Beruflich Dokumente

Kultur Dokumente

EOQ Vs EPQ

Hochgeladen von

Aarti Soun0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

572 Ansichten17 SeitenEconomic Order Quantity (EOQ) is the fixed order quantity (Q) that minimizes the total annual costs of placing orders and holding inventory (TC). Simple Reorder Point uses this method when daily demand is constant.

Originalbeschreibung:

Originaltitel

EOQ vs EPQ

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenEconomic Order Quantity (EOQ) is the fixed order quantity (Q) that minimizes the total annual costs of placing orders and holding inventory (TC). Simple Reorder Point uses this method when daily demand is constant.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

572 Ansichten17 SeitenEOQ Vs EPQ

Hochgeladen von

Aarti SounEconomic Order Quantity (EOQ) is the fixed order quantity (Q) that minimizes the total annual costs of placing orders and holding inventory (TC). Simple Reorder Point uses this method when daily demand is constant.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 17

Economic Order Quantity

The economic order quantity (EOQ) is

the fixed order quantity (Q) that

minimizes the total annual costs of

placing orders and holding inventory

(TC).

Economic Order Quantity

Assumptions

Demand (D) is known and constant

H is known and constant

Order costs (S) are constant

The order quantity arrives in a single

shipment

No quantity discounts are available

All demand will be met (no shortages)

We want to minimize TC

D, S, and H are constant. TC is a function of Q.

1

2 2

D Q H

TC S H DS Q

Q Q

= + = +

Economic Order Quantity (3)

*

2DS

Q

H

=

*

*

2

D Q

TC S H

Q

= +

Let Q

*

be the economic order quantity. Then

For Q

*

, annual order cost = annual inventory cost

*

*

2

D Q

S H

Q

=

Simple Reorder Point

Use this method when daily demand is

constant.

R = reorder point

d = daily demand (may have to compute

this)

L = lead time (Caution: if lead time is given

in weeks, convert this to days).

R = dL

Reorder Point with Safety Stock (2)

How much safety stock (SS) ?

Reorder point with safety stock:

Service level is the probability of having enough

inventory to meet demand during lead time

The probability of a stockout is (1 - service level)

Demand during lead time is normally distributed

with mean and standard deviation o

dL

SS L d R + =

demand daily average = d

L d

Reorder Point with Safety Stock (2)

How much safety stock (SS) ?

z is the number of standard deviations required to

meet the desired service level

SS = zo

dL

Reorder point with safety stock: R = + zo

dL

L d

Reorder Point with Safety Stock

Example

Given

D = annual demand = 10,000

N = number of business days per year = 250

The company operates 5 days per week

= average daily demand

o

dL

= standard deviation of demand during lead time = 20

L = lead time = 1 week

Service level = 96%

Find: reorder point with safety stock: R = + zo

dL

L d

d

Computing Reorder Point

with Safety Stock

1. If average daily demand ( ) is not given,

compute it.

Note: = D/N and D =

= 10,000/250 = 40

2. If the lead time is given in weeks or

months, compute lead time in days.

L = 1 week = 1(5) = 5 days

Note: 1 week is the number of days per week that

the company operates. This may be 5, 6, or 7.

d

d

d d N

Computing Reorder Point

with Safety Stock (2)

3. Find the z value for the service level

(96%)

Probability of

a stockout =

1 service

level = 4%

z

50% 46%

L d

Appendix B gives

this area.

Computing Reorder Point

with Safety Stock (3)

3. Find the z value for the service level (96%) (cont.)

(a) Write the service level as a decimal

96% = 0.9600

(b) Subtract 0.5000 from the service level

0.9600 0.5000 = 0.4600

(c) Use the table in Appendix B, page 652, to find

the area that is closest to 0.4600

The closest area in the table is 0.4599, which

occurs when z = 1.75

Use z = 1.75

Computing Reorder Point

with Safety Stock (4)

4. Compute R

R = L+ zo

dL

= 40(5) + 1.75(20) = 200 + 35

= 235

Note: If the computation gives a fractional

value, round up to nearest integer.

Example: Computed R = 210.2 R = 211

d

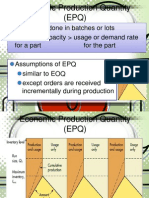

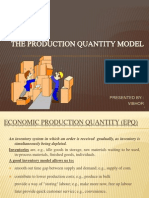

Economic Production Quantity

Key question: How many units of a part or

product should be made at one time?

The economic production quantity (EPQ) is

the production quantity (lot size) that

minimizes the total annual cost of setups

and holding inventory.

Economic Production Quantity (2)

Notation

Q = Amount to make (lot size)

D = annual demand for the item

d = daily demand for the item

p = daily production rate

S = cost of one setup

H = inventory holding cost per unit per year

(commonly called holding cost)

TC = annual cost of setups

+ annual cost of holding inventory

The EPQ is the quantity that minimizes TC

Economic Production Quantity (3)

Assumption: Daily demand < daily production.

When the item is being made, some is sold or used to

make a product. The remainder goes into inventory.

When production stops, the inventory is used until

there is no inventory left. Then production resumes.

Ending inventory

= beginning

inventory

+ production

- sales or usage

Economic Production Quantity (4)

Length of production run = Q/p

During production, d units are sold or used each day. (p d)

units go into inventory.

|

|

.

|

\

|

= =

p

d

Q d p 1 ) (

p

Q

I

MAX

Maximum inventory:

Total cost: |

.

|

\

|

+ |

.

|

\

|

= H

2

I

S

Q

D

TC

MAX

EPQ

Economic production

quantity (EPQ):

|

|

.

|

\

|

=

p

d

1 H

2DS

EPQ

EOQ vs. EPQ

When to use economic order quantity (EOQ):

Demand is independent

Compute how much to order (order quantity)

When to use economic production quantity

(EPQ):

Parts or products will be produced: demand is

dependent

Compute how much to make at one time

(production lot size)

Das könnte Ihnen auch gefallen

- EOQ Vs EPQDokument18 SeitenEOQ Vs EPQParidhi Aggarwal100% (1)

- Chap015 Inventory ControlDokument43 SeitenChap015 Inventory ControlKhushbu ChandnaniNoch keine Bewertungen

- Chap 015Dokument43 SeitenChap 015Ponkiya AnkitNoch keine Bewertungen

- Cycle InventoryDokument13 SeitenCycle InventoryUmang ZehenNoch keine Bewertungen

- Economic Production Quantity (EPQ)Dokument54 SeitenEconomic Production Quantity (EPQ)Bryan Joseph Jumawid100% (3)

- Inventory Control: Operations ManagementDokument43 SeitenInventory Control: Operations ManagementRahul KhannaNoch keine Bewertungen

- Managing Service Inventory: Replenishment Order Replenishment Order Replenishment Order Customer OrderDokument38 SeitenManaging Service Inventory: Replenishment Order Replenishment Order Replenishment Order Customer OrderNitesh RanjanNoch keine Bewertungen

- 5.HW Chap 12 - 2,8,10,14,16Dokument5 Seiten5.HW Chap 12 - 2,8,10,14,16Jyothi VenuNoch keine Bewertungen

- 8 Inventory SystemsDokument48 Seiten8 Inventory SystemsAngeline Nicole RegaladoNoch keine Bewertungen

- 8 Inventory SystemDokument48 Seiten8 Inventory SystemPollyNoch keine Bewertungen

- D464 Formula SheetDokument13 SeitenD464 Formula Sheetyomaira.bastidas.ysNoch keine Bewertungen

- Optimize Inventory with EOQ and ROP ModelsDokument14 SeitenOptimize Inventory with EOQ and ROP ModelsHaider Abdul QadirNoch keine Bewertungen

- Inventory Management 21 PankajDokument34 SeitenInventory Management 21 PankajPankaj Tadaskar TadaskarNoch keine Bewertungen

- Independent Demand Inventory Management: by 2 Edition © Wiley 2005 Powerpoint Presentation by R.B. Clough - UnhDokument38 SeitenIndependent Demand Inventory Management: by 2 Edition © Wiley 2005 Powerpoint Presentation by R.B. Clough - UnhSaurav ShawNoch keine Bewertungen

- Business MathematicsDokument21 SeitenBusiness MathematicsAhmer A. NadeemNoch keine Bewertungen

- Application of Differential CalculusDokument21 SeitenApplication of Differential CalculusTareq Islam100% (1)

- Special Inventory MGMT ModelsDokument42 SeitenSpecial Inventory MGMT ModelsPradeep SethiaNoch keine Bewertungen

- Ch14 Inventory13Dokument22 SeitenCh14 Inventory13ndc6105058Noch keine Bewertungen

- EOQ Model PresentaionDokument18 SeitenEOQ Model PresentaionNauman RashidNoch keine Bewertungen

- (786111951) (U1j-Of - Rwi) Lec15Dokument9 Seiten(786111951) (U1j-Of - Rwi) Lec15Muhammad Harits KebumenNoch keine Bewertungen

- Chapter 17. Inventory Control: Inventory Is The Stock of Any Item or Resource Used in AnDokument21 SeitenChapter 17. Inventory Control: Inventory Is The Stock of Any Item or Resource Used in AnHassan SalamaNoch keine Bewertungen

- Supply Chain Management: Indian Institute of Management LucknowDokument29 SeitenSupply Chain Management: Indian Institute of Management LucknowParidhi VarmaNoch keine Bewertungen

- CHAPTER 11 Inventory ModelDokument24 SeitenCHAPTER 11 Inventory ModelmulunehNoch keine Bewertungen

- CHAPTER 11 Inventory ModelDokument24 SeitenCHAPTER 11 Inventory ModelmulunehNoch keine Bewertungen

- Production Management FormulasDokument3 SeitenProduction Management FormulasAnthony RoyupaNoch keine Bewertungen

- Application of Differential CalculusDokument22 SeitenApplication of Differential Calculusmahbub007Noch keine Bewertungen

- Dr. Abe Feinberg's Inventory NotesDokument5 SeitenDr. Abe Feinberg's Inventory NotesBeautyfull Naina MehtaNoch keine Bewertungen

- Lect 12 - Continuous & Periodic Review SystemsDokument38 SeitenLect 12 - Continuous & Periodic Review SystemsBharath BalasubramanianNoch keine Bewertungen

- Independent Demand Inventory Management: by 2 Edition © Wiley 2005 Powerpoint Presentation by R.B. Clough - UnhDokument38 SeitenIndependent Demand Inventory Management: by 2 Edition © Wiley 2005 Powerpoint Presentation by R.B. Clough - Unhnaveed_nawabNoch keine Bewertungen

- Optimize Inventory Management with EOQ ModelDokument68 SeitenOptimize Inventory Management with EOQ ModelSubhronil BoseNoch keine Bewertungen

- CHAPTER 1: Operations As A Competitive Weapon: Key EquationsDokument12 SeitenCHAPTER 1: Operations As A Competitive Weapon: Key EquationsKristin MackNoch keine Bewertungen

- ALKO Case StudyDokument42 SeitenALKO Case StudySuryakant KaushikNoch keine Bewertungen

- Inventory Theory.S4 Single Period Stochastic InventoriesDokument9 SeitenInventory Theory.S4 Single Period Stochastic InventoriesRajni KumariNoch keine Bewertungen

- 306 CH 12Dokument38 Seiten306 CH 12Mahendra ThengNoch keine Bewertungen

- June 2013 Inventory ManagementDokument68 SeitenJune 2013 Inventory ManagementShasank JalanNoch keine Bewertungen

- Operation Exam NotesDokument16 SeitenOperation Exam NotesZaki KamardinNoch keine Bewertungen

- Log (S20) - Inventory Models-2Dokument40 SeitenLog (S20) - Inventory Models-2Aqib LatifNoch keine Bewertungen

- EOQDokument4 SeitenEOQHassan Ali100% (2)

- CH 15 Inventory ManagementDokument21 SeitenCH 15 Inventory ManagementAshwin MishraNoch keine Bewertungen

- InventoryDokument38 SeitenInventoryNamita DeyNoch keine Bewertungen

- 10 Lecture - 9 - HandoutDokument10 Seiten10 Lecture - 9 - HandoutAbhiNoch keine Bewertungen

- Chap.4 - Inventory Management EditedDokument44 SeitenChap.4 - Inventory Management EditedadmasuNoch keine Bewertungen

- Inventory ManagementDokument20 SeitenInventory ManagementBhawna JaggiNoch keine Bewertungen

- Distribution Inventory Systems: Dr. Everette S. Gardner, JRDokument46 SeitenDistribution Inventory Systems: Dr. Everette S. Gardner, JRahmedmaeNoch keine Bewertungen

- Inventory Control Subject To Uncertain DemandDokument41 SeitenInventory Control Subject To Uncertain DemandAfifahSeptiaNoch keine Bewertungen

- Inventory ControlDokument26 SeitenInventory ControlhajarawNoch keine Bewertungen

- Supply Chain Inventory ManagementDokument36 SeitenSupply Chain Inventory ManagementPreeti AroraNoch keine Bewertungen

- Chapter 05Dokument75 SeitenChapter 05mushtaque61Noch keine Bewertungen

- Lect 12 EOQ SCMDokument38 SeitenLect 12 EOQ SCMApporva MalikNoch keine Bewertungen

- The Production Qauntity ModelDokument21 SeitenThe Production Qauntity ModelVibhor AggarwalNoch keine Bewertungen

- Inventory 1Dokument10 SeitenInventory 1singarajusarathNoch keine Bewertungen

- Om Case Study NewDokument41 SeitenOm Case Study NewSammir MalhotraNoch keine Bewertungen

- Production Order Quantity ModelDokument65 SeitenProduction Order Quantity ModelJatinder Gill100% (1)

- Mathematical Formulas for Economics and Business: A Simple IntroductionVon EverandMathematical Formulas for Economics and Business: A Simple IntroductionBewertung: 4 von 5 Sternen4/5 (4)

- Digital Electronics For Engineering and Diploma CoursesVon EverandDigital Electronics For Engineering and Diploma CoursesNoch keine Bewertungen

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesVon EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesNoch keine Bewertungen

- Advanced C++ Interview Questions You'll Most Likely Be AskedVon EverandAdvanced C++ Interview Questions You'll Most Likely Be AskedNoch keine Bewertungen

- CSR Unit-2Dokument16 SeitenCSR Unit-2Aarti SounNoch keine Bewertungen

- 634581341530852500Dokument32 Seiten634581341530852500Aarti SounNoch keine Bewertungen

- Marico Limited 4decDokument3 SeitenMarico Limited 4decAarti SounNoch keine Bewertungen

- ManiiiiiiiDokument15 SeitenManiiiiiiiAarti SounNoch keine Bewertungen

- Supply Chain Management Part 1 Lecture OutlineDokument17 SeitenSupply Chain Management Part 1 Lecture OutlineEmmanuel Cocou kounouhoNoch keine Bewertungen

- 12 Kaplan India Site Cpa ReviewDokument8 Seiten12 Kaplan India Site Cpa Reviewpsuresh_reddyNoch keine Bewertungen

- Evercore TearsheetDokument1 SeiteEvercore TearsheetJennifer KwonNoch keine Bewertungen

- Good Morning! Please Download Your Lecture Slides HereDokument84 SeitenGood Morning! Please Download Your Lecture Slides HereCiise Cali HaybeNoch keine Bewertungen

- 0efd540ca24e3b7470a3673d1307d5adDokument93 Seiten0efd540ca24e3b7470a3673d1307d5adAtiaTahiraNoch keine Bewertungen

- Saja Al-Jbour ResumeDokument2 SeitenSaja Al-Jbour ResumesajamaljbourNoch keine Bewertungen

- Zara Case StudyDokument9 SeitenZara Case StudySaatvik SethiNoch keine Bewertungen

- Favourite 3rd Party Transfer: SuccessfulDokument1 SeiteFavourite 3rd Party Transfer: SuccessfulMizibalya ImanismailNoch keine Bewertungen

- Ford Case StudyDokument2 SeitenFord Case StudyasrikalyanNoch keine Bewertungen

- Background - Venture Capital and Stages of Financing (Ross - 7th Edition) Venture CapitalDokument8 SeitenBackground - Venture Capital and Stages of Financing (Ross - 7th Edition) Venture CapitalDaniel GaoNoch keine Bewertungen

- ASUG Attendee ListDokument90 SeitenASUG Attendee ListSteve HuntNoch keine Bewertungen

- Final IMC Plan CreatifyDokument22 SeitenFinal IMC Plan CreatifyRizza Mae SuarezNoch keine Bewertungen

- Economic ServicesDokument34 SeitenEconomic ServicesTUMAUINI TOURISMNoch keine Bewertungen

- ABCs of Relationship Selling Through Service 12th Edition Futrell Solutions Manual 1Dokument251 SeitenABCs of Relationship Selling Through Service 12th Edition Futrell Solutions Manual 1autumn100% (26)

- Exploring Social Origins in The Construction of ESDokument37 SeitenExploring Social Origins in The Construction of ESFabioNoch keine Bewertungen

- CostDokument39 SeitenCostJames De Torres CarilloNoch keine Bewertungen

- Dabur Sales ManagementDokument20 SeitenDabur Sales Managementrohitpatil222Noch keine Bewertungen

- Assignment - Env403Dokument6 SeitenAssignment - Env403Mahadi HasanNoch keine Bewertungen

- Lecture 1A - Statement of Financial PositionDokument14 SeitenLecture 1A - Statement of Financial PositionGonzalo Jr. RualesNoch keine Bewertungen

- Technical Delivery Manager IT EDM 040813Dokument2 SeitenTechnical Delivery Manager IT EDM 040813Jagadish GaglaniNoch keine Bewertungen

- Role of Financial Management in Banking SectorDokument18 SeitenRole of Financial Management in Banking SectorAjit DasNoch keine Bewertungen

- Apparel Merchandising - Types of BuyersDokument24 SeitenApparel Merchandising - Types of BuyersNithyaprakashNoch keine Bewertungen

- Test Bank For Strategic Management of Technological Innovation 6th Edition Melissa SchillingDokument13 SeitenTest Bank For Strategic Management of Technological Innovation 6th Edition Melissa Schillingnicholaswileyirzojkpbsc100% (19)

- Business Data Modelling - Why and HowDokument18 SeitenBusiness Data Modelling - Why and HowYoussef El MeknessiNoch keine Bewertungen

- Financial InvestmentDokument7 SeitenFinancial InvestmentGerald de BrittoNoch keine Bewertungen

- On Competitive StrategiesDokument33 SeitenOn Competitive Strategiesmmjmmj100% (1)

- BBA Viva Final Year PDFDokument70 SeitenBBA Viva Final Year PDFPratikBhowmickNoch keine Bewertungen

- Review Question in Engineering Management Answer KeyDokument9 SeitenReview Question in Engineering Management Answer KeysephNoch keine Bewertungen

- Investment Practice ProblemsDokument14 SeitenInvestment Practice ProblemsmikeNoch keine Bewertungen

- Financial Planning & ForecastingDokument44 SeitenFinancial Planning & Forecastingnageshalways503275% (4)