly loss of approx

P ro je c t # 3

£1.43k or an annualised loss of £74.3k

Record and action the initial fruit yield evaluation practice

(reference machine) and track yeilds daily/weekly.

During the first 13 weeks of 2011 the average yield variance

experienced has been 35.78% compared to the budget

Lemon Yield

target of 37.9%. This equates to an average weekly loss of

Review the current practice of short squeezing runs (limes)

approx £1.95k or an annualised loss of £78k

and identify an alternative approach to reduce current yield

losses.

Review the operational effectivness of the "Pigging System"

and establish an effectiveness measure to ensure optimum

return on the system.

During the first 13 weeks of 2011 the average yield variance

experienced across key purees has been approx 10% lower

Puree Yield

than budgeted target This equates to an average weekly

Design a suitable data analysis system for "Blending"

loss of approx £1.5k or an annualised loss of £76k

losses and provide weekly feeback on losses.

Implement the 4 stage "Blending Yield" process

improvement methodology with the night shift teams.

p ro d u c tiv ity F O R 2 0 1 0 O F (F 2 = 4 0 .6 8 % , F 5 = 3 9 .0 8 % ) T O 4 W E E K L Y E X IT L E V E L F

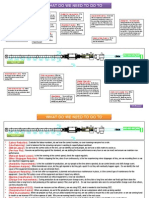

Initative Week 20 Week 21

B o ttlin g lin e la b o u r IM P R O V E O V E R A L L P R O D U C T IO N L IN E O E E F R O M 4 W E E K L Y E

SI Intiative Baseline Target

Owner Measure Savings Measure Savings

Current 16wk average OEE is 38.84%, the "Best of the best"

OEE achieved during this period has been 56.42%. To

Line A achieve this requires a 14% reduction in the average weekly 38.84% 50%

downtime from 1211 mins to 1045mins with an average BPM

of 81

Current 16wk average OEE is 43.36%, the "Best of the best"

OEE achieved during this period has been 50.07%. To

Line B achieve this requires a 2% reduction in the average weekly 43.36% 50%

downtime from 1038 mins to 1024mins with an average BPM

of 50.

Current 16wk average OEE is 28.40%, the "Best of the best"

OEE achieved during this period has been 48.25%. To

28.40% 50%

P ro je c t # 1

Line C achieve this requires a 27% reduction in the average weekly

downtime from 589 mins to 428mins with an average BPM of

OF 50%

67

Current 16wk average OEE is 41.63%, the "Best of the best"

OEE achieved during this period has been 50.27%. To

Line D achieve this requires a 58% reduction in the average weekly 41.63% 50%

downtime from 975mins to 406mins with an average BPM of

82

Current 16wk average OEE is 36.54%, the "Best of the best"

OEE achieved during this period has been 48.01%. To

Line 1 achieve this requires a 23% reduction in the average weekly 36.54% 50%

downtime from 2111mins to 1615mins with an average BPM

of 50

Current 16wk average OEE is 44.59%, the "Best of the best"

OEE achieved during this period has been 58.43%. To

achieve this requires a 25% reduction in the overall average

Line 2 44.59% 50%

weekly downtime from 1845mins to 1377mins with an

average BPM of 45

To achieve an average overall OEE of 50% through a

Overall

targeted reduction in the overall downtime by 25%,

P ro je c t # 2

im p ro v e m e n t

Factory 2

Review the current labour deployement within the factoy and

identify opportunities to improve productivity whilst

maintaining bothe product quality and production efficiency.

Factory 5

C itru s & P u re e Y ie ld im p ro v e m e n t

During the first 13 weeks of 2011 the average yield variance

experienced has been 42.89% compared to the budget

Orange Yield

target of 45.1%. This equates to an average weekly loss of

42.9% 45.1%

approx £4.85k or an annualised loss of £252k

During the first 13 weeks of 2011 the average yield variance

P ro je c t # 3

experienced has been 32.2% compared to the budget target

Lime Yield

of 39.5%. This equates to an average weekly loss of approx

32.2% 39.5%

£1.43k or an annualised loss of £74.3k

During the first 13 weeks of 2011 the average yield variance

experienced has been 35.78% compared to the budget

Lemon Yield

target of 37.9%. This equates to an average weekly loss of

35.8% 37.9%

approx £1.95k or an annualised loss of £78k

During the first 13 weeks of 2011 the average yield variance

experienced across key purees has been approx 10% lower

Puree Yield

than budgeted target This equates to an average weekly

loss of approx £1.5k or an annualised loss of £76k

Das könnte Ihnen auch gefallen

- The Future of Forecasting White Paper - JDADokument3 SeitenThe Future of Forecasting White Paper - JDASanthosh VemisettyNoch keine Bewertungen

- Kaizen FormatdDokument2 SeitenKaizen Formatdsubbu0815Noch keine Bewertungen

- Stakeholder Analysis and Messaging Matrix A and B TemplateDokument3 SeitenStakeholder Analysis and Messaging Matrix A and B Templateshkadry100% (1)

- Skill Development in Ready Made Garment (RMG) : Presented By: Eng. Mohamed El-SayaadDokument12 SeitenSkill Development in Ready Made Garment (RMG) : Presented By: Eng. Mohamed El-SayaadProf Dr Kathirrvelu SubramanianNoch keine Bewertungen

- LocatingDokument91 SeitenLocatingMohammad Taha IrfanNoch keine Bewertungen

- Bow DitchDokument18 SeitenBow DitchRamo KissNoch keine Bewertungen

- School of Samaya Non Profit Organisation in AfricaDokument20 SeitenSchool of Samaya Non Profit Organisation in AfricaKaren KrugerNoch keine Bewertungen

- QMR PDFDokument58 SeitenQMR PDFKhadeer Ahamed100% (1)

- Removal of Factory Plant Equipment Checklist v2Dokument1 SeiteRemoval of Factory Plant Equipment Checklist v2DamianNoch keine Bewertungen

- Supervising People With Disabilities - Hint, It Really Isn't Very Different Than Anyone ElseDokument2 SeitenSupervising People With Disabilities - Hint, It Really Isn't Very Different Than Anyone Elsechoosework0% (1)

- Risk Assessment & Treatment: Business DevelopmentDokument3 SeitenRisk Assessment & Treatment: Business DevelopmentMuath Fawwaz0% (1)

- Stress Managment MeetingDokument22 SeitenStress Managment MeetingReyaz MohemmadNoch keine Bewertungen

- Calibration of Non Automatic Instruments OIML BULLETIN VOLUME XLIVDokument15 SeitenCalibration of Non Automatic Instruments OIML BULLETIN VOLUME XLIVLeonardo G. Pereira NetoNoch keine Bewertungen

- Lesson 2 EOP English For Hotel MaidsDokument3 SeitenLesson 2 EOP English For Hotel MaidsMaría José PeñaNoch keine Bewertungen

- 39-Structuring The Sales InterviewDokument5 Seiten39-Structuring The Sales InterviewHatem AbrasNoch keine Bewertungen

- SC06 - EnglishDokument9 SeitenSC06 - EnglishSumit JindalNoch keine Bewertungen

- Controlled Documents' Masterlist of EPSA CentralDokument85 SeitenControlled Documents' Masterlist of EPSA CentralGetahunNoch keine Bewertungen

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Dokument1 SeiteAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNoch keine Bewertungen

- Kanban SystemsDokument10 SeitenKanban SystemsZeeshange100% (1)

- Chapter 20 - Accounts Receivable and Inventory ManagementDokument22 SeitenChapter 20 - Accounts Receivable and Inventory Managements1137425863Noch keine Bewertungen

- Parts of The Vernier CaliperDokument29 SeitenParts of The Vernier CaliperRobert James Rosales AtienzaNoch keine Bewertungen

- Recruitment, Selection, Process, Methods and Steps, Role of Recruitment Consultant, Advertisment and InductionDokument84 SeitenRecruitment, Selection, Process, Methods and Steps, Role of Recruitment Consultant, Advertisment and InductionvimalsairamNoch keine Bewertungen

- Tones of PassagesDokument10 SeitenTones of Passageseswaraamaraneni100% (1)

- Evolving Role of Finance FinalDokument12 SeitenEvolving Role of Finance FinalVinod HindujaNoch keine Bewertungen

- Professional Dev Training LogDokument4 SeitenProfessional Dev Training LogNewton Learning CenterNoch keine Bewertungen

- Wireharness Assy StationsDokument4 SeitenWireharness Assy StationsFrancisco IrungarayNoch keine Bewertungen

- Customer E-Mail Categorization and Topic ModelingDokument4 SeitenCustomer E-Mail Categorization and Topic ModelingInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Five S Implementation: SORT (Clearing Up Space) OrganizationDokument8 SeitenFive S Implementation: SORT (Clearing Up Space) OrganizationDONNoch keine Bewertungen

- Report The Gallup Employee Engagement Survey May Nan OoDokument10 SeitenReport The Gallup Employee Engagement Survey May Nan Oo3d myanmarNoch keine Bewertungen

- 5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreDokument2 Seiten5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreGeeTheWhizz100% (1)

- Ssfiles Tools FMEAScalesGuideDokument1 SeiteSsfiles Tools FMEAScalesGuideKurt FinkNoch keine Bewertungen

- Calibration Laboratory Depth Gauge: Revision Record SheetDokument6 SeitenCalibration Laboratory Depth Gauge: Revision Record SheetManivasagan VasuNoch keine Bewertungen

- The Recruitment ProcessDokument3 SeitenThe Recruitment ProcessjansimumNoch keine Bewertungen

- 8D:Corrective Actions Request: Claim N°Dokument16 Seiten8D:Corrective Actions Request: Claim N°Alex ReséndizNoch keine Bewertungen

- Communication Plan TemplateDokument1 SeiteCommunication Plan TemplateJorge Octavio Hurtado GonzálezNoch keine Bewertungen

- Free Project Work Plan Template in ExcelDokument9 SeitenFree Project Work Plan Template in ExcelamanNoch keine Bewertungen

- IT Project Management - ch03 by MarchewkaDokument18 SeitenIT Project Management - ch03 by Marchewkapiyawat_siri100% (1)

- Sonia Dahab & José NazárioDokument34 SeitenSonia Dahab & José NazárioGetaw AlamnewNoch keine Bewertungen

- Sustainability Report 2013Dokument44 SeitenSustainability Report 2013rnjs000705Noch keine Bewertungen

- Bina-Kota Pipeline Project: Monthly Progress ReportDokument2 SeitenBina-Kota Pipeline Project: Monthly Progress Reportmansih457Noch keine Bewertungen

- CBAP Application TemplateDokument22 SeitenCBAP Application TemplateMohamed AwadNoch keine Bewertungen

- Kpi Scorecard TemplateDokument2 SeitenKpi Scorecard TemplatePersonalia HC JBSPNoch keine Bewertungen

- Zusammenfassung FIBDokument14 SeitenZusammenfassung FIBHanna MichaelNoch keine Bewertungen

- Accounting Policy Estimate Ind As 8Dokument1 SeiteAccounting Policy Estimate Ind As 8maninderpnnNoch keine Bewertungen

- CDE Frameworks - StagesDokument2 SeitenCDE Frameworks - StagesIyurNoch keine Bewertungen

- Jotun Annual Report 2016 Tcm39 127023Dokument39 SeitenJotun Annual Report 2016 Tcm39 127023EngTamerNoch keine Bewertungen

- How To Read A Value Line ReportDokument15 SeitenHow To Read A Value Line ReportJamie GiannaNoch keine Bewertungen

- 14 - Integration Management - 2013 V5Dokument5 Seiten14 - Integration Management - 2013 V5DougNoch keine Bewertungen

- CBAP Application TemplateDokument19 SeitenCBAP Application Templateshanmuga89Noch keine Bewertungen

- ZRT March 2015 TimesheetsDokument6 SeitenZRT March 2015 TimesheetsEugeneNoch keine Bewertungen

- 2 2 Zero Based Budgeting Training DeckDokument8 Seiten2 2 Zero Based Budgeting Training DeckrhNoch keine Bewertungen

- Agenda: Nainital Bank - Company ProfileDokument4 SeitenAgenda: Nainital Bank - Company ProfileArunima ChatterjeeNoch keine Bewertungen

- Siemens Sirona C1+, M1+ Quick Reference GuideDokument2 SeitenSiemens Sirona C1+, M1+ Quick Reference GuideMarjan StojnevNoch keine Bewertungen

- MutuaL Fund Newsletter - July 2018Dokument68 SeitenMutuaL Fund Newsletter - July 2018Hariprasad ManchiNoch keine Bewertungen

- WhatsApp Tricks and Tips - 10th Edition, 2022 (Etc.) English - 10th - 2022 (Z-Library)Dokument74 SeitenWhatsApp Tricks and Tips - 10th Edition, 2022 (Etc.) English - 10th - 2022 (Z-Library)Murilo MiguelNoch keine Bewertungen

- COBIT Focus Vol 1 2011Dokument16 SeitenCOBIT Focus Vol 1 2011attique@cspNoch keine Bewertungen

- B2B Magazine English LoResDokument25 SeitenB2B Magazine English LoResSuthi Sae DanNoch keine Bewertungen

- 2-Pengaruh Intellectual Capital Terhadap Nilai Perusahaan Dengan Kinerja Keuangan Sebagai Variabel InterveningDokument7 Seiten2-Pengaruh Intellectual Capital Terhadap Nilai Perusahaan Dengan Kinerja Keuangan Sebagai Variabel InterveningSulaiman HanifNoch keine Bewertungen

- Design of ShaftsDokument5 SeitenDesign of ShaftsDamianNoch keine Bewertungen

- Filler RCM StudyDokument4 SeitenFiller RCM StudyDamianNoch keine Bewertungen

- RCM Analysis For SteamDokument13 SeitenRCM Analysis For SteamDamianNoch keine Bewertungen

- Initial Plan For Sonoco Improvement Basic Notes: Example of A Matrix To Prioritise The Line For Performance ImprovementDokument5 SeitenInitial Plan For Sonoco Improvement Basic Notes: Example of A Matrix To Prioritise The Line For Performance ImprovementDamianNoch keine Bewertungen

- RCM Analysis CTN MarianiDokument12 SeitenRCM Analysis CTN MarianiDamianNoch keine Bewertungen

- Operator Asset Care Critical Assessment SectionDokument12 SeitenOperator Asset Care Critical Assessment SectionDamian100% (1)

- 10 Steps To Asset CareDokument13 Seiten10 Steps To Asset CareDamianNoch keine Bewertungen

- Removal of Factory Plant Equipment Checklist v2Dokument1 SeiteRemoval of Factory Plant Equipment Checklist v2DamianNoch keine Bewertungen

- Calculating What It Costs To Run A MotorDokument6 SeitenCalculating What It Costs To Run A MotorDamian100% (1)

- Production Lines Improvement PlanDokument1 SeiteProduction Lines Improvement PlanDamianNoch keine Bewertungen

- 4M Chart For The Section Mgrs & Team LeadersDokument1 Seite4M Chart For The Section Mgrs & Team LeadersDamianNoch keine Bewertungen

- F3 Sanitising Tunnel 1 PMDokument2 SeitenF3 Sanitising Tunnel 1 PMDamianNoch keine Bewertungen

- Calculating What It Costs To Run A MotorDokument6 SeitenCalculating What It Costs To Run A MotorDamian100% (1)

- Production Line Performance Board v3 16-03-11Dokument1 SeiteProduction Line Performance Board v3 16-03-11DamianNoch keine Bewertungen

- Developing A Problem Statement TemplateDokument1 SeiteDeveloping A Problem Statement TemplateDamian0% (1)

- Breakdown Failure Analysis SheetDokument1 SeiteBreakdown Failure Analysis SheetDamianNoch keine Bewertungen

- What Do We Need To Do For PerformanceDokument3 SeitenWhat Do We Need To Do For PerformanceDamianNoch keine Bewertungen

- Attendance Tracker at Morning MeetingsDokument1 SeiteAttendance Tracker at Morning MeetingsDamianNoch keine Bewertungen

- 5W 1H & 5W Analysis Problem Solving TechniqueDokument5 Seiten5W 1H & 5W Analysis Problem Solving TechniqueDamian100% (6)

- Root Cause & Countermeasure Implementation Plan DRMDokument1 SeiteRoot Cause & Countermeasure Implementation Plan DRMDamian100% (1)

- Simplified Root Cause Analysis With Action PlannerDokument1 SeiteSimplified Root Cause Analysis With Action PlannerDamian100% (1)

- Chapter 02 SlidesDokument57 SeitenChapter 02 SlidesZahraa AlQallafNoch keine Bewertungen

- Online Discussion: Enhancing Students' Critical Thinking SkillsDokument8 SeitenOnline Discussion: Enhancing Students' Critical Thinking SkillsThiba KrishnanNoch keine Bewertungen

- WinDokument1 SeiteWinRobert JuricicNoch keine Bewertungen

- CourseOfferingPlanGradF18 S20 20180106Dokument9 SeitenCourseOfferingPlanGradF18 S20 20180106Anshum PalNoch keine Bewertungen

- Lecture 1 IntroductionDokument36 SeitenLecture 1 IntroductionEsraa AliNoch keine Bewertungen

- Table of LFSRDokument6 SeitenTable of LFSRMayur AnvekarNoch keine Bewertungen

- Automated Quality Inspection of Bottles Crates Through Image ProcessingDokument17 SeitenAutomated Quality Inspection of Bottles Crates Through Image ProcessingnasnasNoch keine Bewertungen

- GSM GPRS GNSS HAT User Manual ENDokument32 SeitenGSM GPRS GNSS HAT User Manual ENvinod kumarNoch keine Bewertungen

- 2406 Protomat s3 Serie ManualDokument112 Seiten2406 Protomat s3 Serie ManualOctavio AvendañoNoch keine Bewertungen

- របៀប boost post live page without blue verifiesDokument2 Seitenរបៀប boost post live page without blue verifieskeo linNoch keine Bewertungen

- SEO AdTech Dave ChaffeyDokument44 SeitenSEO AdTech Dave ChaffeysrinivasNoch keine Bewertungen

- MR Cain Richard Mann: Curriculum VitaeDokument4 SeitenMR Cain Richard Mann: Curriculum VitaeDoni MuharomNoch keine Bewertungen

- Dynamodb DGDokument771 SeitenDynamodb DGashishojha1980Noch keine Bewertungen

- Learning SqlalchemyDokument19 SeitenLearning SqlalchemyPushkar DeyNoch keine Bewertungen

- Term PaperDokument13 SeitenTerm PaperGoutam TulsiyanNoch keine Bewertungen

- CMT Eh15Dokument50 SeitenCMT Eh15Eletrônica Maia Comércio e ServiçosNoch keine Bewertungen

- DES NumericalDokument14 SeitenDES NumericalAshish SharmaNoch keine Bewertungen

- Public Records Report by Alameda County Grand JuryDokument6 SeitenPublic Records Report by Alameda County Grand JuryTerry FranckeNoch keine Bewertungen

- Aralin 1 - Dangal Sa PaggawaDokument27 SeitenAralin 1 - Dangal Sa PaggawaPupung MartinezNoch keine Bewertungen

- AmpliTube X-GEAR User ManualDokument84 SeitenAmpliTube X-GEAR User ManualToriano LampkinNoch keine Bewertungen

- Digi Anal5Dokument4 SeitenDigi Anal5NGOUNENoch keine Bewertungen

- Freebitco - in Script MULTIPLY BTC BONUS 2020Dokument2 SeitenFreebitco - in Script MULTIPLY BTC BONUS 2020Mohammadreza EmamiNoch keine Bewertungen

- CT Series: OperationDokument1 SeiteCT Series: OperationcarlosorizabaNoch keine Bewertungen

- Comandos de AutocadDokument23 SeitenComandos de AutocadMartim Tavara AguileraNoch keine Bewertungen

- The Ultimate C - C - TS4CO - 1909 - SAP Certified Application Associate - SAP S/4HANA For Management Accounting Associates (SAP S/4HANA 1909)Dokument2 SeitenThe Ultimate C - C - TS4CO - 1909 - SAP Certified Application Associate - SAP S/4HANA For Management Accounting Associates (SAP S/4HANA 1909)KirstingNoch keine Bewertungen

- Form 15: Name of Member 1Dokument2 SeitenForm 15: Name of Member 1FSADFNoch keine Bewertungen

- ICT X Practice QuestionsDokument3 SeitenICT X Practice QuestionsYash KohaleNoch keine Bewertungen

- Testking - Isc.cissp - Exam.q.and.a.v31.0 DduDokument537 SeitenTestking - Isc.cissp - Exam.q.and.a.v31.0 DduSatyanarayan Bale100% (3)

- Computational Linguistics: Lecture 1: IntroductionDokument25 SeitenComputational Linguistics: Lecture 1: IntroductionDalia AhmedNoch keine Bewertungen

- Chapter Seven Capacitors and InductorsDokument10 SeitenChapter Seven Capacitors and InductorsVimala ElumalaiNoch keine Bewertungen