Beruflich Dokumente

Kultur Dokumente

Pattern Making

Hochgeladen von

Ravi UpadhyeOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pattern Making

Hochgeladen von

Ravi UpadhyeCopyright:

Verfügbare Formate

PATTERN MAKING

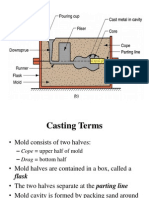

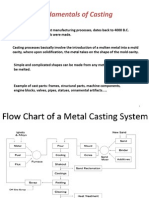

In casting, a pattern is a replica of the object to be cast, used to prepare the cavity into which molten material will be poured during the casting process.[1] [2] Patterns used in sand casting may be made of wood, metal, plastics or other materials. Patterns are made to exacting standards of construction, so that they can last for a reasonable length of time, according to the quality grade of the pattern being built, and so that they will repeatably provide a dimensionally acceptable casting. Under certain circumstances an original item may be adapted to be used as a pattern. The making of patterns, called patternmaking (sometimes styled pattern-making or pattern making), is a skilled trade that is related to the trades of tool and die making and moldmaking, but also often incorporates elements of fine woodworking. Patternmakers (sometimes styled patternmakers or pattern makers) learn their skills through apprenticeships and trade schools over many years of experience. Although an engineer may help to design the pattern, it is usually a patternmaker who executes the design.

Design [edit] Contraction allowances The pattern needs to incorporate suitable allowances for shrinkage; these are called contraction allowances, and their exact values depend on the alloy being cast and the exact sand casting method being used. Some alloys will have overall linear shrinkage of up to 2.5%, whereas other alloys may actually experience no shrinkage or a slight "positive" shrinkage or increase in size in the casting process (notably type metal and certain cast irons). The shrinkage amount is also dependent on the sand casting process employed, for example clay-bonded sand, chemical bonded sands, or other bonding materials used within the sand. This was traditionally accounted for using a shrink rule, which is an oversized rule.

Draft allowances The pattern needs to incorporate suitable allowances for draft, which means that its sides are tapered so that when it is pulled from the sand, it will tend not to drag sand out of place along with it. This is also known as taper which is normally between 1 and 3 degrees. Sprues, gates, risers, cores, and chills The patternmaker or foundry engineer decides where the sprues, gating systems, and risers are placed with respect to the pattern. Where a hole is desired in a casting, a core may be used which defines a volume or location in a casting where metal will not flow into. Sometimes chills may be located on a pattern surface, which are then formed into the sand mould. Chills are heat sinks which enable localized rapid cooling. The rapid cooling may be desired to refine the grain structure or determine the freezing sequence of the molten metal which is poured into the mould.

Das könnte Ihnen auch gefallen

- MP - Module 1 - Casting ProcessesDokument108 SeitenMP - Module 1 - Casting ProcessesrohanNoch keine Bewertungen

- Sand CastingDokument45 SeitenSand CastingwinasharNoch keine Bewertungen

- Sand Casting: Over 70% of All Metal Castings Are Produced Via A Sand Casting ProcessDokument45 SeitenSand Casting: Over 70% of All Metal Castings Are Produced Via A Sand Casting ProcessSUNDRAMNAGANoch keine Bewertungen

- Sand Casting Process Explained in 40 CharactersDokument45 SeitenSand Casting Process Explained in 40 CharactersjmmshahNoch keine Bewertungen

- Pattern MakingDokument11 SeitenPattern MakingPATEL RAHUL100% (1)

- 2,. CastingDokument37 Seiten2,. Castingmohit s sNoch keine Bewertungen

- Sand CastingDokument9 SeitenSand CastingShivaram Subbaraya VelumaniNoch keine Bewertungen

- Lec 1 & 2Dokument43 SeitenLec 1 & 2Omar AssalNoch keine Bewertungen

- MP - Unit I-1 PDFDokument51 SeitenMP - Unit I-1 PDFGuest 128Noch keine Bewertungen

- Casting DetailsDokument8 SeitenCasting DetailsudayraochNoch keine Bewertungen

- IntroductionDokument106 SeitenIntroductionMahalingam SundaradasNoch keine Bewertungen

- Mp1 m1 Short NotesDokument43 SeitenMp1 m1 Short NotesRadhika GandhiNoch keine Bewertungen

- Cast Automobile PartsDokument52 SeitenCast Automobile PartsnunuNoch keine Bewertungen

- Introduction To Metal Casting: by Prof. Keyur Parmar G.I.T.S, PrantijDokument72 SeitenIntroduction To Metal Casting: by Prof. Keyur Parmar G.I.T.S, PrantijtraceminiNoch keine Bewertungen

- Foundary or CastingDokument88 SeitenFoundary or CastingThulasi RamNoch keine Bewertungen

- Casting Manufacturing Lab ReportDokument16 SeitenCasting Manufacturing Lab ReportNiko KoNoch keine Bewertungen

- Manpro Combined (Casting Welding)Dokument400 SeitenManpro Combined (Casting Welding)dhruv rohillaNoch keine Bewertungen

- INVESTMENT CASTING (Shiv)Dokument12 SeitenINVESTMENT CASTING (Shiv)2K20CH39 Kshitij ShubhamNoch keine Bewertungen

- Metal CastingDokument75 SeitenMetal CastingRajaSekarsajjaNoch keine Bewertungen

- Risers and Riser Design: General Design Rules For Riser Necks Used in Iron CastingsDokument62 SeitenRisers and Riser Design: General Design Rules For Riser Necks Used in Iron CastingsGonzalo GiménezNoch keine Bewertungen

- Patterns For Mould MakingDokument21 SeitenPatterns For Mould MakingokicirdarNoch keine Bewertungen

- of ManuDokument87 Seitenof ManuVaibhav BaggaNoch keine Bewertungen

- Lecture2casting 160411082846Dokument190 SeitenLecture2casting 160411082846IgnatiusAbbyNoch keine Bewertungen

- Dr. Chaitanya Sharma Phd. Iit RoorkeeDokument26 SeitenDr. Chaitanya Sharma Phd. Iit RoorkeeTrung Quoc LeNoch keine Bewertungen

- Metal Casting Sand Mold Factories Foundries: Sand Casting, Also Known As Sand Molded Casting, Is ADokument16 SeitenMetal Casting Sand Mold Factories Foundries: Sand Casting, Also Known As Sand Molded Casting, Is AMuneeb Irfan100% (1)

- Casting IntroDokument94 SeitenCasting IntroJith ViswaNoch keine Bewertungen

- INTRODUCTION To MANUFACTURING PROCESS PART-2 (2) .PpsDokument47 SeitenINTRODUCTION To MANUFACTURING PROCESS PART-2 (2) .Ppsmahammad kamaluddeenNoch keine Bewertungen

- Chapter 2 Metal Casting ProcessesDokument59 SeitenChapter 2 Metal Casting Processesdagimawgchew777Noch keine Bewertungen

- Manufacturing Process: I Semester ES-119Dokument170 SeitenManufacturing Process: I Semester ES-119sayan halderNoch keine Bewertungen

- Metal Casting 1Dokument44 SeitenMetal Casting 1PIYUSH SHARMANoch keine Bewertungen

- Design For CastingDokument14 SeitenDesign For CastingArtemis FowlNoch keine Bewertungen

- Quality Casting ManualDokument27 SeitenQuality Casting ManualvisitabhinavNoch keine Bewertungen

- It Is ConsiderationDokument17 SeitenIt Is ConsiderationTulasabai JaiswalNoch keine Bewertungen

- Lecture 1Dokument18 SeitenLecture 1Mayank SharmaNoch keine Bewertungen

- Metal Casting ProcessesDokument61 SeitenMetal Casting ProcessesBinyam HabtamuNoch keine Bewertungen

- Casting Design and Process OptimizationDokument20 SeitenCasting Design and Process OptimizationCHANDRAJEET AMARNoch keine Bewertungen

- CastingDokument46 SeitenCastingamalendu_biswas_1Noch keine Bewertungen

- CastingDokument17 SeitenCastingprince agbekoNoch keine Bewertungen

- Casting TheoryDokument22 SeitenCasting TheoryJairam Atluri100% (1)

- UNit 3 Part A RevisedDokument76 SeitenUNit 3 Part A Revisedraymon sharmaNoch keine Bewertungen

- Unit 1 NotesDokument27 SeitenUnit 1 NotesarunkumarnoolaNoch keine Bewertungen

- Ch.2 Casting Processes, Lec 2Dokument36 SeitenCh.2 Casting Processes, Lec 2Abd El RahmanNoch keine Bewertungen

- Casting Procedure StepsDokument185 SeitenCasting Procedure StepsPraffulla Mynampati100% (1)

- Manufacturing Casting Process GuideDokument41 SeitenManufacturing Casting Process GuideRahul DandugulaNoch keine Bewertungen

- Centrifugal Casting Manufacturing ProcessDokument11 SeitenCentrifugal Casting Manufacturing ProcessPRADIPAN DEYNoch keine Bewertungen

- 1 Hareesha N G Dept Aero Engg, DSCE, BloreDokument47 Seiten1 Hareesha N G Dept Aero Engg, DSCE, Bloremahammad kamaluddeenNoch keine Bewertungen

- Pattern is a replica of the final object to be made with some modificationsDokument95 SeitenPattern is a replica of the final object to be made with some modificationsSaurabh ThakurNoch keine Bewertungen

- FALLSEM2020-21 MEE3501 ETH VL2020210100413 2020-09-08 Reference-Material-IDokument334 SeitenFALLSEM2020-21 MEE3501 ETH VL2020210100413 2020-09-08 Reference-Material-ISiddhant TemghareNoch keine Bewertungen

- Casting & Welding Engineering Course OverviewDokument23 SeitenCasting & Welding Engineering Course OverviewGanesh Badgire ReddyNoch keine Bewertungen

- Metal CastingDokument89 SeitenMetal CastingazeemdcetNoch keine Bewertungen

- Learn Critical Aspects of Pattern and Mould Making in FoundryVon EverandLearn Critical Aspects of Pattern and Mould Making in FoundryNoch keine Bewertungen

- Turning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelVon EverandTurning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelBewertung: 4.5 von 5 Sternen4.5/5 (3)

- The Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationVon EverandThe Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationNoch keine Bewertungen

- The Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerVon EverandThe Fundamentals of Segmented Woodturning: Projects, Techniques & Innovations for Today’s WoodturnerBewertung: 4 von 5 Sternen4/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Von EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Bewertung: 5 von 5 Sternen5/5 (2)

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesVon EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNoch keine Bewertungen

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersVon EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Self-Perception by Lauren BergerDokument44 SeitenSelf-Perception by Lauren BergerCristina TomaNoch keine Bewertungen

- Sacks, Oliver - Musicophilia, Tales of Music and The Brain (Knopf, 2007)Dokument394 SeitenSacks, Oliver - Musicophilia, Tales of Music and The Brain (Knopf, 2007)Cristina Toma100% (17)

- One Bead at A TimeDokument59 SeitenOne Bead at A TimeCristina Toma100% (3)

- NullDokument98 SeitenNullCristina TomaNoch keine Bewertungen

- Compendium Part 1 enDokument24 SeitenCompendium Part 1 encristopher_ceratiNoch keine Bewertungen

- Turkish vowel harmony rulesDokument1 SeiteTurkish vowel harmony rulesCristina TomaNoch keine Bewertungen