Beruflich Dokumente

Kultur Dokumente

Ultrasonic Couplants: BY: Nikesh Ranjan 08BEI046

Hochgeladen von

Shrey SharmaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ultrasonic Couplants: BY: Nikesh Ranjan 08BEI046

Hochgeladen von

Shrey SharmaCopyright:

Verfügbare Formate

ULTRASONIC COUPLANTS

Click to edit Master subtitle style

BY: NIKESH RANJAN 08BEI046

4/15/12

4/15/12

INTRODUCTION Ultrasonic couplants are used in virtually all contact testing applications to facilitate the transmission of sound energy between the transducer and the test piece. Couplants will typically be viscous, nontoxic liquids, gels, or pastes. 4/15/12

USE Their use is necessary because sound energy at the ultrasonic frequencies typically used for nondestructive testing is not effectively transmitted through air. Aside from attenuation effects, air represents a severe acoustic impedance mismatch with respect to both transducer wearplates and typical test materials.

4/15/12

APPLICATION A number of common substances such as water, motor oil, grease, and even some commercial products like hair gel can be used as ultrasonic couplants in many applications. However, for best results in high temperature and normal incidence shear wave testing it is necessary to use specially formulated couplants, and 4/15/12 testing in the nuclear industry

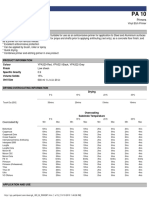

The Panametrics-NDT line of ultrasonic couplants includes seven different products optimized for different applications. A description of each follows, listed according to their Panametrics-NDT part code.

COUPLANT A - PROPYLENE GLYCOL Propylene glycol is a good general purpose couplant that is often used in ambient temperature thickness gaging applications on smooth surfaces. It has 4/15/12

COUPLANT B GLYCERIN Glycerin's advantage is that it is more viscous and has a higher acoustic impedance, making it the preferred couplant for rough surfaces and highly attenuating materials. COUPLANT C - SILICONE OIL Silicone oil is preferred by some inspectors who are doing angle beam testing as a couplant between the transducer and the wedge. Because it does not evaporate and is insoluble in 4/15/12

COUPLANT D GEL Gel type couplants are often recommended for rough surfaces such as sand-cast metals and fiberglass layups, where their high viscosity and relatively high acoustic impedance will maximize sound coupling in a situation where the transducer cannot make smooth contact with the test surface. COUPLANT E ULTRATHERM Ultrasonic testing at high temperatures requires specially 4/15/12 formulated couplants that will remain

COUPLANT F - MEDIUM TEMPERATURE COUPLANT This product has been replaced by Couplant G, which offers superior performance. COUPLANT G - MEDIUM TEMPERATURE COUPLANT Couplant G is a non-toxic, biodegradable gel that is particularly recommended for testing parts that are too hot for ambient temperature couplants, but not hot enough to 4/15/12

Das könnte Ihnen auch gefallen

- O Ring Vacuum SealingDokument15 SeitenO Ring Vacuum SealingManoj SundararajanNoch keine Bewertungen

- Parker O RingDokument0 SeitenParker O RingRazvan C GoranNoch keine Bewertungen

- Oring Guide Europe Ord 5712ukDokument0 SeitenOring Guide Europe Ord 5712ukramchandra rao deshpandeNoch keine Bewertungen

- Raj Rubber ProductsDokument35 SeitenRaj Rubber Productsnaveenraj mNoch keine Bewertungen

- Tankguard 412 Jotun PaintDokument6 SeitenTankguard 412 Jotun PaintGurdeep Sungh AroraNoch keine Bewertungen

- Pa 10Dokument3 SeitenPa 10LymeParkNoch keine Bewertungen

- 59E Agitator Seals in Chemical-En-18.09.2008Dokument24 Seiten59E Agitator Seals in Chemical-En-18.09.2008Daniel CostaNoch keine Bewertungen

- Properties Foster Duct-Fas® Adhesive (Non-Flammable) : Product Data SheetDokument2 SeitenProperties Foster Duct-Fas® Adhesive (Non-Flammable) : Product Data SheetOscar ZelayaNoch keine Bewertungen

- Ar 2030 Kte 9 TXDokument4 SeitenAr 2030 Kte 9 TXbizhanjNoch keine Bewertungen

- Hempel - Hempadur Multi-Strength 45753 (Cold Climate)Dokument3 SeitenHempel - Hempadur Multi-Strength 45753 (Cold Climate)CallumWoodwardNoch keine Bewertungen

- Foster 32 17Dokument2 SeitenFoster 32 17mohabadel87Noch keine Bewertungen

- Epiplus 556Dokument2 SeitenEpiplus 556hareesh13h100% (1)

- Tankguard SF: Technical Data SheetDokument5 SeitenTankguard SF: Technical Data SheetRifki ArifinNoch keine Bewertungen

- MRO Product Range From Project Sales Corp, IndiaDokument43 SeitenMRO Product Range From Project Sales Corp, IndiaProject Sales CorpNoch keine Bewertungen

- Gravitex Plus: Technical Data Sheet & Process GuideDokument3 SeitenGravitex Plus: Technical Data Sheet & Process GuideOluwaseun TaiwoNoch keine Bewertungen

- TDS 2063 Tankguard 412 Euk GBDokument6 SeitenTDS 2063 Tankguard 412 Euk GBAhmad SyawalNoch keine Bewertungen

- GROTH Product Selection GuideDokument12 SeitenGROTH Product Selection GuideJeniferth GaitanNoch keine Bewertungen

- Anti Condensation CatalogueDokument8 SeitenAnti Condensation CatalogueBoBo KyawNoch keine Bewertungen

- Tankguard StorageDokument5 SeitenTankguard StorageBiju_PottayilNoch keine Bewertungen

- Polysulphide Sealant ManufacturerDokument2 SeitenPolysulphide Sealant ManufacturerNeha RathoreNoch keine Bewertungen

- Zyglo ZL-2C, ZL-27A, ZL-37Dokument4 SeitenZyglo ZL-2C, ZL-27A, ZL-37Olivia MendozaNoch keine Bewertungen

- NBR Piston Cup Seal: General Cylinders Pneumatic CylindersDokument10 SeitenNBR Piston Cup Seal: General Cylinders Pneumatic CylindersSHANENoch keine Bewertungen

- 95 44Dokument2 Seiten95 44Vivek VenugopalNoch keine Bewertungen

- Foster 32-17Dokument2 SeitenFoster 32-17Mostafa AymanNoch keine Bewertungen

- Aviation: Silicones inDokument5 SeitenAviation: Silicones inrizviabbas2012Noch keine Bewertungen

- TDS 2063 Tankguard 412 Euk GBDokument6 SeitenTDS 2063 Tankguard 412 Euk GBSrimathi VijayakumarNoch keine Bewertungen

- 7430 - Sigmacover 630Dokument0 Seiten7430 - Sigmacover 630eraswastaNoch keine Bewertungen

- Heresite Technical Data Sheet (VR-514)Dokument5 SeitenHeresite Technical Data Sheet (VR-514)Wadu DetutsNoch keine Bewertungen

- Coalescers ZM E25Dokument2 SeitenCoalescers ZM E25abaskmNoch keine Bewertungen

- Bombas NeumaticasDokument32 SeitenBombas Neumaticasfawllyn guevaraNoch keine Bewertungen

- VP 31a Product Data Met L CheckDokument2 SeitenVP 31a Product Data Met L CheckTopoilServNoch keine Bewertungen

- Busak Shamban GLYD-RINGDokument20 SeitenBusak Shamban GLYD-RINGRodrigo Schaider Dos SantosNoch keine Bewertungen

- Powercrete R150Dokument2 SeitenPowercrete R150welbert001Noch keine Bewertungen

- Technical Date Sheel Jotun Hard Top As. AluminiumDokument5 SeitenTechnical Date Sheel Jotun Hard Top As. Aluminiumafrian_arieNoch keine Bewertungen

- Engineering Flourosilicone Elastomer: Description ApplicationDokument3 SeitenEngineering Flourosilicone Elastomer: Description ApplicationLU CHUNHUINoch keine Bewertungen

- Paint Specification HamadourDokument2 SeitenPaint Specification HamadourAbdul Majid LodhiNoch keine Bewertungen

- Chemflake SpecialDokument5 SeitenChemflake Specialmajmor-1Noch keine Bewertungen

- Klueberfluid C-F 4 Ultra 039071 PI GB enDokument2 SeitenKlueberfluid C-F 4 Ultra 039071 PI GB enwajahat ali KhanNoch keine Bewertungen

- DunlopGRG LPPneumaticFendersBro 29-09-15Dokument8 SeitenDunlopGRG LPPneumaticFendersBro 29-09-15thinh_vu5218Noch keine Bewertungen

- PDS FOSTER - 30-45N - Foamseal Sealant PDFDokument2 SeitenPDS FOSTER - 30-45N - Foamseal Sealant PDFHanafi MansorNoch keine Bewertungen

- X-Tech UraFloor CSDokument2 SeitenX-Tech UraFloor CSLONG LASTNoch keine Bewertungen

- Drfixit Torchshield PDFDokument4 SeitenDrfixit Torchshield PDFshashiNoch keine Bewertungen

- Filler For Contraction JointsDokument5 SeitenFiller For Contraction JointsAshok Maan100% (1)

- Interior Fluid Resistant Epoxy Primer: Technical Data SheetDokument5 SeitenInterior Fluid Resistant Epoxy Primer: Technical Data SheetPannha LangNoch keine Bewertungen

- Kluberfluid C F 3 UltraDokument2 SeitenKluberfluid C F 3 UltraSathykumar MurugesanNoch keine Bewertungen

- RTV157 and RTV159: Technical Data SheetDokument7 SeitenRTV157 and RTV159: Technical Data SheetMichael McQueenNoch keine Bewertungen

- Fluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetDokument4 SeitenFluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetFrancisco RodríguezNoch keine Bewertungen

- TDS-Foster 95-44 EN PDFDokument2 SeitenTDS-Foster 95-44 EN PDFEshaghNoch keine Bewertungen

- Gfps 0515 Manual Rotor X Flow Sensors enDokument12 SeitenGfps 0515 Manual Rotor X Flow Sensors enRodrigoNoch keine Bewertungen

- Flow Transmitter GF Signet 515 Manual PDFDokument8 SeitenFlow Transmitter GF Signet 515 Manual PDFnicoandayNoch keine Bewertungen

- Rd6appspecDokument2 SeitenRd6appspecravi00098Noch keine Bewertungen

- Catalog of Flexicon Flexible Conduit Solutions For Hazardous AreasDokument17 SeitenCatalog of Flexicon Flexible Conduit Solutions For Hazardous AreasIBJSC.comNoch keine Bewertungen

- New Material Seals Better On HVOF CoatingsDokument2 SeitenNew Material Seals Better On HVOF Coatingssandbad2100% (2)

- Man Tek CouplingsDokument8 SeitenMan Tek CouplingsBenjamin StricklandNoch keine Bewertungen

- Carboguard 885 PDSDokument2 SeitenCarboguard 885 PDSsyazwanjohnmazlanNoch keine Bewertungen

- GreenEX - Cataloge - DSPA CompetitorDokument4 SeitenGreenEX - Cataloge - DSPA CompetitorJai GosarNoch keine Bewertungen

- Zetpol HNBR Rubber Elastomers - Zeon ChemicalsDokument17 SeitenZetpol HNBR Rubber Elastomers - Zeon Chemicalscuenta_descarga88Noch keine Bewertungen

- Geotextiles and Geomembranes HandbookVon EverandGeotextiles and Geomembranes HandbookT.S. IngoldBewertung: 5 von 5 Sternen5/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Von EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Noch keine Bewertungen

- Welding Research Council: BulletinDokument28 SeitenWelding Research Council: BulletinRogerio Tropia GranjaNoch keine Bewertungen

- Sindarin-English Dictionary - 2nd EditionDokument192 SeitenSindarin-English Dictionary - 2nd EditionNea Tan100% (1)

- Tank Gauging TankvisionDokument31 SeitenTank Gauging Tankvisionkhangduongda3Noch keine Bewertungen

- Lcnews227 - Nexera SeriesDokument47 SeitenLcnews227 - Nexera SeriesMuhammad RohmanNoch keine Bewertungen

- Case-Study - Decision Making Under UncertaintyDokument21 SeitenCase-Study - Decision Making Under UncertaintyMari GhviniashviliNoch keine Bewertungen

- Chemistry NotesDokument11 SeitenChemistry Notesraifaisal9267% (12)

- Nicotine From CigarettesDokument2 SeitenNicotine From CigarettesAditya Agarwal100% (1)

- Tempera 2018 AbstractsDokument45 SeitenTempera 2018 AbstractsGerard Emmanuel KamdemNoch keine Bewertungen

- NARS Fall 2011 Press File PDFDokument19 SeitenNARS Fall 2011 Press File PDFheather_dillowNoch keine Bewertungen

- Under Pass Wing Wall (4.1m)Dokument12 SeitenUnder Pass Wing Wall (4.1m)Naveed NazNoch keine Bewertungen

- Most Important One Liner Questions and Answers May 2022Dokument15 SeitenMost Important One Liner Questions and Answers May 2022pradeepNoch keine Bewertungen

- HBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris PavlidisDokument4 SeitenHBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris Pavlidissagacious.ali2219Noch keine Bewertungen

- TR189 Kathuria PDFDokument168 SeitenTR189 Kathuria PDFuqiNoch keine Bewertungen

- Aerodrome Advisory Circular: AD AC 04 of 2017Dokument6 SeitenAerodrome Advisory Circular: AD AC 04 of 2017confirm@Noch keine Bewertungen

- Stokerchapter25lipidmetabolism 160320032037Dokument29 SeitenStokerchapter25lipidmetabolism 160320032037Dawlat SalamaNoch keine Bewertungen

- Zetor Crystal 150 170 Tractor Operator Manual PDFDokument234 SeitenZetor Crystal 150 170 Tractor Operator Manual PDFAntonNoch keine Bewertungen

- EB-300 310 Service ManualDokument32 SeitenEB-300 310 Service ManualVictor ArizagaNoch keine Bewertungen

- Diablo Watch Newsletter, FALL 2009 Save Mount DiabloDokument16 SeitenDiablo Watch Newsletter, FALL 2009 Save Mount DiabloIoannqisHatzopoulosNoch keine Bewertungen

- Syntorial NotesDokument13 SeitenSyntorial NotesdanNoch keine Bewertungen

- IFIS - Intraoperative Floppy Iris Syndrome Wa Wa 27-09-2008Dokument18 SeitenIFIS - Intraoperative Floppy Iris Syndrome Wa Wa 27-09-2008JanuszNoch keine Bewertungen

- BTL Info CNC ProgrammDokument132 SeitenBTL Info CNC ProgrammdieulafaitNoch keine Bewertungen

- Advanced Steel Structure Concepts: 2 MonthsDokument4 SeitenAdvanced Steel Structure Concepts: 2 MonthsAnkit SoniNoch keine Bewertungen

- Manual de Taller sk350 PDFDokument31 SeitenManual de Taller sk350 PDFLeo Perez100% (1)

- Ge Druck PTX 7535Dokument2 SeitenGe Druck PTX 7535ICSSNoch keine Bewertungen

- Master of Business Administration in Aviation Management MbaamDokument10 SeitenMaster of Business Administration in Aviation Management MbaamAdebayo KehindeNoch keine Bewertungen

- QTM - Soap Battle CaseDokument7 SeitenQTM - Soap Battle CaseAshish Babaria100% (1)

- Latihan Soal BlankDokument8 SeitenLatihan Soal BlankDanbooNoch keine Bewertungen

- High Performance Dialysis GuideDokument28 SeitenHigh Performance Dialysis GuideRoxana ElenaNoch keine Bewertungen

- IMS Institute BelgradeDokument10 SeitenIMS Institute BelgradeBoško JanjuševićNoch keine Bewertungen

- Refrigeration Engineer Quick ReferenceDokument2 SeitenRefrigeration Engineer Quick ReferenceventilationNoch keine Bewertungen